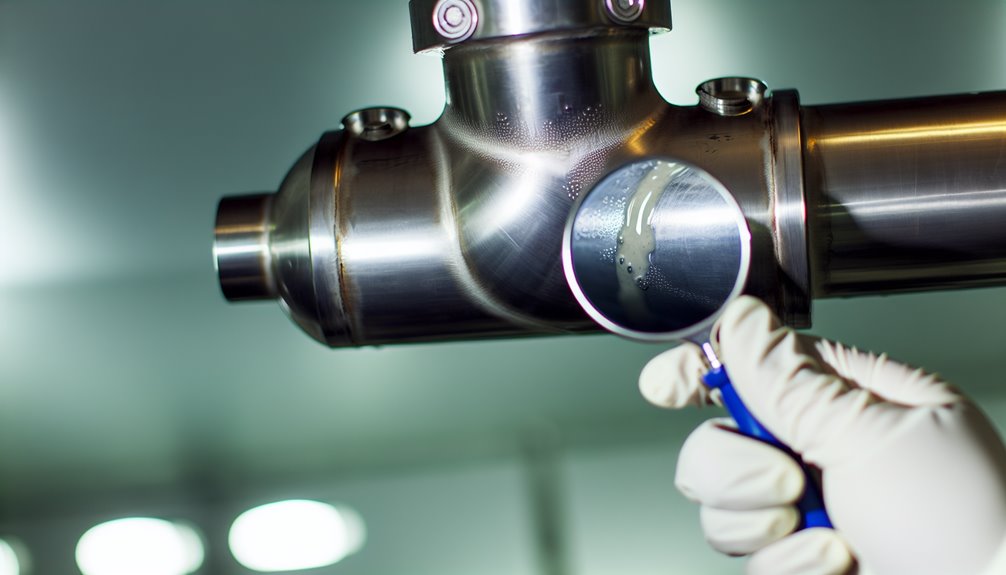

Sanitary tee fittings are routinely installed in food and pharmaceutical process lines, yet they often emerge as weak points during hygienic audits. Their internal geometry can promote dead legs, incomplete drainability, and low-shear zones where soil and microorganisms persist, even when surface finishes meet specification. Weld quality and orientation further influence risk. Understanding why apparently compliant tees still fail in practice requires closer attention to how product and cleaning fluids actually move through these junctions.

During hygienic audits, sanitary tee fittings are often scrutinized more intensely than other components because their internal geometry inherently presents a higher risk of product hold‑up and incomplete cleaning. In many regulated industries, tees are expected to be fabricated from sanitary pipes that meet strict hygienic design and material criteria to maintain product purity and regulatory compliance.

In addition, auditors increasingly review whether the associated tubes and fittings comply with 3-A Sanitary Standards to verify that surface finish, cleanability, and material selection support hygienic performance over the equipment’s lifecycle. Factories that specialize in 316 stainless steel sanitary tubing typically operate under ISO 9001 quality systems and ASTM-based process controls to ensure consistent dimensional accuracy and corrosion resistance that support hygienic performance.

Auditors recognize that, unlike swept elbows, tees introduce a branch that can behave as a sanitary tee dead leg whenever flow, velocity, or CIP spray patterns are sub‑optimal. This geometry–not the “sanitarylabel–drives concern. In many facilities, auditors now expect tees to be manufactured from tubing that meets tight dimensional tolerances and hygienic surface finish requirements to reduce stagnation zones and support effective CIP.

Evidence from swab testing and endoscopic inspections repeatedly links microbial persistence to stagnant zones within tees, even when systems pass CIP validation elsewhere.

As a result, auditors probe tees for CIP cleanability issues: inadequate drainability, insufficient turbulence, and limited solution exchange in the branch.

Any unexplained bioburden trends or allergen positives typically trigger targeted review of all installed tees.

Because tees are often installed in systems built from 316L stainless steel sanitary tubing, auditors will also verify that surface finish and material certifications comply with relevant ASTM sanitary tube standards to minimize corrosion and biofilm risk.

Even when a sanitary tee meets a low Ra surface roughness specification, residues frequently persist at the branch intersection because of unfavorable flow patterns. In addition to geometry, maintaining high-quality welds using techniques such as orbital welding is critical to avoid crevices and porosity that can trap product at these intersections. As part of hygienic design, engineers should confirm that tees comply with relevant sanitary standards such as 3-A, SMS, DIN, or ISO to help ensure compatibility with food safety and cleanability requirements.

Experimental CIP studies show that dead legs, abrupt 90° intersections, and oversized branch stubs dominate cleaning performance more than polish level. In high-risk environments where corrosion resistance and durability are critical, specifying tees fabricated from 316 stainless steel welded pipes can support both long-term hygiene and mechanical reliability.

For risk control, engineers must evaluate internal geometry and flow regime alongside Ra when determining whether a tee is truly cleanable in place. In high-risk environments, selecting fittings made from 316 stainless steel with appropriate internal geometry further enhances long-term hygiene and corrosion resistance.

Because sanitary tees are widely used in sanitary stainless steel pipe systems across food, pharmaceutical, and water treatment applications, uncleanable branch intersections can create hidden hygiene risks that compromise overall process safety.

In CIP systems, sanitary tees are often specified by a target surface roughness (Ra). However, cleanability is governed far more by internal geometry than by surface polish alone. Riboflavin testing and ATP swabbing consistently show residual soil accumulation in tees with unfavourable geometry—even when surface finishes reach Ra ≤ 0.4 µm.

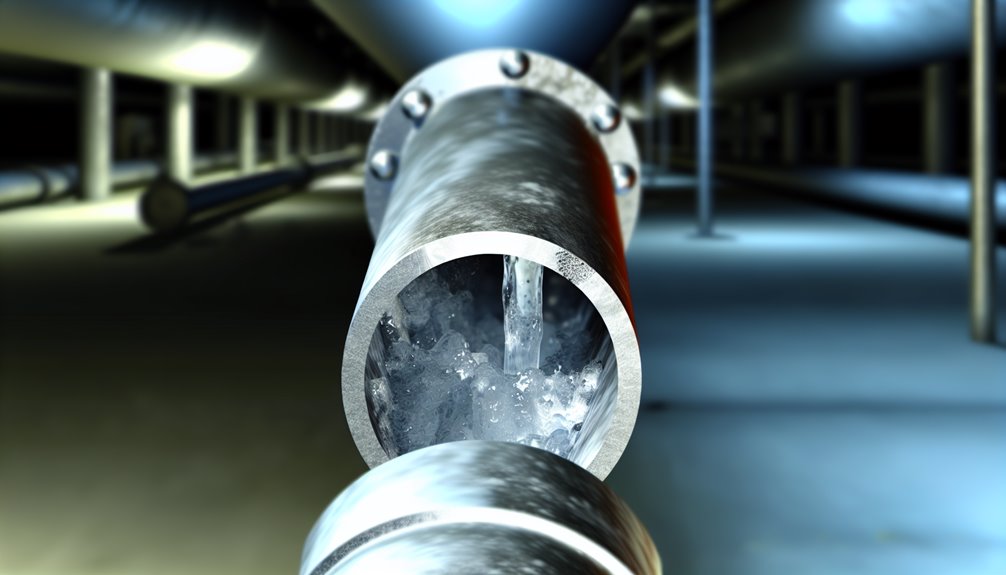

The primary risk arises at the branch intersection, where abrupt transitions, tight crotch angles, or excessive branch length disrupt flow distribution. These geometries create low-shear zones and stagnant pockets, limiting detergent exchange and preventing effective boundary-layer removal during CIP. Over time, such zones can also concentrate corrosion or hidden deposits, increasing the likelihood of leakage, hygiene failure, or validation rejection.

Reliable CIP performance depends on tee designs that maintain continuous velocity, adequate turbulence, and predictable drainage. This is achieved by controlling branch proportions, intersection radii, and tube diameter relationships—rather than relying on polishing alone. Tees proportioned in line with hygienic elbow radius principles (short- or long-radius flow paths) are significantly more likely to sustain uniform washing action and minimise bacterial adhesion.

Manufacturing precision is equally critical. Consistent tube roundness, controlled weld profiles, and stable intersection radii reduce dimensional variability that can otherwise amplify flow disruption. When tee geometry, surface finish, and tube dimensions are aligned with relevant sanitary and ASTM dimensional tolerances, CIP outcomes become far more repeatable and defensible during inspection.

| Design Aspect | CIP Risk Implication |

|---|---|

| Branch angle | Governs local velocity and scouring effectiveness at the crotch |

| Leg length-to-diameter ratio | Determines dead-leg classification and purgeability |

| Intersection radius | Influences vortex formation and soil retention zones |

| Offset vs in-line branch | Affects boundary-layer removal and flow symmetry |

| Flow balancing | Prevents under-washed, low-velocity branches during CIP |

Mirror-polished tees with poor geometric proportioning therefore remain high-risk components, regardless of surface finish specifications.

Dead-leg ratios at sanitary tee branches are frequently misinterpreted because engineers focus on geometric length-to-diameter criteria without validating how fluid actually exchanges between branch and main flow.

Computational and experimental studies show that even branches “within spec�?can behave as functional dead legs when local Reynolds number, branch angle, and velocity profile limit shear and turnover.

This misunderstanding obscures the real risk: stagnant or low-shear zones that harbor contamination despite apparently compliant nominal dimensions.

Why do so many “complianttee branches still behave as dead legs in service? Dead-leg ratios are frequently read straight from drawings, yet a dead leg in hygienic piping is defined by fluid dynamics, not by nominal dimensions.

The effective branch length is the region where velocity is insufficient to refresh the volume during each process or CIP step—often much longer than the measured stub.

Misreading dead‑leg ratios consequently represents a critical hygienic piping design risk, especially where bioburden, biofilm formation, or residue carryover must be tightly controlled.

How far do hygienic standards actually go in guaranteeing a clean, reliable sanitary tee installation? For sanitary tee fittings or any hygienic tee fitting, material and tube standards primarily certify alloy composition, surface finish ranges, dimensional tolerances, and allowed fabrication methods. They also help ensure that core material properties such as corrosion resistance and tensile strength are adequate for long-term performance in demanding hygienic and process environments. In addition to material standards, targeted stainless steel tube testing can identify surface imperfections, weld inconsistencies, and dimensional inaccuracies that may compromise hygienic performance over time.

When 316 stainless steel is specified, these same standards also underpin critical mechanical properties such as yield strength and impact resistance that support long-term structural integrity under thermal and pressure cycling. For 316 stainless steel in particular, adherence to ASTM A270 helps align sanitary tube manufacturing with stringent requirements for surface finish, weld quality, and dimensions in food and pharmaceutical service.

They define a baseline: surface roughness limits, weld quality criteria, and geometric constraints that reduce—but do not eliminate—biofilm risk.

However, compliance does not equal proven cleanability in a specific installation. Standards do not fully capture impact of tee orientation, local flow regime, CIP/SIP validation, soil load, or product rheology.

Certificates also omit aging effects such as rouging or gasket degradation. Consequently, system performance must be evaluated beyond paperwork, using risk-based verification: flow modeling, swab or rinse sampling, and documented cleaning challenge studies. In addition to hygienic design rules, facilities often rely on pharmaceutical grade stainless steel tubing to provide the corrosion resistance, surface finish quality, and material traceability required for long-term sterility assurance.

A sanitary tee becomes a defensible design choice only when process, geometry, and cleaning conditions collectively keep residual risk within acceptable limits.

Evidence shows a stainless steel sanitary tee can perform hygienically where flow regimes remain fully turbulent, line velocities exceed validated CIP thresholds, and no long-term hold-up of product occurs. In such cases, specifying tees manufactured to ASTM A270 sanitary tubing requirements further improves control over surface finish, cleanability, and long-term corrosion resistance. When austenitic stainless steel pipe grades are selected and specified correctly, they also help ensure consistent mechanical properties and corrosion performance across fittings and connecting lines. In some risk‑critical services, aligning tee material and manufacturing controls with the tighter OD tolerances defined for heat‑exchanger tubing can further reduce mismatch, crevices, and long‑term hygienic risk at weld joints. Selecting tees that comply with sanitary tube manufacturing controls and associated inspection requirements further reduces the probability of surface defects and dimensional nonconformities that can harbor biofilm.

A food grade tee fitting is most controllable in low-viscosity media, minimal solids loading, and predictable temperature/chemical exposure. In many of these applications, selecting stainless steel 316 for higher chloride resistance further supports long-term hygienic performance and corrosion control.

Key conditions that typically justify tee use include:

Under certain operating conditions, tee connections shift from routine design elements to potential hygienic weak points that warrant closer examination.

Intermittent flow systems demand particular attention: stop‑start operation allows liquid to stagnate in the branch of a welded sanitary tee, increasing biofilm and deposit risk even when geometry is nominally hygienic.

Similar concerns arise with high‑viscosity or particulate media, where limited shear cannot fully sweep product through the branch, creating slow‑moving or trapped zones.

Marginal sanitary tee CIP performance is another critical trigger for scrutiny.

When CIP velocities are barely at the lower end of validated ranges, the branch of the tee is typically the first location to fall below target shear stress, undermining cleaning assurance and complicating verification of repeatable hygienic outcomes.

Because these stagnation and cleaning challenges depend strongly on temperature limits, corrosion behavior, and chemical resistance, tee designs should be evaluated together with the chosen sanitary pipe materials to avoid hidden incompatibilities that compromise hygienic control.

Many tee‑related hygiene failures can be traced to upstream deficiencies in tube consistency and weld integrity rather than to the tee geometry itself. Specifying tubes manufactured to sanitary standards such as ASTM A270/EN10357 helps ensure consistent dimensional control and weld quality in these upstream runs.

Ovality, wall‑thickness variation, and heat‑distorted weld beads create local steps and crevices exactly where flow divides, compromising branch connection hygiene and confounding root‑cause analysis. Selecting tubes in higher corrosion‑resistant grades such as 316 stainless steel further reduces the risk of pitting and microbial harborage in these disturbed flow regions. Specifying tubing with controlled tolerances and performance—including defined limits on outside dimensions, wall thickness, and twist—helps minimize these disruptive geometric irregularities before they reach the tee. In many food applications, choosing 304 stainless steel for upstream tubing provides an optimal balance of corrosion resistance, cleanability, and long‑term durability around tee transitions.

A rigorous hygienic piping audit typically shows that what appears to be a “bad teeis actually a magnifier of upstream nonconformities:

Controlling these variables upstream reduces downstream hygienic uncertainty more effectively than repeatedly replacing the tee itself. In many systems, specifying tubes manufactured to A270 stainless standards—with controlled weld integrity, inside bead removal, and polished IDs—significantly reduces the likelihood that upstream nonconformities will manifest as tee‑related hygiene failures.

Treating a sanitary tee as a design choice rather than a commodity fitting reframes it as a risk-control element in the system, not just a catalog item. In many systems, selecting between 304 and 316 stainless steel for tee fittings balances cost against the enhanced corrosion resistance of molybdenum‑alloyed 316. In regulated facilities, aligning tee material and fabrication with relevant ASTM standards supports consistency, audit readiness, and interoperability across global supply chains. When tees are fabricated from 304 stainless steel rectangular tube, designers can leverage its standardized mechanical properties, corrosion resistance, and controlled wall thickness to support predictable hygienic and structural performance. Compared with 201 stainless steel, 304’s higher nickel content and superior corrosion resistance further support long-term cleanliness and durability in sanitary tee applications.

In high‑hygiene environments, a pharmaceutical piping tee is neither inherently “goodnor “bad its risk profile is determined by geometry, flow regime, and product consistency.

A tee that is acceptable for low‑viscosity, turbulent flow may trap viscous, shear‑sensitive, or particle‑laden products, creating micro-environments that compromise cleaning validation.

Conversely, a carefully specified tee—correct branch angle, sweep radius, and bore match—can maintain velocity profiles, minimize hold‑up, and support reliable CIP coverage.

Well‑engineered tees align branch angle and bore to preserve velocity, reduce hold‑up, and ensure robust CIP coverage

Correct specification at design stage prevents late-stage redesign, validation delays, and unplanned rework, protecting both schedule and regulatory commitments.

In parallel, material choices such as 304 or 316 stainless steel with a polished surface finish and appropriate wall thickness further reduce contamination risk and support hygienic performance over the system’s lifecycle.

Material selection hinges on process fluid, temperature, cleaning regimen, and regulatory burden; the specifier evaluates corrosion resistance, surface finish, pressure rating, and certification, prioritizing 304/316L stainless for hygienic lines, PVC or ductile iron only for non‑critical, low‑risk services.

They rely on boroscope examination, riboflavin CIP coverage tests, surface roughness measurement (Ra), weld profile inspections, swab or rinse microbiological testing, ATP bioluminescence, and periodic validation under worst-case soils to verify sanitary tees remain fully cleanable and compliant.

Sanitary tees should be fully disassembled at least quarterly, with frequency increased to monthly or per campaign for high-risk products; industry data show biofilm risk rises sharply when reliance rests solely on CIP validation without periodic visual confirmation.

Yes. Operators typically observe rising bioburden counts, unexplained ATP spikes, odor or discoloration at outlets, increased differential pressure, flow instability, foaming, micro‑air entrainment, product quality drifts, or recurring CIP validation failures localized around tee-connected circuits.

Sanitary tees expand validation scope by adding worst-case locations for CQV, cleaning verification, and sampling. They necessitate documented design rationale, surface finish records, weld logs, hygienic certificates, specific CIP/SIP coverage evidence, and periodic requalification focused on potential residue-harboring geometries.

In the end, the process line resembles a canal system: most channels run clear, yet each side inlet can become a silted backwater. Sanitary tees are those quiet coves, compliant in appearance but prone to unseen deposits. Evidence from audits and failures shows risk concentrates here—in dead legs, poor drainage, and flawed welds. Treating each tee as an intentional hydraulic and hygienic choice, not a commodity, is how engineers keep the whole watershed clean.