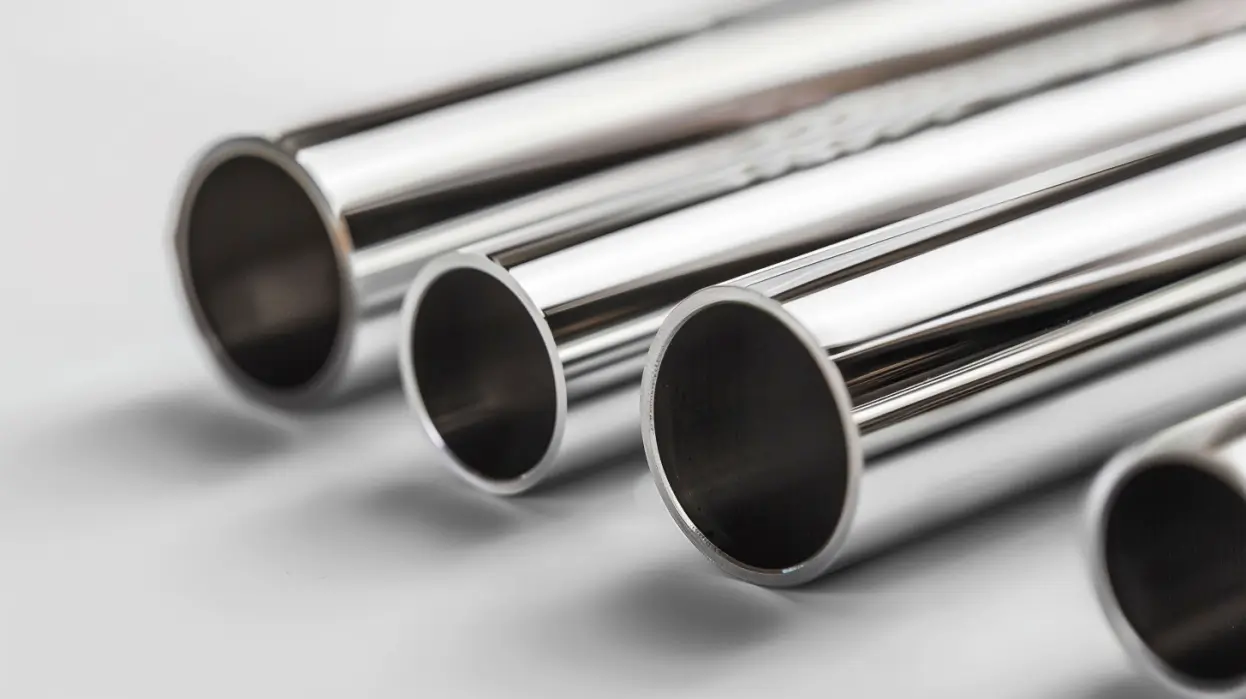

When strength meets elegance, mirror polished stainless steel tubing becomes the go-to choice for architects, designers, and engineers alike. Known for its highly reflective, glass-like surface, this finish transforms ordinary stainless steel into a premium material that delivers both durability and aesthetics. From luxury interiors and modern architecture to sanitary piping in food, medical, and pharmaceutical industries, mirror-finished tubing offers unmatched versatility.

In this guide, we’ll explore what mirror polishing really means, how the process works, its key benefits, applications across industries, and what to consider when choosing the right tubing for your project.

Whether you’re an industry professional seeking technical insights or a designer looking for the perfect finishing touch, this article will help you understand why mirror polished stainless steel tubing is more than just a shiny surface—it’s a smart investment in performance and style.

Mirror polished stainless steel tubing is stainless steel that has been polished to achieve a smooth, highly reflective, mirror-like finish. Often referred to as a “#8 mirror finish” in the industry, this surface treatment eliminates imperfections and enhances both the look and performance of the metal.

Unlike standard mill finishes or brushed stainless, the mirror finish provides:

Due to these qualities, mirror-polished tubes are ideal for industries that require both visual impact (such as architecture and design) and stringent hygiene standards (such as food processing, pharmaceuticals, and medical equipment).

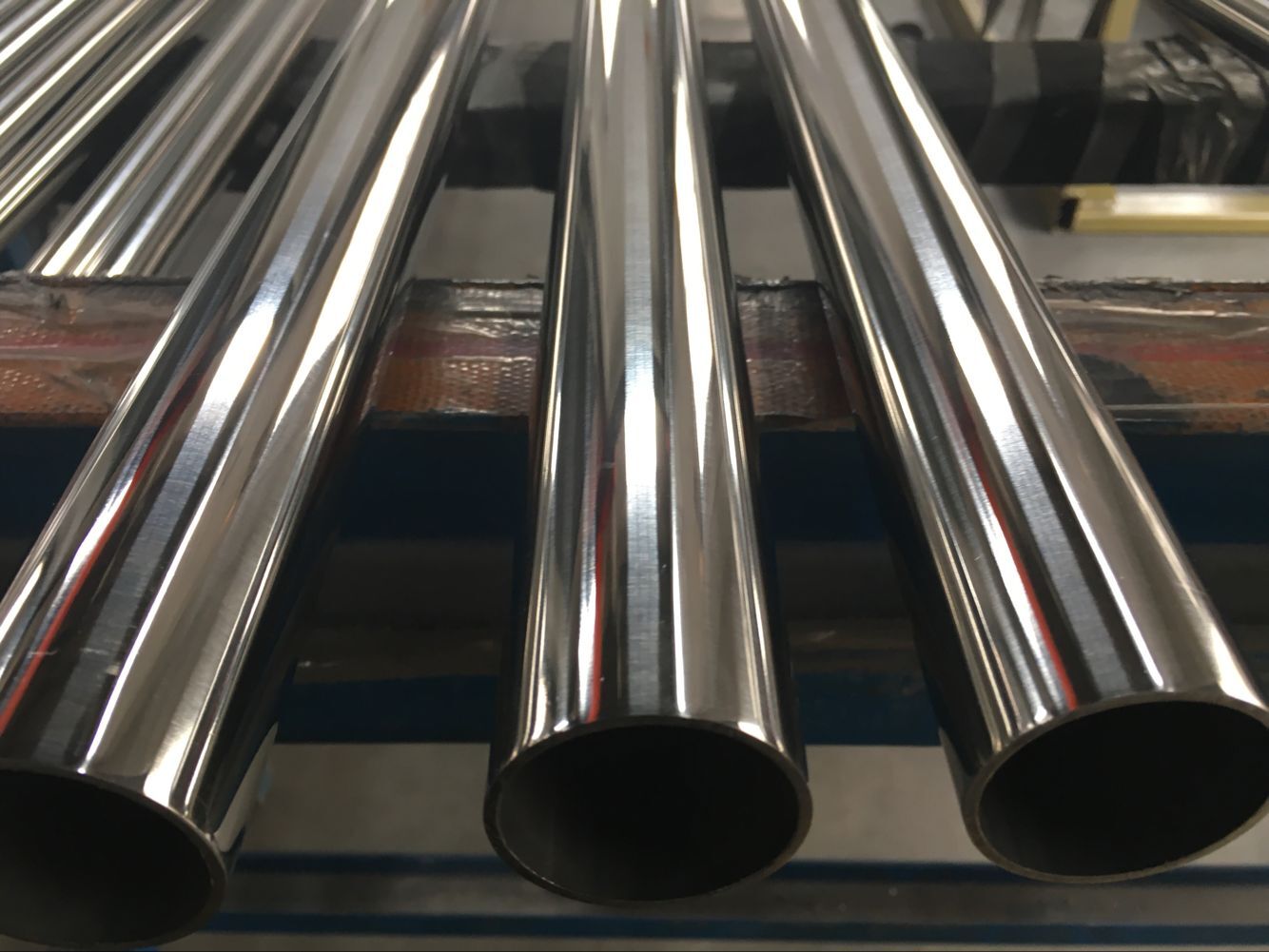

Creating mirror polished stainless steel tubing requires precision, the right raw materials, and a multi-stage finishing process. Unlike basic stainless steel tubes, which may have a dull or brushed appearance, mirror-polished tubes undergo specialized treatments to achieve their flawless, reflective surface.

Here’s how the process typically works:

1. Material Selection

High-quality stainless steel grades—most commonly 304 and 316—are chosen for their corrosion resistance, strength, and suitability for polishing.

2. Tube Forming

Learn More: Stainless Steel Tube Welded VS Seamless

3. Surface Preparation

4. Multi-Stage Polishing

5. Final Cleaning & Inspection

The result is a tube with exceptional brilliance, smoothness, and performance, ready for use in industries where aesthetics and hygiene are equally critical.

Choosing mirror polished stainless steel tubing isn’t just about aesthetics—it’s about performance, hygiene, and long-term value. Here are the main advantages that make it stand out:

The mirror finish provides a luxurious, high-end look that instantly elevates any project. Whether it’s for architectural handrails, display fixtures, or interior design elements, the reflective surface adds sophistication and modern appeal.

A smoother surface reduces microscopic crevices where moisture, dirt, and chemicals can accumulate. This not only improves the tube’s resistance to corrosion and rust but also extends its service life, even in demanding environments.

The seamless, polished surface makes cleaning fast and efficient. Bacteria, dust, and contaminants have fewer places to hide, which is why mirror polished tubing is widely used in food processing, medical, and pharmaceutical industries.

While mirror finishing adds an extra step in production, it results in a tube that’s not only beautiful but also highly durable. The added resistance to scratches and stains ensures long-lasting performance with lower maintenance costs over time.

From luxury architecture and automotive trim to sanitary piping and marine equipment, mirror polished stainless steel tubing adapts to diverse industries where both form and function matter.

Due to its unique combination of visual appeal, durability, and hygiene, mirror-polished stainless steel tubing is utilized in a wide range of industries. Let’s look at the most common applications:

Mirror-polished tubes are a favorite for handrails, balustrades, columns, and decorative trims. Their reflective surface enhances modern buildings, shopping malls, airports, and luxury residences, delivering both safety and style.

In environments where cleanliness is non-negotiable, such as dairies, breweries, commercial kitchens, and bottling plants, mirror polished tubing ensures smooth, sanitary flow with minimal contamination risk.

The hygienic, easy-to-clean surface makes these tubes essential for pharmaceutical production, laboratories, and medical equipment, where sterility and precision are critical.

From exhaust tips and trim to custom interiors, mirror polished stainless steel is valued in the automotive and transportation sector for its durability under extreme conditions while offering a sleek, high-performance look.

The combination of corrosion resistance and aesthetic brilliance makes polished tubing perfect for yacht fittings, railings, and other marine hardware, where exposure to saltwater would otherwise compromise ordinary metals.

In retail, hospitality, and exhibition design, mirror polished tubes are used for display stands, fixtures, and signage, creating an elegant impression that attracts attention.

Like any specialized material, mirror polished stainless steel tubing comes with clear advantages but also some considerations to keep in mind. Understanding both will help you decide if it’s the right solution for your project.

If your project values appearance, hygiene, and performance, mirror polished stainless steel tubing is worth the investment. For purely functional, low-visibility applications, a simpler finish may suffice.

While mirror polished stainless steel tubing is durable and resistant to corrosion, proper care is essential to preserve its shine and extend its lifespan. Here are the best practices:

Do not use bleach, chlorine-based solutions, or strong acids, as they can dull the finish and compromise corrosion resistance.

For industrial applications, especially in food, pharma, or marine environments, perform regular inspections to ensure there are no dents, scratches, or surface buildup.

Pro Tip: A little maintenance goes a long way. Consistent cleaning not only preserves the mirror-like shine but also reinforces the material’s hygienic and anti-corrosion properties.

Selecting the right supplier is just as important as choosing the right tubing. High-quality mirror polished stainless steel tubing ensures consistency, durability, and a flawless finish, while a reliable supplier can provide technical guidance, customization options, and timely delivery.

Here’s what to look for:

Vinmay has over a decade of experience producing high-quality stainless steel tubes, including mirror polished finishes, making it a trusted partner for international clients.

A supplier that offers a variety of grades (304, 316), shapes (round, square, rectangular), and finishes (BA, 6K, 8K) allows you to select the best option for your project.

For architectural or decorative projects, Vinmay’s ornamental stainless steel tubes can be tailored to exact specifications.

For food, pharma, or medical industries, our sanitary stainless steel tubing ensures compliance with hygiene standards.

Fast and reliable delivery, flexible payment terms, and technical support are key to project success.

Vinmay offers efficient logistics, free samples, and online factory inspections, helping you make confident purchasing decisions.

Tip: Partnering with a supplier like Vinmay ensures you get high-quality mirror polished stainless steel tubing with the support and customization needed for both aesthetic and functional applications.

Choosing the right mirror polished stainless steel tubing requires understanding the technical specifications that impact performance, durability, and suitability for your application. Here’s a breakdown of key factors:

Tip: When selecting mirror polished tubing, consider grade, shape, finish, and intended application together to ensure both aesthetic and functional performance.

Blog Series:

Mirror polished stainless steel tubing combines strength, durability, and stunning aesthetics, making it a versatile choice for architects, designers, engineers, and industrial professionals alike. Whether you’re working on luxury handrails, sanitary piping, medical equipment, or decorative displays, choosing the right grade, finish, and supplier is key to achieving optimal results.

By understanding the manufacturing process, benefits, applications, and maintenance requirements, you can confidently select tubing that meets both functional and visual standards. High-quality suppliers, like Vinmay, provide expert guidance, precise customization, and consistent, reliable products that ensure your project stands out.

Ready to elevate your project with mirror polished stainless steel tubing? Contact Vinmay today for custom solutions, free samples, and expert support to help you find the perfect tube for your needs.