Our Company always considers quality as the core of market competition after foundtion, because of the successful positoning and strong sense of quality from all our staffs, Vinmay can be one of the best stainless steel welded tubes suppliers in the world.

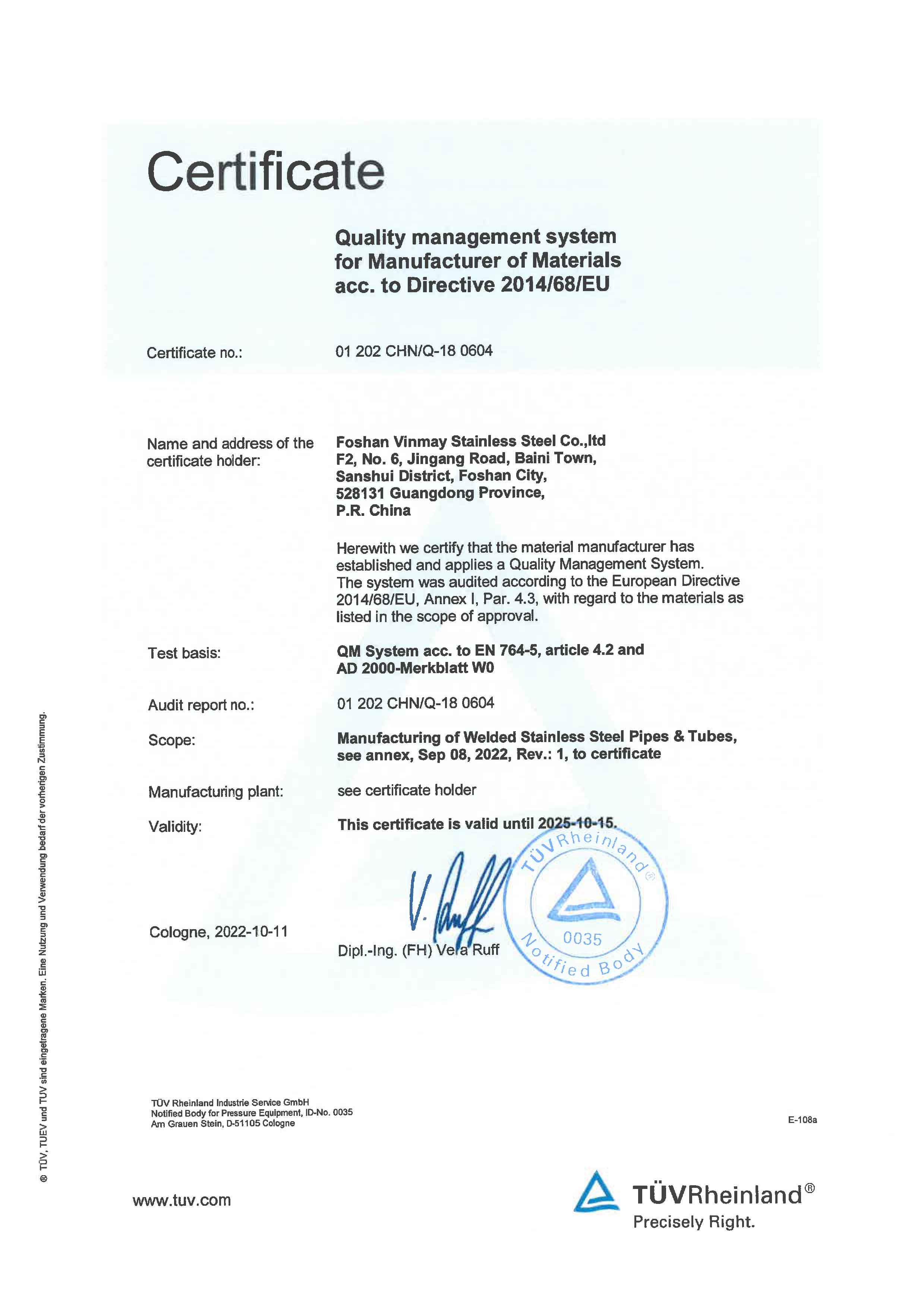

All of the tubes from Vinmay are produced under strict quality management systems: ISO 9001 and PED. ( European pressure equipment certification)

All of the raw material in Vinmay are from TISCO, BAOSTEEL, TSINGSHAN and other high quality steel supply refining furnace materials, which can make sure a high stability and corrosion resistance to all of our products.

In addition, we can provide the quality inspection report of raw materials.