Selecting a reliable stainless steel pipe supplier requires a detailed evaluation of material quality, confirming adherence to industry standards and certifications that affirm product durability. Analyzing the product range and customization options guarantees compatibility with project specifics. Supplier reputation, fortified by experience and accolades, offers insights into reliability. Cost transparency allows informed budgeting, while efficient logistics guarantee timely delivery. Recognizing these factors helps form a strategic decision, guiding you towards further valuable insights.

When selecting a stainless steel pipe supplier, the quality of materials is one of the most critical factors to consider. High-quality stainless steel ensures durability, corrosion resistance, and optimal performance across various industrial applications. Here’s what to look for when evaluating material quality:

Not all stainless steel pipes are created equal. The grade and composition of stainless steel determine its strength, resistance to corrosion, and suitability for specific environments.

A reliable supplier should clearly specify the grades available and provide detailed material composition data to ensure compatibility with your project requirements.

Related Articles:

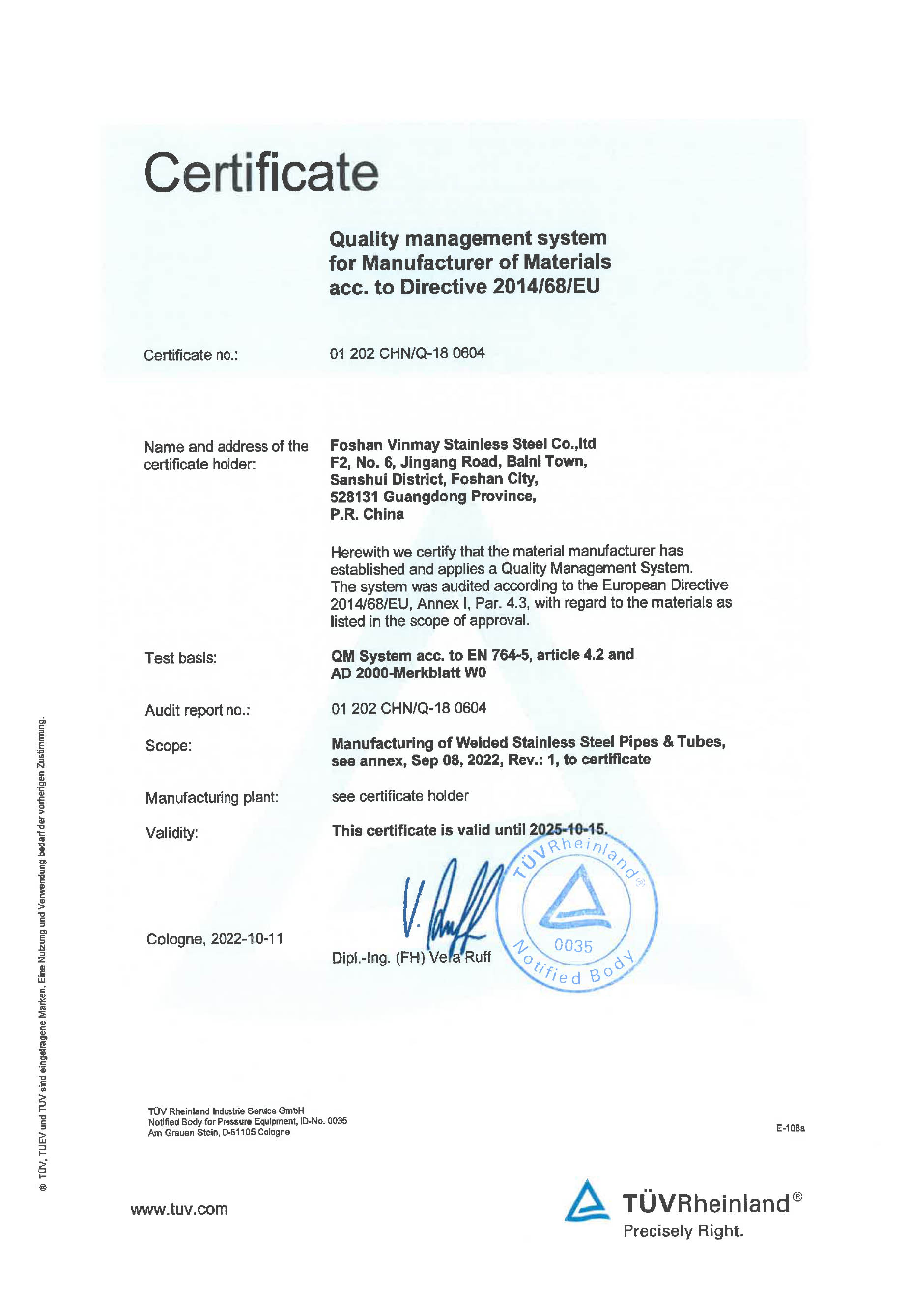

Reputable stainless steel pipe suppliers must adhere to industry standards that guarantee product quality and safety. Some key certifications to check for include:

When evaluating a supplier, request certification documents or mill test reports (MTRs) to verify compliance with these industry standards.

To ensure top-notch quality, stainless steel pipes should undergo rigorous testing before being shipped. Some key tests include:

A trustworthy supplier will transparently provide test reports and allow third-party inspections upon request.

Each stainless steel pipe should come with clear markings that include:

Having traceability ensures that materials meet compliance requirements, especially for industries with strict regulatory standards such as pharmaceuticals, aerospace, and food processing.

A reliable stainless steel pipe supplier should prioritize material quality, certifications, and testing to ensure long-term performance and safety. Before making a purchase, always verify certifications, request test reports, and ensure proper traceability to get the best value for your investment.

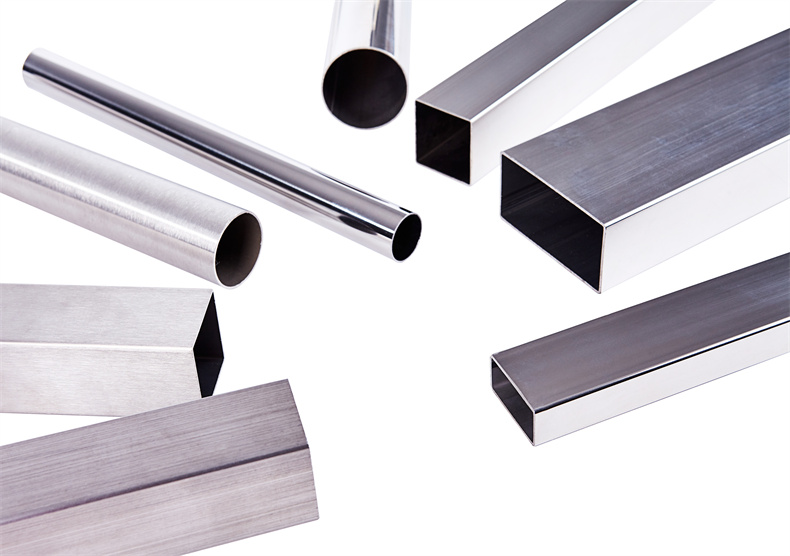

When choosing a stainless steel pipe supplier, it's crucial to assess their product range and customization capabilities. A supplier with diverse offerings and flexible manufacturing options ensures you get the right product for your specific application.

A reliable supplier should provide multiple types of stainless steel pipes to meet different industry needs. Some common types include:

✅ Seamless Stainless Steel Pipes

✅ Welded Stainless Steel Pipes

Learn More: Stainless Steel Pipe Welding Process

✅ ERW (Electric Resistance Welded) Stainless Steel Pipes

✅ Schedule Pipes (SCH 10, 40, 80, etc.)

✅ Polished & Decorative Stainless Steel Pipes

A good supplier should offer a wide selection and help you determine the best type of stainless steel pipe for your needs.

Learn More: Welded Vs. Seamless Stainless Steel Pipes

Not all projects require standard sizes. If your application demands customized stainless steel pipes, your supplier should provide:

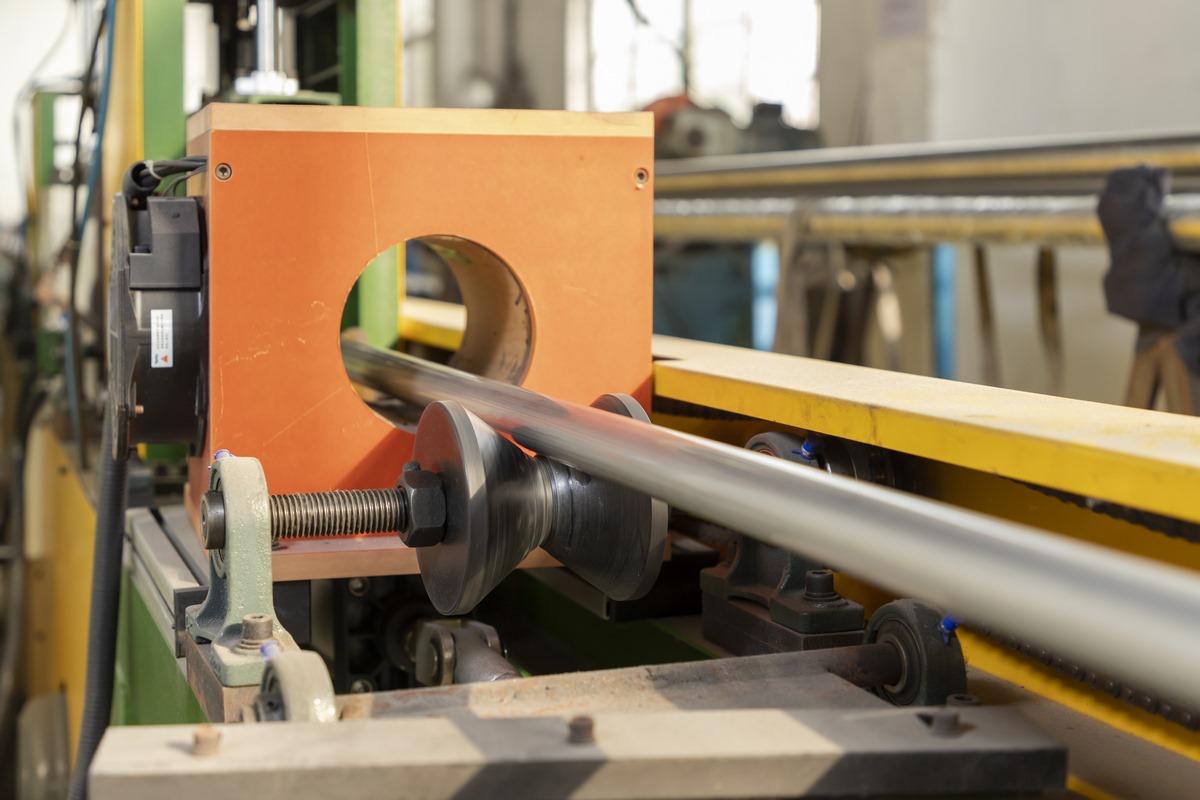

Check if the supplier has in-house processing facilities for cutting, bending, or machining to save time and costs.

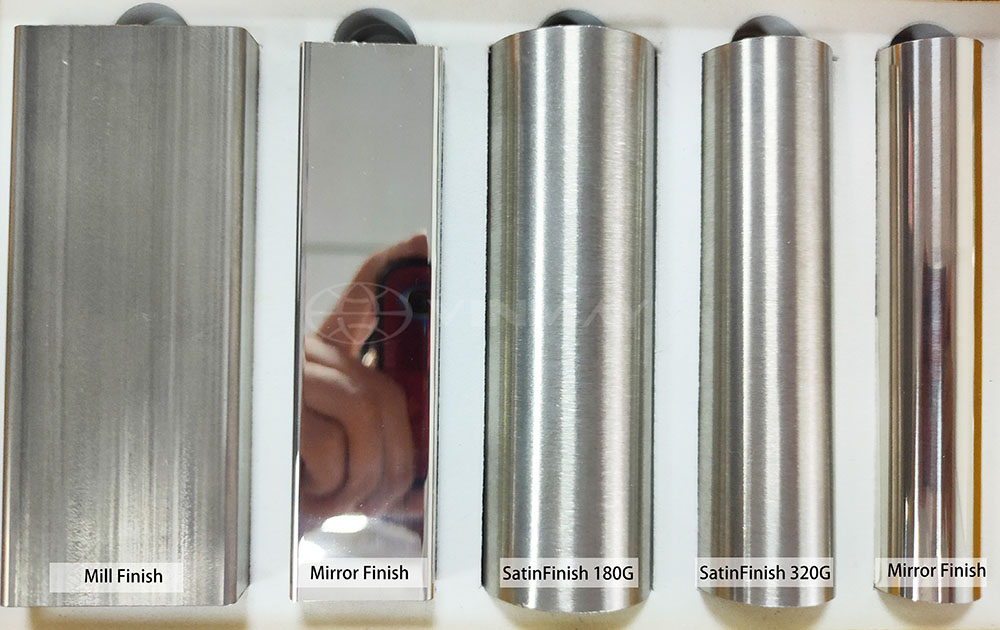

Different industries require different surface finishes and coatings to improve aesthetics, corrosion resistance, and durability. Common options include:

A reliable stainless steel pipe supplier should cater to specific industry needs by offering:

A top-tier stainless steel pipe supplier should provide a broad product range, custom sizing, and industry-specific modifications to meet your exact requirements. Before choosing a supplier, verify their capabilities, finishing options, and customization expertise to ensure you receive pipes that fit your project needs perfectly.

You may also like:

Selecting a stainless steel pipe supplier with a strong industry reputation and proven experience is essential for ensuring product reliability, on-time delivery, and excellent customer service. Here’s how to evaluate a supplier’s credibility before making a purchase.

A supplier’s years of operation can indicate their stability and experience in the market. Look for:

💡 Tip: Check the company’s "About Us" page, client list, and past projects to understand their industry experience.

Click to Learn the Top 60 Stainless Steel Tubing Manufacturers around the world.

Customer feedback is a valuable indicator of a supplier’s reliability. Here’s how to assess their reputation:

🚩 Red Flags to Watch For:

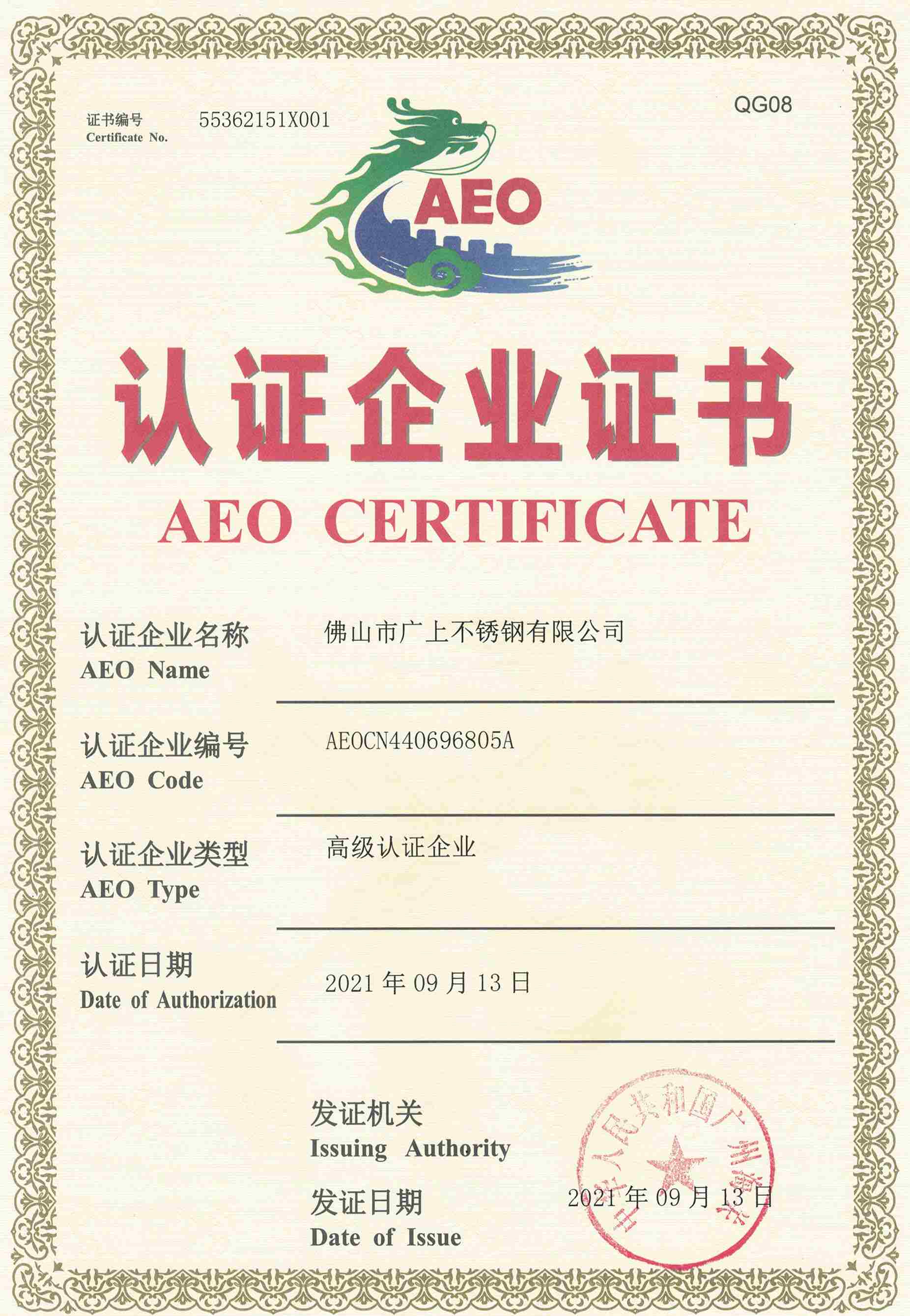

A supplier’s certifications reflect their commitment to quality and industry standards. Look for:

💡 Tip: Ask for quality control documentation and factory inspection reports before placing bulk orders.

If you require international shipping or bulk orders, evaluate the supplier’s global distribution capabilities:

💡 Tip: Ask about average lead times, customs clearance support, and order tracking options.

A reputable supplier should provide fast and efficient customer service for inquiries, orders, and after-sales support. Consider:

🚩 Red Flags to Watch For:

A trusted stainless steel pipe supplier should have a strong reputation, positive customer feedback, industry certifications, and a robust global supply chain. By conducting thorough research and asking the right questions, you can confidently partner with a supplier who meets your quality and service expectations.

When choosing a stainless steel pipe supplier, pricing plays a crucial role in decision-making. However, the lowest price doesn’t always mean the best value. Understanding cost structures, pricing transparency, and hidden fees can help you make a well-informed purchase.

The cost of stainless steel pipes fluctuates due to various factors, including:

💡 Tip: If the price seems too low, check if the supplier is compromising on material quality, certifications, or manufacturing standards.

To ensure you’re getting a fair deal, follow these steps:

💡 Tip: Beware of hidden costs like packaging fees, customs clearance, and additional taxes that may not be included in the initial quote.

Some suppliers might offer low upfront prices but include hidden charges later. Common hidden costs include:

💡 Tip: Always ask for a final total cost estimate, including all applicable fees, before placing an order.

A good supplier should offer flexible payment options and be open to negotiation, especially for bulk orders. Key points to discuss:

💡 Tip: If negotiating, highlight your order volume, long-term potential, and repeat business to secure better pricing.

A transparent pricing structure is a key sign of a trustworthy stainless steel pipe supplier. Before finalizing an order, ensure you understand all cost factors, hidden fees, and payment terms to avoid unexpected expenses.

Timely delivery is crucial when sourcing stainless steel pipes, especially for projects with strict deadlines. A reliable supplier should have a well-structured logistics and supply chain to ensure smooth and efficient delivery. Here’s what to consider when evaluating a supplier’s shipping and logistics capabilities.

Different suppliers offer varying shipping methods based on location, order volume, and urgency. Some common delivery options include:

💡 Tip: Always ask about estimated lead times and ensure the supplier has an efficient order processing system to avoid delays.

A supplier with multiple warehouses or a strategic distribution network can ensure:

🚩 Red Flag: If a supplier frequently experiences stock shortages or long lead times, it could indicate poor inventory management.

A good supplier should provide real-time tracking so you can monitor your shipment’s progress. Key tracking features to look for:

💡 Tip: Choose suppliers who proactively communicate about delays, customs issues, or changes in shipping schedules.

For international orders, ensure the supplier provides proper shipping documentation to avoid customs delays. Essential documents include:

📄 Commercial Invoice – Lists product details, pricing, and supplier information.

📄 Packing List – Includes weight, dimensions, and package details.

📄 Bill of Lading (BOL) – Confirms shipment details and serves as a transportation contract.

📄 Certificates of Origin & Compliance – Required for import duties and regulatory compliance.

📄 Customs Clearance Documentation – Necessary for smooth import/export processing.

🚩 Red Flag: If a supplier is unfamiliar with customs regulations or fails to provide clear documentation, it may lead to delays and extra fees.

For large-scale projects, it's important to assess a supplier’s ability to handle:

💡 Tip: If you require recurring shipments, negotiate a long-term supply agreement for better pricing and priority shipping.

An efficient delivery and logistics system ensures that your stainless steel pipes arrive on time, in good condition, and with proper documentation. Before choosing a supplier, clarify lead times, stock availability, shipping methods, and tracking options to avoid costly delays.

Choosing a stainless steel pipe supplier isn’t just about product quality and pricing—it’s also about the level of customer service and after-sales support they provide. A reliable supplier should offer prompt assistance, technical guidance, and issue resolution to ensure a smooth purchasing experience.

Good customer service starts with clear and timely communication. Before finalizing a supplier, assess:

🚩 Red Flags:

💡 Tip: Before placing a large order, send a few test inquiries to gauge their response time and professionalism.

A reputable stainless steel pipe supplier should provide expert advice on:

💡 Tip: If you need specialized materials or custom fabrication, choose a supplier with engineering or metallurgical expertise.

A reliable supplier should offer a clear warranty and return policy in case of defects or quality issues. Key points to check:

🚩 Red Flags:

💡 Tip: Always request the supplier’s warranty terms in writing before placing a bulk order.

For industrial applications, it’s crucial to partner with a supplier that offers:

💡 Tip: Ask if the supplier maintains regular stock levels and can fulfill repeat orders quickly.

Before committing to a supplier, check real-world customer feedback regarding their support and service:

🚩 Red Flags:

A trustworthy stainless steel pipe supplier should provide reliable customer support, technical expertise, and strong after-sales service. Before placing an order, evaluate their responsiveness, warranty policies, and reputation to ensure a hassle-free purchasing experience.

Even if a supplier looks good on paper, certain warning signs can indicate potential risks, hidden costs, or quality issues. Here are key red flags to be aware of before finalizing your decision:

💡 Tip: Always verify certifications by cross-checking them with official industry databases or third-party inspectors.

💡 Tip: If a deal seems too good to be true, it probably is. Verify product quality before placing large orders.

💡 Tip: Test their responsiveness by sending a preliminary inquiry before making a commitment.

💡 Tip: Demand a written agreement outlining delivery timelines, costs, and liability for delays or damages.

💡 Tip: Research the supplier’s reputation online, check reviews on Google, Trustpilot, Alibaba, or LinkedIn, and ask for references from past clients.

Avoiding unreliable suppliers can save you from financial losses, project delays, and quality failures. If you spot multiple red flags, it's best to walk away and find a more trustworthy supplier.

When it comes to choosing a stainless steel pipe supplier, Vinmay offers a strategic advantage that ensures your business receives the highest standards of quality and reliability.

With over 15 years of experience in the industry, we adhere to strict standards such as ASTM, EN, DIN, and AS to guarantee a competitive edge for our clients. Our commitment to sustainability aligns with modern industry trends, making us the ideal partner for businesses focused on minimizing their environmental impact while maintaining top-notch product quality.

At Vinmay, we take pride in our stringent quality control protocols, reinforced by certifications like PED, AEO, and ISO. This solid foundation ensures that we consistently deliver superior stainless steel pipes that meet exact specifications and standards. Serving a wide range of industries, we provide an extensive variety of pipes, each manufactured to precise dimensions to suit diverse needs.

Our impressive production capacity, which includes 60 continuous forming lines, allows us to operate efficiently and scale as needed. Moreover, with our fast 15-day delivery, we ensure that your orders arrive promptly, helping you meet deadlines and maintain operational continuity.

Choose Vinmay for all your stainless steel pipe needs. Contact us today to discuss your requirements, and let's build a reliable partnership that enhances your business's performance. Reach out now to get started!

Stainless steel pipes offer significant advantages over other materials due to their exceptional corrosion resistance, high temperature tolerance, and aesthetic appeal. These attributes make them a strategic choice for industries prioritizing durability, efficiency, and visual impact.

See Also - Different Pipe Materials

"Measure twice, cut once" aptly applies to stainless steel pipe measurements. Industry specifications dictate varying sizes according to application standards, ensuring precise fit and functionality across sectors like pharmaceuticals, construction, and food processing, enhancing operational efficiency and safety.

Stainless steel tubing is prevalent in automotive manufacturing, food processing, and construction applications due to its durability, corrosion resistance, and ability to withstand high temperatures and pressures, providing strategic advantages in maintaining operational efficiency and safety standards.

"Measure twice, cut once" applies to tubing choices: seamless advantages include better strength for high-pressure scenarios, while welded applications offer cost-effectiveness. Performance comparison reveals seamless's integrity under pressure, contrasting welded's suitability for less demanding tasks.

Stainless steel pipe pricing is influenced by supply chain dynamics, market demand fluctuations, and production costs. Strategic management of these factors allows for controlled pricing, ensuring competitive edge and budget adherence in a volatile economic environment.

In the pursuit of excellence, selecting a stainless steel pipe supplier is a balancing act between quality and cost, innovation and reliability. While some suppliers falter with subpar materials and opaque pricing, others shine with certifications and transparent practices. A strategic choice prioritizes suppliers who not only meet industry standards but also anticipate future needs with robust support and logistics. Consequently, the right supplier becomes a cornerstone of operational success, blending durability with trust in every project.