Brushed stainless steel tubing has become a preferred choice in industries where durability, corrosion resistance, and a refined appearance are equally important. Unlike mirror-polished tubing, the brushed finish provides a matte, low-glare surface that not only delivers modern aesthetics but also helps conceal fingerprints and minor wear.

Selecting the right tubing goes beyond surface finish. Material grade, mechanical strength, and compliance with industry standards all play a crucial role in long-term performance—especially in demanding environments such as marine structures, food processing equipment, and architectural systems.

This guide explores the essentials of brushed stainless steel tubing, including grades (304 vs 316), surface finish details, specifications, applications, cost considerations, and supplier selection tips—helping you make confident and informed sourcing decisions.

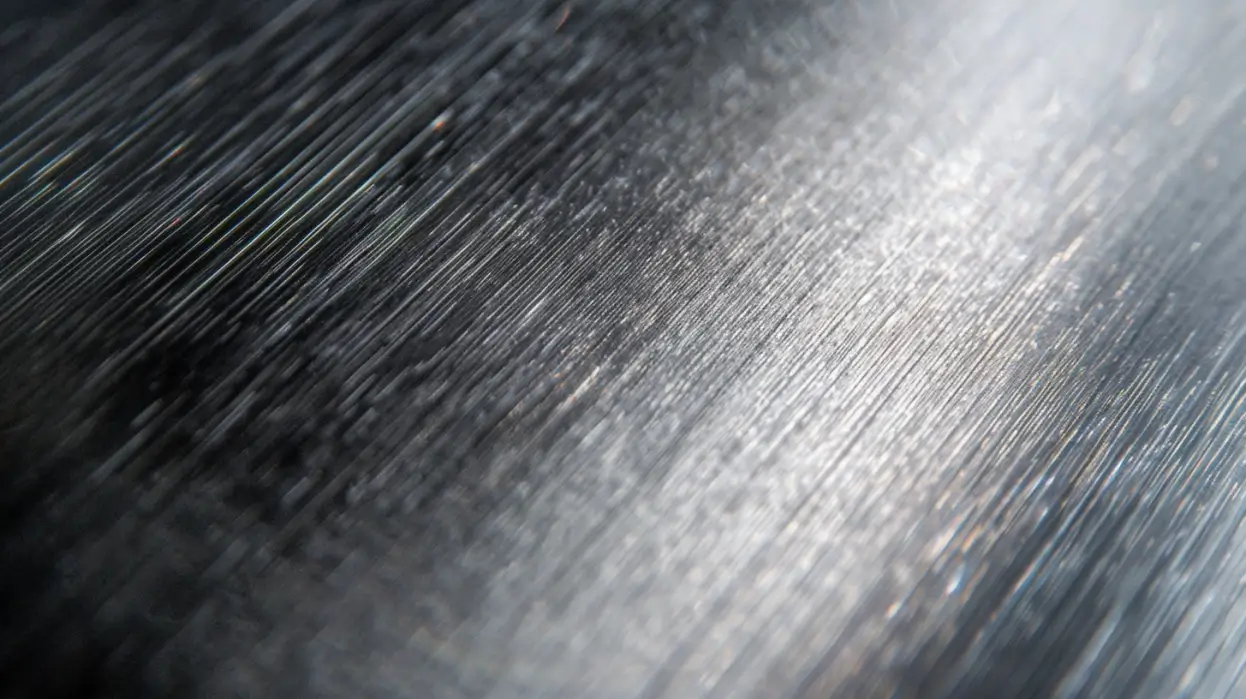

Brushed stainless steel tubing is a type of stainless steel tube that has been mechanically finished with an abrasive belt or brush to create a uniform, linear grain pattern on the surface. This process produces a smooth, satin-like appearance that is less reflective than mirror-polished finishes, making it ideal for projects that require both modern aesthetics and practical durability.

The brushed finish not only enhances the visual appeal but also provides functional advantages: it reduces visible fingerprints and scratches, offers a professional look for exposed structures, and remains easy to clean and maintain. Depending on the required application, brushed stainless steel tubing is typically manufactured in grades 304 or 316, each chosen for its proven balance of strength and corrosion resistance.

In industries such as architecture, marine construction, and food equipment manufacturing, this finish strikes the perfect balance between appearance, performance, and long-term reliability.

Choosing the right stainless steel grade is just as important as the finish itself. Both 304 and 316 stainless steel are widely used for brushed tubing, but each comes with distinct properties that influence performance, cost, and suitability for different environments.

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good for most indoor and mild outdoor environments | Superior, especially in marine and coastal applications due to added molybdenum |

| Strength | High strength, suitable for structural and decorative uses | Comparable strength with added pitting resistance |

| Cost | More cost-effective | Higher cost due to enhanced alloy content |

| Applications | Railings, furniture, architectural features | Marine fittings, food processing, chemical equipment |

When selecting brushed stainless steel tubing, consider environmental exposure, structural requirements, and budget to ensure the chosen grade delivers both performance and value.

The defining feature of brushed stainless steel tubing is its distinct surface texture. Achieved by mechanically brushing the surface with abrasive belts or pads, this process leaves a fine, directional grain pattern that creates a satin-like, matte appearance.

In technical specifications, the quality of a brushed finish is often described by its Ra value (roughness average). A typical brushed finish falls between Ra 0.2 – 0.8 μm, which balances aesthetic appeal and ease of cleaning.

Read Also: Stainless Steel Surface Roughness Explained

The brushed finish is not just about looks:

This makes brushed stainless steel tubing a practical, long-lasting choice for industries that demand both reliability and modern design.

When sourcing brushed stainless steel tubing, it is essential to verify that the product complies with recognized international standards. These standards define the chemical composition, mechanical properties, tolerances, and surface finish requirements that ensure tubing performs reliably in demanding applications.

By ensuring compliance with the correct standards and verifying dimensional tolerances, decision-makers can confidently select brushed stainless steel tubing that meets both regulatory requirements and project expectations.

Related Article: Stainless Steel Tube Welded VS Seamless

Brushed stainless steel tubing is valued for its balance of strength, corrosion resistance, and modern aesthetics, making it suitable across multiple industries:

In architecture and construction, brushed stainless steel tubing is a popular choice for handrails, balustrades, façades, and structural accents. Its refined brushed finish complements modern building designs, while its inherent strength and durability ensure long-term performance. Whether used in indoor spaces or outdoor structures, architectural stainless steel tubing delivers both aesthetic appeal and reliable resistance to daily wear.

For marine and coastal environments, 316 stainless steel brushed tubing is the preferred choice. It is widely used in boat fittings, dock rails, and coastal barriers, where saltwater corrosion resistance and long-lasting durability are critical. The brushed finish helps maintain a clean, professional appearance even under harsh coastal conditions, making marine stainless steel tubing a trusted solution for seaside projects.

In the food and beverage industry, brushed stainless steel tubing is widely used for processing equipment, conveyors, and hygienic piping systems. The smooth brushed surface not only enhances durability but also ensures easy cleaning and sanitation compliance, making food-grade stainless steel tubing a reliable choice for environments where hygiene and corrosion resistance are non-negotiable.

In pharmaceutical and medical environments, brushed stainless steel tubing is valued for its ability to maintain sterility and hygiene. It is commonly used in equipment frames, supports, and fluid transfer systems, where corrosion resistance, easy cleaning, and compliance with strict industry standards are critical. This makes pharmaceutical-grade and medical stainless steel tubing an ideal choice for projects that demand long-term reliability and safety.

In furniture and interior design, brushed stainless steel tubing is often chosen for tables, shelving, and decorative frames. The subtle satin finish provides a modern, elegant look, while the inherent strength of stainless steel ensures stability and long-term use. This makes furniture stainless steel tubing an excellent solution for projects that demand both aesthetic appeal and structural reliability.

For industrial equipment and machinery, brushed stainless steel tubing offers robust performance in guards, frames, and structural components. Its durability and resistance to mechanical stress make it ideal for environments where tubing is subject to frequent handling, vibration, and heavy use. With its combination of strength and wear resistance, industrial stainless steel tubing is a reliable choice for long-lasting equipment construction.

Across these industries, brushed stainless steel tubing delivers a reliable combination of performance and visual appeal, ensuring long service life in both functional and exposed applications.

While the initial cost of brushed stainless steel tubing may be higher than alternatives like mild steel or aluminum, the long-term value makes it a cost-effective choice. Its durability, corrosion resistance, and minimal upkeep significantly reduce replacement and repair expenses over time.

To preserve the brushed appearance and extend service life:

With proper care, brushed stainless steel tubing offers decades of reliable service, delivering a high return on investment for projects that demand both performance and design appeal.

304 stainless steel offers good corrosion resistance for indoor and mild outdoor environments, while 316 stainless steel contains molybdenum for superior corrosion resistance in marine, coastal, and chemically aggressive conditions. Both grades can be finished with a brushed surface, but 316 is preferred for long-term durability in harsh environments.

The brushed finish is created by mechanically polishing the surface with an abrasive belt or brush, producing a linear grain pattern. The finish can vary by grit size (120–320), which affects surface smoothness and appearance.

Yes, welding is possible, but post-weld finishing or brushing is often required to restore a uniform surface texture. Using low-carbon versions like 304L or 316L can reduce the risk of discoloration and maintain finish integrity.

Typical applications include architecture and construction (handrails, balustrades), marine environments, food and beverage processing, pharmaceutical equipment, and industrial machinery. The brushed finish provides a modern look while reducing visible fingerprints and scratches.

Brushed tubing typically ranges from 6 mm to 168 mm OD with wall thicknesses from 0.5 mm to 3.0 mm. Lengths are commonly 6 meters, with custom cutting and finishing available. Ensure the supplier complies with ASTM, EN, or ISO standards for consistent quality.

You may also like: Hairline Finish Vs. Brushed finish Vs. Satin Finish Stainless Steel Tube

Brushed stainless steel tubing combines durability, corrosion resistance, and a refined appearance, making it an ideal choice for projects that require both performance and aesthetics. By selecting the right grade, finish, and supplier, you can ensure that your installations meet structural requirements, regulatory standards, and long-term reliability.

At Vinmay, we provide certified, high-quality stainless steel tubing in a variety of grades, sizes, and finishes. Our consistent brushed finishes, strict quality control, and customization options make it easy to source tubing that fits your specific project needs.

Explore our range of brushed stainless steel tubing, request technical specifications or samples, and work with our team to select the best solution for your application. With Vinmay, you get reliable products, expert guidance, and peace of mind for every project.