Essential Tips for Purchasing Stainless Steel Welded Pipe

Stainless steel welded pipe has high tensile strength and corrosion resistance. It requires low maintenance and has superior chemical composition and mechanical properties.

It is suitable for high-pressure conditions and has various applications in construction, petrochemical, food processing, marine systems, and transportation. Factors to consider when purchasing stainless steel welded pipe include size, wall thickness, length, quality control, and production process.

Introduction

Stainless steel welded pipe is a widely used product in the industrial world due to its numerous advantages, such as high tensile strength,

corrosion resistance and low maintenance. Due to its durability and corrosion resistance, stainless steel welded pipe offers a variety of advantages for many types of applications.

When purchasing stainless steel welded pipes, it is important to consider factors such as size, wall thickness, length, quality control and production process to determine which type of pipe best suits your requirements. Additionally, one must also take into account the application and cost associated with the purchase.

In this article we will provide you with key tips on how to effectively go through the process of purchasing stainless steel welded pipes. Let introduces the tips for you one by one.

Major Enquiry/Ordering Information

When ordering stainless steel welded pipe, customers must consider the material grade, standards, size or outside diameter, wall thickness and length, and finish required. The material grade is important as it will determine the properties of the pipe such as its tensile strength and corrosion resistance. The relevant standards should also be taken into consideration in order to ensure that requirements are met for mechanical properties and dimensions.

1.Material Grade of stainless steel welded pipe

Choosing the right

stainless steel grade is crucial in various industries and applications due to its significant impact on the performance, durability, cost and safety of the final product. The following are the major grade of stainless steel welded pipe

Austenitic:

201,

304/304L,

316/316L, 317/317L, 347/347H, 321/321H, 904L

Ferritic: 409, 430, 439, 441, 434, 436, 444, 446

Martensitic: 403, 410, 410S, 414/L, 441, 418, 420, 440, 416

Duplex: 2205/S31803, S32750, S32760

2.Stainless Steel Welded Pipe Standards

The

standards of stainless steel welded pipe are used as a basis for the production of quality stainless steel welded pipes with specific applications. It is important that these standards are strictly adhered to in order for the end product to meet its intended purpose.

Industrial Pipes: ASTM A312, A358, A778These standards provide a reliable platform for the creation of quality welded pipes that will meet industrial needs. Let’s have a short introduction of them:

ASTM A312 is a widely recognized standard for seamless and welded stainless steel pipes. It encompasses a comprehensive range of grades and sizes, making it suitable for various applications, including high-temperature and corrosive environments.

ASTM A358 pertains specifically to electric-fusion-welded (EFW) austenitic chromium-nickel stainless steel pipes for high-temperature and general corrosive service. A358-compliant pipes are commonly used in industries such as petrochemical, chemical processing, and power generation.

ASTM A778 sets the standards for welded, unannealed austenitic stainless steel pipes for general corrosion resistance and low-temperature applications.

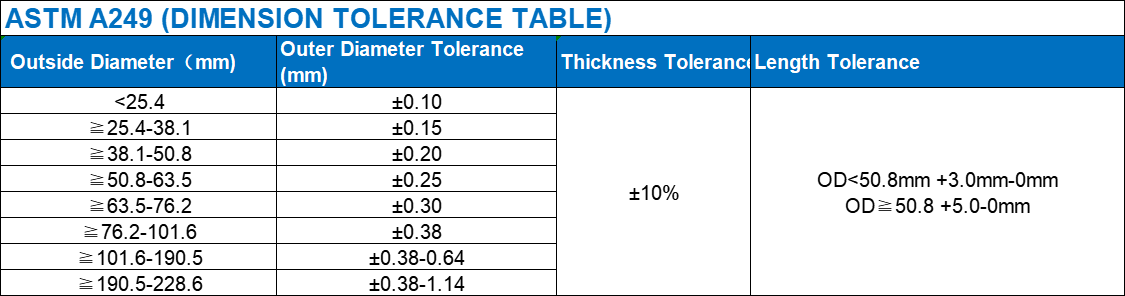

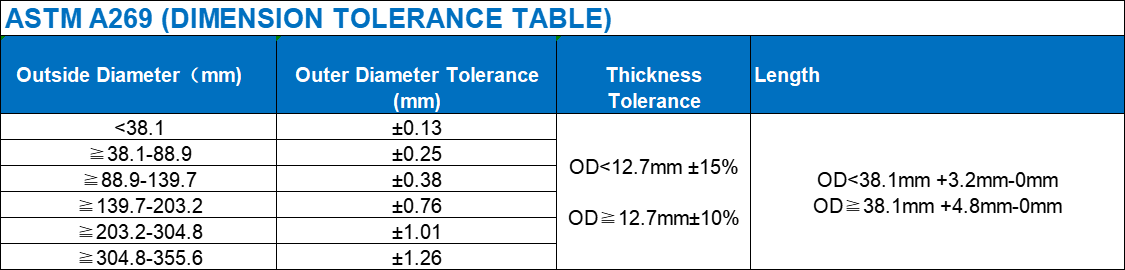

Tubes for Boiler and Heat-Exchanger, General Service Tubing: ASTM ASTM A249, A269, EN10217-7ASTM A249, A269 is a respected standard that specifies welded austenitic steel tubes for heat-exchanger and general service applications.

They are extensively used in industries such as petrochemical, pharmaceutical, and food processing. EN10217-7 is a European standard that governs the production of welded stainless steel tubes for pressure purposes.

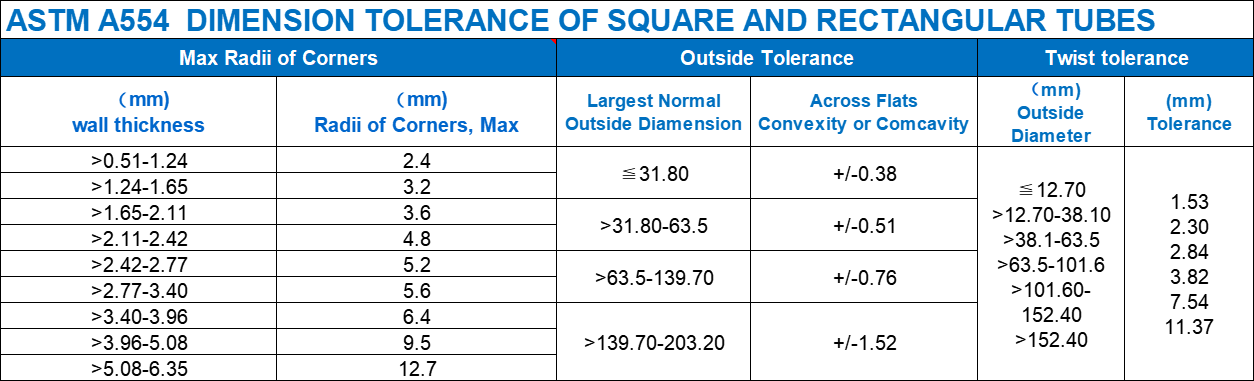

Mechanical and Structural Tubes:ASTM A554/EN10296-2Moving on, we'll explore

ASTM A554 which covers mechanical and structural tubing used in many applications. It is an important part of stainless steel welded pipe and has the following features:

Available in round, square, rectangular or special shapes

Made from 304, 316L grade materials

Possesses superior formability and smooth finish

Has excellent corrosion resistance

SS welded pipes are strong and durable.

Stainless Steel Water Tube:EN10312EN10312 is a European standard that specifies the requirements for stainless steel welded and seamless water tube systems. These tubes are specifically designed for use in water supply and heating applications where the corrosion resistance and durability of stainless steel are essential.

Sanitary Stainless Steel Tube: ASTM A270/EN10357/DIN11850Sanitary Stainless Steel Tubes, produced in accordance with

ASTM A270, EN10357, and DIN11850 standards, are essential components in industries where hygiene and quality are paramount. These tubes are specifically designed for applications that require the transportation of fluids in a sanitary and contamination-free manner.

ASTM A270 is an American standard that defines the specifications for seamless and welded stainless steel sanitary tubing. Tubes manufactured under this standard are renowned for their cleanliness, smooth interior surfaces, and precise dimensions

EN10357 is a European standard that outlines the requirements for welded stainless steel tubes in food, chemical, and pharmaceutical industries.

DIN11850 is a German standard that specifies the dimensions and quality requirements for stainless steel tubes used in the food, chemical, and pharmaceutical industries.

3.Stainless Steel Welded Pipe Size

Stainless steel welded pipe size or outside diameter is an important consideration when selecting a stainless steel welded pipe.

The following form list the different standards of stainless steel welded pipe and their corresponding grade and diamension range

Product Name | Executive Standard | Dimension | Stainless Steel Grade |

Tubes for Boiler and Heat-Exchanger, General Service Stainless Steel Pipe | ASTM A249, A269,EN10217-7 | OD: 12.00-159.00mm

Thickness:0.6mm-3.05mm | 304, 304L, 316L |

Mechanical and Structural Tubes | ASTM A554, EN10296-2 | OD: 7.9-152.4mm

Thickness:0.6-5.0mm | 201,304, 304L, 316L, 430 |

Square Tubes | ASTM A554, EN10296-2 | OD: 10x10-150x150mm

Thickness:0.6-5.0mm | 201,304, 304L, 316L, 430 |

Rectangular Tubes | ASTM A554, EN10296-2 | OD: 10x20-100x200mm

Thickness:0.6-5.0mm | 201,304, 304L, 316L, 430 |

Sanitary Tubing | ASTM A270, EN10357, DIN11850 | OD: 24-159mm

Thickness: 0.6-3.05mm | 304, 304L, 316L |

Stainless Steel Water Pipe | EN10312 | OD: 9.5-219.08mm

Thickness: 0.8-4.0mm | 304, 304L, 316L |

4.Length

The length of the pipe is a critical factor in determining its strength and durablity. Its length should be carefully measured, as cutting a pipe too short can compromise its structural integrity. Depending on the application, pipes generally range from 6 inches to 13 meters long. Most of the stainless steel welded pipe length are in 20 feet or 6 meters.

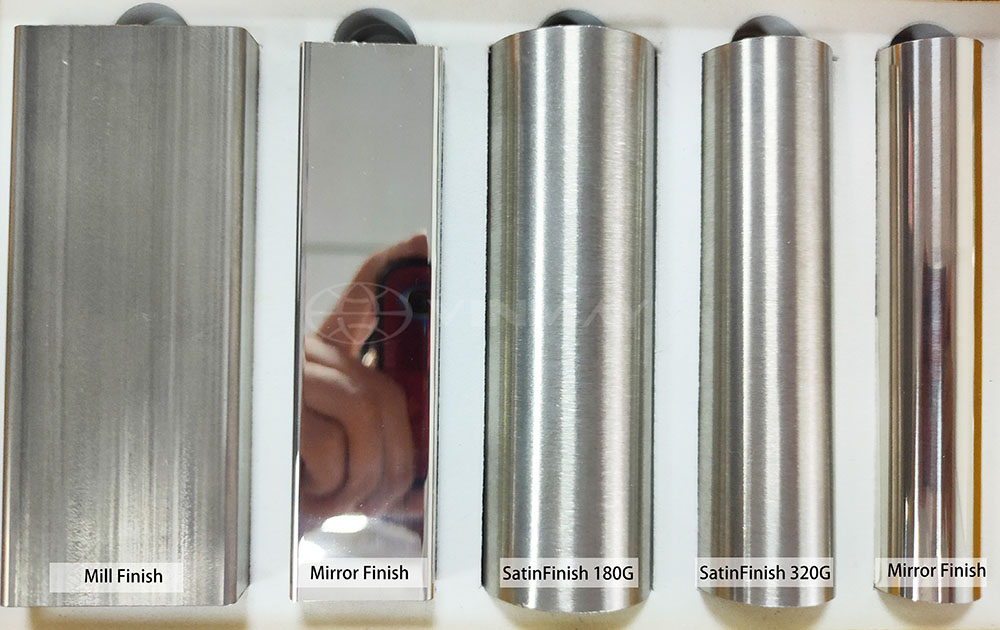

5.Finish Required

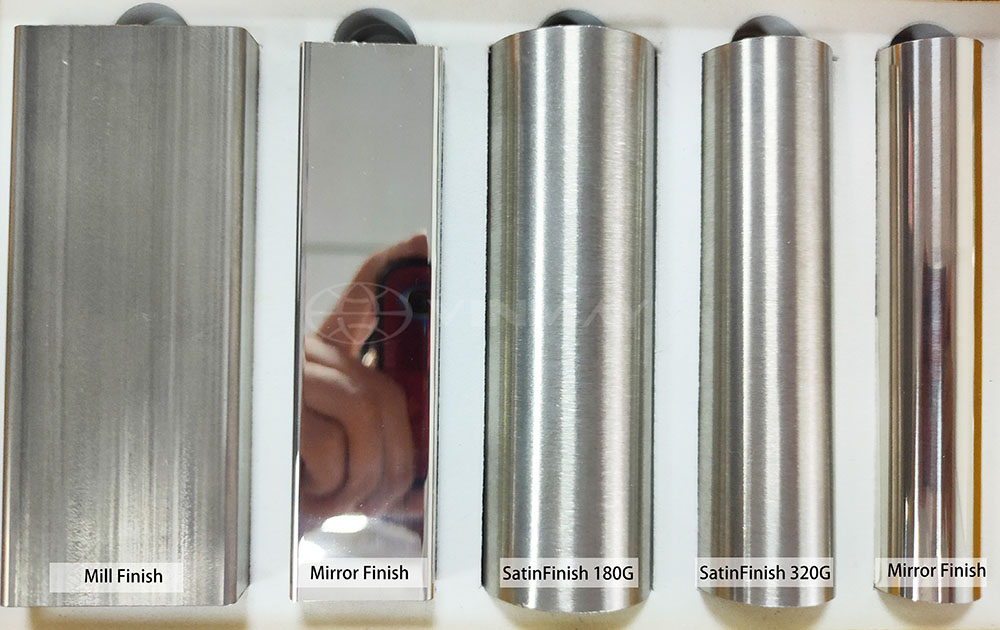

Mill Finish (MF)

This is the basic finish applied after the welding process. It has a raw, unpolished appearance and is often used for industrial or structural applications. Mill finish stainless steel has a dull, grayish surface.

Brushed or Satin Finish ( 240Grit,320grit ,400grit)

This finish is achieved by mechanically brushing the stainless steel surface to create a uniform, matte appearance. It provides a sleek, attractive look and is commonly used in architectural and decorative applications.

Mirror Finish (600grit,800grit)

Also known as a polished finish, it's the shiniest and most reflective option. Mirror-finished stainless steel has a highly reflective, almost mirror-like appearance and is often used in decorative and high-end applications.

Bead Blasted Finish

This finish involves shooting tiny glass beads at the stainless steel surface under pressure. It creates a uniform, matte appearance with a slight texture.

Electropolished Finish

Electropolishing is an electrochemical process that removes a thin layer of surface material, leaving a smooth, highly reflective finish. It not only enhances the appearance but also improves corrosion resistance and makes the surface easier to clean. It's commonly used in pharmaceutical, food processing, and semiconductor industries.

Pickled Finish

After welding, the stainless steel is immersed in an acid solution to remove scale, oxides, and other contaminants. This process creates a clean, slightly dull surface. Pickled finish is often followed by passivation to improve corrosion resistance.

Discover More :

Comprehensive Guide to Stainless Steel Tube Surface Finishes

Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

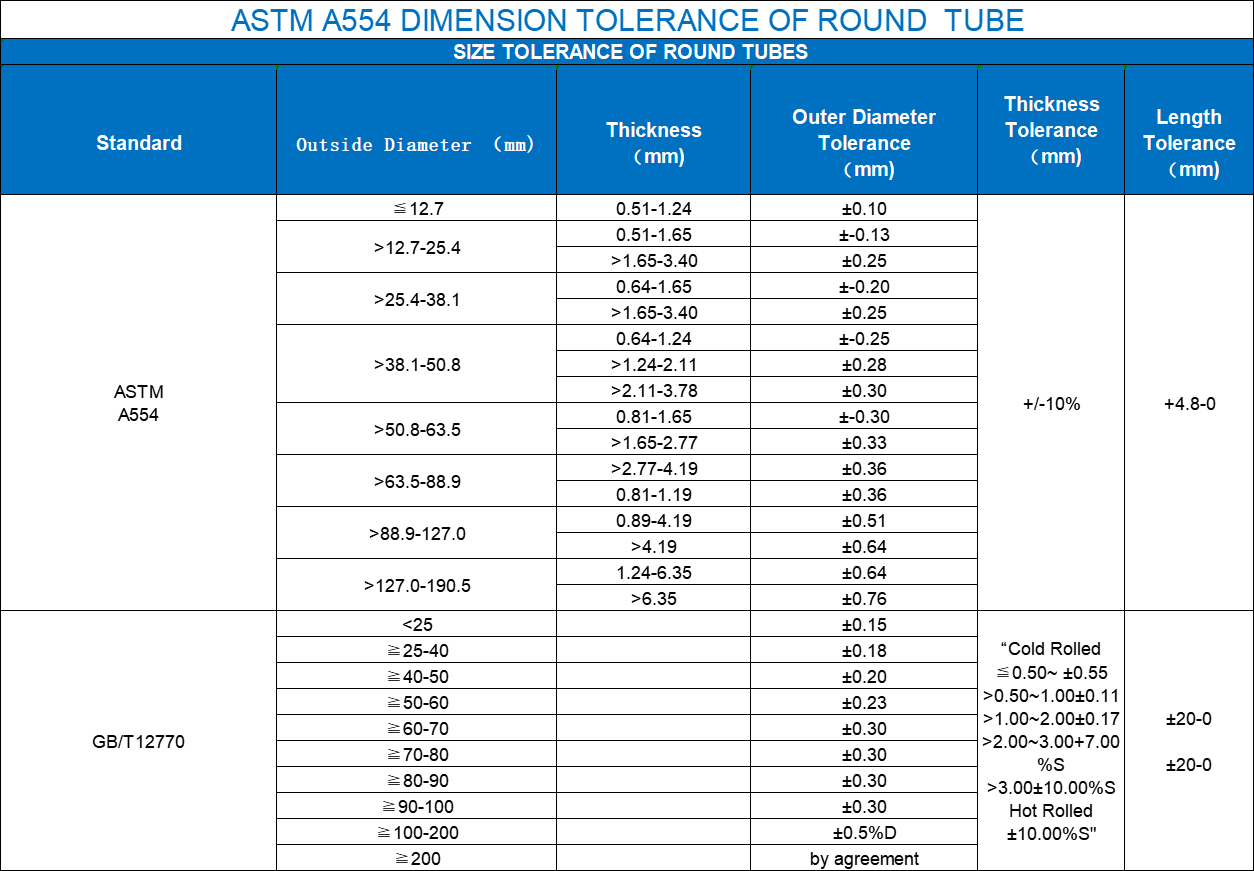

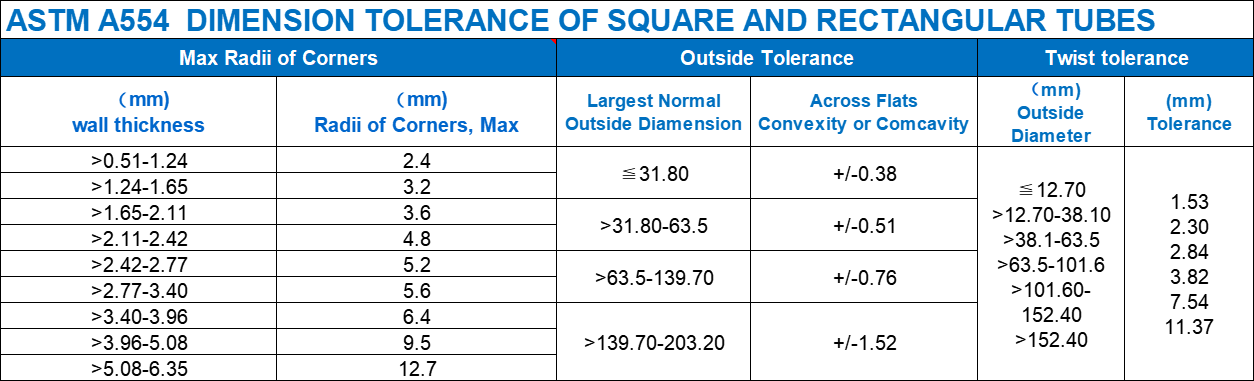

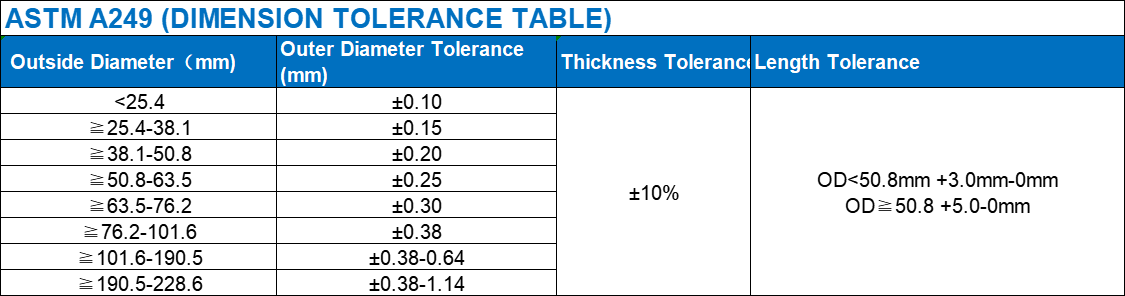

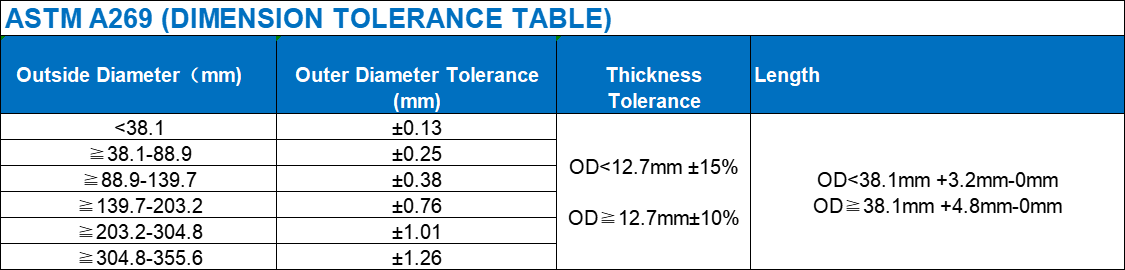

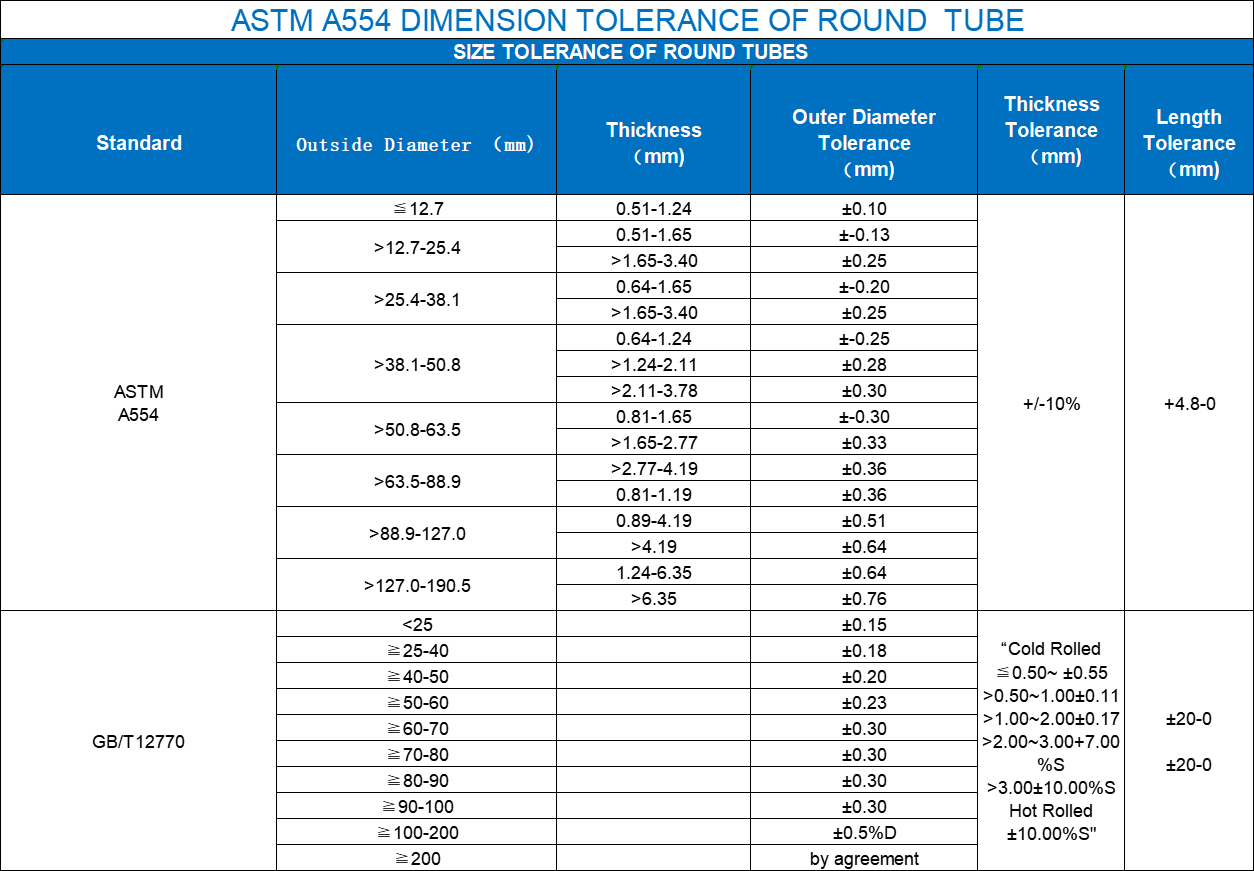

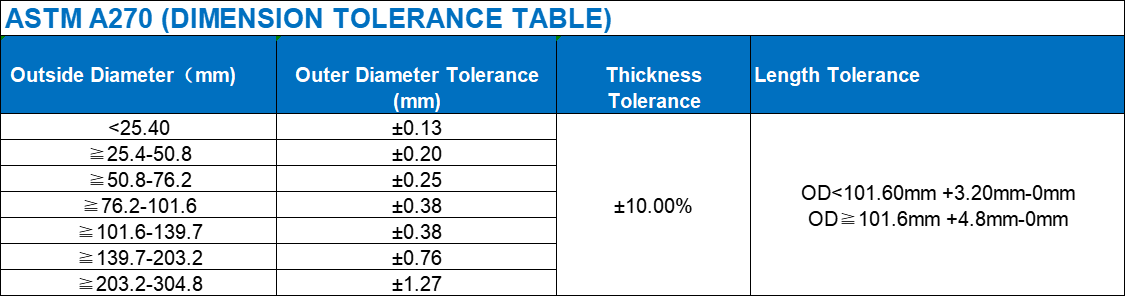

6.Stainless Steel Welded Pipe Tolerance

During the production process, it can be challenging to achieve the exact nominal pipe size. Often, the actual size deviates, either larger or smaller than the nominal size. Therefore, industry standards define tolerances for these deviations. An excess in size is termed a positive deviation, while a reduction is referred to as a negative deviation.

Understanding Nominal Pipe Size vs Actual Pipe Size

A. Nominal Pipe Size: This represents the size specified in standards such as ASME B36.10m and ASME B36.19m. It is the ideal size that both users and manufacturers aim to achieve, as well as the size outlined in contractual agreements.

B. Actual Pipe Size: This corresponds to the size obtained during the production process, which may deviate from the nominal size, being either larger or smaller. This deviation from the nominal size is termed as a deviation.

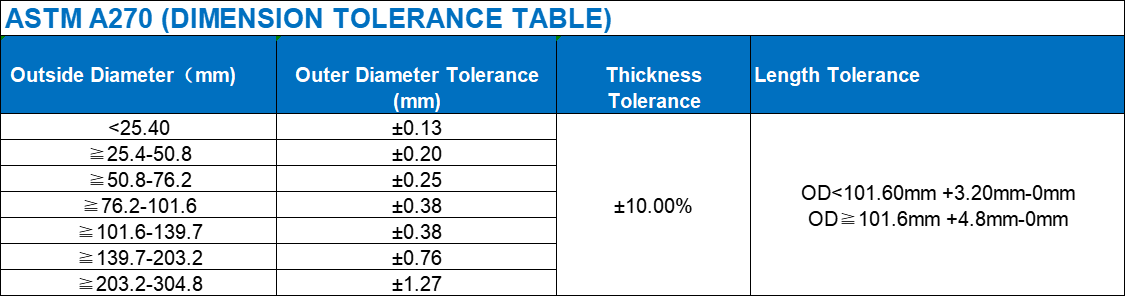

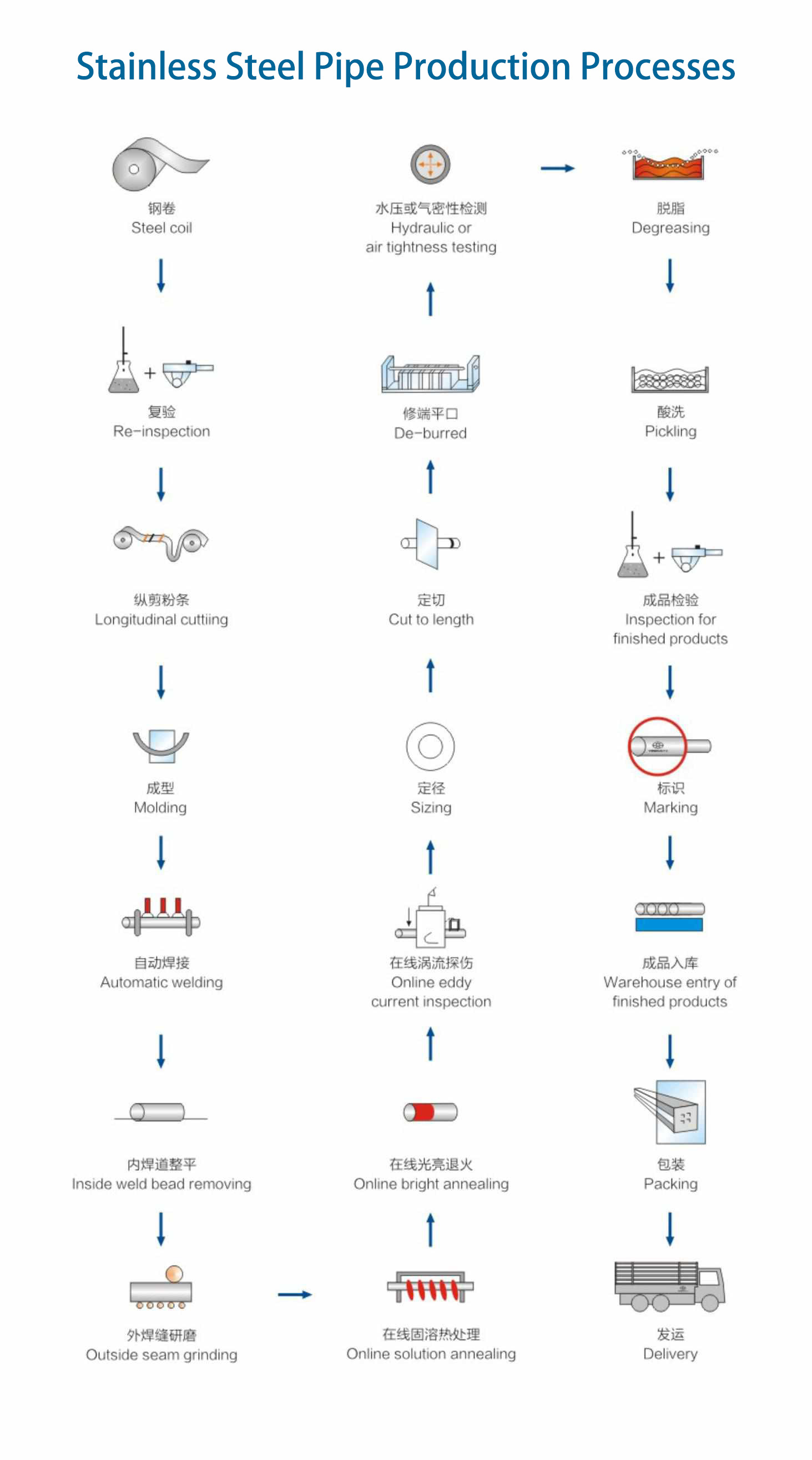

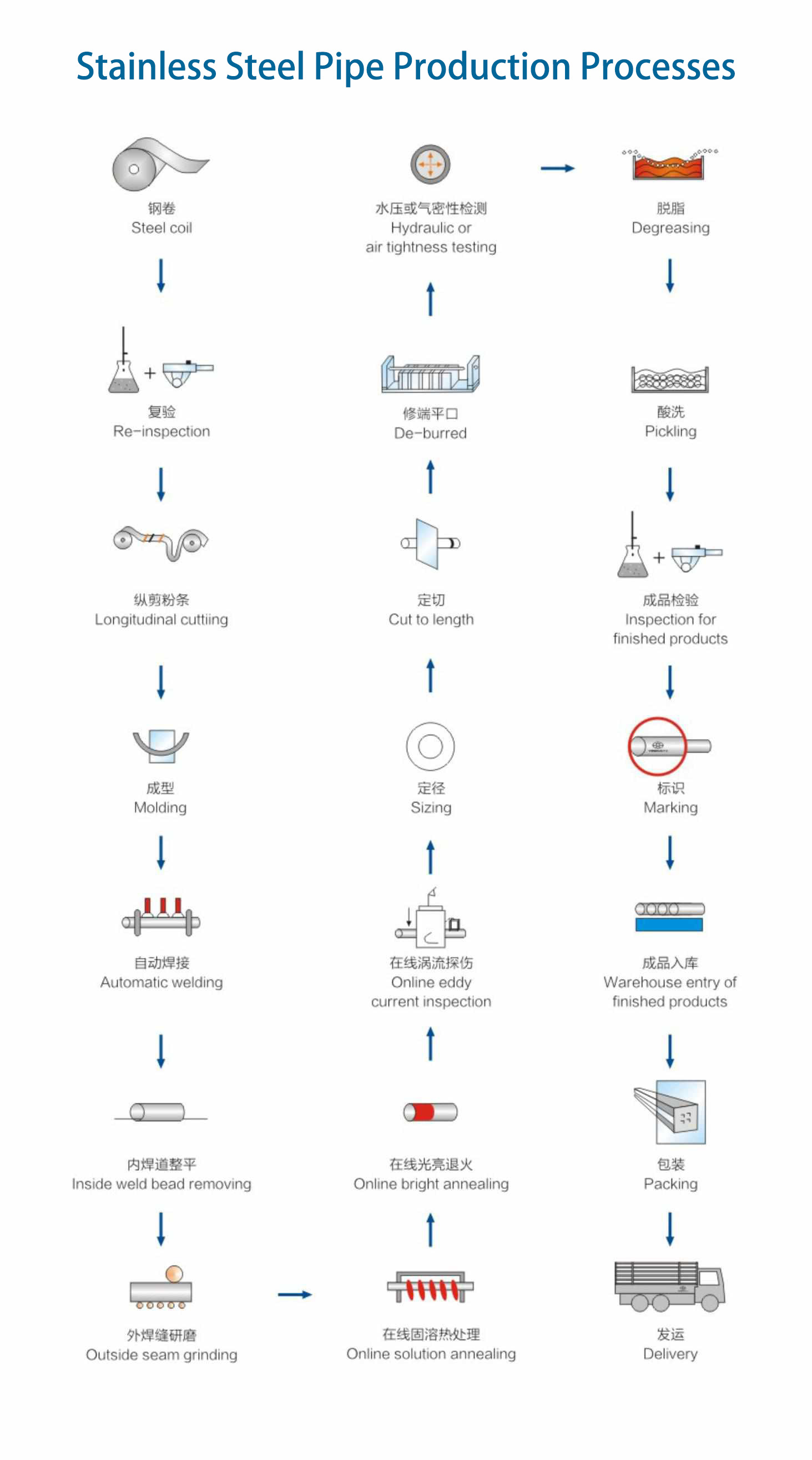

Learn about Manufacturing process of Stainless Steel Welded Pipe

It is important to gain an understanding of the manufacturing process for stainless steel welded pipes in order to better comprehend the product and its characteristics. This knowledge can help with making informed decisions when it comes to selecting a suitable pipe, as well as gaining insight into its production costs. Moreover, it can allow one to assess quality control measures taken by suppliers during the fabrication process.

You may also like:

Introduction of Stainless Steel Pipe Manufacture ProcessesStainless Steel Tubing Welding 101: Tips for SuccessThe Difference of Stainless Steel Pipe TIG Welding and HF Welding

Learn about the Inspection & Quality Control of stainless steel welded pipe

Knowledge of the inspection process for stainless steel welded pipes is essential for ensuring high-quality results. It is important to take into account:

* The manufacturing process and any potential errors that may occur

* Meeting the standards set by industry regulations

* Potential damage caused during transit or handling

* Flaws in design, fittings, or other components of the pipe assembly

* Making sure there are no defects or corrosion present in the pipe.

The

quatlity inspection processo of stainless steel welded pipe included:

Chemical Composition Analyzing

Metallographic Test

Mechanical Properties Test

Hydraulic Test

Non-destructive Test, including X-Ray Flaw Detection

Dimensional Checking

Flattening

Flare & Flange

Reverse Bend

Reverse Flattening

Tensile Strength

Hardness Test

Budget Wisely

While it's essential to prioritize quality and performance, budget constraints may also play a role in your purchasing decision. Be sure to get quotes from multiple suppliers and compare prices. Keep in mind that lower-cost options may not always offer the best long-term value if they sacrifice quality or durability.

Learn More:

Deciphering the Dynamics: Unraveling Stainless Steel Round Tube PricesSeek Expert Advice

In order to make the most out of a budget when shopping for stainless steel welded pipes, it is important to seek expert advice. This type of product requires research and knowledge to ensure that the right type of pipe is purchased.

Professionals in the field can provide valuable insight into different types of stainless steel welded pipes, their characteristics, and which are best suited for a particular application. Additionally, they can help with cost comparisons between various brands and models, as well as other factors like installation costs.

Check Supplier Reputation

Verifying the reputation of suppliers when shopping for welded pipes is important. To ensure that the product will meet expectations and that the process will be smooth, it is essential to evaluate all aspects of a supplier's operations. Items that should be considered include

Quality Assurance and Control System

Delivery Lead Time

Cost Efficiency

Product Range

Technical Support

Learn More :

A Comprehensive Guide to Top Stainless Steel Round Tube Suppliers WorldwideComprehensive Guide to Stainless Steel Tubing Manufacturers WorldwideCustom Solutions With a Stainless Steel Square Tubing SupplierConclusion

Purchasing stainless steel welded pipes requires careful consideration of various factors to ensure the pipes meet your project's requirements and provide long-lasting performance.

By understanding your needs, selecting the right size and material grade, evaluating welding quality, and considering factors like surface finish and corrosion resistance, you can make an informed decision that meets both your immediate and long-term objectives. Partnering with a reputable supplier is also crucial to ensure the reliability and quality of the stainless steel welded pipes you acquire.

At Vinmay Stainless Steel ,we take pride in being a leading professional stainless steel welded pipe manufacturer in China. Our expertise in producing stainless steel welded pipe for decorative purpose, food industry, heat treatment and water supply system . If you are looking for stainless steel welded pipe or have any questions, please don't hesitate to reach out to us. We are here to assist you and provide the information you need.

Contact us today for all your tile requirements.