Copper tubing comes in various types, each suitable for specific applications. The pros of using copper pipes include their malleability, thermal conductivity, and effectiveness in certain applications like radiators.

However, the cons of copper pipes involve susceptibility to external corrosion, limitations in high-velocity systems, and higher thermal conductivity leading to increased heat loss.

Soft copper tubing is a flexible and versatile type of piping material commonly used in various plumbing applications due to its malleability and ease of installation.

Through the annealing process, soft copper gains its pipe flexibility, allowing for tight shapes and radii.

This type of tubing exhibits good corrosion resistance, contributing to its pipe longevity.

Secure joints using methods like brazing are essential for reliable installations.

One commonly utilized type of copper tubing in plumbing applications is rigid copper, distinguished by its inflexible structure and durability.

Type K pipes are a specific type of copper tubing known for their high durability and resistance to corrosion in plumbing applications. Compared to other grades, Type K pipes offer excellent corrosion resistance and material strength.

They have high pressure ratings and are commonly used due to their efficient installation methods and welding techniques. Type K pipes also exhibit good thermal conductivity and insulation requirements, with positive environmental impacts and sustainability benefits.

Introduction to Copper Pipe Types includes a detailed examination of Type L pipes, a significant variant in copper tubing utilized for specific applications in plumbing systems.

Copper pipes designated as Type M offer specific characteristics and applications within plumbing systems. See the table below for a comparison between Type M copper pipes and stainless steel pipes regarding pressure ratings, material comparison, installation differences, corrosion resistance, and sustainable options.

| Aspect | Type M Copper Pipes | Stainless Steel Pipes |

|---|---|---|

| Pressure Ratings | Lower | Higher |

| Material Comparison | Copper | Stainless Steel |

| Installation | Easier | More complex |

Discussing the drainage, waste, and vent (DWV) pipes in plumbing systems involves understanding the various kinds of copper tubing used for different applications

Copper pipes offer health benefits as they are non-toxic and do not leach harmful substances into the water supply.

Their resistance to corrosion guarantees longevity and reliability in plumbing systems.

Additionally, the malleability of copper makes it easy to work with, allowing for secure joints and intricate installations.

Utilizing copper pipes in plumbing systems offers a multitude of health benefits and advantages that make them a preferred choice in various applications.

Health benefits: Copper has natural antimicrobial properties.

Environmental impact: Copper is recyclable and sustainable.

Longevity comparison: Copper pipes have a long lifespan.

Cost efficiency: Copper is cost-effective in the long run due to its durability.

When considering the benefits of copper pipes, their exceptional resistance to corrosion stands out as a significant advantage.

In a corrosion resistance comparison, copper fares well against environmental impacts due to its strength and durability.

Additionally, its sustainability factors are notable, although proper disposal is important.

Copper also exhibits good insulation properties, making it a reliable choice for various plumbing applications.

In plumbing applications, the non-toxic nature of copper pipes is a significant advantage that contributes to their desirability and suitability for various systems.

Environmental impact: Copper is sustainable but can cause pollution if disposed of incorrectly.

Material comparison: Copper is less toxic compared to other materials like lead.

Cost analysis: Initial copper pipe cost may be higher, but long-term health benefits outweigh the expense.

Health considerations: Copper pipes are safe for transporting drinking water.

Copper pipes offer exceptional ease of manipulation and installation due to their malleability and compatibility with basic hand tools. When working with copper pipes, tool compatibility is essential for successful bending techniques and soldering advantages. Compared to stainless steel, copper pipes require different welding methods and joining techniques. These attributes make copper pipes a preferred choice for those seeking efficient and straightforward plumbing solutions.

| Attributes | Copper Pipes |

|---|---|

| Tool Compatibility | Basic hand tools |

| Bending Techniques | Malleability |

| Welding Comparison | Different methods |

| Soldering Advantages | Efficient |

| Joining Methods | Versatile |

The expenses associated with the installation of copper piping can present significant drawbacks when considering the overall cost-effectiveness of utilizing this material for plumbing systems.

Cost Analysis:

Copper installation can be pricier than other materials.

Installation Efficiency:

Copper's malleability can lead to easier installation.

Longevity Comparison:

Copper pipes may require more maintenance over time.

Material Sustainability:

Concerns about copper's environmental impact and sustainability arise.

Considering the propensity for leaks and drips, a critical evaluation of copper piping reveals significant drawbacks in its application for plumbing systems. Leaks often stem from corrosion, poor installation, or external damage. Repair solutions may involve soldering or replacing sections. Maintenance tips include regular inspections and addressing issues promptly. Prevention methods encompass proper installation techniques and protecting pipes from physical harm. Detection techniques involve pressure testing and visual inspections.

| Repair Solutions | Soldering, Section Replacement |

|---|---|

| Maintenance Tips | Regular Inspections, Prompt Action |

| Prevention Methods | Proper Installation, Pipe Protection |

You may also like:

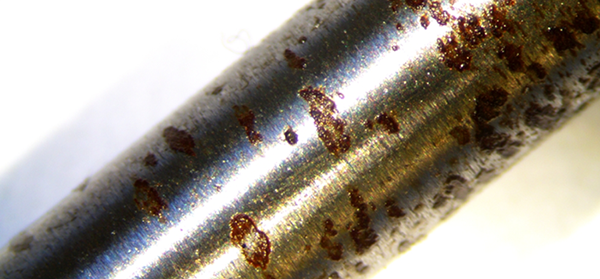

Copper piping systems can corrode externally when exposed to certain environmental factors at elevated levels. These factors include gases such as carbon dioxide, sulfur dioxide, and hydrogen sulfide, as well as hard water that is rich in chlorine, chlorides, or has a pH outside the 6.5-7 range. Acidic environments can lead to water discoloration and copper poisoning, making the water unsafe for human consumption.

Stainless steel piping has excellent corrosion resistance, particularly in the full range of potable waters, including soft waters. While stainless steel can corrode in the presence of high chloride levels, it is generally more corrosion-resistant than copper.

The high level of corrosion resistance in stainless steel is due to a thin, adherent chromium oxide surface film that forms immediately upon contact with oxygen. This film allows the pipe surface to effectively heal itself if scratched.

In addition to this external surface healing process, piped water supplies contain adequate levels of oxygen to facilitate this healing and protective process inside the stainless steel pipe. The resilience of this chromium oxide layer is enhanced by the presence of molybdenum.

The nickel in stainless steel piping promotes the formation of a crystalline structure called austenite, which improves ductility and formability.

The distinctive green coloration observed on copper surfaces is a result of oxidation caused by exposure to environmental elements. This process leads to the formation of a protective oxide layer that gives copper its characteristic green hue.

Here are four key points to keep in mind regarding why copper turns green:

Understanding the reasons behind the green coloration of copper highlights the intricate relationship between the material and its surrounding environment, emphasizing the significance of sustainable practices in its usage.

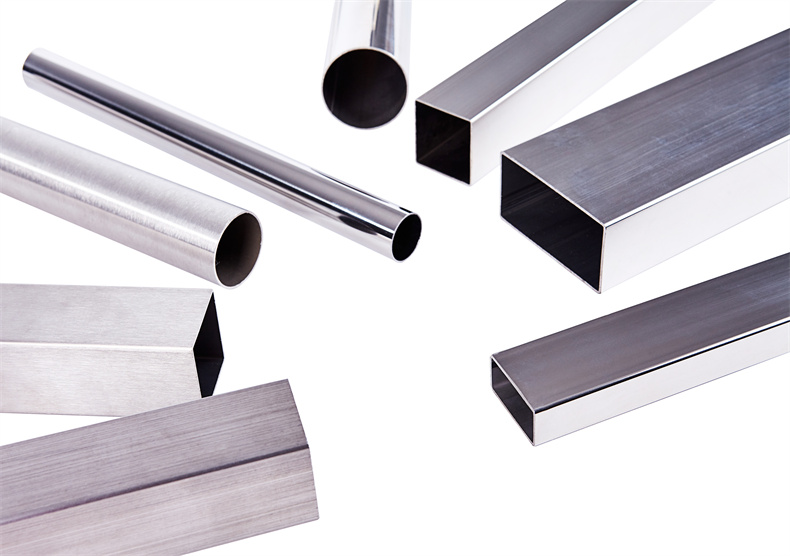

Comparing the physical properties of copper vs stainless steel pipe helps in understanding their practical applications.

Tensile strength is a crucial consideration, as it reflects a material's ability to withstand external forces. Stainless steel exhibits higher tensile strength than copper, making it more suitable for applications that demand greater structural integrity.

Taking the widely utilized 304 grade thin-walled stainless steel pipe as an example, its tensile strength measures 530-750 MPa, outperforming galvanized pipes by twofold and copper pipes by threefold. This distinct strength advantage enables thinner dimensions for the stainless steel pipes (0.6mm), aligning with material conservation policies. It simultaneously ensures structural robustness and contributes to reduced building weight.

Thermal conductivity and expansion coefficients are also vital factors. Copper is a superior conductor of heat, making it a preferred choice for applications requiring efficient heat transfer, such as HVAC systems. Conversely, stainless steel possesses lower thermal conductivity but compensates with a lower coefficient of thermal expansion, ensuring stability in varying temperature conditions.

The thermal conductivity of thin-walled stainless steel pipes registers at 15 W/m℃ (100℃), only a quarter of carbon steel pipes and a mere 1/23 of copper pipes. This excellent heat insulation property makes thin-walled stainless steel pipes ideal for hot water conveyance. The economic viability extends to insulation layer thickness, construction expenses, and maintenance costs.

Thin-walled stainless steel pipes exhibit an average thermal expansion coefficient of 0.017 mm/(m℃), akin to copper pipes. This similarity underscores the suitability of metal pipes for transporting hot water. The inner surface of these stainless steel pipes, treated externally and internally, boasts a smooth and pristine finish. The inner wall's equivalent roughness, Ks, of 0.00152mm, is smaller than that of copper tubes. Consequently, opting for thin-walled stainless steel pipes augments water flow, minimizes turbulence, fortifies corrosion resistance, and effectively reduces noise.

Comparing the strength and durability between copper vs stainless steel pipes reveals significant differences in their mechanical properties and performance characteristics. Stainless steel demonstrates superior strength to copper, with a 40% increase in strength and rigidity. This enhanced strength allows stainless steel to endure high pressure ratings, a feature absent in copper pipes.

Additionally, stainless steel maintains its pressure rating consistency across various stainless steel pipe sizes, unlike copper, whose pressure rating decreases as the pipe size increases. Concerning sustainability, stainless steel has a lower carbon footprint and is 100% recyclable, making it a more environmentally friendly option.

While copper's raw material costs fluctuate, especially in larger sizes, stainless steel press-fit pipes offer larger diameter capabilities, potentially leading to cost savings in installations. When evaluating factors like corrosion resistance, thermal conductivity, cost analysis, pressure ratings, and sustainability, stainless steel emerges as the stronger and more durable choice compared to copper.

Copper's reputation for being more malleable and easier to cut compared to stainless steel is a notable factor in evaluating the strength and durability differences between the two materials in piping applications. When considering cutting techniques and durability, the following points should be noted:

Understanding these differences in cutting ease, malleability, strength, and fabrication challenges can help in making informed decisions regarding material costs, installation challenges, and overall performance differences in piping systems.

In strength and durability, the flexibility advantage of copper comes at the expense of its long-term resilience when compared to stainless steel pipes. While copper's flexibility allows for easy shaping and installation, it lacks the durability of stainless steel in terms of corrosion resistance and longevity.

Stainless steel pipes outperform copper in durability comparison due to their superior corrosion resistance, making them more suitable for long-lasting applications. The flexibility trade-off of copper makes it vulnerable to damage from external factors like environmental gases and hard water, leading to potential corrosion issues over time.

On the other hand, stainless steel's corrosion-resistant properties and longevity evaluation guarantee a reliable and sustainable piping solution. When considering material sustainability and the necessity for a strong and long-lasting piping system, stainless steel emerges as the preferred choice over copper for applications where durability is crucial.

When evaluating the longevity and durability of piping systems, the comparison between copper vs stainless steel pipe reveals significant differences in performance and lifespan.

Copper pipes have a lifespan ranging from 20 to 50 years, depending on various factors such as water quality, installation practices, and maintenance procedures. Copper pipes are durable and resistant to corrosion, but they may require more maintenance over time compared to stainless steel pipes. Regular inspections, cleaning, and potential repairs are essential to guarantee the longevity of copper piping systems.

In contrast, stainless steel pipes have a longer lifespan, typically lasting 50 to 100 years or more. They have lower maintenance requirements, are more resistant to environmental factors, and offer better longevity without the need for frequent upkeep.

While copper pipes are cost-effective initially, the longer lifespan and lower maintenance needs of stainless steel pipes make them a more cost-effective choice in the long run. Installation considerations for copper pipes include proper support and protection from external damage to maximize their lifespan.

Stainless steel pipes tend to be more expensive than copper pipes due to the complexities of their manufacturing process and the materials used.

Stainless steel retains its color over time, avoiding fading or discoloration that can occur with certain other metal materials. The cost of stainless steel varies according to the grade, typically falling within the range of approximately $3 to $5 per square foot.

Copper pipes, while generally more cost-effective, offer excellent value considering their longevity, corrosion resistance, and overall performance.

Copper's price fluctuates in accordance with its grade, and there exist four prevalent grades. As a general estimate, the cost of copper typically spans from approximately $2 to $3 per square foot.

Cost considerations play a pivotal role in any project. Balancing upfront costs with long-term benefits is crucial when deciding between these two materials.

Learn More:

Deciphering the Dynamics: Unraveling Stainless Steel Round Tube Prices

Stainless steel pipes excel in applications where high pressure and fluid velocity are critical factors, offering superior strength and resistance to corrosion.

On the other hand, copper pipes are suitable for low-pressure systems and applications with restricted fluid flow, owing to their malleability and ease of installation.

Understanding the specific requirements of a piping system, such as the nature of fluids, pressure levels, and flow rates, is essential in determining whether copper or stainless steel pipes are the best choice for a particular application.

For fluid applications, copper and stainless steel pipes exhibit distinct characteristics that determine their suitability for various use cases in plumbing and industrial settings.

In high-pressure applications, the comparison between copper and stainless steel pipes reveals significant differences in their performance and suitability for various use cases.

Stainless steel excels in pressure resistance, material sustainability, thermal conductivity, and corrosion protection, making it ideal for demanding environments.

Although stainless steel may have a higher initial cost, its long-term durability and cost efficiency often outweigh the investment compared to copper in high-pressure scenarios.

When considering the use of copper and stainless steel pipes in different applications, their performance in high-velocity scenarios showcases distinct advantages and limitations.

Copper pipes are not suitable for high-velocity applications due to increased internal corrosion risks as flow rates rise. In contrast, stainless steel pipes can withstand water velocities of up to 30m/s, making them more appropriate for high-velocity systems.

Understanding the flow rate limitations of copper and stainless steel pipes is essential in determining their suitability for specific applications.

In high-velocity applications, the flow rate that copper pipe is suitable for becomes a critical factor when evaluating its performance against stainless steel piping.

Stainless steel pipe's suitability for various flow rates is an essential consideration in comparing its application to copper piping in high-velocity systems. With high pressure tolerance, stainless steel can accommodate water velocities up to 30m/s, surpassing copper's velocity limitations.

Its superior corrosion resistance and robust structure make it ideal for demanding environments. Additionally, stainless steel's installation requirements are less stringent due to its greater tensile strength, reducing the need for extensive bracketing.

When considering piping materials for specific applications, it is important to be aware of the limitations of copper in certain scenarios. Copper has specific restrictions that make it unsuitable for certain applications:

Considering these limitations, stainless steel emerges as a more suitable alternative for these specific applications due to its ability to handle diesel, high pressures, large diameters, and corrosive fluids effectively.

Utilizing copper vs stainless steel pipe can offer potential health benefits due to stainless steel's superior corrosion resistance and self-healing properties, making it a favorable choice for various applications.

When considering the health impacts of using stainless steel instead of copper piping, the following points should be noted:

Stainless steel piping requires fewer brackets due to its greater tensile strength and rigidity, reducing the need for additional support compared to copper piping. The installation benefits of stainless steel include bracketing savings of up to 40%, leading to cost effectiveness in commercial plumbing and seismic restraints.

This reduction in bracketing needs not only saves on material and labor costs but also provides sustainability advantages due to the lower amount of support required. The corrosion resistance of stainless steel further enhances its suitability for applications where bracketing is a concern, ensuring long-term durability without compromising structural integrity.

When considering the cost effectiveness comparison copper vs stainless steel pipe, the reduced bracketing requirements of stainless steel contribute to its overall economic viability, making it a favorable choice for various piping systems where efficient installation and long-term performance are essential.

Copper piping may not be suitable for chlorinated water supplies due to the risk of pitting corrosion resulting from exposure to chlorine.

In comparing health implications and material durability, stainless steel may offer a more reliable and sustainable option for chlorinated water supplies.

Regarding heat retention properties, stainless steel exhibits distinct characteristics that set it apart from other materials used in piping systems. A thermal conductivity analysis reveals that stainless steel has lower thermal conductivity compared to copper, resulting in improved temperature retention.

This lower thermal conductivity of stainless steel leads to reduced heat loss, making it an excellent choice for applications where heat retention is vital. Studies on temperature retention show that stainless steel pipes can effectively maintain the desired temperature of the fluid being transported, enhancing overall system efficiency.

Additionally, the insulation effectiveness required for stainless steel pipes is lower compared to copper due to its inherent properties, resulting in cost savings and easier maintenance. Heat transfer evaluations further support stainless steel's ability to offer improved heat retention, making it a reliable option for various industrial and commercial piping systems.

The insulation required for stainless steel piping systems should be free of chlorides to guarantee top performance and longevity. When considering the insulation needs for stainless steel pipes, there are several important factors to take into account:

Ensuring the insulation used with stainless steel pipes is chloride-free is essential for maximizing their durability, preventing corrosion, regulating temperature effectively, and promoting environmental sustainability.

In evaluating bore smoothness, stainless steel exhibits superior characteristics compared to copper in piping applications. Stainless steel pipes offer a smoother surface finish, ensuring better pipe smoothness and internal coating compared to copper.

This enhanced surface quality not only provides improved hydraulic performance but also contributes to a higher level of corrosion resistance, making stainless steel pipes more durable in various environments. Additionally, stainless steel pipes have higher pressure ratings than copper, allowing them to withstand elevated pressures with greater reliability.

The combination of superior surface finish, enhanced pipe smoothness, internal coating, corrosion resistance, and higher pressure ratings makes stainless steel a preferred choice for applications where bore smoothness is essential.

Connecting stainless steel pipe with copper pipe can be accomplished through the use of compatible fittings and proper installation techniques. Here are some key considerations when connecting these two types of pipes: