The 304 Stainless Steel Rectangular Tube, known for its durability, corrosion resistance, and versatility, finds ample usage in diverse industries. Crafted as per the ASTM A554 Standard, its unique design, featuring both inside and outside radius corners, along with a protruding interior weld seam, ensures superior high and cold temperature working properties.

Its environmental sustainability, owing to recyclability and energy-efficient stainless steel pipe welding procedure specification, adds to its appeal. Let's unfold the technical intricacies, examine its comprehensive applications, and discuss its pivotal role in structural frameworks and marine applications.

The 304 stainless steel rectangular tube is a widely utilized structural element manufactured from T304 stainless steel, which is renownd for its heat and corrosion resistance. This product conforms to the stainless steel tube standards of ASTM A554 and features nonmagnetic properties, making it suitable for various applications including framework, braces, and marine environments.

Its specifications encompass a range of stock sizes, finish options, and mechanical properties, contributing to its versatility in both workability and application.

Renowned for its versatility and durability, 304 Stainless Steel Rectangular Tube is a type of stainless steel material that boasts superior corrosion resistance and nonmagnetic properties. Its strength and reliability make it ideal for various applications, including marine environments, offering design flexibility to engineers and architects.

Its high corrosion resistance makes it suitable for exposure to a wide range of chemical and atmospheric conditions. The ease of welding techniques used with this material allows for custom stainless steel tube fabrication, meeting specific design requirements. Furthermore, the nonmagnetic properties of this stainless steel variant add to its appeal in applications where magnetic interference must be avoided.

In essence, the 304 Stainless Steel Rectangular Tube is an invaluable resource in industries requiring robust, durable, and versatile materials.

Building upon its aforementioned properties and applications, the 304 Stainless Steel Rectangular Tube is characterized by specific technical specifications that enhance its functionality in various industrial environments. It's a non-magnetic variant of stainless steel, renowned for its high tensile strength and superior corrosion resistance.

| Tube Specifications | Material Properties |

|---|---|

| Non-magnetic | High Tensile Strength |

| Superior Corrosion Resistance | Non-polished, Mill Finish |

The order process is simple and efficient, catering to different lengths and custom cutting options. Despite its robustness, the 304 Stainless Steel Rectangular Tube also minimizes environmental impact, underlining its sustainability. Its durability and cost-effectiveness make it an ideal choice for those seeking to belong to a community that values quality, performance, and environmental responsibility.

In relation to the 304 stainless steel rectangular tube, it is crucial to explore its associated items and their relevance in various industrial applications.

The material properties of the tube, notably its corrosion resistance and non-magnetic characteristics, make it a preferred choice for numerous sectors. Various welding techniques can be employed, offering versatility in custom fabrication.

Related items such as end caps, brackets, and connectors are integral to the tube's application, enhancing its usability in construction, automobile, and marine industries.

The tube's ductility allows for it to be shaped based on specific project needs, further underlining the importance of understanding the relationship between the tube and its related items.

The focus on these aspects ensures the right selection for efficient performance.

We now shift our focus to the technical data of the 304 Stainless Steel Rectangular Tube. This encompasses its mechanical properties, physical properties, and chemical composition. These parameters are pivotal in understanding the material's strength, durability, resistance characteristics, and suitability for various applications.

Detailed examination of these aspects will provide a comprehensive understanding of its overall performance and versatility.

The 304 Stainless Steel Rectangular Tube boasts impressive mechanical properties, including a Brinell hardness of 170, tensile strength of 85,000 +/-, yield strength of 34,000 +/-, and distinct nonmagnetic properties. A comprehensive mechanical properties analysis underscore its robustness and reliability for various applications.

The material strength evaluation reveals high tensile and yield strengths, indicating its capacity to withstand stress and resist deformation. This evaluation is crucial for structural design considerations, ensuring the tube's ability to support load and maintain stability.

Corrosion resistance testing affirms its durability in various environments, contributing to its longevity. Furthermore, temperature performance assessment demonstrates its capacity to maintain structural integrity under different temperature conditions.

With its exceptional physical properties, 304 Stainless Steel Rectangular Tube offers superior technical performance in diverse applications. It is manufactured through a process that ensures optimal dimensional accuracy, enhancing its compatibility with various welding techniques.

The tube exhibits high corrosion resistance, a result of its unique formulation and manufacturing process. It stands up to a wide range of corrosive environments, attributing to its longevity and reliability. Further, its excellent thermal conductivity facilitates efficient heat transfer, making it a preferred choice in industries such as chemical processing or power generation.

The physical properties of this material, paired with its manufacturing process, make the 304 Stainless Steel Rectangular Tube a versatile and high-performing choice in various applications.

Understanding the chemical composition of the 304 Stainless Steel Rectangular Tube is crucial, as it directly influences the material's impressive physical properties and versatile performance capabilities. This composition is a critical factor in the manufacturing process, contributing to the tube's excellent corrosion resistance, heat treatment capabilities, and overall material properties.

Its chemical composition is as follows:

Recommended: Can 304 Stainless Steel Rust

What Is Food Grade 304 Stainless Steel?

Is 304 Stainless Steel Surgical Grade?

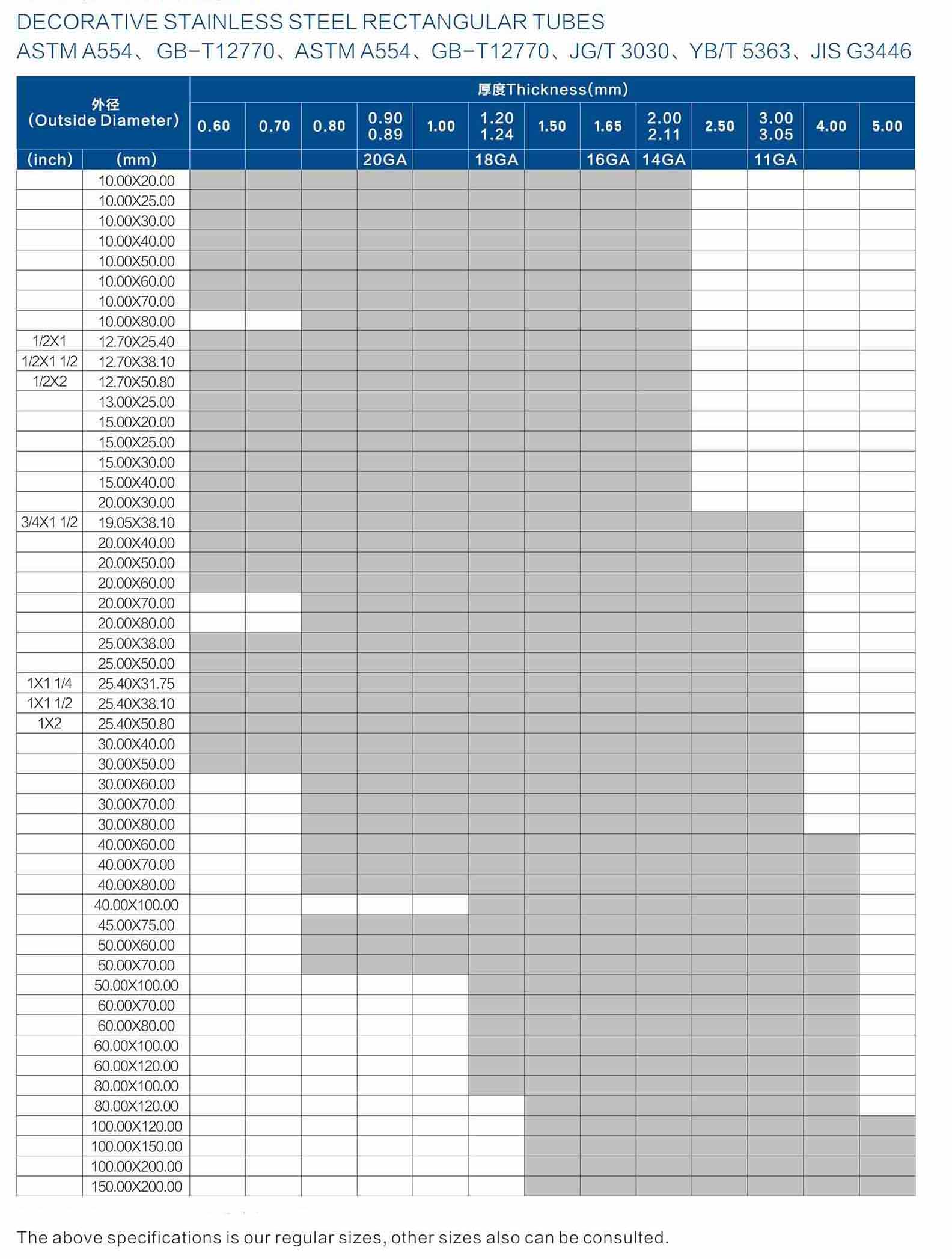

The dimensions of a 304 stainless steel rectangular tube are crucial to its functionality and application.

As such, we will focus our attention on three primary aspects: the tolerance, the wall thicknesses, and the diameter of the tube.

Understanding these dimensional elements will enable the correct selection and usage of the tube in various industrial settings.

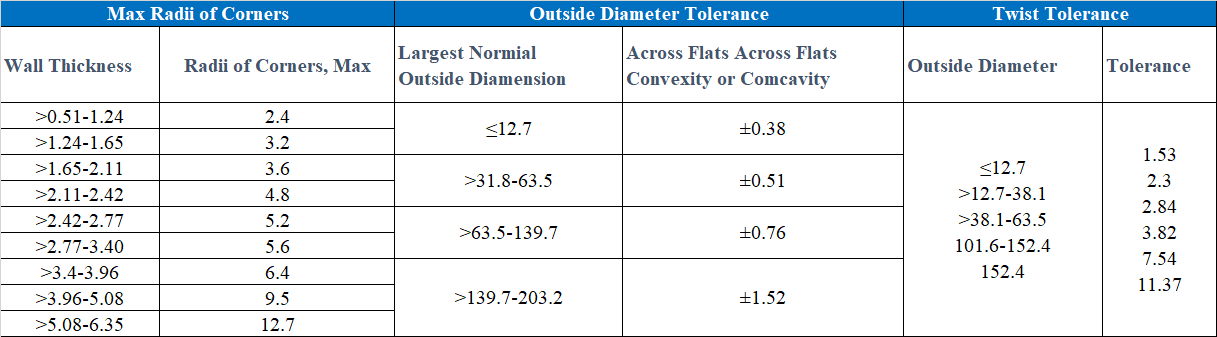

Given its critical role in various applications, the tolerance of the 304 Stainless Steel Rectangular Tube is meticulously maintained, with precise dimensions that adhere strictly to industry standards. This precision is fundamental for the material's application in architectural design and other areas requiring exact measurements.

The manufacturing tolerances of the 304 stainless steel rectangle tube ensure a uniform size and shape, thereby providing consistency in its application.

Advanced welding techniques are employed during the tube's fabrication, guaranteeing a seamless finish that further maintains the tube's dimensional accuracy.

The inherent material properties of 304 stainless steel, like its outstanding corrosion resistance and strength, are not compromised during the product's manufacturing process.

Therefore, these elements together ensure that the 304 stainless steel rectangle tube reliably meets the stringent quality and precision requirements across different industries.

In addition to the meticulous tolerance control, the wall thickness of the Stainless Steel 304 Rectangle Tube is another crucial dimension that significantly influences its performance and suitability for various applications. Wall thickness variations can affect the tube's strength, weight, and capacity to withstand forces.

Welding techniques applied during manufacturing can also impact the wall thickness and overall tube integrity. These tubes exhibit excellent corrosion resistance, a characteristic enhanced by the selected wall thickness. Custom fabrication can further modify wall thickness according to specific application needs.

Lastly, various surface treatment options are available, influencing the tube's appearance, corrosion resistance, and adhesion of applied coatings. Understanding these factors ensures optimal selection and application of Stainless Steel 304 Rectangle Tubes.

Examining the diameter or diamension of 304 Rectangle Tubes, one will find it to be a critical factor that influences both their functionality and adaptability in various applications. The tube diameter directly impacts:

Regardless of the application, the stainless steel 304 rectangle tube's diameter is imperative for its overall performance. By understanding this, one can appreciate the significance of its detailed specification in the manufacturing industry.

| Material | 304 |

| Size | 10x20mm-150x200mm |

| Surface | Mill Finish, Mirror Finish, Satin Finish (MF,180G,320G,400G,600G) |

| Thickness | 0.6mm-5.0mm |

| Length | 5.8 M,6M,20 Feet or Customized |

| Delivery Time | 30 days for a container quantity |

| Payment Terms | T/T, LC, Cash, etc. Normally 30% by T/T in advance, balance to be paid before shipment. |

| Packing | Each tube will be packed in a plastic bag, then several tubes will be packed in hollow plates or weaving bags. |

| Application | Apply in handrails, furniture, sanitary ware, display shelves, sanitary ware, machinery equipment |

Down load stainless steel tube size list of Vinmay

Predominantly used in fabrication and construction projects, it is also utilized in automotive industries for frame making among other uses.

These applications exploit the tube's corrosion resistance, durability, and heat-resisting properties.

With its excellent formability and weldability, the 304 stainless steel rectangular tube is often employed in various fabrication applications, including the creation of structures, supports, and frames. These tubes are highly versatile due to their unique material properties, allowing for a range of fabrication techniques.

When it comes to construction projects, 304 stainless steel rectangular tubes find extensive application due to their exceptional durability, versatility, and resistance to various environmental conditions.

These tubes are consistently chosen in recent design trends and construction innovations for their ability to withstand heavy loads and adverse weather conditions. The material selection is a vital part of project management, where durability and cost-effectiveness are key.

These tubes meet these criteria, offering a long-lasting solution with minimal maintenance. Furthermore, the use of these tubes aligns with sustainability practices. They are recyclable, reducing waste and the environmental impact.

Therefore, 304 stainless steel rectangular tubes are an optimal choice for construction projects, providing a harmonious blend of strength, flexibility, and environmental sustainability.

Utilizing 304 stainless steel rectangular tubes in frame making offers notable benefits due to its superior strength, corrosion resistance, and workability. This material is particularly favored in the construction of frames due to its unique material properties. The combination of high yield strength and excellent corrosion resistance makes it an ideal choice for various structural applications.

This combination of attributes greatly enhances the overall efficiency and performance of frames constructed using 304 stainless steel rectangular tubes.

Beyond the realm of frame making, the 304 stainless steel rectangular tube also finds significant application in the automotive industry, owing to its exceptional mechanical properties and corrosion resistance. Its structural integrity withstands the demanding conditions of automotive applications, ensuring durability and longevity. The corrosion resistance contributes to the tube's high performance in various environments, including the marine industry.

Welding techniques are crucial in automotive applications, and the 304 stainless steel rectangular tube lends itself well to a range of methods, further enhancing its appeal. Its versatility and resilience make it a preferred choice in the industry.

| Automotive Component | Advantage |

|---|---|

| Exhaust Systems | Corrosion Resistance |

| Structural Elements | Structural Integrity |

| Marine Applications | Resistance to Saline Environments |

The surface finish of the 304 stainless steel rectangular tube significantly contributes to its functionality and aesthetics.

The finishes can include brushed polish, mill finish, or polished polish.

Each finish provides different visual appeal and surface properties, affecting the tube's resistance to corrosion, its maintainability, and overall lifespan.

Offering an aesthetically pleasing finish, the 304 stainless steel rectangular tube can be supplied with a brushed polish finish, which not only enhances the product's appearance but also increases its resistance to corrosion. This surface finish option brings a sophisticated look to the material applications, blending seamlessly in an array of environments.

The brushed polish finish is achieved through meticulous custom fabrication processes, employing advanced welding techniques that ensure a smooth, uniform appearance. It provides:

While the brushed polish finish provides a sleek and refined look, the mill finish of the 304 stainless steel rectangular tube offers its own unique features and advantages.

The mill finish, a default surface treatment, preserves the raw, industrial aesthetic of the 304 stainless steel. This finish enhances the corrosion resistance of the tube, a crucial feature in environments prone to oxidative damage.

The structural integrity of the steel, critical for load-bearing applications, is also maintained. Welding capabilities are improved, as the finish doesn't interfere with the formation of robust joints.

In contrast to the rugged aesthetic of the mill finish, a polished finish on the 304 stainless steel rectangular tube enhances the material's aesthetic appeal while maintaining its superior functional properties. This polished finish, a result of a meticulous surface treatment process, lends a mirror finish that reflects light, contributing significantly to the tube's aesthetic value.

The benefits of such a polished finish are threefold:

Recommended: Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

The utilization of 304 Stainless Steel Rectangular Tubes offers manifold benefits, which can be categorized into four primary areas: structural advantages, versatility, cost-effectiveness, and environmental sustainability.

The structural advantages are exemplified through their superior strength, resistance to bending, and capacity to withstand diverse environmental conditions.

Their versatility is demonstrated by their wide range of applications, compatibility with other materials, and easy fabrication, while their cost-effectiveness is reflected in their material efficiency, lower installation costs, and longevity.

Offering exceptional strength and load-bearing capacity, the 304 Stainless Steel Rectangular Tube provides significant structural advantages in construction and fabrication projects. This tube is renowned for its structural durability, allowing it to withstand severe environmental impacts without compromising its integrity. This strength makes it ideal for various construction applications, from building frameworks to marine structures.

The 304 Stainless Steel Rectangular Tube also offers:

With these benefits, the 304 Stainless Steel Rectangular Tube truly stands out as an exceptional choice for construction materials.

Beyond its undeniable structural advantages, the 304 Stainless Steel Rectangular Tube exhibits remarkable versatility, making it a highly beneficial choice for a diverse range of project applications. It provides significant design flexibility, allowing engineers to innovate and create custom solutions to meet specific requirements.

The customization options offered by this material extend to varied dimensions, wall thicknesses, and finishes. Its compatibility with numerous welding techniques ensures seamless integration in complex structures, enhancing both aesthetics and functionality.

The tube's notable corrosion resistance, attributed to its chromium content, ensures its suitability for use in harsh environments, reinforcing its reputation as a versatile construction material. Collectively, these attributes make the 304 Stainless Steel Rectangular Tube a preferred choice for projects demanding versatility and reliability.

Investing in 304 Stainless Steel Rectangular Tubes offers significant cost benefits due to its material efficiency, lower installation expenses, and reduced maintenance requirements. These tubes are recognized for their cost-effectiveness, offering a higher return on investment over time.

In addition, the environmental impact of these tubes is minimized through material efficiency, contributing to their overall value proposition. This combination of benefits makes 304 Stainless Steel Rectangular Tubes a financially smart choice for diverse applications.

Read More : Navigating the Cost Considerations of Stainless Steel Square Tubing

The environmental sustainability of 304 Stainless Steel Rectangular Tubes significantly contributes to their appeal. They demonstrate both recyclability and energy efficiency in production, aligning with sustainable construction practices. These tubes are considered eco-friendly materials and a preferred choice in green building practices.

Their manufacture minimizes environmental impact, making them a cornerstone in conservation efforts. The 304 Stainless Steel Rectangular Tubes require less energy to produce than many alternatives, which helps reduce carbon emissions. Moreover, their durability and long lifespan result in less frequent replacement, minimizing waste.

Using these tubes benefits not only the structure's integrity but also the planet, fostering a sense of belonging and responsibility towards our environment.

When handling and installing tubes, durability is essential. Use protective gear and appropriate installation tools. Follow safe handling techniques and safety procedures to prevent accidents and ensure the tube's integrity and longevity.

Yes, 304 stainless steel rectangular tubes can withstand extreme temperatures due to their high temperature resistance, low thermal expansion, and minimal corrosion risk. However, tube insulation and correct material selection are essential.

We offer various shipping and delivery options, accommodating various needs. Delivery times and costs vary, influenced by Tube Durability, Pricing Variations, Customization Options and Manufacturer Comparison. We ensure minimal Environmental Impact in our delivery processes.

The longevity of any material depends on regular maintenance. For optimal corrosion resistance, routine surface cleaning, occasional chemical treatments, awareness of abrasion effects, and potential tube coatings are advisable.

The 304 stainless steel rectangular tube adheres to the ASTM A554 standard. This certification ensures the tube's dimensions, material source, applications, production process, and cost factors meet stringent industry and safety standards.

Blog Series:

316 Stainless Steel Rectangular Tube

Exploring the Versatility and Durability of 304 Stainless Steel Round Tubing: A Comprehensive Guide

Mastering 304 Stainless Steel Square Tubing: Complete Guide

Unveiling the Strength and Versatility: A Comprehensive Guide to Stainless Steel Round Tubes

Foshan Vinmay Stainless Steel Co.,ltd is a large-scale international enterprise which concentrates on manufacturing and selling of stainless steel weled tubes and the related fittings.

Our product are strictly produced according to a various of international standards including ASTM A554 , ASTM A270 , ASTM A249 , ASTM A269, EN 10312. Rectangular stainless steel tube is our popular product we can produce the rectangular tube size in 304 201 316 grade with the size range from 10x20 to 150x200mm . For more information , please contact us. Free sample can be sent.