Like a conductor of electricity, stainless steel tubes are the backbone of many industries and applications. Offering incredible strength, durability, and malleability, they are a reliable choice for many projects.

In this article, we'll take a deep dive into the world of wholesale stainless steel tubes, exploring their types, grades, shapes, sizes, applications, customization options, and more.

Come with us as we explore the fascinating world of stainless steel tubes.

Key Takeaways

Gaining an understanding of wholesale stainless steel tubes is essential for businesses that purchase these products in bulk. Stainless steel is a corrosion-resistant metal alloy that is composed of iron, chromium, and nickel, and can be used in many applications due to its durability. It is a popular choice for businesses due to its health benefits, environmental impact, and cost efficiency.

In addition to corrosion protection, stainless steel tubes have excellent welding properties, allowing them to be easily joined together. This makes them ideal for a variety of projects, including pipes, fittings, and tubing. It is also easy to clean and maintain, making it a popular choice for hygiene-critical applications.

Wholesale stainless steel tubes provide businesses with an efficient, cost-effective option for their projects. The material is highly durable and resistant to corrosion, so it can be used in a wide range of applications without fear of damage. It is also easy to weld and offers excellent protection against chemicals, making it a great choice for industrial and medical applications.

Wholesale stainless steel tubes come in various types, each distinguished by their manufacturing process and functional characteristics. Here, we'll delve into their classifications based on these two significant aspects:

These stainless steel welded tubes are crafted by welding stainless steel sheets or strips together. Wholesale stainless steel welded tubes are cost-effective and available in a wide range of sizes and shapes, suitable for various applications.

See Also - Stainless Steel Pipe Welding Standards

Seamless tubes are manufactured without any welding seams, providing excellent structural integrity and uniformity. They are often preferred for applications requiring high-pressure resistance and corrosion protection.

Read More: Welded stainless steel tube Vs. Seamless

Specifically designed to withstand high temperatures and pressure variations, these tubes facilitate the efficient transfer of heat between two mediums. They are commonly used in industries such as HVAC, chemical processing, and power generation.

Related Article: Stainless Steel Tube for Heat Exchanger

These stainless steel sanitary tubes adhere to stringent cleanliness and hygiene standards, making them ideal for applications in the food, beverage, pharmaceutical, and biotechnology industries. Their polished surfaces prevent bacterial growth and facilitate easy cleaning.

Related Articles:

Engineered to withstand high-pressure environments, these tubes are commonly used in hydraulic systems, automotive applications, and in industrial machinery where pressure resistance is crucial.

Designed with specific mechanical properties, these tubes are suitable for structural applications, precision components, and machinery parts requiring strength, durability, and dimensional accuracy.

Precision-engineered for instrumentation and control systems, these tubes offer excellent corrosion resistance and are used in industries such as oil and gas, chemical processing, and aerospace for accurate measurement and control.

Characterized by polished finishes and aesthetic appeal, these tubes find use in architectural designs, furniture, and interior decorations due to their visual appeal and corrosion resistance.

Categorizing stainless steel tubes by their manufacturing process or functional purpose offers insights into their diverse applications and suitability for specific industries and use cases. Understanding these distinctions helps in selecting the right type of stainless steel tube for various projects and applications.

Stainless steel, known for its durability, corrosion resistance, and aesthetic appeal, is available in a variety of grades, each suited to specific industrial and commercial applications. When considering wholesale orders, understanding the different types and their characteristics can ensure the best material choice for your needs. Below is a detailed look at the most common stainless steel grades available for bulk purchase:

Austenitic stainless steels are the most commonly used type of stainless steel, comprising over 70% of global production. They are defined by their high chromium and nickel content, which gives them excellent corrosion resistance and formability. They are non-magnetic and maintain their strength at both high and low temperatures, making them extremely versatile.

Related Article: Differences Between 316 and 316L Welded Stainless Steel Pipe

Duplex stainless steels have a unique microstructure combining both austenitic and ferritic characteristics. This dual-phase structure gives them enhanced strength and excellent resistance to stress corrosion cracking, making them a popular choice for demanding environments.

Ferritic stainless steels are primarily composed of chromium, making them magnetic and offering good corrosion resistance in mild environments. They are less ductile than austenitic steels but are valued for their ability to resist oxidation and stress corrosion cracking.

Martensitic stainless steels are known for their high hardness and strength due to higher carbon content. These steels are magnetic and can be heat treated to achieve greater mechanical strength and wear resistance, though they offer lower corrosion resistance compared to austenitic and duplex grades.

By understanding the properties and applications of each stainless steel grade, wholesale buyers can make informed decisions to match the material with their project needs, ensuring optimal performance and longevity.

When purchasing stainless steel tubes in bulk, the shape of the tube plays a significant role in determining its suitability for different applications. Manufacturers offer a variety of wholesale stainless steel tube shapes to meet a range of structural, mechanical, and aesthetic requirements. Choosing the right shape is essential to ensure that the material performs well in its intended environment.

One of the most common shapes for stainless steel tubes is the round tube. Its cylindrical design ensures uniform strength distribution, making it ideal for applications where pressure and stress need to be evenly managed. Round stainless steel tubes are commonly used in pipelines, structural frameworks, exhaust systems, and the transportation industry. Their smooth, continuous shape also lends itself to modern architectural projects and furniture design, where a clean, polished appearance is important.

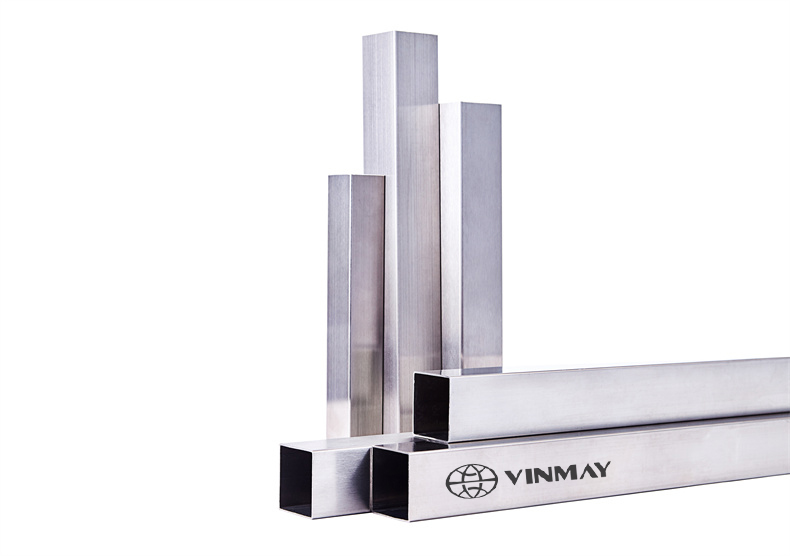

Square stainless steel tubes offer a more angular look and are known for their structural stability. These tubes are easy to join and weld, making them a popular choice for construction, machinery, and architectural applications such as railings and gates. Their balanced shape allows for even stress distribution, making them strong and versatile, suitable for both structural and decorative uses.

Rectangular stainless steel tubes are similar to square tubes but feature longer sides, offering greater surface area along one axis. This shape provides excellent strength-to-weight ratios and is often used in projects where higher load-bearing capacity is required in one direction. Rectangular tubes are commonly used in construction frameworks, building support systems, transportation infrastructure, and even in some architectural designs for a sleek, modern look.

For those seeking a more distinctive option, oval stainless steel tubes provide an elliptical cross-section that combines functionality with visual appeal. Oval tubes are often preferred in situations where aerodynamic efficiency is needed, such as in the automotive industry for exhaust systems. Their unique shape also makes them a popular choice for furniture and architectural elements, providing a streamlined and contemporary design aesthetic.

In addition to these standard shapes, many manufacturers offer the option of customized stainless steel tube designs. These can include complex geometries like hexagonal or triangular tubes or even tubes with intricate internal structures for specialized industrial applications. Custom-shaped tubes are typically used in niche industries where specific design or performance criteria must be met, making them an ideal choice for specialized machinery or custom architectural projects.

Overall, the wide range of wholesale stainless steel tube shapes available allows buyers to select the most appropriate option for their specific needs, ensuring that the material not only performs well but also enhances the overall design of the project. Whether for structural stability, aesthetic appeal, or specialized functionality, choosing the right shape can greatly impact the success of an application.

Related Article: Stainless Steel Welded Square Pipes Vs. Round Pipe

Wholesale stainless steel tubes offer a versatile range of sizes, catering to diverse industrial and commercial needs. Vinmay, as a premier supplier, provides an extensive selection of stainless steel tubing sizes to accommodate various applications seamlessly.

1. Diameter Ranges: Stainless steel tubes in wholesale come in a spectrum of diameters, spanning from the smaller dimensions suitable for intricate applications to larger diameters ideal for heavy-duty industrial uses. These diameters typically range from as compact as 6mm to as extensive as 1200mm, ensuring adaptability across a wide spectrum of projects.

| Diameter (mm) | Application |

|---|---|

| 6 - 25 | Precision Instrumentation, Small Piping |

| 26 - 100 | Structural Components, General Fabrication |

| 101 - 500 | Construction, Industrial Piping |

| 501 - 1200 | Heavy-Duty Industrial Applications |

2. Wall Thickness Variation: Another critical aspect of wholesale stainless steel tubes is the variation in wall thickness, ensuring compatibility with distinct pressure and load requirements. These tubes encompass diverse wall thicknesses, starting from thin-walled tubes measuring around 0.5mm to robust, heavy-walled tubes reaching up to 25mm or more. This breadth of thickness options allows for precise selection based on specific project needs.

| Wall Thickness (mm) | Recommended Application |

|---|---|

| 0.5 - 2 | Lightweight Tubing, Precision Instruments |

| 2.1 - 5 | General Purpose Usage, Structural Support |

| 5.1 - 15 | High-Pressure Systems, Industrial Machinery |

| 15.1+ | Rigorous Industrial Environments, Heavy Loads |

3. Length Options: In addition to diameter and wall thickness variations, wholesale stainless steel tubes are available in varying lengths. Standard lengths are commonly offered, ranging from 6 meters to 12 meters per tube, catering to different installation and fabrication needs. Additionally, customized lengths can be arranged upon request to meet specific project specifications.

| Length (meters) | Common Use |

|---|---|

| 6 | Standard Length for Various Applications |

| 12 | Extended Length for Large-Scale Projects |

4. Specialized Custom Sizes: Vinmay also specializes in providing custom sizes tailored to meet unique project demands. These bespoke sizes address unconventional or specialized requirements, ensuring a perfect fit and functionality within niche applications or unique industrial settings.

This wide range of sizes available in wholesale stainless steel tubes from Vinmay enables businesses and industries to access precisely tailored tubes that align with their exact project specifications, ensuring optimal performance and reliability.

More article:

Utilizing its corrosion-resistant properties and durability, wholesale stainless steel tube has a variety of applications across many industries. Its customization needs, quality control, and manufacturing techniques are all met to global standards while maintaining competitive price points.

Wholesale stainless steel tube is often used in gas and oil pipelines, pressure vessels, heat exchangers, and boilers. Its superior strength and corrosion-resistant properties make it ideal for the construction of medical equipment components and other parts that need to withstand direct contact with bodily fluids. It is also commonly used in the construction of food processing and storage systems, as it is a non-toxic and hygienic material that is easy to clean and maintain.

In addition, stainless steel tubes can be used in many other applications such as architecture, automotive, and engineering. Its high malleability allows for the creation of complex shapes, which can be used in decorative and structural applications. Its superior strength, corrosion resistance, and durability make it a great choice for many industrial applications.

| Application | Benefits |

|---|---|

| Gas and Oil Pipelines | Customization needs, quality control, and manufacturing techniques met to global standards while maintaining competitive price |

| Pressure Vessels | Non-toxic, hygienic, and easy to clean and maintain |

| Heat Exchangers | High malleability for complex shapes, suitable for decorative and structural applications |

| Boilers | Superior strength, corrosion resistance, and durability |

| Medical Equipment | Corrosion-resistant properties and durability |

| Food Processing Systems | Non-toxic and hygienic |

| Automotive | High malleability for complex shapes |

| Architecture | High malleability for complex shapes |

| Engineering | Superior strength, corrosion-resistance, and durability |

When opting for wholesale stainless steel tubes from Vinmay, customers gain access to a plethora of customization opportunities tailored to meet specific project requirements. These options extend beyond the conventional sizes and shapes, offering a range of enhancements to elevate the functionality and aesthetics of the tubes.

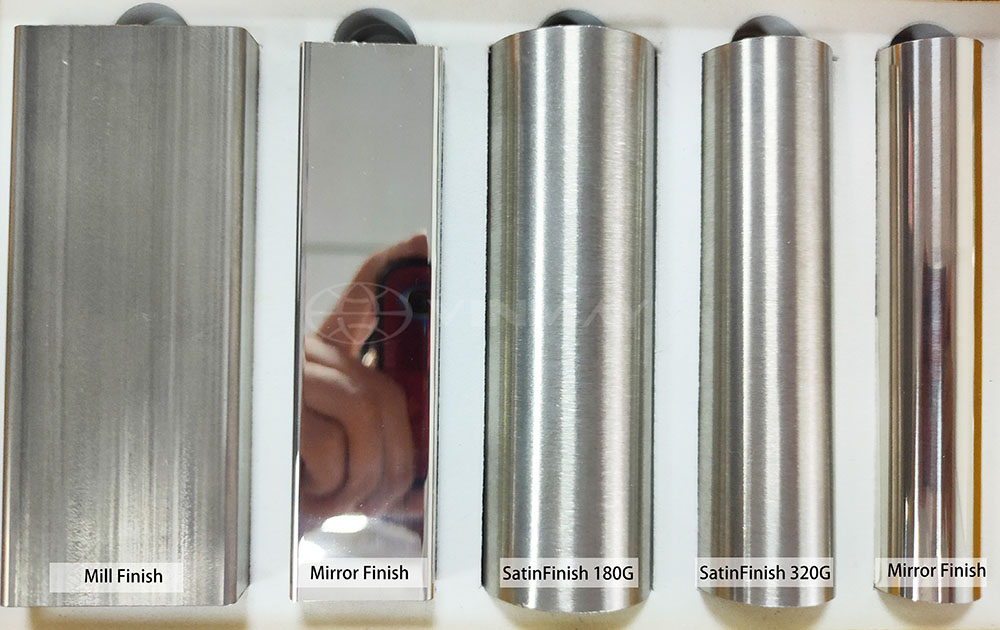

Vinmay provides various finishing options to match diverse applications. These options encompass a spectrum of surface treatments, including:

Beyond standard measurements, Vinmay offers custom dimensions and modifications, catering to unique project specifications. This includes:

Vinmay's customization capabilities extend to specialized processing techniques, allowing for:

Vinmay facilitates customized marking and identification on wholesale stainless steel tubes, enabling:

Customers can request customized packaging and labeling solutions, including:

Vinmay's dedication to providing comprehensive customization options ensures that wholesale stainless steel tubes meet precise project requirements, allowing customers to optimize functionality, durability, and aesthetic appeal.

The production of wholesale stainless steel tubes involves several intricate manufacturing processes aimed at achieving high-quality, durable, and precision-engineered products. Here's an overview of the key stages involved in the manufacturing process:

1. Material Selection

The process begins with the careful selection of raw materials, primarily stainless steel, ensuring it meets the required standards and specifications for tube manufacturing. Different grades and compositions of stainless steel are chosen based on the intended application and specific requirements.

2. Tube Formation

The manufacturing process typically includes two primary methods of tube formation: welding and seamless manufacturing.

Recommended: How to Weld Stainless Steel Tubing Like a Pro

3. Cold Drawing or Cold Rolling

Both welded and seamless tubes often undergo cold drawing or cold rolling processes. Cold drawing involves pulling the tube through a die or series of dies to achieve the desired dimensions, while cold rolling utilizes rollers to reduce the diameter or modify the shape of the tube without heating the material, enhancing its mechanical properties.

4. Annealing and Heat Treatment

Annealing, a crucial step in the manufacturing process, involves heating the tubes to a specific temperature and then cooling them slowly to relieve internal stresses and improve their mechanical properties. Heat treatment processes might also be employed to modify the stainless steel's properties for specific applications.

5. Finishing and Inspection

After the primary manufacturing processes, the tubes undergo various finishing stages. This includes surface treatments like polishing, pickling, or passivation to achieve the desired surface finish and corrosion resistance. Additionally, stringent quality checks and inspections are carried out to ensure dimensional accuracy, surface quality, and adherence to industry standards.

6. Packaging and Shipment

Once the tubes pass through quality checks, they are carefully packaged to prevent damage during transportation. Proper packaging ensures that the tubes reach customers in optimal condition, ready for use in various industrial applications.

The meticulous manufacturing processes employed in creating wholesale stainless steel tubes at Vinmay ensure exceptional quality, precision, and reliability, meeting the diverse needs and stringent requirements of customers across various industries.

In the realm of wholesale stainless steel tubes, adherence to stringent quality standards stands as a hallmark of reliability and durability. Vinmay, as a leading stainless steel tubing manufacturer, prides ourselves on an exhaustive array of inspection processes embedded within its quality assurance framework. These rigorous inspections encompass various critical stages, ensuring that every wholesale stainless steel tube leaving the production line meets the highest industry benchmarks.

1. Raw Material Inspection: Before the manufacturing process commences, Vinmay meticulously inspects the raw materials, ensuring they meet precise specifications and quality requisites. All raw materials at Vinmay are sourced from reputable entities like TISCO, BAOSTEEL, TSINGSHAN, and other high-quality steel supply refining furnace materials, guaranteeing high stability and corrosion resistance across all products.

2. Surface Inspection: Vinmay conducts thorough surface inspections, meticulously examining every inch of the tube's surface to guarantee flawlessness and uniformity in the finish.

3. Dimension Inspection: Precision matters. Vinmay verifies the dimensional accuracy of each wholesale stainless steel tube, assuring conformity to the specified measurements.

4. Roughness Inspection: The surface roughness of stainless steel tubes undergoes scrutiny to meet the stipulated smoothness standards, essential for various applications.

5. Chemical Composition Testing: Ensuring the correct chemical composition is vital for the integrity and performance of the stainless steel tubes. Vinmay conducts rigorous tests to certify the material's composition.

6. Eddy Current Testing: Employing advanced technology, Vinmay conducts eddy current testing to detect any surface or subsurface defects that might affect the tube's quality.

7. Mechanical Properties Testing: Evaluating mechanical properties such as tensile strength, yield strength, and elongation ensures that the tubes possess the necessary mechanical characteristics for their intended applications.

8. Intergranular Corrosion Testing: Vinmay rigorously tests for intergranular corrosion susceptibility, a crucial assessment to guarantee the tubes' corrosion resistance, especially in demanding environments.

All of the tubes from Vinmay are produced under strict quality management systems: ISO 9001 and PED (European Pressure Equipment Certification), assuring customers of consistent quality and compliance with international standards. Additionally, Vinmay offers the provision of quality inspection reports for raw materials, providing transparency and assurance of material quality from the source.

By employing this comprehensive suite of inspection processes and adhering to top-tier quality management systems, Vinmay ensures that each wholesale stainless steel tube meets or exceeds the established quality standards, solidifying its reputation as a provider of top-tier stainless steel tubes in the wholesale market.

International standards play a pivotal role in governing the production, quality, and reliability of stainless steel tubes in the wholesale market. These standards ensure uniformity, compatibility, and safety across global industries. The following are the most prevalent international standards for stainless steel tubes.

ASTM standards are comprehensive and cover various aspects of stainless steel tubes, including grades, specifications, dimensions, mechanical properties, and corrosion resistance. For stainless steel tubes, ASTM A269/A269M covers seamless and welded tubes for general corrosion-resisting and low- or high-temperature service. ASTM A554 covers wholesale welded stainless steel tubes for ornamental, structural, and mechanical applications. ASTM A270/A270M outlines standards for seamless and welded austenitic and ferritic/austenitic stainless steel sanitary tubing.

| ASTM Standard | Description |

|---|---|

| ASTM A213 | Seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes |

| ASTM A269/A269M | Seamless and welded stainless steel tubes for general corrosion resistance and various temperatures |

| ASTM A312 | Seamless, welded, and heavily cold-worked austenitic stainless steel pipes for high-temperature and general corrosive service |

| ASTM A554 | Welded stainless steel tubes for ornamental, structural, and mechanical applications |

| ASTM A778 | Welded, unannealed, austenitic stainless steel tubular products for general corrosion-resistant service |

| ASTM A789 | Seamless and welded ferritic/austenitic stainless steel tubing for general service |

| ASTM A270/A270M | Seamless and welded stainless steel sanitary tubing |

EN standards, established by the European Committee for Standardization (CEN), include multiple standards governing stainless steel tubes. EN 10216-5 specifies technical delivery conditions for stainless steel tubes in various applications, including pressure purposes and mechanical properties at specific temperatures. EN 10217-7 outlines requirements for welded austenitic and austenitic-ferritic stainless steel tubes for pressure purposes. EN 10312 covers wholesale welded stainless steel tubes for the conveyance of water and other aqueous liquids.

| EN Standard | Description |

|---|---|

| EN 10216 | Seamless steel tubes for pressure purposes |

| EN 10217 | Welded steel tubes for pressure purposes |

| EN 10312 | Welded stainless steel tubes for the conveyance of water and other aqueous liquids |

JIS standards are set by the Japanese Industrial Standards Committee and are important in Japan and other Asian countries. JIS G 3459 specifies stainless steel pipes for industrial uses, focusing on corrosion resistance, heat resistance, and low-temperature service. JIS G 3468 covers large diameter welded stainless steel pipes for corrosion resistance.

| JIS Standard | Description |

|---|---|

| JIS G 3459 | Stainless steel pipes for corrosion resistance and heat-resisting applications |

| JIS G 3463 | Seamless and welded ferritic stainless steel pipes for boiler and heat exchanger tubes |

| JIS G 3468 | Large diameter welded stainless steel pipes for corrosion resistance |

ISO standards related to stainless steel tubes cover a broad range of aspects. ISO 1127 specifies nominal sizes for stainless steel tubes for general purposes. ISO 2037 outlines standards for sanitary tubes, including dimensions and mechanical properties. ISO 2852 provides specifications for stainless steel clamp pipe couplings for the food industry.

| ISO Standard | Description |

|---|---|

| ISO 1127 | Specifies nominal sizes for stainless steel tubes for general purposes |

| ISO 2037 | Outlines standards for sanitary tubes, including dimensions and mechanical properties |

| ISO 2852 | Provides specifications for stainless steel clamp pipe couplings for the food industry |

DIN Standards are specifications established by the German Institute for Standardization, defining various technical aspects for industrial products.

| DIN Standard | Description |

|---|---|

| DIN 17456 | Specifies general dimensions for seamless circular stainless steel tubes |

| DIN 17457 | Covers welded circular austenitic stainless steel tubes for general service |

| DIN 17459 | Outlines technical delivery conditions for seamless circular high-temperature austenitic stainless steel tubes |

| Standard | Description |

|---|---|

| GOST 9941 | Covers hot-deformed and cold-deformed seamless stainless steel tubes |

| BS 3605 | Specifies seamless and welded austenitic stainless steel pipes and tubes |

| GB 13296 | Outlines specifications for seamless stainless steel tubes for boilers and heat exchangers in China |

Certification of compliance with these standards indicates that the wholesale stainless steel tubes have undergone rigorous testing and adhere to the defined parameters, assuring customers of their quality and suitability for various industrial uses.

More Details: A Guide to Stainless Steel Tube Standards

When choosing stainless steel tubes, two of the most commonly considered grades are 304 and 316. Both are part of the austenitic family, known for their excellent corrosion resistance, durability, and versatility. However, there are key differences between the two that make them more suitable for specific environments and applications. Here’s an in-depth comparison to help you decide which grade is right for your needs.

The primary difference between 304 and 316 stainless steel lies in their chemical composition, which influences their corrosion resistance and mechanical properties.

Both grades have excellent resistance to corrosion, but 316 stainless steel offers superior protection, particularly in more aggressive conditions.

Both grades offer excellent strength and durability, but 316 stainless steel is slightly more robust due to its composition.

Due to the addition of molybdenum and higher nickel content, 316 stainless steel is typically more expensive than 304 stainless steel.

Because of their different strengths and corrosion resistance, 304 and 316 stainless steel tubes are suited for different types of applications.

304 Stainless Steel Tubes: Best suited for less aggressive environments where high corrosion resistance is not the primary concern. It’s commonly used in:

316 Stainless Steel Tubes: Ideal for more demanding environments where exposure to chlorides, saltwater, or chemicals is likely. Common applications include:

Both 304 and 316 stainless steels are highly weldable and can be easily fabricated. However, 316 stainless steel may require special handling when welding due to the presence of molybdenum.

Related Article:

Understanding the key differences between 304 and 316 stainless steel can help you select the right material for your specific needs, ensuring long-lasting performance and efficiency.

Learn more: Stainless Steel 304 vs. 316 vs. 304L vs. 316L

Adopting a strategic approach to buying wholesale stainless steel tubes can help ensure a successful purchase. Careful consideration of factors such as distribution costs, vendor selection, material selection, and price comparisons can help buyers find the best product for their needs. Additionally, understanding the importance of corrosion resistance is essential for selecting the right stainless steel tube.

| Factors | Considerations |

|---|---|

| Distribution Costs | Research shipping costs and delivery times to determine the most cost-effective option. |

| Vendor Selection | Select a vendor with a good reputation and comprehensive product selection. |

| Material Selection | Analyze the size, grade, and wall thickness of the tube for the intended purpose. |

| Price Comparisons | Compare prices from multiple vendors to find the best deal. |

| Corrosion Resistance | Look for tubes that are resistant to corrosion for optimal longevity. |

Related article: Tips for Purchasing Stainless Steel Welded Pipe

At Vinmay, our position as a leading provider of wholesale stainless steel tubes stems from our dedication to delivering exceptional value to our clients. With a global footprint extending across 100+ countries, we proudly rank among the top five importers of stainless steel tubing. What sets us apart in the wholesale market is our unwavering commitment to meeting diverse client needs through:

At Vinmay, our commitment to excellence and decades of experience in the industry set us apart, allowing us to consistently exceed expectations and provide unmatched solutions for your wholesale stainless steel tubing requirements.

The cost of a stainless steel tube depends on a variety of factors such as shipping options, quality standards, corrosion resistance, size selection and pricing structure. Prices can vary greatly, so it's important to consider these factors to find the best value. Researching and understanding the options available will help you make an informed decision.

Yes! Customers can purchase stainless steel tubes in small quantities with ease. Buying locally is a great option with quality assurance and pricing structure. Shipping options are available as well. Our highly experienced customer service staff can provide further assistance with any questions. We are confident that our products meet customer needs with the highest level of control.

Delivery time for an order of stainless steel tubes depends on the shipping option chosen, quality assurance, and metal grade. Quality assurance and corrosion resistance are key factors in ensuring packaging options are secure. Customers can rest assured their orders will be processed and shipped quickly.

When buying steel tubes, it's important to consider the order amount - typically, orders must meet a minimum of 500 lbs. Quality Assurance, Design Options, and Weight Considerations should also be taken into account. Buying Tips, such as researching Shipping Policies, can help ensure a successful purchase. With careful planning, buyers can have control over their wholesale stainless steel tube purchase.

When purchasing wholesale stainless steel tubes, customers can expect additional services such as quality assurance, custom fabrication, certified suppliers, shipping logistics, and bulk discounts. These services ensure a secure and efficient purchase with quality assurance and control.

For premium-quality wholesale stainless steel tubes tailored to your needs, partner with Vinmay. Our commitment to stringent quality, customization, and sustainability ensures your projects stand out. Contact us now to discover the Vinmay advantage in stainless steel tube procurement.

Elevate your projects with Vinmay's expertise in wholesale stainless steel tubes. Contact us today to experience superior quality and unmatched service.