Stainless steel round tubes, known for their robust properties and versatile applications, have become indispensable in various industries. From their impeccable corrosion resistance to their outstanding mechanical strength, these tubes are engineered to withstand demanding environments. The intricate stainles steel pipe manufacturing these tubes involves meticulous attention to detail, ensuring high-quality.

As we explore the stainless steel tube standards, mechanical properties, and grades associated with stainless steel round tubes, it becomes evident that these components play a significant role in numerous sectors. But what sets them apart regarding finish, size, and welding techniques? Let's investigate further.

The composition and properties of stainless steel round tubes are crucial factors to consider when defining their suitability for various applications. Here are some key points to understand:

ASTM A554 is a standard specification for mechanical stainless steel welded tube. This standard is commonly used for structural, ornamental, and decorative purposes. It's often employed in architectural applications, such as handrails, balustrades, and furniture, as well as in automotive and industrial equipment where aesthetic appeal and corrosion resistance are important.

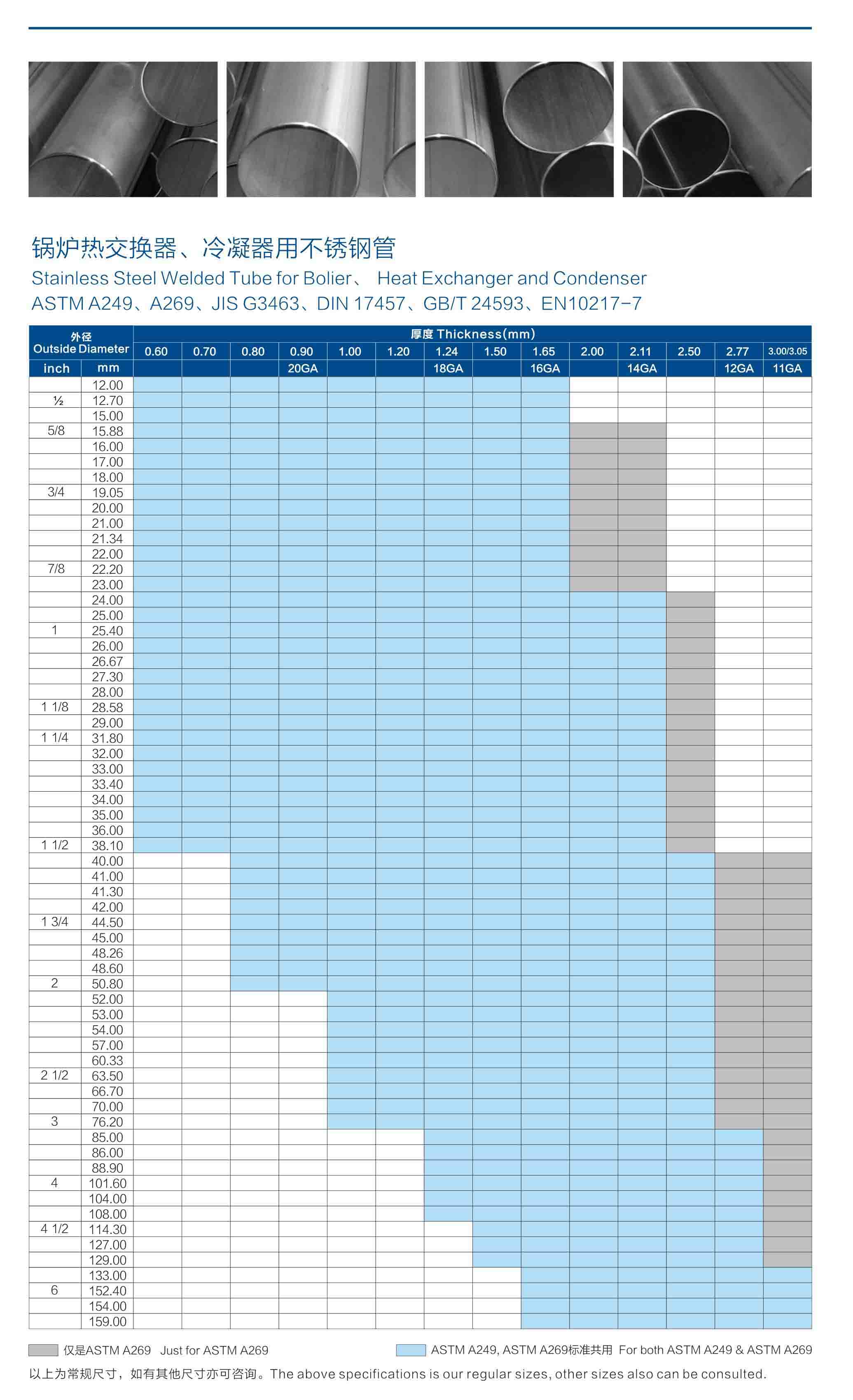

ASTM A249 is a standard specification for welded austenitic steel boiler, superheater, heat-exchanger, and condenser tubes. It apply in the industries such as chemical processing, petroleum refining, power generation, and food processing. They are designed to withstand high temperatures and corrosive environments.

ASTM A269 is a standard specification for seamless and stainless steel welded round tube for general service.

This standard covers a wide range of applications including general corrosion-resistant and high-temperature service. It's commonly used in industries such as pharmaceuticals, food and beverage, aerospace, chemical processing, and instrumentation where cleanliness, durability, and corrosion resistance are critical.

ASTM A270 is a standard specification for seamless and welded austenitic stainless steel sanitary tubing intended for use in dairy and food industry and having special surface finishes.

ASTM A511 sets standards for seamless stainless steel mechanical tubing, ensuring precise dimensions, mechanical properties, and surface finish quality. These standards cover aspects vital for various applications, such as corrosion resistance, strength, and durability.

Adhering to ASTM A511 guarantees that stainless steel round tubes meet industry requirements for performance and reliability.

For applications requiring adherence to ASTM A511 standards, stainless steel round tubes are utilized in various industries for their superior quality and performance characteristics.

Stainless steel round tubes exhibit a tensile strength of 85,800 psi, showcasing their exceptional mechanical properties for various applications. This high tensile strength is vital for guaranteeing structural integrity and durability in demanding environments.

Here are four key points regarding the tensile strength of stainless steel round tubes:

Essential Strength: 85,800 psi tensile strength provides the tubes with the ability to withstand heavy loads and high-stress conditions.

Dependable Performance: Consistent tensile strength ensures the tubes maintain their structural integrity over time.

Versatile Applications: Suitable for a wide range of industries including construction, automotive, aerospace, and manufacturing due to their robust mechanical properties.

Quality Assurance: High tensile strength guarantees the reliability and safety of the stainless steel round tubes in various applications.

With a focus on mechanical properties, particularly the yield point, stainless steel round tubes demonstrate robust characteristics that contribute to their structural integrity and performance across diverse industrial applications.

The yield point of stainless steel round tubes is measured at 34,000 psi, indicating the stress level at which the material begins to deform plastically. This essential parameter signifies the point at which the material shifts from elastic deformation to plastic deformation, highlighting its ability to withstand substantial loads without permanent damage.

Understanding and optimizing the yield point of stainless steel round tubes is vital in ensuring their reliability and longevity in various demanding environments, making them a preferred choice for applications requiring high strength and resilience.

When evaluating the mechanical properties of stainless steel round tubes, a key parameter to consider is the elongation, which indicates the extent of deforation the material can undergo before failure. Elongation is essential in understanding how much a material can stretch before breaking, providing insights into its ductility and flexibility.

Definition: Elongation measures the percentage increase in length of a material during tension testing.

Significance: Higher elongation values suggest greater ductility and ability to deform without fracturing.

Calculation: Expressed as a percentage, calculated by comparing the final and initial lengths of the material.

Application: Vital for applications requiring materials to withstand deformation without failure, such as in structural components or forming processes.

When evaluating the mechanical properties of stainless steel round tubes, one significant aspect to take into consideration is the elasticity, which characterizes the material's ability to return to its original shape after deformation.

Elasticity is an important mechanical property as it indicates the flexibility and resilience of the stainless steel tube when subjected to external forces. In the case of stainless steel round tubes, a high elasticity value, such as the 29,000 ksi typical for this material, signifies that it can endure deformation and return to its initial form without permanent damage.

This property guarantees that the tube can withstand bending, forming, and other shaping processes without losing its structural integrity, making it a reliable choice for various applications requiring consistent performance under stress.

The shearing strength of stainless steel round tubes is an essential mechanical property that determines their resistance to forces applied parallel to their surface. Here are four key points to understand about the shearing strength of stainless steel round tubes:

Definition: Shearing strength is the maximum amount of shear force a material can withstand before undergoing structural failure.

Importance: It indicates the tube's ability to resist forces that cause parts of the material to slide past each other in opposing directions.

Testing: Shearing strength test is typically determined through mechanical testing methods to guarantee structural integrity.

Application: Knowledge of shearing strength is vital in designing and selecting stainless steel round tubes for applications requiring high resistance to shear forces.

The Brinell Hardness test is a fundamental method used in material science to evaluate the hardness of stainless steel round tubes. This test involves indenting the surface of the material with a specified load and measuring the diameter of the impression left. Stainless steel round tubes typically exhibit a Brinell Hardness of 170, indicating a significant level of hardness. This property is essential in determining the material's ability to resist deformation and wear under applied forces. The table below provides a comparison of Brinell Hardness values for different materials:

| Material | Brinell Hardness |

|---|---|

| Stainless Steel | 170 |

| Aluminum | 95 |

| Mild Steel | 120 |

| Copper | 35 |

Copper VS Stainless Steel Pipe Which one is right for you ?

Density plays a pivotal role in determining the mechanical properties of stainless steel round tubes. Here are four key points regarding the density of stainless steel tubes:

Definition: Density refers to the mass per unit volume of a material, typically measured in pounds per cubic inch.

Impact on Mechanical Properties: Higher density materials tend to have better strength and durability.

Stainless Steel Density: Stainless steel has a density of 0.289 lb/in³, making it a relatively lightweight yet strong material.

Application Significance: The density of stainless steel round tubes influences their suitability for various industries, ensuring they meet specific weight and strength requirements.

The selection of stainless steel grades such as 201, 304, 316, 409, and 321 plays a pivotal role in determining the performance and characteristics of round tubes. Each grade offers unique properties regarding corrosion resistance, strength, and durability, catering to specific application requirements.

Understanding the distinctions between these grades is essential for choosing the most suitable stainless steel round tube for various industries and environments.

201 stainless steel is a type of austenitic stainless steel that is part of the 200 series, known for its high manganese and low nickel content compared to other austenitic grades like 304. Here are some key characteristics and uses of 201 stainless steel:

201 stainless steel is used in a variety of applications where high strength and moderate corrosion resistance are required. Common applications include:

Advantages:

Disadvantages:

You may also like :

Mastering the Art of 201Stainless Steel Welding

304 stainless steel is one of the most commonly used stainless steel alloys, known for its excellent corrosion resistance, durability, and versatile application range. Here are the key characteristics and properties of 304 stainless steel:

The Life Expectancy of 304 Stainless Steel

304 stainless steel welded pipe is used in a wide range of industries, including:

316 stainless steel is another popular grade of stainless steel, known for its enhanced corrosion resistance, especially against chlorides and other industrial solvents. Here are the key characteristics and properties of 316 stainless steel:

316 stainless steel is used in a variety of demanding environments due to its enhanced corrosion resistance:

409 stainless steel is a ferritic stainless steel that is commonly used for automotive exhaust systems and other applications requiring good oxidation and corrosion resistance. It is known for its combination of good mechanical properties and moderate corrosion resistance, making it an economical choice for applications where high strength and corrosion resistance are not the primary requirements.

The manufacturing process of stainless steel round tubes involves several key points. These include forming and welding, finishing techniques, and unique or innovative production methods.

Forming and welding are essential steps in creating the shape and structure of the tube, while finishing techniques ensure a smooth and polished surface.

Additionally, manufacturers may employ unique or innovative production methods to enhance the quality and efficiency of the manufacturing process.

Forming and welding processes are crucial steps in the manufacturing of stainless steel welded round tubes. These processes play a significant role in shaping and joining the stainless steel material, ensuring the production of high-quality and durable tubes.

Here are some key aspects of forming and welding in the manufacturing process:

Tube forming : The stainless steel material undergoes various forming techniques, such as cold drawing, rolling, or extrusion, to shape it into a round tube.

Tube welding: Welding is employed to join the edges of the formed stainless steel tube together. This process ensures a strong and seamless bond.

Weld inspection: After welding, the tubes are inspected to ensure the weld integrity and quality. This step ensures that the tubes meet the required standards and specifications.

Post-weld treatment: The welded tubes may undergo further processes, such as annealing or pickling, to improve their surface finish and remove any impurities.

Discover More:

How to TIG Weld Stainless Steel Pipe ?

Stainless Steel Pipe Welding Procedure Specification

The Difference of Stainless Steel Pipe TIG Welding and HF Welding

Stainless Steel Welding Issues Exploration

To ensure a polished and high-quality appearance, stainless steel round tubes undergo various finishing techniques as part of the manufacturing process. These techniques aim to remove any imperfections, enhance the surface smoothness, and provide a protective layer against corrosion.

One common finishing technique is grinding, which involves the use of abrasive materials to smooth out any rough edges or surface irregularities.

Another technique is polishing, which utilizes polishing compounds and buffing wheels to create a smooth and reflective surface.

Additionally, electropolishing can be employed to remove microburrs and improve the overall surface finish.

Finally, passivation is often applied to stainless steel tubes to remove any remaining contaminants and create a passive oxide layer that enhances corrosion resistance.

These finishing techniques not only contribute to the aesthetic appeal of stainless steel round tubes but also ensure their durability and longevity.

When it comes to producing stainless steel round tubes, manufacturers employ several unique and innovative production methods to ensure high-quality and efficient production. These methods include:

Seamless tube production: Utilizing advanced technology, stainless steel round tubes are manufactured without the need for welding, resulting in a seamless finish that enhances the tube's durability and appearance.

Cold drawing: This process involves pulling the stainless steel tube through a die to reduce its diameter and improve its surface finish. Cold drawing also enhances the tube's mechanical properties, making it stronger and more resistant to corrosion.

Welded tube production: In this method, stainless steel strips are welded together using various techniques such as TIG or laser welding. This process is cost-effective and allows for the production of tubes with larger diameters.

Precision machining: Manufacturers employ precision machining techniques to ensure accurate dimensions and smooth surface finishes of stainless steel round tubes. This process involves using specialized machinery and tools to remove excess material and create the desired shape.

The finish of stainless steel round tubes plays a vital role in determining their aesthetic appeal and functionality. Common finishes include Mirror Finish, Satin Finish, and Mill Finish, each offering distinct characteristics and applications.

Understanding these finish options is essential for selecting the most suitable stainless steel round tube for specific industrial or commercial requirements.

A mirror finish stainless steel round tube exhibits a high-gloss reflective surface achieved through a meticulous polishing process. This finish is not only aesthetically pleasing but also offers enhanced corrosion resistance and durability.

Here are some key points regarding mirror finish stainless steel round tubes:

Satin Finish stainless Steel Round Tube boasts a refined surface texture that enhances both aesthetics and functionality in various applications requiring a sleek appearance and durability. This finish is achieved through a process that creates a smooth, even texture with fine parallel lines.

The satin finish provides a modern look while maintaining the inherent corrosion resistance and durability of stainless steel. It is ideal for architectural elements, interior design, furniture, and automotive applications where a sophisticated appearance is desired.

The satin finish is achieved by sanding the surface with progressively finer abrasives until the desired texture is achieved. This finish is popular for its ability to hide fingerprints, scratches, and wear, making it a practical and stylish choice for a wide range of projects.

You may also like:

The Ultimate Guide to Grade of Stainless Steel Pipe

What sets apart the Mill Finish stainless Steel Round Tube regarding its surface presentation and properties in comparison to other finishes?

Appearance: The Mill Finish stainless Steel Round Tube has a raw, unpolished surface, giving it a matte appearance.

Texture: The surface of the Mill Finish tube is smooth but not reflective, distinguishing it from polished finishes.

Cost-Effectiveness: Due to minimal processing, the Mill Finish is a more economical option compared to other finishes.

Versatility: This finish is versatile and can be further processed or coated to meet specific requirements.

The Mill Finish stainless Steel Round Tube offers a unique aesthetic and cost-effective solution, suitable for various applications where a polished finish is not necessary.

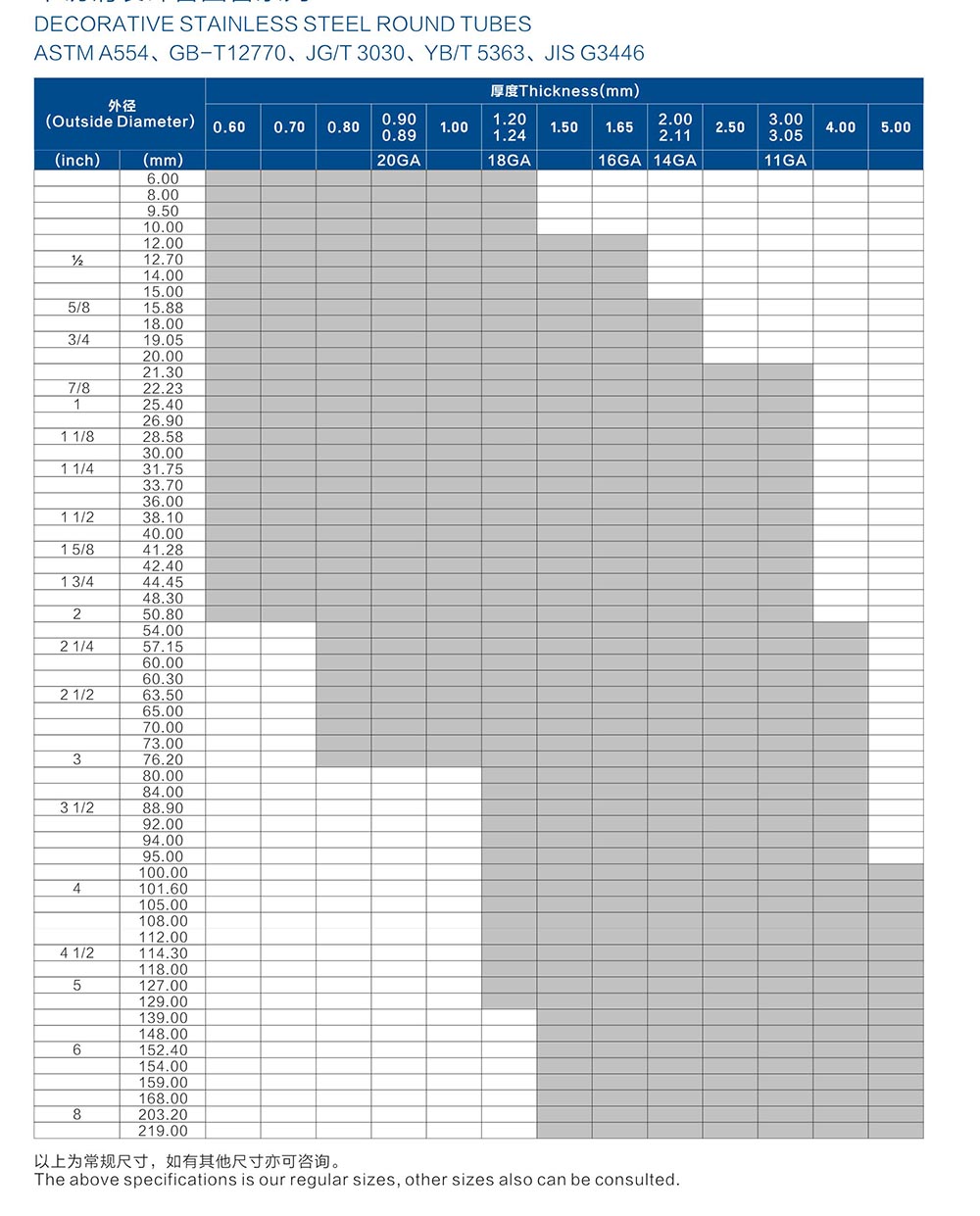

When it comes to stainless steel round tubes, there are various varieties and stainless steel round pipe sizes available in the market. Standard dimensions and thicknesses are commonly used in many applications, providing a reliable and versatile option.

Additionally, specialized types of stainless steel round tubes are also available to cater to specific industries or projects, ensuring optimal performance and durability.

Standard dimensions and thicknesses for stainless steel round tubes vary depending on the specific variety and size. To provide clarity and precision, here are some key points to consider:

Variety : Stainless steel round tubes are available in various grades, such as 304, 316, and 201, each offering different properties and corrosion resistance.

Size: The outer diameter (OD) and wall thickness (WT) are the primary dimensions to consider. Common OD sizes range from 1/8 inch to 12 inches, while wall thicknesses can vary from 0.035 inches to 0.500 inches.

Tolerances: Stainless steel round tubes adhere to specific tolerances for OD, WT, and length to ensure consistency and accuracy in their dimensions.

Customization: Manufacturers can also provide custom sizes and thicknesses to meet specific project requirements.

Stainless steel round tube sizes vary depending on the standards they adhere to. Various size charts exist for different standards.

Several reputable stainless steel round tube suppliers cater to various industries, offering a range of options to meet specific needs and requirements. When selecting a supplier for stainless steel round tubes, it is crucial to take into account factors such as quality, certifications, lead times, and customer service. Below is a table showcasing three top stainless steel round tube suppliers:

| Supplier | Specialization | Certifications |

|---|---|---|

| Company A | Construction, Automotive | ISO 9001, ASTM A554 |

| Company B | Aerospace, Manufacturing | AS9100, ISO 13485 |

| Company C | Food & Beverage, Pharma | FDA, ASTM A269 |

These suppliers are known for their adherence to industry standards, product quality, and on-time delivery. Choosing a supplier that aligns with your industry requirements and values can lead to a successful partnership for your stainless steel round tube needs.

Stainless steel round tube prices vary based on factors such as material grade, dimensions, and finish, influencing the overall cost for different applications and industries. When considering the cost of stainless steel round tubes, the following factors play an important role:

Material Grade: Different stainless steel grades like 304 and 316 come with varying price points due to their unique properties.

Dimensions: The outer diameter, wall thickness, and length of the tube impact the pricing.

Finish: Finishes such as polished, brushed, or satin can affect the final cost.

Market Conditions: Fluctuations in raw material prices and market demand influence the overall pricing structure.

Understanding these factors is essential for businesses and industries looking to procure stainless steel round tubes at competitive prices while ensuring the desired quality for their specific applications.

When comparing stainless steel round tube welded versus seamless, it is important to analyze the manufacturing processes, applications, and strength and durability.

The manufacturing process differs significantly, with welded tubes being formed by welding stainless steel strips, while seamless tubes are manufactured through an extrusion process without a welded seam. Understanding these distinctions is essential for selecting the appropriate tube type based on the specific application requirements, such as cost-effectiveness, corrosion resistance, and strength under pressure.

Evaluating the strength and durability aspects of welded and seamless stainless steel round tubes is necessary to guarantee excellent performance in various industries and applications.

In the manufacturing processes of stainless steel round tubes, the distinction between welded and seamless tubes lies in their production methods and structural characteristics.

Welded Tubes:

Seamless Tubes:

The distinction between welded and seamless stainless steel round tubes greatly impacts their application versatility and suitability for specific industry requirements.

Welded tubes, being more cost-effective, find extensive use in various industries such as construction and industrial machinery due to their excellent corrosion resistance. They are commonly chosen for heavy-duty industrial machinery and automotive applications.

On the other hand, seamless tubes are known for their superior strength and corrosion resistance, making them ideal for high-pressure and temperature applications. They are particularly suitable for precision applications like automotive parts manufacturing, where the absence of a weld seam eliminates potential structural weaknesses and guarantees exceptional performance in extreme conditions.

To evaluate the strength and durability of stainless steel round tubes, the distinction between welded and seamless varieties plays a critical role in determining their performance under varying conditions.

Welded Tubes:

Seamless Tubes:

When considering stainless steel round tubes, the manufacturing process impacts their strength, durability, and overall performance.

Welded tubes offer cost-efficiency and versatility, while seamless tubes provide superior strength and corrosion resistance, making them ideal for high-pressure and precision applications.

Foshan Vinmay Stainless Steel Co.,ltd is a manufacturer of stainless steel welded tube in various standard.

With 16 years experience, we mainly produce stainless steel welded tube for ornamental purpose ( ASTM A554 /EN 10296-2); stainless steel welded tube for food industry ( ASTM A270, EN10357); stainless steel welded tube for heat exchanger ( ASTM A249, EN10217-7) and stainless steel water tube (EN10312).

Vinmay is a quality and service oriented company. We follow strict quality management system and establish a customer satisfaction management system which is applied to serve over 1000 companies from 60 countries. Currently we export more than 25000 tons of stainless steel welded tubes every year, of which the export volume of ASTM A554 tubes ranks 1 st place in China.

You may also like:

A Comprehensive Guide to Top Stainless Steel Round Tube Suppliers Worldwide

To summarize, stainless steel round tubes are essential components in various industries due to their exceptional strength, corrosion resistance, and durability. Adhering to stringent industry standards and offering excellent mechanical properties, these tubes provide reliability and functionality in diverse applications.

With different sizes, finishes, and grades available, stainless steel round tubes guarantee high-quality material composition and dimensional accuracy. Overall, stainless steel round tubes are a versatile and reliable choice for structural components and fluid handling systems in the industry.