Custom stainless steel tubes are precisely tailored to meet specific requirements across diverse industries, including aerospace, medical, and oil & gas. Available in various sizes, diameters, and wall thicknesses, these tubes are fabricated from high-quality alloys like 304, 316, and duplex stainless steel. They come in seamless or welded forms with finishes such as electropolishing and sandblasting. Manufactured to stringent ASTM and ISO standards, custom tubes offer optimal performance in high-pressure and critical environments. The advanced fabrication processes include CNC machining, laser cutting, and welding. Discover more on how these versatile tubes enhance efficiency and reliability in specialized applications.

Comparing standard stainless steel tubes to custom stainless steel tubes necessitates an understanding of their distinct manufacturing processes, material specifications, and application-specific advantages. Standard stainless steel tubes are produced in bulk by stainless steel tube manufacturers following industry norms, offering uniformity in dimensions and material properties. These tubes adhere to predefined specifications, making them suitable for general-purpose applications with predictable requirements.

In contrast, custom stainless steel tubes are tailored to meet specific client needs, involving unique dimensions, wall thicknesses, and material grades. Custom tubing manufacturers employ advanced techniques such as precision welding, seamless extrusion, and custom alloy compositions to produce tubes that meet stringent engineering criteria. This flexibility allows for optimization in performance, durability, and corrosion resistance, essential for specialized industries like aerospace, medical, and chemical processing.

The material properties of custom stainless steel tubes can be finely tuned to enhance mechanical strength, thermal stability, and resistance to environmental stressors. This customization ensures that the end product meets exact operational demands, providing a significant edge in applications where standard tubes may fall short.

Recommended - Wholesale Stainless Steel Tube Varieties

The types of custom stainless steel tubes can be broadly categorized into seamless and welded tubing, each offering distinct advantages in terms of strength and manufacturing complexity.

Additionally, specialized forms such as hypodermic, fractional, and metric tubing, along with pipe, cater to specific dimensional and application requirements.

Understanding these variations is crucial for selecting the appropriate tube for industrial, medical, and structural applications.

Understanding the distinctions between seamless and welded custom stainless steel tubing is crucial for selecting the appropriate type for specific industrial applications.

Seamless tubing is manufactured through extrusion, resulting in a tube that has no longitudinal weld seam. This process makes seamless thin wall stainless steel tubing ideal for high-pressure applications and environments requiring superior corrosion resistance due to its uniform structure and absence of impurities. Its intrinsic strength and durability make it a preferred choice for critical applications, including aerospace and oil and gas industries.

In contrast, welded custom steel tubing is produced by rolling a flat strip of stainless steel into a tube and welding the seam. Although this method introduces a potential weak point at the weld, advancements in welding techniques have significantly enhanced the quality and reliability of welded stainless steel pipe. Welded tubing generally offers cost advantages and greater availability in larger diameters and longer lengths compared to seamless tubing. It can be specifically tailored to various needs, making it suitable for less demanding applications where high pressure or extreme environmental conditions are not primary concerns.

Understanding these material properties ensures that decision-makers can exert precise control over their selection process, optimizing performance and cost efficiency.

Hypodermic tubing, characterized by its stringent outer diameter (OD) and inner diameter (ID) tolerances, is essential for applications requiring precise dimensions and superior corrosion resistance. Designed predominantly from 304 and 316 stainless steel, hypodermic tubing is available in various gauge sizes and wall thickness options, including Regular Wall (RW) and Thin Wall (TW).

Key features of hypodermic tubing include:

Hypodermic tubing is not recommended for pressure applications; instead, it serves well in roles demanding precision and reliability. Custom orders and large quantities can be accommodated, including cut-to-length steel tubing services.

For those seeking alternatives, custom plastic tubing offers a complementary solution, while stainless steel pipe options provide broader applications.

Fractional tubing, utilized extensively in commercial applications, demands superior corrosion resistance and strength, starting at an outer diameter (OD) of 1/32 inch and is commonly manufactured from 304 and 316 stainless steel. These materials are well-regarded for their durability and resistance to various corrosive environments, making them ideal for a wide range of industrial uses. Fractional tubing is also available in other metals and alloys, including nickel alloys like 200, 400, and 600, as well as specific stainless steel grades such as 321 and 347.

Typically stocked in an annealed temper condition, fractional tubing can be ordered in both welded and seamless forms. Compliance with commercial ratings like ASTM-A-269 ensures consistent quality and performance. Custom sizes can be produced in-house, facilitating reduced lead times and ensuring that specific application needs are met. Tolerances for OD range from ±0.005 to ±0.010 inches, while wall thickness tolerances vary from ±5% to ±10%, depending on the size.

Metric tubing, crafted to meet strict dimensional tolerances and quality standards, offers versatility and precision for a myriad of industrial applications. These tubes are available in various outer diameter (OD) and wall thickness combinations, ensuring that specific requirements can be met with high accuracy. The OD tolerance varies by size, maintaining a consistent wall tolerance of +/- 15% for diameters between 3 mm to 6 mm, and improving to +/- 10% for diameters from 14 mm to 24 mm.

Key attributes of metric tubing include:

For those needing precise control over their projects, metric tubing provides an optimal solution, balancing flexibility in customization with stringent quality adherence.

In addition to metric tubing, custom stainless steel pipes are engineered to address diverse industrial demands with a focus on durability and high performance. These pipes are available in various grades, including 304, 316, and 321 stainless steel, each offering distinct advantages.

For instance, 304 stainless steel pipes provide excellent resistance to oxidation and corrosion, making them highly suitable for general industrial applications. On the other hand, 316 stainless steel pipes incorporate molybdenum, enhancing resistance to pitting and crevice corrosion, particularly in chloride environments.

The manufacturing process of custom stainless steel pipes involves precision techniques such as welding, seamless extrusion, and cold drawing, ensuring dimensional accuracy and structural integrity. These pipes are designed to withstand high pressure and temperature variations, thereby maintaining performance in both static and dynamic conditions.

Surface finishes range from mill finish to highly polished, depending on the application requirements. Additionally, the customization extends to wall thickness, diameter, and length, providing tailored solutions for specific operational demands.

The versatility and robustness of these custom stainless steel pipes make them indispensable in sectors such as petrochemical, marine, and manufacturing, where reliability and longevity are paramount.

Read More:

Custom stainless steel tubes are available in a wide range of sizes and weights, tailored to meet specific project requirements.

These tubes can be manufactured with varying lengths, diameters, and wall thicknesses, ensuring optimal performance for various applications.

Additionally, stainless steel tolerance levels are meticulously maintained to guarantee precision and consistency in every custom order.

When specifying custom stainless steel tubes, precise measurements, and weight calculations are paramount to ensuring optimal performance and structural integrity. The choice of dimensions and associated weights impacts not only the mechanical properties but also the material's compatibility with the intended application.

Here are four critical factors to consider:

Stainless steel tubes are available in various grades, each offering distinct properties such as corrosion resistance, weldability, and tensile strength. By meticulously selecting the appropriate size and weight, engineers and designers can ensure that the stainless steel tubes meet the rigorous demands of their specific applications.

For detailed information on sizes and weights, refer to the Vinmay Size List.

Specifying the appropriate length for custom stainless steel tubes is critical to ensuring their suitability for the intended application and minimizing material waste. Precision in length specification can enhance operational efficiency and reduce costs.

Custom stainless steel tubes can be manufactured to a wide range of lengths, from a minimum of 0.030 inches to a maximum of 480 inches. This extensive range offers flexibility to meet diverse application requirements, from small, intricate components to extensive structural elements.

The choice of length must take into consideration the mechanical properties and intended use of the tube. For instance, in applications where structural integrity is paramount, longer lengths may necessitate additional support or specific alloy compositions to maintain strength and durability. Conversely, shorter lengths may be appropriate for components where precision and minimal material use are prioritized.

Furthermore, specifying the correct length can impact the finishing process. Stainless steel tubes may require specific surface treatments or finishes, and the length can influence the uniformity and quality of these finishes. Ensuring precise length measurements is essential for achieving the desired aesthetic and functional performance, thereby maximizing the tube's utility and lifespan.

The extensive range of diameters available for custom stainless steel tubes ensures that they can meet the precise requirements of diverse applications, from intricate medical instruments to robust industrial machinery. These tubes are meticulously engineered to offer unmatched flexibility and precision, enabling seamless integration into various systems.

The range of diameters is defined as follows:

1. Outside Diameter

2. Inside Diameter

This comprehensive range allows for customization to suit specific project needs, underpinning the versatility and adaptability of stainless steel tubes. The precision in the manufacturing process ensures that the dimensional tolerances adhere strictly to industry standards, thereby guaranteeing optimal performance and reliability.

The choice of diameter has a significant impact on the mechanical properties and flow characteristics of the tube. Smaller diameters are ideal for applications requiring high precision and minimal space, such as in medical devices and instrumentation. Conversely, larger diameters cater to applications demanding higher flow rates and structural integrity, such as in chemical processing and heavy machinery.

With wall thicknesses ranging from a minimal 0.002 inches to a robust 0.280 inches, custom stainless steel tubes offer exceptional versatility to meet the stringent demands of various applications. This broad spectrum of wall thicknesses allows for precise customization, catering to both delicate and heavy-duty requirements.

A minimal wall thickness of 0.002 inches is ideal for applications necessitating lightweight structures, such as in the medical and aerospace industries, where precision and sensitivity are paramount.

Conversely, a maximum wall thickness of 0.280 inches provides the necessary durability for more rigorous environments. This thickness range enhances the tube's ability to withstand high pressures and mechanical stresses, making it suitable for industrial processes, automotive applications, and construction projects.

The material properties of stainless steel, including high tensile strength, corrosion resistance, and thermal stability, are maintained across this range, ensuring reliability and longevity.

The ability to specify exact wall thicknesses within this extensive range offers unparalleled control over the tube's performance characteristics. This precision ensures that engineers and designers can optimize material usage, balancing strength and weight according to the specific needs of their projects, thereby achieving both economic and functional efficiency.

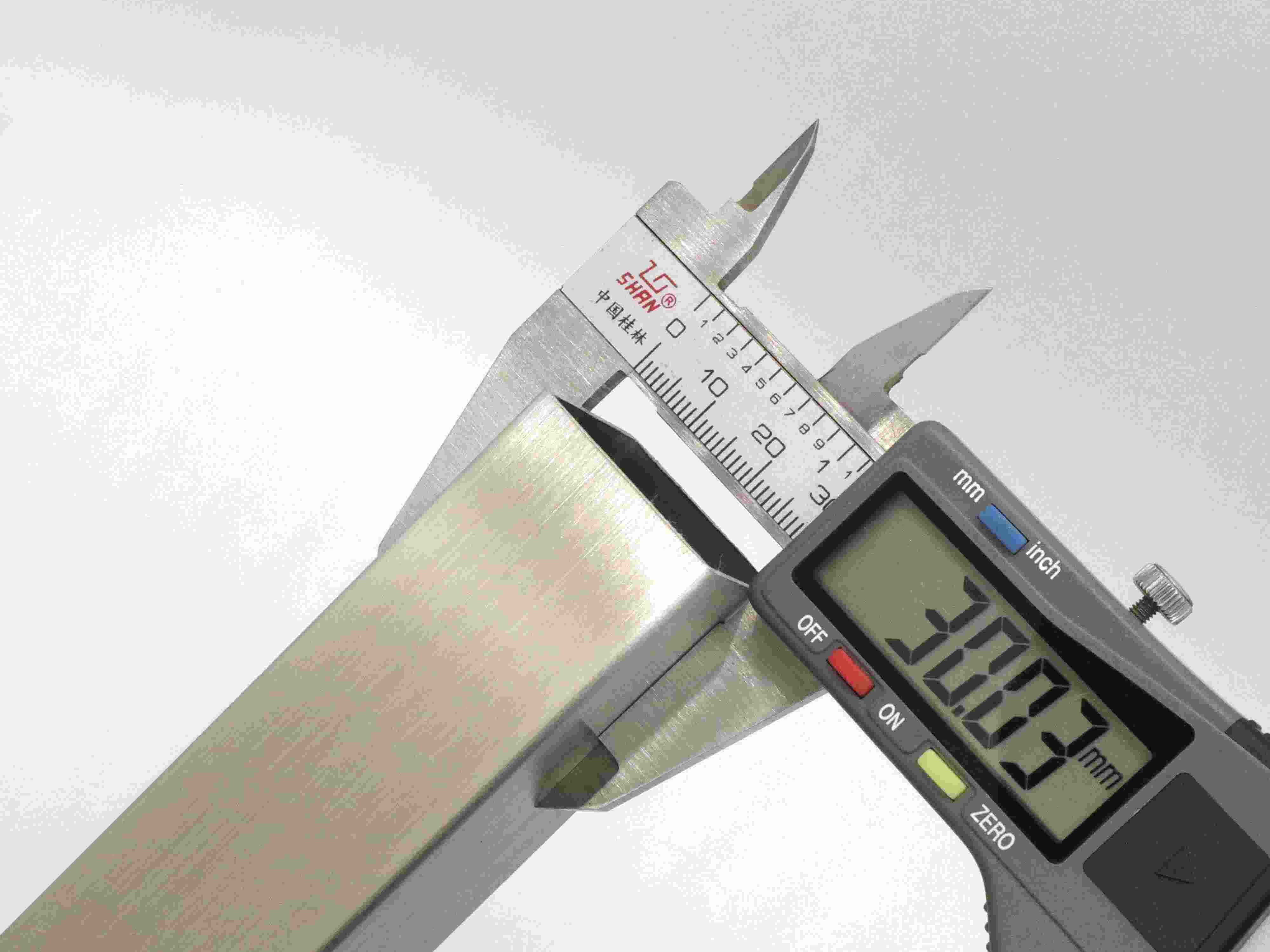

Achieving precise dimensional accuracy, custom stainless steel tube tolerances ensure optimal performance and reliability across diverse applications. These stringent specifications are critical in fields where precision is paramount, such as aerospace, medical devices, and high-performance engineering.

Custom stainless steel tubes can achieve exceptionally tight tolerances, which can be broken down as follows:

These tolerances are achieved through advanced manufacturing techniques and rigorous quality control processes. The ability to maintain such exacting standards speaks to the material's properties, notably its machinability and stability under various conditions.

For applications demanding the utmost in precision and control, custom stainless steel tubes provide a reliable solution, ensuring that every component performs to its exact specifications.

Custom stainless steel tubes are available in a variety of shapes, each offering unique structural and aesthetic properties tailored to specific applications. Key shapes include round, rectangular, square, oval, and slot tubes, with each form exhibiting distinct mechanical strengths and surface characteristics.

These variations enable precise alignment with project requirements, optimizing both performance and visual appeal in diverse engineering and architectural contexts.

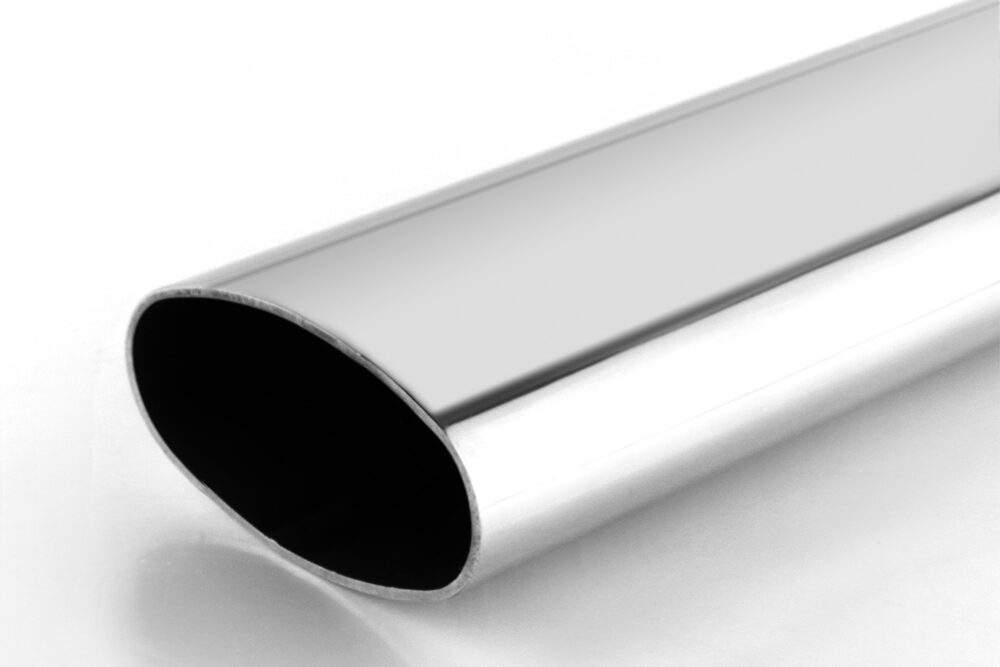

Stainless steel round tubes, known for their exceptional strength-to-weight ratio and corrosion resistance, are integral components in various industrial applications, including automotive, aerospace, and structural engineering. These tubes offer unparalleled versatility, making them a preferred choice for engineers and designers seeking robust and reliable solutions.

Key attributes of stainless steel round tubes include:

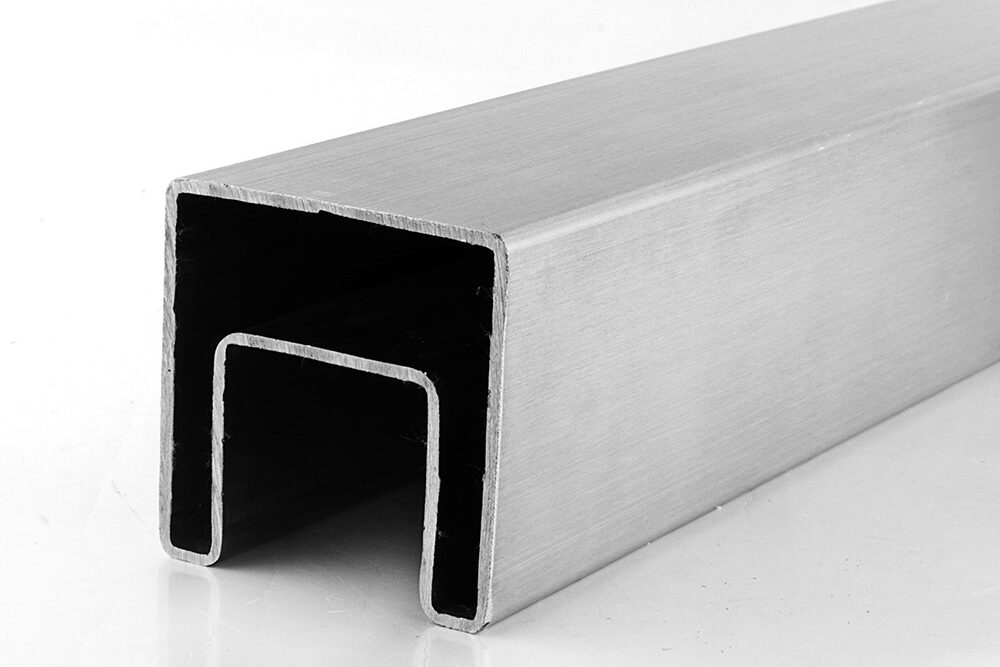

Rectangular stainless steel tubes, characterized by their high structural integrity and versatile applications, are crucial in industries ranging from construction to transportation. These tubes are engineered for both strength and durability, making them ideal for frameworks, supports, and various load-bearing components. The precision in their fabrication ensures consistent wall thickness and uniformity, vital for maintaining mechanical properties under stress.

Material selection is paramount; grades such as 304 and 316 stainless steel are commonly utilized due to their superior corrosion resistance and strength-to-weight ratio. The rectangular cross-section offers an optimal balance between rigidity and flexibility, allowing for efficient load distribution and resistance to bending and torsional forces. This makes them particularly effective in applications where both strength and weight are critical factors.

The manufacturing process involves cold or hot rolling, followed by welding or seamless extrusion, depending on the desired specifications. Surface treatments, such as polishing and passivation, enhance corrosion resistance and aesthetic appeal.

Customization options, including dimensions, wall thickness, and surface finish, allow for tailored solutions to meet specific project requirements.

Leveraging their distinct geometric profile, square stainless steel tubes provide exceptional structural stability and uniform load distribution, making them indispensable in a variety of engineering and architectural applications. These tubes are particularly valued for their ability to withstand high stress and resist deformation, attributes that are critical for both aesthetic and functional designs.

The material properties of stainless steel square tubes include high tensile strength, corrosion resistance, and durability, which contribute to their widespread use. Custom fabrication allows for precise specifications in terms of dimensions, wall thickness, and grade of stainless steel, ensuring that the tubes meet specific project requirements.

Key benefits include:

In addition to square tubes, oval stainless steel tubes offer unique advantages due to their aerodynamic profile and enhanced aesthetic appeal, making them ideal for specialized applications where both form and function are paramount.

The oval shape inherently minimizes air resistance and drag, which is particularly beneficial in automotive and aerospace industries where efficiency and performance are critical. Additionally, the smooth, continuous curves of oval tubes contribute to a sleek and modern appearance, often sought after in architectural and interior design projects.

From a material properties perspective, stainless steel oval tubes maintain the robust mechanical strengths and corrosion resistance characteristic of stainless steel alloys. This ensures longevity and reliability in demanding environments. The versatility in alloy compositions, such as 304 and 316 grades, allows for tailored solutions to specific environmental conditions and mechanical stresses.

Manufacturing these tubes requires precise control over the forming and welding processes to maintain uniform wall thickness and structural integrity. Advanced fabrication techniques, including cold drawing and precision welding, are employed to achieve the desired oval profile while adhering to stringent industry standards.

This meticulous attention to detail ensures that custom stainless steel oval tubes meet exacting specifications, providing both practical utility and refined aesthetic qualities.

Stainless steel slot tubes, characterized by their longitudinal openings, offer specialized functionality for applications requiring secure attachment points and enhanced accessibility. These tubes are engineered with precision, ensuring that they meet stringent specifications and performance criteria. The slot design enhances usability by allowing for easy installation and removal of components, making them ideal for various industrial and architectural applications.

The material properties of stainless steel slot tubes include high corrosion resistance, structural integrity, and aesthetic appeal, ensuring long-term durability and performance.

The following key points highlight the advantages of using stainless steel slot tubes:

Related Article:

Among the most commonly utilized stainless steel alloys are the 300 and 400 series. The 304 alloy, known for its excellent corrosion resistance and formability, is widely used in food processing, chemical, and architectural applications. Similarly, the 316 alloy offers superior resistance to chlorides and acidic environments, making it indispensable in marine and pharmaceutical industries.

Renowned for their robustness and resistance to corrosion, stainless steel alloys are integral to the fabrication of custom tubing solutions across various industries. The inherent material properties of stainless steel alloys make them particularly suitable for demanding applications that require high strength, durability, and resistance to various forms of degradation.

For applications requiring enhanced strength and hardness, the 400 series alloys such as 410 and 420 provide significant benefits. These martensitic stainless steels exhibit high wear resistance and can be heat-treated for increased mechanical properties, making them suitable for cutlery, surgical instruments, and industrial components.

Furthermore, duplex stainless steels like 2205 combine the best attributes of austenitic and ferritic grades, offering exceptional strength and stress-corrosion cracking resistance. These properties are crucial for applications in oil and gas, petrochemical, and paper milling industries.

Related Article:

Selecting the appropriate surface finish for custom stainless steel tubes is crucial for optimizing both functional performance and aesthetic appeal in diverse applications. Surface finishes impact corrosion resistance, ease of cleaning, and compliance with design specifications.

There are several surface finish options, each tailored to specific needs:

These options underscore the importance of selecting the right finish to meet both performance and design objectives.

Custom stainless steel tubing fabrication processes encompass a range of techniques, including bending, capping, chamfering, and CNC machining, each tailored to achieve precise dimensions and intricate designs for specialized applications. Bending involves the precise manipulation of tubing to achieve specific angles and radii without compromising the material's integrity. This is critical for applications requiring exact fitments, such as in automotive or aerospace assemblies.

Capping and chamfering are essential for sealing and finishing tube ends. Capping involves securely closing the end of a tube, which is crucial for preventing contamination and ensuring structural integrity. Chamfering, on the other hand, involves beveling the tube ends to facilitate easy insertion into other components, thus enhancing assembly efficiency.

CNC machining offers unparalleled precision in creating complex geometries and intricate designs with tight tolerances. This computer-controlled process ensures repeatability and accuracy, which is vital for high-standard industries such as medical or electronics.

Additionally, the incorporation of advanced techniques like laser cutting and welding, hydroforming, and EDM (Electrical Discharge Machining) allows for meticulous detailing and superior surface finishes. These processes ensure that the custom stainless steel tubes meet rigorous performance and aesthetic requirements, thereby catering to the exacting standards of various high-tech industries.

Recommended - Inside the World of Stainless Steel Tube Factories

When manufacturing custom stainless steel tubes, adherence to industry standard specifications such as ASTM standards is crucial for ensuring material integrity and performance consistency. These standards define key parameters including tensile strength, corrosion resistance, and dimensional tolerances, which are essential for quality assurance.

Compliance with additional industry standards, such as those set by ISO or DIN, further guarantees the suitability of the tubing for specialized applications across various sectors.

ASTM standard specifications such as A213, A269, A511, and A554 provide rigorous criteria for the manufacture and performance of stainless steel tubes across various applications. These specifications ensure that the materials meet stringent performance standards and exhibit the necessary mechanical and chemical properties.

Beyond ASTM specifications, various other industry standards such as ANSI, AS, ASME, ISO, Mil-T Spec, NIST, AMS, GE, LCS, and Pratt Whitney play pivotal roles in defining the quality, performance, and manufacturing criteria for stainless steel tubes in specialized applications.

ANSI (American National Standards Institute) and AS (Australian Standards) ensure consistency in material properties and dimensions, enhancing interoperability across different regions. ASME (American Society of Mechanical Engineers) focuses on the mechanical integrity and safety of pressure vessels and piping.

ISO (International Organization for Standardization) provides global standards to ensure reliability and efficiency. Mil-T Spec (Military Specifications) guarantees that stainless steel tubes meet stringent defense-related criteria for durability and performance under extreme conditions. NIST (National Institute of Standards and Technology) supports innovation through precise measurement standards.

AMS (Aerospace Material Specifications) is critical for aerospace applications, ensuring materials meet stringent requirements for heat resistance and strength. Industry-specific standards from companies such as GE, LCS, and Pratt Whitney further refine specifications to meet proprietary performance benchmarks. These standards collectively ensure that stainless steel tubes not only meet but exceed the rigorous demands of various high-stakes industries, providing assurance of safety, reliability, and optimal performance.

Recommended: A Guide to Stainless Steel Tube Standards

Custom stainless steel tubes are integral components across a multitude of industries due to their exceptional durability, corrosion resistance, and versatility in various applications. Their adaptability to stringent performance requirements makes them indispensable in sectors that demand high precision and reliability.

Key industries that benefit from custom stainless steel tubes include:

The unique properties of stainless steel, such as high tensile strength, resistance to pitting and crevice corrosion, and ease of fabrication, make it an ideal choice for these and other industries like automotive, chemical processing, and marine. Customization options further enhance its applicability, allowing for tailored solutions that meet specific operational and environmental demands, thereby empowering industries to achieve optimal performance and longevity in their applications.

Read Also - Stainless Steel Sanitary Tubes

When considering the optimal solution for specific industrial applications, it is important to distinguish between stainless steel tubing and stainless steel pipe, as each offers unique characteristics tailored to different functional and performance requirements.

Stainless steel tubing, particularly round tubes, is favored in scenarios where precision and a smooth interior surface are paramount. These attributes make tubing ideal for applications such as instrumentation, automotive components, and medical devices, where tolerances are tight and surface finish is critical.

In contrast, stainless steel pipes are predominantly used for the conveyance of fluids or gases under pressure in industrial and plumbing applications. The inherent design of pipes, always round, optimizes them for structural integrity and pressure handling, thus making them suitable for high-stress environments such as oil and gas pipelines, water treatment facilities, and chemical processing plants.

Furthermore, while pipes are standardized according to schedule and nominal diameter, tubes are specified by their exact outer diameter and wall thickness, allowing for greater customization. Tubes can also be manufactured in various shapes, including round, square, and rectangular, offering flexibility for a wide array of design requirements.

The choice between tubing and pipe, therefore, hinges on the specific demands of the application, balancing precision, structural requirements, and fluid dynamics.

To determine the right tube for your project, evaluate factors such as mechanical properties, corrosion resistance, dimensional tolerances, and fabrication requirements. Consulting material specifications and project parameters ensures optimal performance and control over application outcomes.

Like a tailor-made suit, custom stainless steel tubes provide precise dimensions, enhanced material properties, and optimized performance. This customization ensures superior corrosion resistance, strength, and fit, ultimately offering greater control over project specifications and outcomes.

The cost of custom stainless steel tubes is typically higher than standard tubes due to tailored specifications, specialized manufacturing processes, and unique material properties, but can be justified by enhanced performance, longevity, and precise fit for specific applications.

The typical lead time for manufacturing ranges from four to eight weeks, depending on the complexity of the design, the availability of materials, and the precision required. Factors such as production capacity and order volume also influence timelines.

Yes, eco-friendly options are available, such as utilizing recycled stainless steel or adopting advanced manufacturing techniques that minimize waste and energy consumption, ensuring sustainable production while maintaining the material's superior properties and performance standards.

Custom stainless steel tubes exemplify engineering excellence with their versatile shapes, finishes, and precise alloy compositions. These tubes meet stringent industry specifications and ensure optimal performance across various applications.

Vinmay offers high-quality custom stainless steel tubes tailored to your specific needs. Whether you need unique shapes, precise tolerances, or specialized finishes, our expert team is ready to assist you.

Visit our website to explore our product offerings and capabilities. For inquiries or to request a quote, contact us today.

For more detailed information, download our comprehensive brochure on custom stainless steel tubing, discover how Vinmay can meet your requirements with precision and expertise.

Blog Series: Custom Stainless Steel Tubes for Every Application