Stainless steel rectangular tubes play a vital role in various industries due to their standardized dimensions and quality adherence. Understanding the stainless steel rectangular tube standard size specifications, such as those set by ASTM A554, is essential for ensuring seamless integration into diverse structural applications. The precision and consistency offered by these stainless steel rectangular tube standard sizes not only streamline project planning and execution but also uphold the integrity and functionality of the structures they support. As we explore the significance of stainless steel rectangular tube standard sizes, it becomes evident why these specifications are pivotal in the field of structural engineering and industrial applications.

The introduction of rectangular tube stainless steel encompasses specifications, applications, workability, and mechanical properties.

Understanding the specifications such as stainless steel tube material type, surface finish, and stainless steel tube standards is important for various applications like framework, marine structures, and food processing.

Additionally, the mechanical properties, including Brinell hardness, tensile strength, and yield strength, play a significant role in determining the tube's performance in different environments.

Stainless steel rectangular tubes, like other stainless steel products, are available in various grades of stainless steel pipe depending on their intended use and properties required for specific applications. Some common stainless steel grades used for rectangular tubes include:

304 Stainless Steel: As mentioned earlier, 304 stainless steel is one of the most common grades used for tubing. It offers good corrosion resistance, weldability, and formability, making it suitable for a wide range of applications, including structural, architectural, and decorative purposes.

You may also like:

What Is Food Grade 304 Stainless Steel?

Is 304 Stainless Steel Surgical Grade?

316 Stainless Steel: Similar to 304 stainless steel but with added molybdenum, 316 stainless steel provides enhanced corrosion resistance, particularly in marine and harsh environments. It's often chosen for applications where corrosion resistance is critical.

409 Stainless Steel: This ferritic stainless steel grade is suitable for applications requiring moderate corrosion resistance and good formability. It's commonly used in automotive exhaust systems and structural applications.

430 Stainless Steel: Another ferritic stainless steel grade, 430 offers good corrosion resistance and formability. It's often used in applications where appearance is less critical, such as automotive trim, kitchen equipment, and architectural components.

Duplex Stainless Steels (e.g., 2205): Duplex stainless steels offer a combination of high strength and excellent corrosion resistance, making them suitable for demanding structural and industrial applications.

Other Specialized Grades: Depending on the specific requirements of an application, other stainless steel grades such as 321, 347, 17-4 PH, and precipitation hardening grades may be used for rectangular tubing

When selecting a grade of stainless steel for rectangular tubes, factors such as corrosion resistance, strength, weldability, formability, and cost should be considered based on the intended application and environmental conditions.

Discover More :

what is the difference between 201 and 304 stainless steel?

Establishing the standard specifications for stainless steel rectangular tubes is essential for ensuring structural integrity and compatibility within various applications.

ASTM A554 is the standard specification for these tubes, ensuring precise dimensions, material quality, and surface finish requirements.

This standard guarantees that stainless steel rectangular tube standard size meet industry benchmarks for construction, fabrication, and performance in diverse structural projects.

Surface finish plays a significant role in determining the aesthetic appeal and corrosion resistance of stainless steel rectangular tubes, ensuring quality and longevity in various structural applications.

The surface finish of stainless steel tubes can vary depending on the manufacturing process and the intended application. Here are some common surface finishes for stainless steel tubes:

Mill Finish: This is the standard finish directly from the mill without any additional treatment. It typically has a slightly rough surface.

Polished Finish: Stainless steel tubes can be polished to achieve a smooth, reflective surface. There are different levels of polishing, including:

Embossed or Patterned Finish: Stainless steel tubes can also be given textures or patterns for aesthetic purposes or to improve grip.

Pickled Finish: Pickling is a chemical process used to remove surface impurities and contaminants from stainless steel, leaving a clean, matte finish.

Passivated Finish: Passivation is a chemical treatment to enhance the corrosion resistance of stainless steel by forming a protective oxide layer on the surfaced.

Electro-Polished Finish: This finish involves using an electrochemical process to polish the stainless steel surface, resulting in improved corrosion resistance and a smooth, shiny finish.

Coated Finishes: Stainless steel tubes can be coated with various materials for specific purposes, such as to improve corrosion resistance, enhance aesthetics, or provide additional protection against wear and tear.

Each of these surface finishes has its own advantages and is chosen based on factors such as aesthetics, functionality, and environmental considerations.

Learn More: Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

Stainless steel rectangular tubes find extensive application across various industries due to their structural versatility and exceptional corrosion resistance properties. Commonly referred to as structural stainless tubes or stainless box tubes, they are utilized in a wide range of applications including framework construction, braces, supports, marine environments, and the food industry.

These tubes are easy to weld and possess moderate cutting, forming, and machining capabilities, making them a versatile choice for various projects. With superior corrosion resistance and durable mill finish, stainless steel rectangular tubes offer a reliable solution for structural needs where longevity and strength are essential.

The workability of stainless steel rectangular tubes is characterized by their ease of welding and moderate cutting, forming, and machining capabilities, making them a versatile choice for various structural projects.

When evaluating the mechanical properties of stainless steel rectangular tube standard size, it is essential to take into account key factors such as Brinell hardness, tensile strength, and yield strength.

Stainless steel type 304 rectangular tubes typically exhibit a Brinell hardness of 170, providing good resistance to surface indentation. The tensile strength of these tubes averages around 85,000 pounds per square inch, ensuring robust structural integrity under tension. Additionally, the yield strength of approximately 34,000 pounds per square inch signifies the point at which the material permanently deforms under stress.

These mechanical properties, combined with the nonmagnetic nature of stainless steel, make type 304 rectangular tubes an excellent choice for various applications requiring strength, durability, and corrosion resistance.

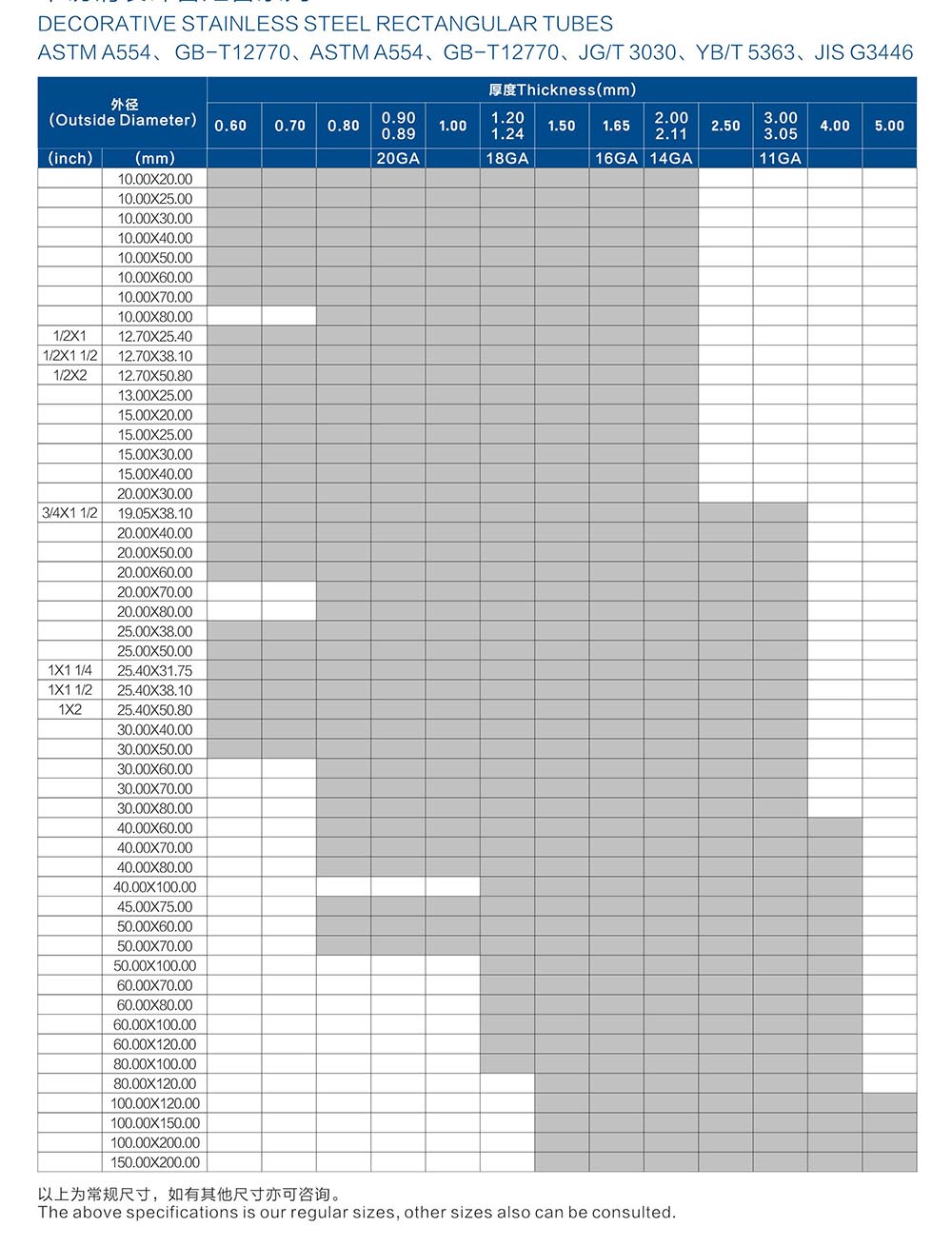

In the domain of structural stainless steel tube manufacturing and standards, the stainless steel rectangular tube standard size typically adhere to specific dimensions outlined by ASTM guidelines. The following table shows the dimensions of stainless steel rectangular tubes standard size.

Learn More:

A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

The engineering data for structural tubing encompasses critical aspects such as tolerances for outside dimensions and wall thickness of stainelss steel tubes, the maximum twist permissible in hollow structural sections, and the lengths with allowable variations in structural steel tubing.

These factors are vital for ensuring the structural integrity and dimensional accuracy of the tubing, thereby impacting the overall performance and suitability for various applications.

Understanding and adhering to these engineering data points is essential in maintaining quality standards and meeting the specific requirements of structural projects.

HSS tubing is crafted from stainless steel round tube using specialized rolls on a reducing mill. Square hollow structural sections typically range from 1/2” to 16” in size, while stainless steel rectangular tube standard size spans from 1/2” x 1” to 12” x 20”. ASTM A513 standards govern manufacturing for sizes smaller than 2” square and equivalent rectangles with a wall thickness below 0.120. Sizes 2” and larger, with a wall thickness of 0.120 or greater, adhere to ASTM A500 specifications.

| Largest outside dimension across flats, inches | 2 1/2 & under | Over 2 1/2 to 3 ½ incl. | Over 3 1/2, 5 1/2 incl. | Over 5 1/2 |

| Tolerance for outside dimensions including convexity or concavity | 0.020 | 0.025 | 0.030 | 1% |

| Wall thickness tolerance | 10% of nominal wall thickness exclusive of weld area. | |||

Twist is assessed by securing one end of a stainless steel welded square tube or rectangular structural steel tube on a flat surface plate and observing the variation in height of the opposing corners above the plate. Similarly, for heavier hollow structural sections, this distinction in height can be gauged with an appropriate measuring instrument. The permissible discrepancy in height should not surpass the specified limits, and measurements for twist should be avoided within 2 inches of either end of the product.

| Specified dimensions of longest side, inches | 2 to 2 1/2 incl. | Over 2 1/2 to 4 incl. | Over 4 to 6 incl. | Over 6 to 8 incl. | Over 8 |

| Maximum twist per 3 feet of length, inches | .062 | .075 | .087 | .100 | .112 |

| Tube lengths | 22 feet and under | Over 22 feet |

| Length tolerance for specified mill length, inches | 1/2 over and 1/4 under | 3/4 over and 1/4 under |

| Squareness of sides | Adjacent sides may deviate from 90 degrees by a tolerance of +/- 2 degree maximum. | |

| Variations from exact straightness | Permissible variation shall be 1/8” times the number of feet of total length divided by 5. | |

The radius of any outside corner of the hollow structural section shall not exceed three times the nominal wall thickness.

The measurement of stainless steel rectangular tube standard size involves evaluating the outside dimensions and wall thickness with precision and accuracy. To provide a clearer understanding, the following table outlines the key parameters used in measuring stainless steel rectangular tubing:

| Measurement Parameter | Description |

|---|---|

| Outside Dimensions | Length and width of the tubing |

| Wall Thickness | Thickness of the tubing walls |

These two critical measurements guarantee the proper fit and structural integrity of the tubing in various applications. By accurately evaluating these dimensions, stainless steel welded tube manufacturers and engineers can determine the suitability of the stainless steel rectangular tubing for specific projects. Precision in measurement is crucial to ensure the quality and performance of the tubing in structural applications.

Rectangular structural tubing offers significant benefits in terms of strength and durability due to its shape and design, making it ideal for various applications where structural integrity is essential.

Additionally, its ease of fabrication allows for efficient customization and shaping to suit specific project requirements, contributing to cost-effectiveness in manufacturing processes.

Moreover, the corrosion resistance and stability of stainless steel rectangular tubing make it a reliable choice for applications exposed to harsh environmental conditions, ensuring long-term performance and longevity.

Strength and durability are key characteristics that make stainless steel rectangular structural tubing a preferred choice in various applications due to its superior mechanical properties and corrosion resistance.

With its exceptional workability and fabrication properties, stainless steel rectangular structural tubing offers significant advantages in various construction and manufacturing applications. The ease of stainless steel tubing fabrication from its moderate cutting, forming, and machining capabilities. This allows for efficient welding processes, making it a preferred choice for structures requiring precise dimensions and strong joints.

Stainless steel rectangular tubing's malleability and ductility further enhance its ease of manipulation during fabrication, ensuring that complex shapes can be achieved with accuracy. These characteristics contribute to cost-effective production processes and streamlined manufacturing operations, making stainless steel rectangular structural tubing a versatile and practical solution for a wide range of structural and design requirements.

The cost-effectiveness of stainless steel rectangular structural tubing is underscored by its efficient fabrication properties and versatility in meeting precise structural and design requirements.

These factors make stainless steel rectangular tubing a financially prudent choice for various construction and design applications, providing both immediate and long-term cost savings while ensuring structural integrity and design flexibility.

The corrosion resistance of stainless steel rectangular structural tubing enhances its longevity and makes it a preferred choice for applications requiring durability in harsh environments.

Stainless steel, such as T304, is known for its superior corrosion resistance due to the presence of chromium, forming a protective oxide layer that prevents rust and corrosion. This property guarantees the structural integrity of the tubing over an extended period, even in challenging conditions where exposure to moisture, chemicals, or extreme temperatures may occur.

Rectangular structural tubing provides inherent stability through its geometric design and material composition, ensuring reliable structural support in various applications.

These benefits make rectangular tubing an excellent choice for applications where stability and structural integrity are paramount, offering a dependable solution for diverse construction projects.

Recyclability is a key advantage of utilizing construction tubing, particularly in rectangular form, due to its sustainable attributes and environmental benefits. Stainless steel rectangular tubes can be recycled repeatedly without losing their inherent properties, making them a preferred choice for eco-conscious projects.

The process of recycling stainless steel involves melting down the material and reforming it into new products, reducing the need for raw materials and energy consumption. By choosing stainless steel rectangular tubing, industries contribute to a circular economy model by promoting resource efficiency and waste reduction.

This sustainable approach aligns with modern environmental standards and regulations, ensuring a responsible and eco-friendly solution for structural applications.

Customization of stainless steel rectangular tubes for specific applications is a common practice in the industry. Manufacturers offer various options in dimensions, finishes, and properties to meet diverse needs, ensuring precision and suitability for specialized projects.

Special coatings like powder coating, electrophoretic deposition, or plating can be applied to stainless steel rectangular tubes for enhanced protection against corrosion or to achieve specific aesthetic requirements, expanding their versatility in various applications.

Typical packaging options for shipping stainless steel tubes include wooden crates, cardboard boxes, or steel racks. Each method guarantees secure transport and protection against damage during handling and transit, maintaining the integrity of the tubes.

When purchasing stainless steel rectangular tubes, the minimum order quantity requirement varies by supplier. It is advisable to check with the specific stainles steel tube supplier or manufacturer for their minimum order quantity policies to guarantee compliance with your project needs.

Utilizing stainless steel rectangular tubes offers sustainability benefits such as high corrosion resistance, durability, and recyclability. These tubes reduce maintenance needs, enhance longevity in various applications, and contribute to eco-friendly practices in construction and manufacturing industries.

To sum up, stainless steel rectangular tubes offer a standardized and reliable solution for structural needs in various industries.

With precise dimensions, excellent corrosion resistance, and compliance with industry standards like ASTM A554, these tubes provide durability and dependability for a wide range of structural projects.

Their engineering data and benefits make them an essential component in construction, marine environments, and the food industry, ensuring structural integrity and compatibility across applications.