Sanitary pipes form the backbone of numerous industries, ensuring the integrity of processes and products. The diversity of materials used in these pipes reflects the varied demands of different applications and environments. From the durability of stainless steel to the versatility of PVC, each material brings unique benefits to the table. Understanding these distinctions is essential for making informed decisions that align with operational requirements and regulatory standards. Let's explore the nuances of these materials further to grasp the importance of selecting the right type of sanitary pipe for specific needs.

Sanitary pipes play a vital role across various industries by ensuring the safe and hygienic transportation of fluids to maintain product quality and protect public health. These pipes are essential components of industrial processes where maintaining cleanliness, hygiene, and preventing contamination are paramount.

By facilitating the transportation of fluids in a secure and controlled manner, sanitary pipes help to uphold the integrity of products and ensure compliance with stringent regulatory standards. Industries such as pharmaceuticals, food and beverage, biotechnology, cosmetics, and many others rely on sanitary pipes to convey liquids, gases, and semi-solids without compromising the quality or safety of the end products.

The significance of sanitary pipes lies in their ability to prevent cross-contamination, maintain sterile environments, and uphold the integrity of the materials being transported. In essence, these pipes serve as the backbone of industrial operations where maintaining sanitary conditions is critical for ensuring product quality and safeguarding public health.

When selecting the appropriate materials for sanitary pipes, it is imperative to meticulously evaluate factors such as temperature resistance, corrosion susceptibility, and chemical compatibility to ensure optimal system performance.

| Factor | Description | Importance |

|---|---|---|

| Temperature Resistance | Ability to withstand varying temperature ranges | Prevents material degradation |

| Corrosion Susceptibility | Resistance to corrosion from fluids or gases | Ensures longevity of the pipes |

| Chemical Compatibility | Suitability to interact with transported substances | Prevents chemical reactions |

Considering these factors is crucial to guarantee the longevity, efficiency, and safety of the sanitary pipe system. Temperature resistance prevents material deterioration, corrosion resistance ensures durability and chemical compatibility prevents unwanted reactions. By carefully assessing these aspects, you can select the most suitable material that aligns with the specific requirements of your application, leading to a reliable and high-performing sanitary piping system.

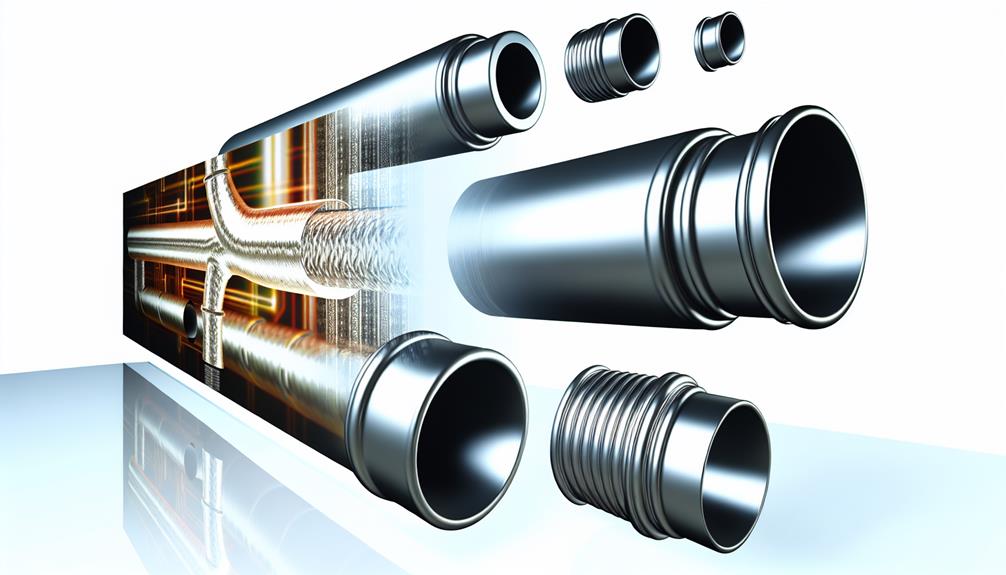

Stainless steel stands as a prominent choice for sanitary piping due to its prevalent use and reliability in various industries. Understanding the types and grades of stainless steel available is crucial for selecting the most suitable material for specific applications.

This material offers notable advantages such as corrosion resistance, durability, and ease of maintenance, yet it is essential to consider potential drawbacks like costs and susceptibility to galvanic corrosion.

A popular choice in the realm of piping materials known for its exceptional properties, stainless steel is widely utilized for various sanitary applications, with specific emphasis on its types and grades.

Stainless steel, primarily composed of iron with chromium, nickel, and other elements, offers excellent corrosion resistance and durability. The two most common grades used in sanitary pipes are Stainless Steel 304 and 316, with the latter providing superior corrosion resistance due to its higher molybdenum content.

These austenitic stainless steel grades are renowned for their exceptional weldability, forming capabilities, and overall performance across a range of applications, making them a preferred choice for sanitary piping systems.

Renowned for their exceptional resistance to corrosion and durability, stainless steel sanitary pipes offer crucial advantages in various industrial applications.

In considering stainless steel sanitary pipes for industrial applications, it is important to acknowledge that despite their notable advantages, these pipes also present certain drawbacks that warrant careful consideration.

One significant disadvantage of stainless steel pipes is their relatively high cost compared to materials like PVC or HDPE. The initial investment for stainless steel pipes can be higher due to factors such as grade, size, and manufacturing process.

Additionally, stainless steel pipes are susceptible to galvanic corrosion when they come into contact with dissimilar metals like copper or carbon steel in the presence of an electrolyte. Proper isolation between metals and cautious installation practices are essential to prevent galvanic corrosion and ensure the longevity of sanitary stainless steel piping systems.

Related blogs:

Aluminum is a lightweight material commonly utilized in sanitary piping applications. Despite its lightweight nature, aluminum is susceptible to cracking and warping over time.

Furthermore, its limited resistance to corrosion and damage necessitates frequent replacement, impacting its overall longevity in sanitary pipe systems.

A prevalent material utilized in sanitary piping, aluminum features characteristics that warrant careful consideration in various industrial applications.

With its distinctive characteristics and considerations in industrial applications, aluminum presents specific advantages that cater to certain needs within sanitary piping systems. Aluminum is favored for its lightweight properties, making it easy to handle and install in various applications.

Its malleability allows for flexibility in design and customization, accommodating complex layouts within piping systems. In addition, aluminum exhibits good thermal conductivity, aiding in the efficient transfer of heat in specific processes.

This material is also recyclable, aligning with sustainable practices and environmental initiatives. While aluminum may not be as corrosion-resistant as other materials, its advantages in weight, customization, thermal conductivity, and recyclability make it a suitable choice for specific sanitary piping requirements.

Despite its lightweight properties and malleability, aluminum poses notable disadvantages within sanitary piping systems that warrant careful consideration.

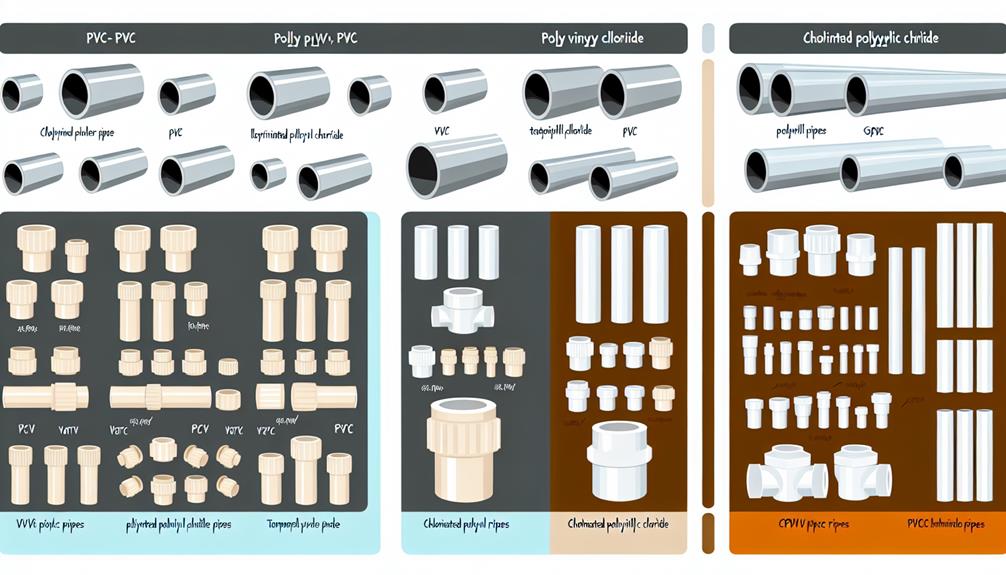

PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride) pipes are commonly used in sanitary applications due to their distinct characteristics. PVC pipes are known for their lightweight nature, corrosion resistance, and affordability, whereas CPVC pipes offer enhanced heat resistance and chemical stability.

Understanding the advantages and disadvantages of PVC and CPVC pipes is crucial in determining the most suitable material for specific sanitary pipe systems.

Polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) are two commonly utilized plastic materials in the realm of sanitary pipes, distinguished by their unique characteristics and suitability for specific applications.

Known for their lightweight nature and exceptional corrosion resistance, PVC and CPVC pipes offer significant advantages in various industrial applications.

The low density of PVC and CPVC pipes makes them easy to handle, transport, and install, reducing labor costs and installation time. Additionally, their corrosion resistance properties make them suitable for a wide range of applications, as they do not rust, corrode, or degrade when exposed to various chemicals, fluids, and gases.

Moreover, these pipes are cost-effective compared to materials like stainless steel or copper, making them an attractive choice for projects where budget constraints are a concern.

The combination of lightweight design, corrosion resistance, and cost-effectiveness makes PVC and CPVC pipes a preferred option in the sanitary piping industry.

In industrial applications, the utilization of PVC and CPVC pipes is often hindered by their lower temperature resistance compared to alternative materials like stainless steel or copper. These limitations are crucial to consider:

These drawbacks highlight the importance of selecting the most suitable material for specific sanitary piping applications to ensure optimal performance and longevity of the systems.

Copper pipes are widely used in sanitary systems, offering both rigid and flexible applications for various purposes. These pipes feature antimicrobial properties, exceptional temperature resistance, and a long service life exceeding 50 years.

While they provide numerous advantages such as durability and cost-effectiveness, copper pipes are susceptible to corrosion, and water chemistry reactions, and require proper water treatment to maintain their longevity.

Utilized extensively in plumbing applications for centuries, copper pipes come in two primary forms - rigid copper pipes and flexible copper pipes.

With its natural antimicrobial properties and exceptional temperature resistance, copper pipes offer a range of advantages that make them a preferred choice for sanitary pipe systems in various applications.

The antimicrobial properties of copper help inhibit the growth of harmful microorganisms, ensuring a hygienic environment and reducing the risk of disease transmission.

Additionally, copper pipes can withstand a wide range of temperatures, making them suitable for diverse uses such as hot and cold water supply, heating systems, and steam distribution.

Their longevity, lasting over 50 years due to durability and resistance to wear, proves cost-effective in the long term despite higher initial costs.

Copper pipes are a reliable, durable, and efficient option for sanitary piping needs.

Given the susceptibility to specific types of corrosion and potential reactions with varying water chemistries, copper pipes present notable disadvantages that warrant careful consideration in sanitary piping applications.

Recommended: Copper VS Stainless Steel Pipe

High-Density Polyethylene (HDPE) pipes are characterized by their excellent strength-to-weight ratio, flexibility, chemical resistance, and corrosion resistance. These pipes are known for being cost-effective, impact-resistant, and suitable for various conditions.

While offering advantages such as corrosion resistance, flexibility, durability, and cost-effectiveness, HDPE pipes also come with limitations like limited temperature resistance and chemical incompatibility, necessitating compatibility checks and alternative materials in high-temperature environments.

Derived from a thermoplastic polymer sourced from petroleum, High-Density Polyethylene (HDPE) boasts exceptional strength-to-weight ratios, flexibility, and resistance to chemicals and environmental stress cracking, making it a preferred material for various applications, including sanitary pipes.

With its outstanding corrosion resistance and exceptional durability, HDPE pipes stand out as an optimal choice for sanitary pipe systems. HDPE pipes exhibit excellent flexibility and durability, making them suitable for various environmental conditions, ground movements, and pressure changes.

Their ability to bend without breaking allows for trenchless installations and applications with complex layouts. Additionally, HDPE pipes offer exceptional impact resistance, reducing the risk of damage during handling, transportation, and installation.

In terms of cost-effectiveness, HDPE pipes are generally more economical than materials like stainless steel, copper, or polypropylene. Their lower cost, combined with easy installation and minimal maintenance requirements, makes HDPE pipes a highly attractive option, especially for projects with budget constraints.

One notable drawback of HDPE pipes, despite their numerous advantages in sanitary pipe systems, is their limited temperature resistance compared to materials like stainless steel or copper.

Utilizing titanium in sanitary piping applications is often constrained by its elevated cost, despite its exceptional attributes of corrosion resistance and strength.

Titanium, renowned for its durability and resistance to corrosion, presents a viable option for industries requiring high-performance materials.

While its initial expense may deter widespread use, titanium can be strategically combined with other metals, such as stainless steel, to offer more cost-effective alternatives without compromising on its advantageous properties.

Particularly advantageous in environments producing acidic food or beverages, titanium exhibits superior longevity and reliability, contributing to the overall efficiency of sanitary piping systems.

Although cost considerations play a significant role in its application, the unique benefits of titanium make it a desirable choice for industries prioritizing durability and resilience in their sanitary pipe installations.

The utilization of glass in sanitary piping applications, while offering visibility and ease of cleaning, is often restricted due to concerns regarding its potential breakage during food or beverage production processes.

Glass, while advantageous in terms of cleanliness and visibility, faces limitations in sanitary piping applications due to the challenges associated with its fragility. Manufacturers must carefully assess the trade-offs between the benefits of using glass and the risks associated with potential breakage, particularly in industries where the reliability and durability of piping materials are paramount.

For optimal material selection in sanitary piping systems, consulting with experts is essential to ensure informed decisions and efficient system operation. Engineers, contractors, or manufacturers offer valuable insights, recommendations, and guidance crucial for the performance and longevity of piping systems. Expert consultation minimizes material incompatibility risks, ensuring proper installation and reliable system operation.

By leveraging their expertise, potential issues such as corrosion susceptibility, temperature limitations, and chemical compatibility can be effectively addressed, leading to the selection of the most suitable materials based on specific application requirements. Expert advice aids in the evaluation of material properties, and optimizing system functionality while considering factors like temperature, pressure, chemical compatibility, and budget constraints.

Selecting the right materials not only minimizes maintenance needs and repairs but also enhances the overall efficiency and reliability of sanitary pipe systems, promoting safe and hygienic fluid transportation in various industries.

Glass materials can be a suitable choice for sanitary piping systems due to their cleanliness, visibility, and chemical inertness. However, limitations exist concerning breakage risks, durability, and practicality, making stainless steel a more common and reliable option.

Consider using titanium in sanitary pipes like employing a reliable shield. Its corrosion resistance, strength, and compatibility with stainless steel offer durability. While cost may limit its use, titanium is advantageous for acidic food production.

Experts play a crucial role in selecting proper sanitary pipe materials by providing informed decisions, insights, and recommendations. Their guidance optimizes system performance, minimizes risks, and ensures efficient operation, considering factors like temperature, pressure, chemical compatibility, and budget constraints.

Regulations for plastics used in food-grade piping are stringent, as they must comply with FDA guidelines. Materials are scrutinized for food safety, chemical compatibility, and hygiene. Compliance ensures safe food production and consumer protection.

Aluminum can be a cost-effective option for sanitary pipe installations due to its lightweight nature and ease of use. However, it may require frequent replacement as it is prone to cracking and warping, lacking corrosion resistance.

In summary, the meticulous choice of materials for sanitary pipes is paramount for maintaining impeccable standards of hygiene and safety in fluid transportation across diverse industries. Factors like temperature resilience, corrosion resistance, and chemical compatibility must be diligently weighed to guarantee product integrity and regulatory adherence.

For expert guidance in material selection tailored to your specific needs, we invite you to consult with Vinmay. Our team of seasoned professionals is dedicated to assisting you in making informed decisions that optimize performance and efficiency. Remember, the meticulous selection of sanitary pipes is fundamental in safeguarding operational safety and ensuring impeccable cleanliness. Let Vinmay be your trusted partner in achieving excellence in fluid transportation solutions.

Read More: Exploring the Different Types of Sanitary Pipes: A Comprehensive Guide