The integrity of stainless steel tubes is crucial across various sectors, necessitating comprehensive stainless steel tube test protocols to ensure reliability and performance. A variety of methodologies, from magnetic and acid tests to non-destructive techniques, play a pivotal role in identifying potential defects. Understanding these processes not only aids in compliance with industry standards but also mitigates risks associated with material failures. However, the intricacies of these testing methods and their implications for different applications reveal a more complex landscape that warrants further exploration. What are the underlying factors that influence the choice of testing method?

The necessity for stainless steel testing arises from its susceptibility to localized corrosion phenomena, such as pitting and stress corrosion cracking, which can lead to significant structural failures if undetected. Ensuring the durability of stainless steel components is critical for industries that rely on these materials, as they are often subject to harsh environments.

The importance of rigorous testing cannot be overstated; it serves as a front line defense in corrosion prevention, safeguarding both the integrity of structures and the safety of personnel.

Adhering to established industry standards is imperative to maintain quality assurance throughout the manufacturing and installation processes. Testing methods, ranging from visual inspections to advanced techniques like eddy current testing and acoustic emission, provide essential data on the condition of stainless steel.

By implementing a systematic testing regimen, organizations can identify weaknesses early, allowing for timely interventions and mitigating the risks associated with corrosion.

The proactive approach of stainless steel tube test not only enhances material longevity but also reinforces operational reliability. Ultimately, a commitment to testing translates into a culture of safety, quality, and excellence, fostering a sense of belonging among professionals dedicated to upholding these standards.

Identifying stainless steel tube requires the application of several analytical stainless steel tube tests to ascertain their composition and properties.

Key methodologies include the magnetic test, nitric acid point test, copper sulfate point test, sulfuric acid test, and hydrochloric acid test, each providing distinct insights into the material's characteristics.

Employing these techniques effectively enables accurate differentiation between stainless steel and other metal types, facilitating informed decision-making in material selection and application.

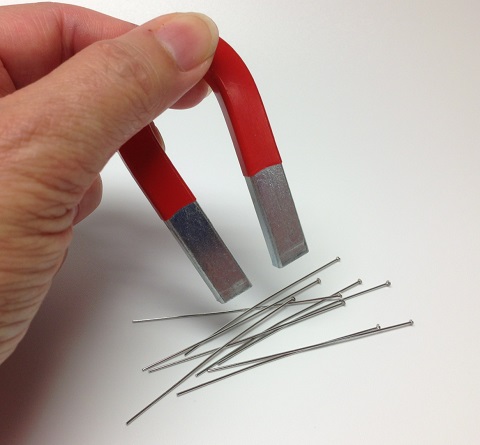

A magnetic test serves as a quick and effective method for distinguishing austenitic stainless steel tube from ferritic stainless steel, with the former typically exhibiting non-magnetic properties. This test is vital in various stainless steel applications, as it aids in ensuring compliance with industrial standards and optimizing material performance analysis.

Key considerations in the magnetic test include:

Magnetic Properties: Austenitic stainless steels are generally non-magnetic, while ferritic steels display pronounced magnetism.

Cold Working Effects: Cold working can induce slight magnetism in austenitic steels, necessitating careful evaluation during testing innovations.

Test Simplicity: The magnetic test provides a simple and rapid identification method, allowing for immediate assessment in field applications.

Employing corrosion prevention strategies is essential, as improper identification may lead to material failures.

By utilizing the magnetic test, professionals can enhance their approach to stainless steel selection, ensuring that the appropriate grades are utilized for specific environments.

This method serves as an initial screening tool, paving the way for more detailed evaluations when necessary, thereby reinforcing the integrity and longevity of stainless steel installations.

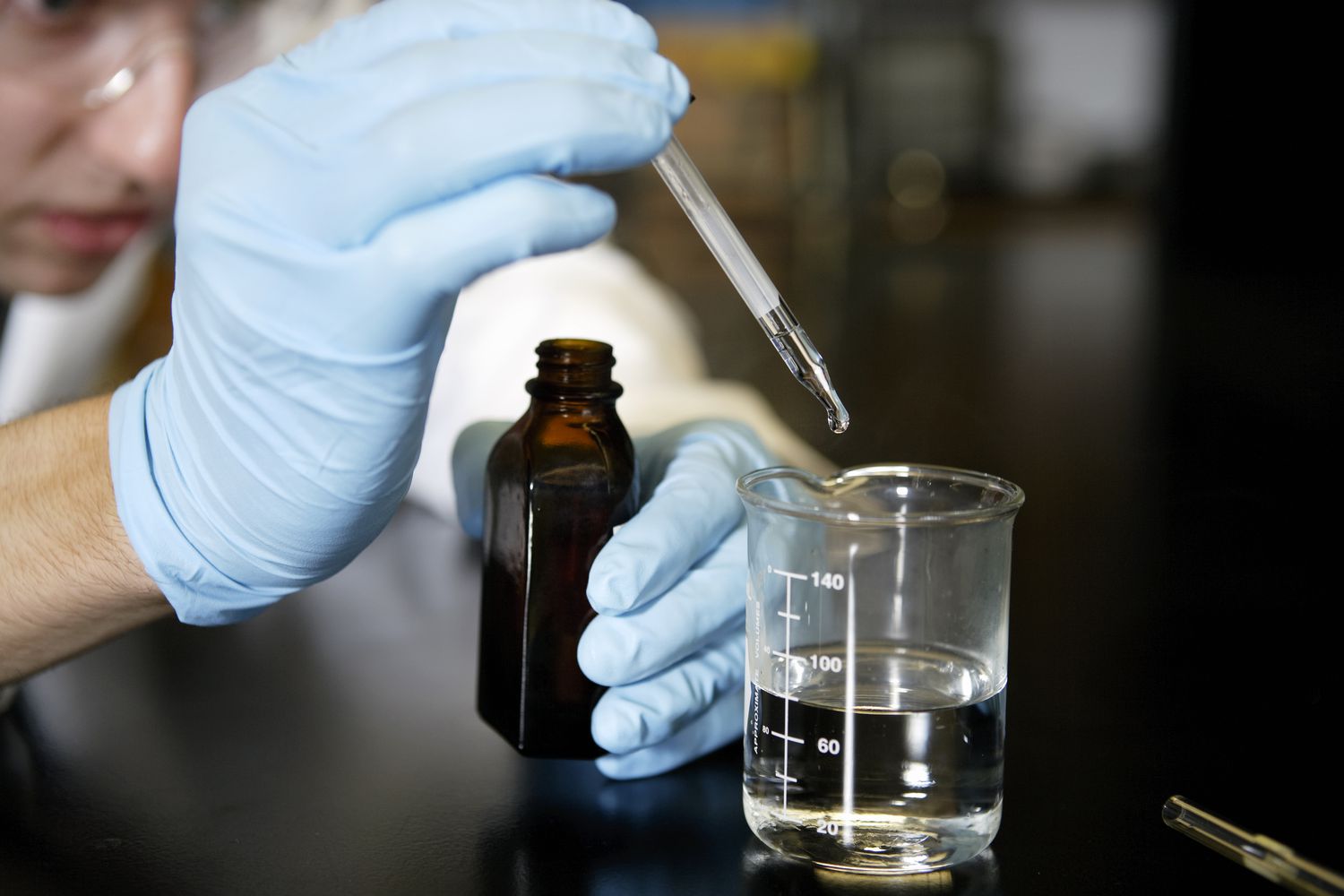

Utilizing the nitric acid point test facilitates the effective identification of stainless steel tube by assessing their inherent corrosion resistance to nitric acid, distinguishing them from other metals based on their reaction to concentrated and diluted solutions. This testing technique is particularly valuable in field applications where rapid differentiation is necessary.

The methodology involves applying concentrated nitric acid to the metal surface, observing the resultant reaction. Stainless steel exhibits minimal corrosion, while other non-ferrous metals will corrode immediately, and high carbon steels may show slight corrosion. This characteristic makes the nitric acid point test a reliable method for identifying stainless steel in various environments.

| Material Type | Reaction to Nitric Acid |

|---|---|

| Stainless Steel | Minimal to no corrosion |

| High Carbon Steel | Slight corrosion visible |

| Non-Ferrous Metals | Immediate corrosion |

The copper sulfate point test serves as a rapid and effective technique for distinguishing stainless steel tube from ordinary carbon steel through the observation of their distinct reactions to a copper sulfate solution. This test is particularly beneficial in field applications, where quick identification of material types is essential for ensuring corrosion resistance and material integrity.

The testing procedure involves:

Preparation: Cleaning and polishing the test area to ensure accurate results.

Application: Applying a 5-10% copper sulfate solution to the surface.

Observation: Noting the reaction; ordinary carbon steel will form a metallic copper layer within seconds, while stainless steel will not exhibit any copper precipitation.

This method capitalizes on the unique properties of stainless steel, particularly its superior corrosion resistance compared to carbon steels.

By adopting the copper sulfate point test, professionals can efficiently verify material specifications, reducing the risk of material failure in critical applications.

Consequently, this test emerges as a valuable tool for engineers and inspectors seeking to uphold the standards of quality and safety in their respective fields.

Employing the sulfuric acid test provides a reliable method for distinguishing between various grades of stainless steel, specifically 201, 304, 316, and 317, based on their distinct corrosion reactions in a controlled acidic environment. This test is an essential tool in sulfuric acid applications, enabling effective corrosion resistance evaluation and facilitating accurate stainless steel classifications.

In this methodology, samples are subjected to a 10% sulfuric acid solution, heated to 71°C, after undergoing fine grinding and passivation in nitric acid. The acid exposure effects reveal that grades 302 and 304 exhibit rapid corrosion, characterized by bubbling and a color change to black. In contrast, grades 316 and 317 demonstrate significantly higher resistance, often remaining unchanged and retaining their original appearance.

Comparing this testing methodology to others, such as the nitric acid point test or copper sulfate point test, underscores its efficacy in identifying stainless steel grades. The sulfuric acid test not only enhances the understanding of stainless steel's performance under acidic conditions but also supports informed decisions in material selection for various applications.

Thus, it plays a vital role in maintaining the integrity and safety of stainless steel installations.

Conducting the hydrochloric acid test allows for the differentiation of low-chromium steels, such as 403, 410, 416, and 420, from higher chromium variants like 430, 431, and 440 based on their distinct reactions to a 50% hydrochloric acid solution.

This method leverages the unique chemical reactions exhibited by various stainless steel grades when exposed to hydrochloric acid, providing valuable insight into their corrosion resistance properties.

Key features of the hydrochloric acid test include:

Rapid Results: Observable reactions typically occur within three minutes, allowing for quick identification of stainless steel types.

Visual Indicators: Changes in solution color and specific odors reveal crucial information about the chromium content in the steel.

Effective Differentiation: The test effectively distinguishes low-chromium steels from their higher-chromium counterparts, critical for applications where corrosion resistance is paramount.

When assessing stainless steel, three critical detection considerations must be addressed: the material's magnetic properties, the challenges of identifying pitting and cracking, and the implications of insulation removal.

Understanding the magnetic characteristics is essential for selecting appropriate testing methods, particularly since austenitic stainless steels are typically non-magnetic.

Furthermore, effective detection strategies must account for the difficulties posed by localized corrosion and the logistical challenges associated with accessing the material for thorough inspection.

How do the magnetic properties of stainless steel influence the selection of effective detection methods? The magnetic behavior of stainless steel is a critical factor that determines the appropriateness of various detection techniques. This is particularly relevant given the diverse stainless steel applications across industries, where alloy composition, corrosion resistance factors, fabrication techniques, and maintenance practices play significant roles.

Austenitic stainless steels are typically non-magnetic, while ferritic types exhibit magnetic characteristics.

Cold working can induce minor magnetism in austenitic steels, complicating detection strategies.

Magnetic particle testing is unsuitable for non-magnetic materials, necessitating alternative methods such as eddy current testing or visual inspection.

Understanding these magnetic properties is essential for effectively identifying potential corrosion issues or structural integrity concerns. The choice of detection methods must align with the specific stainless steel type in use, ensuring that corrosion detection is both accurate and reliable to maintain long-term performance and safety in various applications.

The detection of pitting and cracking in stainless steel requires a strategic approach that considers the material's inherent properties and the limitations of various inspection techniques. Understanding pitting mechanisms is crucial, as localized corrosion can compromise the integrity of stainless steel applications.

A comprehensive detection strategy should prioritize methods that effectively identify these defects, such as ultrasonic testing and eddy current techniques, which are specifically designed for non-ferromagnetic materials.

Regular inspection frequency is essential to ensure early detection and facilitate cracking prevention, particularly in environments prone to stress corrosion. The corrosion resistance of stainless steel varies with alloy composition, making it imperative to tailor inspection approaches according to specific material properties and service conditions.

Moreover, adopting a combination of inspection techniques enhances the likelihood of identifying hidden pitting and cracks, thus safeguarding structural integrity and operational reliability.

Ultimately, a rigorous inspection regime not only mitigates potential failures but also extends the lifespan of stainless steel components, fostering a culture of safety and reliability in engineering practices.

Insulation removal presents significant challenges for effective corrosion detection in stainless steel, necessitating a careful evaluation of access methods, moisture exposure risks, and the integrity of insulation materials. The interplay between inspection frequency and insulation integrity is critical, as improper removal can compromise both.

Key considerations include:

Moisture Exposure Risks: Removing insulation increases the likelihood of moisture ingress, which can accelerate corrosion and undermine stainless steel's protective characteristics.

Energy Efficiency: Replacing insulation post-inspection must prioritize energy efficiency, as poorly executed insulation reinstatement can lead to significant thermal losses.

Maintenance Planning: Developing a robust maintenance plan that integrates regular inspections can mitigate corrosion risks while ensuring insulation remains effective.

Given these factors, it is imperative to balance the need for thorough corrosion detection with the preservation of insulation integrity.

A strategic approach that includes assessing the condition of insulation materials before and after removal can enhance overall maintenance planning and extend the service life of stainless steel components.

During stainless steel tube test, several common defects can be identified that may compromise the integrity and performance of the material.

These defects encompass surface imperfections, weld inconsistencies, dimensional inaccuracies, and material flaws, each of which can significantly impact the overall quality and reliability of the tubes.

A thorough understanding of these defects is essential for ensuring compliance with industry standards and maintaining operational safety.

Common surface defects identified in stainless steel tube testing include pitting, stress corrosion cracking, and surface roughness, each posing significant risks to structural integrity and performance. These defects can arise during pipe manufacturing processes and can severely impact stainless steel applications across various industries. Implementing effective corrosion prevention strategies is essential to mitigate these issues.

Key defects include:

Pitting: Localized corrosion leading to small holes, often exacerbated by environmental factors.

Stress Corrosion Cracking: A combination of tensile stress and corrosive environments that can lead to sudden failures.

Surface Roughness: Deterioration of surface finish, which can influence fluid dynamics and promote corrosion.

Addressing these defects requires a comprehensive approach, including an environmental impact assessment to understand how external factors contribute to corrosion.

Furthermore, integrating energy efficiency measures during manufacturing can enhance the durability of stainless steel tubes.

Regular inspections and adherence to best practices in maintenance can significantly reduce the occurrence of these surface defects, ensuring reliable performance in critical applications.

Weld defects in stainless steel tube test can significantly compromise the integrity and performance of the final product, with issues such as incomplete penetration, porosity, and cracking frequently observed. These defects adversely affect weld integrity, resulting in reduced strength and potentially leading to premature failure under operational conditions.

Porosity, often caused by trapped gases during the welding process, diminishes the corrosion resistance of the weld, which is critical for applications in corrosive environments. Incomplete penetration may occur due to improper alignment or inadequate heat input, leaving weak points that are susceptible to stress and fatigue. Cracking can arise from thermal stresses or improper cooling rates, presenting serious concerns for structural reliability.

To ensure the highest standards of quality assurance, employing robust inspection techniques is essential. Non-destructive testing methods, such as ultrasonic and radiographic stainless steel tube test, can effectively identify weld defects before they compromise functionality.

When defects are detected, following established repair procedures is crucial to restore the integrity of the weld and maintain the overall performance of the stainless steel tubes. Through diligent inspection and adherence to quality standards, the risks associated with weld defects can be effectively mitigated.

Dimensional defects in stainless steel tubes, such as variations in wall thickness, diameter inconsistencies, and misalignment, can significantly impact their performance and suitability for specific applications.

These defects not only compromise the integrity of the tubes but also pose challenges in achieving effective corrosion prevention strategies. Ensuring that dimensional specifications are met is crucial for maintaining the quality and reliability of stainless steel applications.

Common dimensional defects include:

Wall Thickness Variations: Inconsistent wall thickness can lead to reduced strength and increased susceptibility to corrosion.

Diameter Inconsistencies: Variations in diameter can affect fitting compatibility and installation precision, impacting overall system performance.

Misalignment: Misalignment during installation can lead to stress concentrations, increasing the risk of failure.

Implementing stringent manufacturing quality control measures is essential to mitigate these defects.

Furthermore, employing proper pipe installation techniques and adhering to maintenance best practices can enhance the longevity and functionality of stainless steel tubes.

Material defects in stainless steel tubes, such as inclusions, voids, and improper alloy composition, can significantly compromise their mechanical properties and overall performance. This necessitates thorough testing and inspection to ensure reliability in critical applications. These defects may lead to unexpected material fatigue, increasing the likelihood of failure during service, particularly in demanding stainless steel applications.

Corrosion prevention strategies are essential in mitigating the effects of material defects, as inadequate resistance can exacerbate deterioration. Regular maintenance best practices, including scheduled inspections and material fatigue analysis, contribute to the longevity and safety of stainless steel tubes. Furthermore, these inspections often involve environmental impact assessments to determine the sustainability of materials used in various applications.

The consequences of undetected material defects can extend beyond immediate failures, leading to costly downtime and potential environmental harm. Thus, adopting a comprehensive approach that integrates quality assurance, advanced testing methods, and ongoing monitoring is vital for maintaining the integrity of stainless steel structures.

In the field of stainless steel tube test, several detection methods are employed to assess structural integrity and identify defects.

Visual inspection offers a straightforward approach for initial evaluations, while X-ray techniques provide non-invasive insights into potential internal flaws.

The Eddy Current Technique stands out for its effectiveness in detecting surface and near-surface defects, particularly in non-magnetic stainless steel materials, thereby complementing other methods in a comprehensive detection strategy.

Utilizing visual inspection as a primary detection method allows for the identification of surface-level corrosion and defects in stainless steel tube test, although its effectiveness diminishes in larger installations and areas obscured by insulation. This method is particularly beneficial for stainless steel applications where quick assessments are necessary. However, it cannot replace comprehensive inspection strategies due to its limitations in visibility and depth.

Key considerations for effective visual inspection include:

Corrosion Resistance: Recognizing areas prone to corrosion, such as welds or joints, can guide maintenance practices.

Alloy Composition: Understanding the specific alloy can inform expectations regarding performance and degradation patterns.

Fabrication Techniques: Awareness of how components were fabricated aids in identifying potential failure points.

While visual inspection is a cost-effective tool for initial assessments, it should be complemented with other methods to ensure thorough detection of issues such as pitting or stress corrosion cracking.

Regular application of maintenance practices, alongside visual checks, ensures the longevity and reliability of stainless steel structures.

X-Ray radiography serves as a valuable non-invasive technique for detecting structural anomalies in stainless steel, allowing for the evaluation of corrosion and other defects without the need for insulation removal.

X-ray applications in industrial contexts facilitate the identification of internal flaws, such as voids and inclusions, which might compromise the material's integrity. This method excels in providing clear X-ray imaging of larger components, thus offering a comprehensive overview of the structure.

However, it is essential to understand the X-ray limitations, particularly its reduced effectiveness for detecting localized phenomena such as pitting and stress corrosion cracking. While X-ray technology is instrumental in certain assessments, its use must be complemented with other methods to achieve a holistic evaluation.

X-ray safety is paramount, necessitating proper shielding and protocols to protect personnel from radiation exposure. Training in safe handling and interpretation of X-ray results is crucial for effective implementation.

The Eddy Current Technique (ECT) is a widely recognized method for detecting surface and near-surface flaws in stainless steel tubes.

This technique comprises two primary variants: Conventional Eddy Current, effective for a range of defect types, and Pulsed Eddy Current, which excels in assessing corrosion beneath insulation without requiring direct contact.

Understanding the distinct applications and limitations of each variant is essential for optimizing defect detection strategies in stainless steel materials.

Conventional Eddy Current testing employs electromagnetic induction to detect surface and near-surface defects in stainless steel components, making it a favored method for assessing corrosion and material integrity.

Applications: Effective for material integrity assessments.

Advantages: High sensitivity to small cracks.

Limitations: Less effective on thick materials.

Eddy current calibration techniques enhance accuracy, and a comparison with ultrasonic methods shows distinct advantages and limitations in specific scenarios.

Utilizing electromagnetic induction principles, Pulsed Eddy Current (PEC) testing serves as an effective method for detecting corrosion under insulation without necessitating direct contact with the material.

This innovative pulsed technology enhances corrosion monitoring capabilities, ensuring material integrity while preserving insulation.

PEC demonstrates significant advancements in eddy applications, making it a vital tool in modern stainless steel tube test innovations for industrial applications.

Foshan Vinmay Stainless Steel Co.,ltd is a large-scale international enterprise which concentrates on producing stainless steel welded tubes and the related fittings. With the large-scale production capacity, advance equipments and technology, a professional sales and management team and the good credit guarantee, Vinmay has been offering high quality and value added products and service to our clients all over the world.

The assessment of stainless steel tubes at Vinmay encompasses a comprehensive suite of inspection processes designed to ensure product integrity and compliance with industry standards.

Key procedures include raw material inspection for quality verification, surface inspection to identify defects, and dimension inspection to confirm adherence to specifications.

Additionally, roughness inspection and chemical composition testing are critical for evaluating the mechanical properties and corrosion resistance of the tubes.

Conducting thorough raw material inspections is essential to ensure the integrity and performance of stainless steel tubes, employing a series of specialized testing processes that adhere to industry standards.

Effective raw material inspections encompass several key processes, including:

Chemical Composition Analysis: We will use a professional spectrometer to check whether the material of the stainless steel pipe raw materials meets the specifications.

Mechanical Testing: We will use a hardness tester to measure the hardness of the raw materials.

Thickness Testing: We will use a hardness tester to measure the hardness of the raw materials.

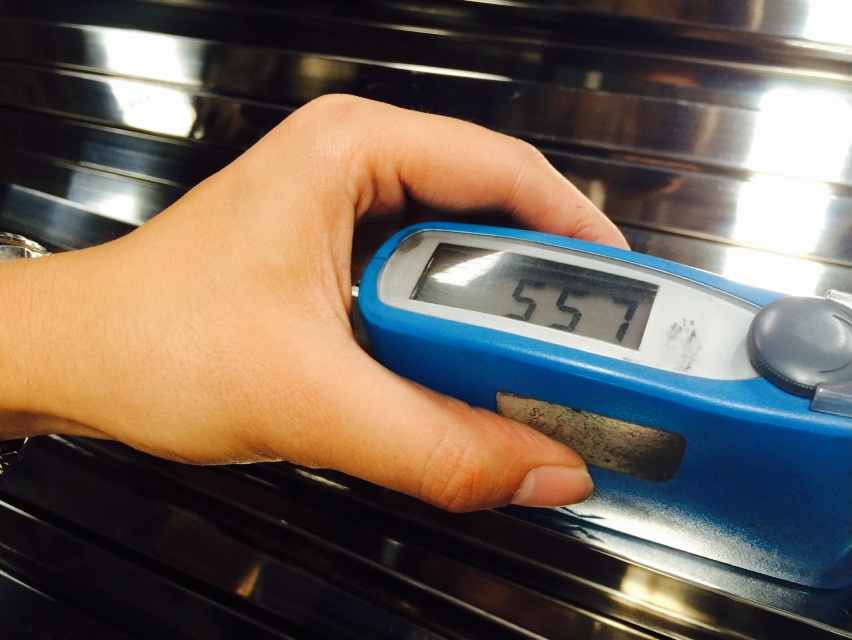

Surface inspection primarily involves visual examination to check for scratches, dents, depressions, welding defects, and other surface imperfections on the stainless steel tube. Additionally, we will use a brightness tester to measure the brightness of the stainless steel tube according to the customer's requirements.

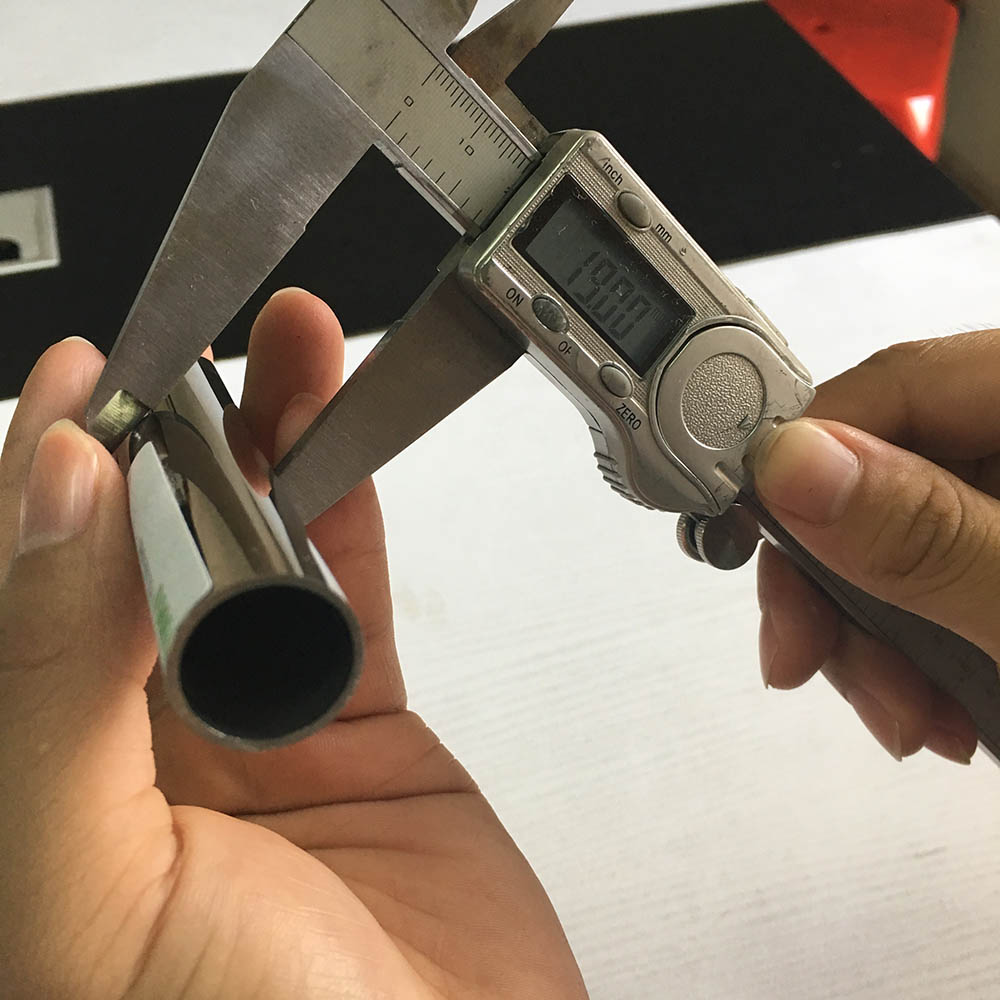

External diameter inspection: We use calipers to check whether the external diameter of the stainless steel tube meets customer specifications.

Thickness inspection: We use a micrometer to check whether the thickness of the stainless steel tube meets customer specifications.

Length inspection: We use a tape measure to check whether the length of the stainless steel tube meets tolerance standards.

We will use a roughness tester to measure the internal roughness of the stainless steel pipe, which is primarily focused on fluid piping.

Used to detect defects or quality issues in conductive materials (mainly to check for welding defects and abnormal sand holes in stainless steel tube).

Mechanical properties testing of stainless steel tubes is a critical process employed by Vinmay to evaluate the performance characteristics such as tensile strength, ductility, and hardness. This ensures that materials meet specified engineering standards and application requirements. This testing is vital in predicting potential mechanical failure and understanding the material's response to various stress factors and environmental impacts. We will use a universal testing machine for testing.

Key aspects of mechanical properties testing include:

Tensile Strength: Determines the maximum load-bearing capability before failure, crucial for structural integrity.

Ductility Assessment: Evaluates the material's ability to deform under stress, essential for applications requiring flexibility.

Hardness Testing: Measures resistance to deformation, allowing for assessments of wear resistance and suitability for different environments.

Intergranular corrosion testing is an essential process employed by Vinmay to assess the susceptibility of stainless steel tubes to localized attack along grain boundaries, which can significantly compromise structural integrity and performance in service. This type of corrosion can occur in stainless steel alloys that have been improperly heat-treated or sensitized, rendering them vulnerable to environmental factors.

Like a well-crafted shield against adversity, stainless steel tubes exhibit varying lifespans in harsh environments, influenced by corrosion resistance, material selection, maintenance practices, environmental compatibility, and performance evaluation, necessitating tailored strategies for optimal longevity.

You may also like:

The Life Expectancy of 316 Stainless Steel

The Life Expectancy of 304 Stainless Steel

Environmental factors significantly influence corrosion types in stainless steel, with alloy composition and protective coatings playing critical roles. Regular maintenance practices and reduced environmental exposure can mitigate corrosion rates, enhancing the longevity of stainless steel components.

Absolutely! Stainless steel can be recycled after testing, with robust recycling processes in place. Various stainless steel grades are considered, ensuring compliance with industry standards while minimizing environmental impact, thus supporting sustainable practices within the industry.

The costs associated with stainless steel testing encompass various testing standards, inspection techniques, and a detailed cost breakdown. Adhering to material specifications and industry regulations is essential to ensure compliance and optimize resource allocation.

In a world reminiscent of a bygone era, stainless steel tubes should undergo performance evaluation through regular inspections, following industry standards. Testing methods and maintenance practices dictate an inspection frequency of at least annually to ensure integrity.

In conclusion, the rigorous testing of stainless steel tubes is paramount in safeguarding structural integrity and ensuring optimal performance across various applications.

As the ancient adage suggests, 'an ounce of prevention is worth a pound of cure,' which resonates profoundly in the context of stainless steel testing.

By employing advanced methodologies and maintaining stringent inspection protocols, industries can avert catastrophic failures and uphold safety standards, thus reinforcing the reliability of stainless steel products in demanding environments.