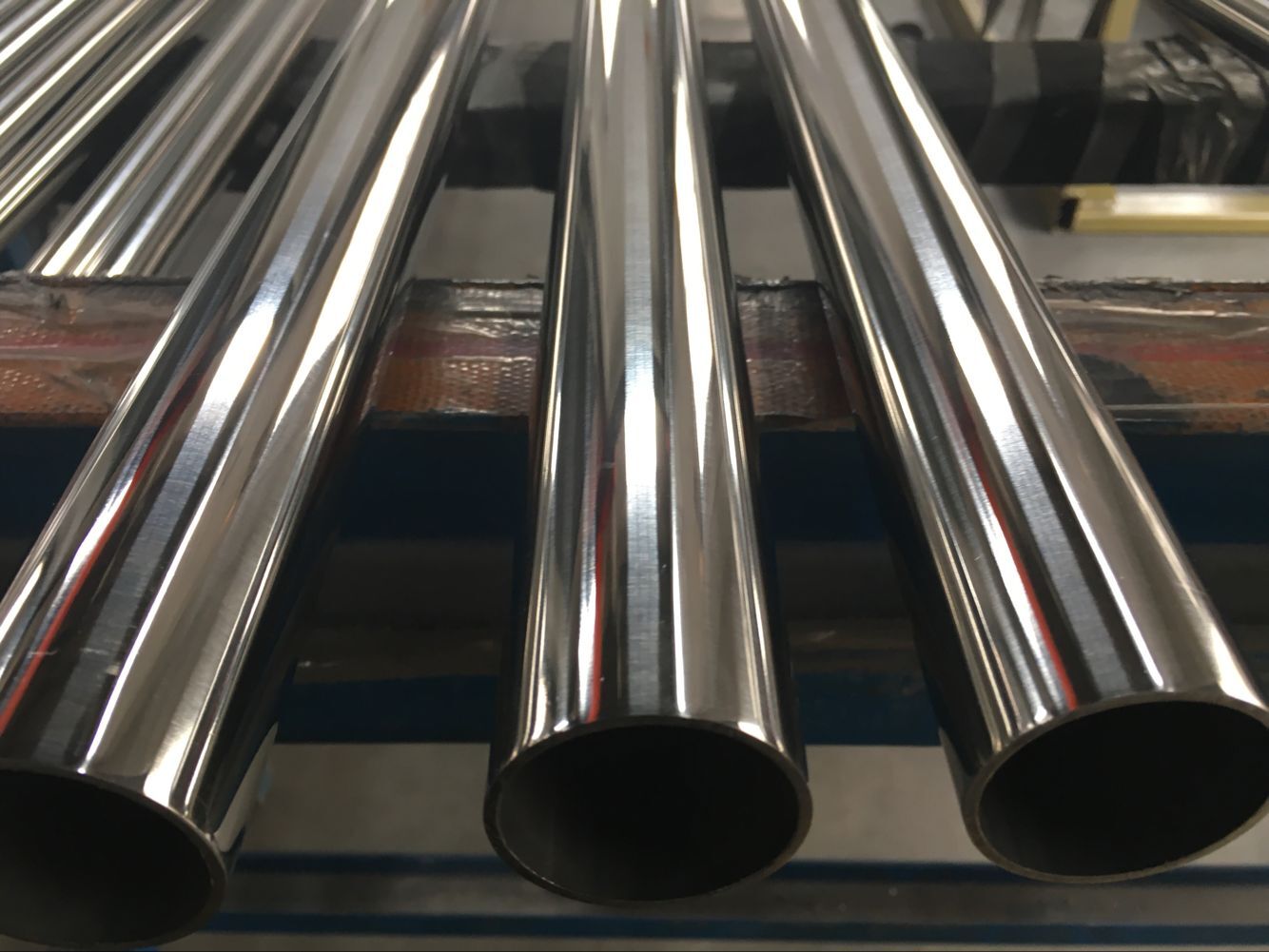

Do you want your stainless steel tube to shine like a diamond in the rough? Well, you're in luck because polishing stainless steel tube is the key to achieving that brilliant, mirror-like finish you desire.

Whether it's for your kitchen, bathroom, or any other stainless steel fixtures, polishing stainless steel tube not only enhances the aesthetics but also protects against corrosion and wear.

By using the right tools and materials, and following a step-by-step process, you can transform your stainless steel tube into a stunning masterpiece.

And don't worry, we'll also cover maintenance and protection to keep that shine lasting for years to come.

So, let's dive into the world of polishing stainless steel tube and make your space truly shine with belonging.

Polishing stainless steel tubes helps maintain their appearance and prevent corrosion.

- Regular polishing extends the lifespan of stainless steel tubes.

- Abrasive compounds such as silicon carbide, alumina, and diamond are commonly used for polishing stainless steel tubes.

- Polishing wheels and compounds are essential tools for achieving a smooth and shiny finish on stainless steel tubes.

To understand stainless steel, you need to familiarize yourself with its unique properties and characteristics. Stainless steel is a versatile and durable material that's commonly used in various industries, such as construction, automotive, and manufacturing. It's known for its corrosion resistance, high strength, and aesthetic appeal.

One of the key properties of stainless steel is its corrosion resistance. Unlike other metals, stainless steel is highly resistant to corrosion, making it suitable for applications where exposure to moisture or harsh environments is common. This property is due to the presence of a thin oxide layer on the surface of the steel, which acts as a protective barrier against corrosion.

Additionally, stainless steel is known for its strength. It has a high tensile strength, which means it can withstand heavy loads and stress without deforming or breaking. This makes stainless steel an ideal choice for structural applications.

Furthermore, stainless steel offers excellent aesthetic appeal. Its smooth, shiny surface gives it a modern and clean look, making it popular in architectural and design applications.

Polishing stainless steel tube is an essential step in maintaining its appearance and preventing corrosion. When stainless steel is exposed to elements such as moisture, heat, and chemicals, it can become dull, discolored, and susceptible to corrosion. By regularly polishing the surface of stainless steel tubes, you can restore their shine and protect them from corrosion.

The importance of polishing stainless steel tube lies in its ability to remove surface imperfections, such as scratches, stains, and oxidation. These imperfections not only compromise the aesthetic appeal of the stainless steel, but they also create micro crevices where contaminants can accumulate. Polishing smooths out these imperfections, making it easier to clean and sanitize the surface.

Furthermore, polishing helps to maintain the passive layer on the stainless steel surface. This layer, formed by the combination of chromium and oxygen, provides excellent corrosion resistance. However, over time, this layer can become damaged or depleted. Polishing helps to restore and strengthen the passive layer, preventing corrosion and extending the lifespan of the stainless steel tube.

To begin discussing the tools and materials required for polishing stainless steel tube, there are several key points to consider.

Firstly, abrasive compounds are essential for removing imperfections and achieving a smooth finish.

Secondly, polishing wheels or discs are necessary for applying the abrasive compounds effectively.

Lastly, polishing compounds are used to further enhance the shine and luster of the stainless steel.

Additionally, it's important to wear appropriate protective gear such as gloves and safety goggles to ensure safety during the polishing process.

With the right abrasive compounds, you can achieve a polished finish on your stainless steel tube. Abrasive compounds are essential tools for removing imperfections and creating a smooth, mirror-like surface. When selecting abrasive compounds, consider factors such as the material of the tube, the desired finish, and the level of abrasiveness needed.

Common abrasive compounds used for stainless steel tube polishing include silicon carbide, alumina, and diamond. Silicon carbide is ideal for initial rough grinding, while alumina provides a finer finish. Diamond compounds are used for the final polishing stages to achieve a high level of shine.

It's crucial to choose abrasive compounds that are compatible with your polishing equipment and to follow the manufacturer's recommendations for usage and application. By using the right abrasive compounds, you can achieve a professional and flawless polish on your stainless steel tube.

You can achieve a polished finish on your stainless steel tube by using high-quality polishing wheels. Polishing wheels are essential tools for removing scratches, imperfections, and oxidation from the surface of the tube, resulting in a smooth and shiny appearance.

These wheels are typically made of various materials, such as cotton, sisal, or felt, which are densely packed and bonded together. The hardness of the wheel material should be chosen based on the level of polishing required. Additionally, the wheels can be impregnated with abrasive compounds to enhance their polishing capabilities.

When using polishing wheels, it's important to ensure that they're properly mounted on a suitable polishing machine or handheld tool, and to follow the manufacturer's instructions for speed and pressure.

To achieve a high-quality polished finish on your stainless steel tube, it's essential to have the right tools and materials, such as polishing compounds.

Polishing compounds are abrasive substances used to remove scratches, stains, and other imperfections on the surface of stainless steel. These compounds come in various forms, including powders, pastes, and creams.

They're made up of abrasive particles suspended in a binder material. The abrasive particles act like tiny sandpaper, smoothing out the surface of the stainless steel. The binder material helps to hold the abrasive particles together and provides lubrication during the polishing process.

When selecting a polishing compound, consider the level of abrasiveness needed for your specific application and the type of stainless steel being polished. Remember to follow the manufacturer's instructions for proper usage and safety precautions.

For optimal safety and efficiency, equip yourself with the necessary protective gear when working with tools and materials for polishing stainless steel tubes. It's crucial to prioritize your safety by wearing appropriate protective gear.

Start by wearing safety goggles to shield your eyes from any potential sparks, debris, or chemical splashes. Additionally, make sure to wear sturdy work gloves to protect your hands from sharp edges, cuts, or abrasions.

To protect your respiratory system from inhaling dust particles or chemical fumes, a respirator with suitable filters is essential.

Furthermore, wearing a long-sleeved shirt and pants made of non-flammable material will safeguard your skin from any potential burns.

Lastly, ensure that you have a fire extinguisher nearby, as well as a first aid kit, in case of any accidents.

To achieve a polished finish on a stainless steel tube, you need to follow a step-by-step polishing process.

This process involves:

- Surface preparation

- Selecting the right abrasive

- Using the correct polishing technique

- Achieving the final finish.

Each of these points is crucial in achieving a smooth and shiny surface on your stainless steel tube.

Start by gathering all the necessary tools and materials for the surface preparation process of polishing stainless steel tube. You'll need a clean cloth or rag, stainless steel cleaner or polish, gloves, and safety goggles. Ensure that you're working in a well-ventilated area and have proper protective gear.

Begin by removing any dirt, dust, or debris from the surface of the stainless steel tube using a cloth or rag.

Next, apply the stainless steel cleaner or polish to the cloth and rub it onto the surface of the tube in a circular motion. Make sure to cover the entire surface evenly.

Continue this process until the stainless steel tube is clean and free of any stains or marks.

To select the right abrasive for the step-by-step polishing process of stainless steel tube, consider the specific requirements of the surface and the desired finish.

The choice of abrasive plays a crucial role in achieving the desired result. There are various types of abrasives available, each with its own characteristics and applications.

For rougher surfaces that require significant material removal, coarse abrasives such as aluminum oxide or silicon carbide are suitable options. These abrasives are highly effective in removing scratches, weld marks, and other imperfections.

For finer finishes, such as a mirror-like shine, finer abrasives like diamond compounds or polishing powders can be used. These abrasives provide a smoother and more polished surface.

It's important to match the abrasive to the specific requirements of the surface and the desired finish to ensure optimal results.

Once you have selected the right abrasive, it's time to begin the step-by-step polishing process of your stainless steel tube.

First, make sure the surface is clean and free from any dirt or debris.

Next, secure the tube in a holder or vice to keep it stable during the polishing process.

Start with a coarse grit abrasive and move the tube in a back-and-forth motion along the length of the tube, applying even pressure. Repeat this step until all visible scratches are removed.

Then, switch to a finer grit abrasive and repeat the process, gradually moving to a higher grit until the desired level of polish is achieved.

Finally, finish off the polishing process with a buffing wheel and a polishing compound to give the tube a smooth and shiny finish.

Remember to clean the tube thoroughly after each step to remove any residue or particles.

To achieve the final finish in the step-by-step polishing process of your stainless steel tube, begin by switching to a finer grit abrasive and gradually increase the level of polish.

This step is crucial as it helps to eliminate any remaining scratches or imperfections on the surface of the tube. Start by using a polishing compound with a finer grit, such as 400-grit, to refine the surface and remove any visible scratches.

Apply the compound to a soft cloth and work it onto the tube in a circular motion. Continue this process, gradually increasing the grit size of the abrasive, until you reach the desired level of polish.

Remember to clean the tube thoroughly between each step to remove any residue and ensure a smooth and even finish.

Learn More :

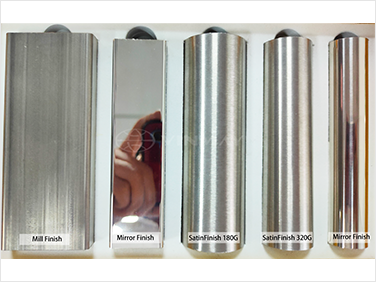

Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

Comprehensive Guide to Stainless Steel Tube Surface Finishes

After you have polished your stainless steel tube, it's important to properly maintain and protect it. By following a few simple steps, you can ensure the longevity and appearance of your stainless steel tube.

Firstly, it's crucial to regularly clean the surface of the tube. This can be done using a mild detergent and warm water. Avoid using abrasive cleaners or harsh chemicals, as they can damage the stainless steel. Gently scrub the surface with a soft cloth or sponge, moving in the direction of the grain to avoid scratching.

Secondly, it's recommended to apply a protective coating to the stainless steel tube. This will help prevent stains, corrosion, and fingerprints. There are various types of protective coatings available, such as clear lacquer or wax. Apply the coating evenly, following the manufacturer's instructions.

Additionally, it's important to avoid exposing the stainless steel tube to harsh environments or substances that can cause damage. This includes exposure to saltwater, acidic solutions, or abrasive materials. If the tube does come into contact with any of these substances, promptly clean and dry the surface to prevent corrosion.

Lastly, regular inspections should be conducted to identify any signs of damage or wear. If any scratches or dents are found, they should be repaired promptly to prevent further corrosion.

To summarize, proper maintenance and protection are essential for preserving the longevity and appearance of your stainless steel tube. By following the recommended maintenance practices, you can ensure that your stainless steel tube continues to perform at its best and maintains its aesthetic appeal for years to come.

Regular cleaning is crucial to prevent the build-up of dirt, grime, and stains on the surface of the stainless steel tube. Use mild cleaning agents and non-abrasive tools to remove any contaminants without causing damage to the tube. Avoid using harsh chemicals or abrasive materials that can scratch or corrode the surface.

In addition to cleaning, applying a protective coating can help shield the stainless steel tube from environmental elements and prevent corrosion. There are various types of protective coatings available, such as clear coats or wax-based products, that provide a barrier against moisture, chemicals, and oxidation. Regularly inspect the coating for any signs of wear or damage and reapply as necessary.

Furthermore, it's important to handle the stainless steel tube with care to minimize the risk of dents, scratches, or other physical damages. Avoid dragging or dropping the tube and use appropriate lifting equipment when necessary.

In conclusion, the process of polishing stainless steel tubes is vital for maintaining their aesthetic appeal and preventing corrosion. By using the right tools and materials, following a step-by-step process, and implementing regular maintenance and protection, a polished finish can be achieved.

This not only enhances the overall appearance of the stainless steel tube but also prolongs its lifespan. Proper polishing techniques are essential for ensuring the longevity and durability of stainless steel tubes.

With the "customer first and integrity" business philosophy, after 15 years of development, Vinmay has developed in to one of the top stainless steel welded tube exporters in China, in the field of decorative welded tubes, we have been the first in China for many years with an annual export volume over 20000 tons.

Our products are strictly produced according to a various of international standards including stainless steel welded tubes for ornamental and mechanical structure purposes ( ASTM A554/ EN10296-2);stainless steel welded tube for heat treatment (ASTM A249/A269/ EN10217-7) and stainless steel sanitary tube ( ASTM A270, EN10357).

We provide stainless steel welded tube in size range from diameter 6mm to 219mm with thickness 0.4mm to 6.9mm. The surface of tube can be produce with satin finish ( 180grit, 320 grit, 400 grit) and mirror finish (600grit, 800 grit) and mill finish.

Contact us for the free sample today! It will be our pleasure to cooperate with you.