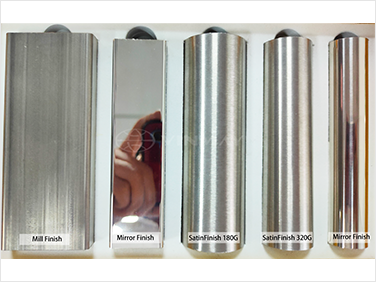

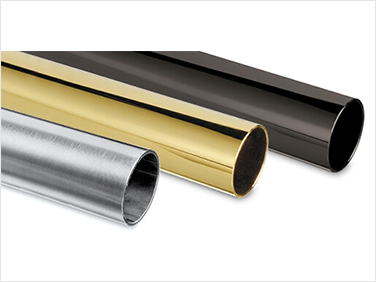

Welcome to Vinmay - Your Premier Stainless Steel Welded Pipe Supplier. Since our inception in 2008, Vinmay has excelled as a dedicated manufacturer, specializing in premium stainless steel welded tubes and fittings. Over 15 years of expertise enable us to offer a comprehensive range of pipes adhering to ASTM, EN, DIN, and AS standards, catering to diverse industries such as decoration, water supply, dairy, food, and chemicals.

Our commitment to quality is unwavering, underpinned by stringent QC protocols. Vinmay proudly holds PED, AEO, and ISO certifications, ensuring the satisfaction of more than 400 clients across 80+ countries.

At Vinmay, we believe in empowering our clients' success. Our high-quality products are designed to elevate your market presence, aligning with our motto, 'Cooperate with Vinmay, Win the world'. Explore our range and experience excellence.