Stainless steel tubing fabrication is a complex process that requires meticulous attention to detail and expertise in manipulating stainless steel materials. The precision involved in crafting tubing to meet specific requirements for various industrial applications is paramount. From seamless production to bending and welding techniques, every step in the fabrication process contributes to the final product's quality and performance. Understanding the nuances of stainless steel tubing fabrication not only ensures functionality but also plays a crucial role in maintaining industry standards. The intricate balance between strength, corrosion resistance, and durability in stainless steel tubing fabrication sets the stage for a discussion that delves into the intricate world of metallurgy and engineering.

Stainless steel tubing specifications encompass crucial factors such as:

Understanding these specifications is essential for selecting the appropriate tubing for specific applications. Each parameter plays a significant role in determining the performance, durability, and compatibility of the stainless steel tubing in various industrial settings.

Stainless steel tubing is available in a variety of grades, each offering specific properties suited for different environments and applications. Understanding the characteristics of each grade is essential for selecting the most appropriate material for your project.

Each stainless steel grade offers distinct advantages based on its chemical composition and microstructure. By selecting the appropriate grade for your specific application requirements, you can ensure optimal performance, longevity, and cost-effectiveness of your stainless steel tubing solution.

1. Corrosion Resistance: Identify the environment in which the stainless steel will be used. For example, if it will be exposed to marine environments or corrosive chemicals, a grade with high corrosion resistance like 316 or duplex stainless steel may be suitable.

2. Temperature Resistance: Determine the operating temperature range of your application. For high-temperature environments, grades like 321 stainless steel, which offer resistance to chromium carbide precipitation, are preferable.

3. Strength and Toughness: Assess the mechanical properties required for your application, such as strength, hardness, and toughness. Consider precipitation-hardening stainless steels for high-strength applications or martensitic stainless steels for applications requiring hardness and wear resistance.

4. Fabrication and Formability: Evaluate the ease of fabrication, welding, and forming required for your project. Grades like 304 stainless steel are known for their excellent formability and weldability, making them versatile for various fabrication processes.

5. Cost Considerations: Consider the budget constraints for your project. Some stainless steel grades may be more expensive due to their alloy composition or specialized properties. Balancing performance requirements with cost considerations is essential.

6. Regulatory Compliance: Ensure that the selected grade complies with industry standards, regulations, and specifications relevant to your application, such as ASTM or ASME standards for specific industries.

7. Consultation with Experts: If you're unsure about which grade to choose, consult with materials engineers, metallurgists, or stainless steel suppliers who can provide expert guidance based on your application requirements.

Recommend:

Standard stainless steel tubing sizes are crucial in understanding the specifications of stainless steel tubing. The inner diameter (ID) and outer diameter (OD) are key parameters that dictate the tubing's dimensions and applications.

Analyzing these dimensions is fundamental for selecting the appropriate tubing for specific industrial uses.

Download Stainless Steel Tubing Size List

Understanding the ID and OD specifications of stainless steel tubing is crucial for selecting the appropriate sizes to meet your application requirements. Additionally, it's essential to consider the wall thickness, which directly influences the relationship between the ID and OD. Thicker walls reduce the available space inside the tubing (decreasing the ID) while increasing the overall diameter (OD), affecting factors such as strength, pressure resistance, and weight.

The wall thickness of stainless steel tubing is a crucial specification that directly impacts its strength, durability, and performance in various industrial applications.

When selecting the appropriate wall thickness for your stainless steel tubing, consider factors such as the operating pressure, temperature, fluid or gas compatibility, and structural requirements of your application. It's essential to choose a wall thickness that can withstand the anticipated stresses and pressures without compromising safety or performance.

Additionally, be mindful of the manufacturing process used to produce the tubing, as this can impact the consistency and integrity of the wall thickness. Seamless tubing, produced through extrusion or piercing methods, typically has more uniform wall thicknesses and higher structural integrity compared to welded tubing, which may exhibit variations in thickness along the weld seam.

Stainless steel tubing length specifications play a critical role in determining the structural integrity and functionality of the tubing in various industrial applications.

When determining tubing length, consider factors such as installation requirements, space constraints, and the need for seamless integration with other components. By choosing the right tubing length, you optimize installation ease, minimize material waste, and ensure the functionality and longevity of your stainless steel tubing system.

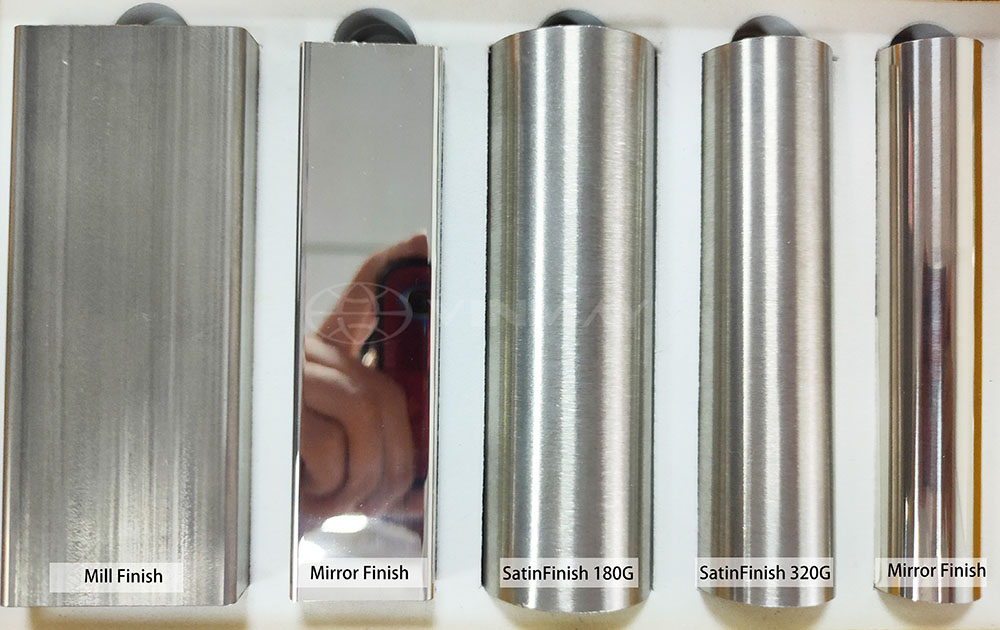

The surface finish of stainless steel tubing affects its appearance, cleanliness, and corrosion resistance. Common surface finishes include:

Proper surface finishing not only enhances the visual appeal but also contributes significantly to the overall performance and durability of the tubing.

Related Article: Comparisons of hairline finish, brushed finish, and satin finish stainless steel tube

Tolerance refers to the allowable deviation from the specified dimensions of stainless steel tubing. Tight tolerances ensure precise fit and compatibility with other components, while looser tolerances may be acceptable for less critical applications. Tolerance considerations include outer diameter (OD), inner diameter (ID), wall thickness, and length. Stainless steel tubing manufacturers provide tolerance specifications based on industry standards or customer requirements to ensure product quality and performance.

Understanding these detailed specifications empowers engineers, designers, and procurement professionals to make informed decisions when selecting stainless steel tubing for their projects.

Compliance with industry standards and regulations is paramount when selecting and using stainless steel tubing for various applications. Here's an overview of key standards and regulations to consider:

When selecting stainless steel tubing, it's essential to consider the applicable standards and regulations relevant to your industry and application. Ensuring compliance with these standards not only guarantees the quality and performance of the tubing but also helps mitigate risks and liabilities associated with non-compliance. Additionally, consulting with industry experts and suppliers knowledgeable about relevant standards can provide valuable guidance in selecting the right tubing for your specific needs while meeting regulatory requirements.

See Also:

Manufacturing stainless steel tubing involves two primary methods: welded and seamless.

Welded tubing is formed through a welding process after coils are processed and shaped, while seamless tubing is created using methods like piercing, gun drilling, or extrusion.

Each method results in a different type of stainless steel pipe, each with specific advantages and applications, catering to diverse industrial needs.

Stainless steel tubing undergoes a meticulous process of fabrication, involving precise steps to ensure quality and integrity in the final product. Welded stainless steel tubing is initially provided in coils, which undergo processing for finishing and alterations before being shaped through rollers for welding.

Whether hot or cold-formed, the welding techniques remain consistent. Key steps in the welding process include coil separation, forming, welding seam sealing, weld bead conditioning, possible weld roll-down, sizing for dimensions, and tube cutting methods like shear cutting and abrasive cutting.

Cold-formed stainless steel tubing exhibits strong mechanical characteristics and precise tolerances, making it ideal for various applications, with the welding process being uniform regardless of the coil-forming method used.

Recommended:

Seamless stainless steel tubing is crafted through meticulous processes using specialized methods like piercing, extrusion, or gun drilling to ensure high-quality production. Seamless tubing offers advantages such as superior corrosion resistance, high precision, and the ability to create custom designs tailored to specific applications. The tubing fabrication processes involve techniques like cold drawing and cold pilgering for unique compositions or dimensions. These methods result in tubes that outperform those produced by other means. The seamless nature of this tubing reduces the risk of weak points and leakages, making it ideal for industries requiring reliability and durability.

| Advantages | Tubing Fabrication Processes | Custom Designs |

|---|---|---|

| Corrosion resistance | Piercing | High precision |

| High precision | Extrusion | Customizable |

| Custom designs | Gun drilling | Tailored |

At Vinmay Stainless Steel, we pride ourselves on delivering precision and quality in every piece of stainless steel tubing we fabricate. Our advanced fabrication process involves several key steps, each meticulously executed to ensure the highest standards. Here’s an in-depth look at our stainless steel tubing fabrication process:

The first step in our fabrication process is selecting the appropriate stainless steel grade for your specific application. We offer a range of grades, including 304, 316, and 321, each known for its unique properties such as corrosion resistance, strength, and durability. Our experts work with you to determine the best material based on your project requirements.

Precision cutting is crucial to achieving the desired dimensions and shapes for your tubing. We utilize various cutting techniques, including:

Bending and forming are essential for creating the specific shapes and angles required for your application. Here’s a detailed look at our bending and forming process:

Objective: Achieving a smooth, round bend is a common goal in tube bending. This process is easier when the tube has a heavy wall thickness and is bent to a large radius.

Wall Factor Calculation: Determines if a tube is thin-walled or thick-walled.

Bend Severity Calculation: Degree of Bend = Bend Centerline Radius ÷ Tube Outside Diameter

Support Necessity: Small-diameter tubes with thick walls need less interior support, while larger-diameter tubes with thin walls are weaker and require support (mandrels) to prevent distortion.

Bending Rectangular and Square Tubing: Less distortion occurs when rectangular tubing is bent the "hard way."

Welding is a critical step in the fabrication process, particularly for creating welded stainless steel tubing. We use several welding techniques to ensure strong, durable welds:

Each weld undergoes a thorough inspection to ensure it meets our stringent quality standards.

The final step in our fabrication process is finishing. Proper finishing enhances the durability and appearance of the stainless steel tubing. Our finishing options include:

Each piece of tubing is carefully finished to meet your specific requirements, ensuring both functionality and visual appeal.

Recommended: The Art of Polishing Stainless Steel Tubes

Throughout our fabrication process, we maintain rigorous quality control measures. This includes:

Our commitment to quality ensures that you receive stainless steel tubing that meets the highest industry standards. Our stainless steel tubing fabrication process combines advanced technology, skilled craftsmanship, and stringent quality control to deliver superior products.

Whether you need standard tubing or custom solutions, Vinmay Stainless Steel is dedicated to providing the best results for your project. Contact us today to discuss your stainless steel tubing needs and discover how we can help you achieve precision and excellence in every aspect of your application.

In various industries ranging from aerospace to automotive and from oil and gas to electronics, stainless steel tubing serves a critical role due to its exceptional versatility and corrosion resistance. Custom applications of stainless steel tubing are prevalent across industries such as aerospace, where its high strength-to-weight ratio is vital for aircraft structures.

In the automotive industry, stainless steel tubing is used for exhaust systems, fuel lines, and hydraulic tubing due to its durability and resistance to heat and corrosion. Aerospace applications benefit from the material's ability to withstand extreme temperatures and harsh environments, making it ideal for various aircraft components.

Additionally, the medical industry relies on stainless steel tubing for its hygienic properties, using it extensively for medical tubing due to its biocompatibility and ease of sterilization. In industrial uses, stainless steel tubing finds applications in diverse sectors, showcasing its adaptability and reliability in demanding environments.

Related Articles:

In the realm of custom solutions, stainless steel tubing's adaptability shines, catering to a myriad of unique applications. Fabrication techniques expertly mold the metal to meet specialized requirements, offering industry-specific solutions with precision.

Recommended: Custom Stainless Steel Tubes

The manufacturing process and cost vary between seamless and welded tubing. Strength and corrosion resistance distinguish seamless, while welded offers application flexibility. Quality control and lead times differ. Both exhibit durability and unique aesthetics.

Recommended: Stainless Steel Tube Welded VS Seamless

When determining stainless steel tubing dimensions and tolerances, the manufacturing process is crucial. Material properties, quality control, adherence to industry standards, and cost considerations play key roles. Precision in measurement, calibration, and inspection ensures optimal performance.

Regulatory requirements dictate material composition, surface finish, corrosion resistance, and cleaning procedures for stainless steel tubing in food processing. Compliance ensures safety, hygiene, and durability, meeting stringent standards for food industry applications.

Partnering with Vinmay Stainless Steel for tubing needs offers cost savings, quick turnaround, high quality, custom solutions, and technical support. With over four decades of experience, they ensure efficient, precise, and tailored solutions for diverse applications.

Stainless steel tubing plays a pivotal role in numerous industries due to its exceptional versatility and corrosion resistance, making the decision to partner with Vinmay Stainless Steel a strategic choice for those seeking premium stainless steel welded tubes and fittings. Vinmay Stainless Steel stands out for several reasons:

Partner with Vinmay Stainless Steel for quality assurance, timely delivery, and unmatched reliability in stainless steel tubing solutions. Contact us now to elevate your industry standards!