When it comes to selecting the right sanitary stainless steel tubing sizes, precision is key. The diverse range of available sizes can significantly impact the efficiency and effectiveness of your industrial processes, making informed decisions crucial.

Understanding the nuances of various tubing dimensions and standards is essential for optimal performance. Stay tuned to discover how the right tubing size can enhance your operations and ensure seamless functionality in your specific applications.

Sanitary Stainless Steel Tubing is a specialized form of stainless steel tubing designed for applications requiring high levels of cleanliness and corrosion resistance. The material composition of sanitary stainless steel tubing typically includes 304 or 316L stainless steel, providing excellent corrosion resistance in various environments. Welding techniques used in manufacturing this tubing are crucial to maintain the integrity of the material and prevent contamination. Common techniques include Tungsten Inert Gas (TIG) welding, ensuring a clean and precise weld.

Surface finishes play a vital role in sanitary stainless steel tubing, with options like mechanical polishing or electropolishing enhancing corrosion resistance and minimizing the potential for bacterial growth. Pressure ratings for this tubing are determined by factors such as wall thickness, material grade, and welding quality. It is essential to adhere to industry standards to ensure the tubing can withstand the required pressure levels.

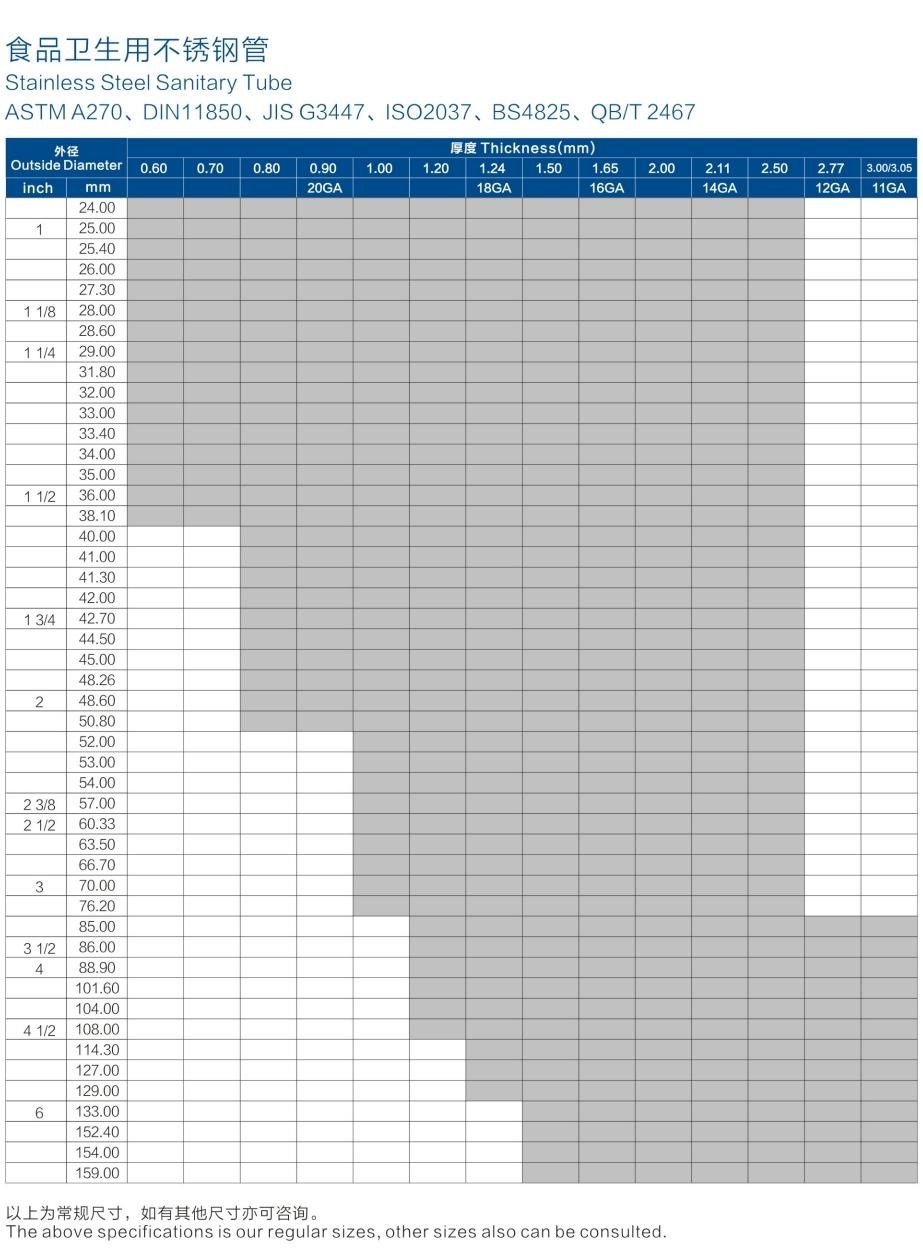

When considering the specifications for sanitary stainless steel tubing, an important aspect to focus on is the range of common sizes and adherence to industry standards for optimal performance in various applications. Tubing dimensions play a crucial role in determining the compatibility and functionality of the tubing in different systems. To further assist in selecting the appropriate tubing size, below is a chart illustrating common sanitary stainless steel tubing sizes:

Common sizes for sanitary stainless steel tubing typically range from ½ inch to 6 inches in diameter, with varying wall thicknesses to accommodate different pressure requirements.

Industry standards, such as ASTM A270 for seamless and welded austenitic stainless steel sanitary tubing, ensure that the material composition meets specific criteria for hygiene, durability, and corrosion resistance. Common industry standards for sanitary stainless steel tubing include:

These standards provide guidelines for the material composition, dimensions, fabrication methods, and performance criteria of sanitary stainless steel tubing, ensuring compliance with hygiene, durability, and corrosion resistance requirements in various industries.

Pressure ratings are assigned based on the tubing dimensions and material strength to guarantee safe operation under varying fluid pressures. Additionally, the corrosion resistance of the stainless steel tubing is essential for maintaining sanitary conditions and longevity in applications where exposure to corrosive substances is a concern.

Adhering to these standards and selecting the appropriate tubing size is critical for the successful implementation of sanitary systems across industries.

Selecting the appropriate tubing size for a specific application requires a meticulous assessment of system requirements and operational parameters. When choosing the right tubing size, several key factors must be considered.

Firstly, material compatibility is crucial to ensure that the tubing can withstand the substances it will come into contact with without corroding or degrading.

Secondly, pressure requirements must be evaluated to determine the tubing's ability to handle the internal pressure of the system without failure.

Additionally, the flow rate needs to be taken into account to ensure that the tubing size allows for the necessary flow of liquids or gases.

Installation considerations such as space constraints and connection methods should also be factored in.

Lastly, cost efficiency plays a significant role in selecting the tubing size, and balancing performance requirements with budget constraints.

Efficient system performance can be enhanced significantly by optimizing tubing sizing to match operational requirements and flow dynamics. When considering sizing, factors such as flow optimization, pressure requirements, material compatibility, and installation techniques play crucial roles.

Sizing considerations involve selecting the appropriate diameter and wall thickness to ensure the tubing can handle the required flow rates without excessive pressure drops. Flow optimization entails minimizing turbulence and restrictions within the tubing to maintain efficient fluid movement.

Pressure requirements dictate the strength of the tubing needed to withstand internal pressures without deformation or leakage. Material compatibility is essential to prevent corrosion, contamination, or degradation of the system due to interactions between the tubing material and the conveyed substances.

Proper installation techniques, including precise cutting, bending, and welding, ensure leak-free connections and optimal system performance. By carefully addressing these aspects, operators can maximize efficiency and reliability in their sanitary stainless steel tubing systems.

To meet your requirements for sanitary stainless steel tubing, consider partnering with Vinmay, a reputable manufacturer specializing in stainless steel welded tubes and related fittings. Vinmay offers custom fabrication services tailored to your specifications, ensuring the perfect fit for your needs.

With a strong focus on quality assurance, Vinmay provides materials such as 304, 304L, and 316L stainless steel, all certified with PED, ISO, and MTC, AEO certificates. Our extensive range of surface finishes, diameter options from 24mm to 159mm, and thicknesses from 0.6mm to 5.0mm allow for versatile applications across various industries.

Vinmay's adherence to international standards guarantees precision in material selection and manufacturing processes, making us a trusted partner for industry applications like food, pharmaceuticals, electronics, and more. Additionally, Vinmay offers international shipping services, ensuring timely delivery of your orders worldwide.

Contact Vinmay today for your sanitary stainless steel tubing needs at rose@vinssco.com.

Discover the inner workings of the stainless steel tube factory industry in our comprehensive guide.

Seamless sanitary stainless steel tubing is manufactured through a continuous extrusion process, offering superior corrosion resistance due to the lack of welded areas. Welded tubing, while more cost-effective, may have lower pressure ratings and is suitable for less demanding applications.

Customization options for sanitary stainless steel tubing include length flexibility and shape possibilities. Tailored solutions can be achieved through precision engineering, allowing for specific lengths and shapes to meet unique requirements in various industries.

Navigating the realm of sanitary stainless steel tubing demands adherence to strict installation requirements, material specifications, industry standards, quality control, and maintenance procedures. Compliance with regulations ensures optimal performance and safety within various applications.

Electropolished sanitary stainless steel tubing offers a superior surface finish, enhancing corrosion resistance and aesthetics. Its hygienic design ensures cleanability, high purity, and longevity. Additionally, it provides cost efficiency and versatility, making it ideal for various industries.

The surface finish of sanitary stainless steel tubing significantly influences its performance across various applications. It impacts corrosion resistance, surface roughness, product purity, material durability, and adherence to industry standards. The appropriate surface treatment ensures optimal functionality.

In conclusion, it is imperative to carefully consider the selection of sanitary stainless steel tubing sizes to ensure optimal efficiency and performance in various applications.

By adhering to industry standards and partnering with a reputable supplier like Vinmay, you can rest assured that your tubing needs will be met with precision and reliability.

Remember, 'measure twice, cut once' to avoid costly mistakes and maximize productivity.

Blog Series: The Ins and Outs of Sanitary Stainless Steel Tube Sizes