The discourse surrounding rectangular tube stainless steel , particularly its application and structural benefits, offers an intriguing perspective on modern construction and design methodologies. Esteemed for its durability and corrosion resistance, this material has ushered in innovative applications across various industries.

However, the debate often pivots on the comparative advantages of using stainless steel rectangular tubes over other forms, such as square hollow sections or traditional steel pipes. As we explore the distinct characteristics and standards, such as the ASTM A554, that define its quality and utility, one can't help but ponder the broader implications of material choice on project outcomes and efficiency.

This prompts a closer examination of how these materials shape the architectural landscape and the factors influencing their selection.

Rectangular tube stainless steel is commonly classified as either ornamental or structural stainless steel tube. It includes various products like hot roll steel rectangular tube and stainless steel box sections, each tailored to meet specific mechanical and chemical properties for different applications. The fabrication of these tubes follows rigorous standards to guarantee their suitability for structural frameworks, supports, and aesthetic architectural elements.

Having distinct characteristics and applications, rectangular tube satinless steel are versatile components in construction and design projects. They offer durability, corrosion resistance, and a sleek appearance, making them ideal for both functional and decorative purposes.

Ornamental rectangular tube stainless steel , characterized by its unique blend of aesthetic appeal and structural functionality, serves as a versatile material in various design and architectural projects. Its incorporation into structures not only enhances visual appeal but also provides solid support owing to its robustness and durability.

Particularly favored in the following contexts:

This tubing seamlessly blends into the design landscape, providing both functional and decorative benefits, and fostering a sense of belonging among designers and architects who prioritize both form and function.

Hot Roll Steel Rectangular Tube is distinct from its stainless steel counterpart, offering a versatile and cost-effective solution for a wide range of structural applications. Its material properties are engineered for superior load-bearing capacity, making it an ideal choice for frameworks that demand robustness.

Advanced welding techniques allow for seamless connections, enhancing structural integrity without compromising on strength. Despite its susceptibility to corrosion compared to stainless steel, protective measures can be applied to extend its lifespan.

The customization options available with hot roll steel rectangular tubes cater to unique project requirements, allowing for tailored dimensions that meet specific engineering needs. This adaptability, coupled with its commendable mechanical properties, renders it an invaluable resource in construction and manufacturing sectors.

Rectangular tubes stainless steel, specifically the 304 grade, are highly regarded for their exceptional strength and versatility in various structural and architectural applications. These components exhibit a remarkable blend of durability and aesthetics, making them a preferred choice for a wide range of projects. Their inherent qualities contribute significantly to the structural integrity of constructions where they are employed.

When comparing stainless steel rectangular hollow sections (RHS) to steel square hollow sections (SHS), it is essential to consider their structural advantages and application-specific suitability. The debate between RHS and SHS is rooted in their hollow section strength, structural comparisons, geometric properties, beam considerations, and load capacities.

RHS offers distinct advantages due to its elongated shape, providing greater strength in one axis and making it preferable for applications requiring higher resistance to bending and torsion. The geometric properties of RHS, including its moment of inertia and section modulus, are superior in scenarios where loads are predominantly unidirectional. This makes RHS an ideal choice for beams where asymmetrical load-bearing capacity is crucial.

Conversely, SHS, with its equal dimensions, presents a symmetrical geometric profile, leading to uniform strength properties in all directions. This isotropy makes SHS suitable for applications where load conditions are more evenly distributed or where aesthetic considerations favor symmetry.

Structural comparisons between RHS and SHS highlight the importance of selecting the appropriate section based on specific load capacities and beam considerations. Each section type offers unique benefits, and the choice between RHS and SHS should be informed by a thorough analysis of the structural requirements and geometric properties.

Learn More :

Exploring the Advantages of Stainless Steel Square Tubing

Mastering Fabrication Techniques for Stainless Steel Square Tubing

Understanding the distinction between steel pipes and steel tubes is pivotal in selecting the correct material for various engineering and construction applications.

While both are cylindrical and metallic in structure, their classification, dimensions, and intended use exhibit significant differences.

This analysis aims to clarify these distinctions, facilitating informed decision-making regarding their application in projects.

Steel pipes, distinguished from steel tubes, primarily serve for the transportation of fluids and gases, featuring circular cross-sections and specific dimensional standards that facilitate this purpose.

Steel pipe applications highlight their critical role in conveying water, oil, and natural gas, underscoring their indispensability in various industries.

Corrosion resistance is a significant attribute of steel pipes, ensuring longevity and reliability in harsh environments.

Stainless steel properties contribute to their widespread use, offering a blend of strength, resistance, and versatility in applications.

Rectangular tubing advantages include superior load bearing capacity, making them suitable for structural applications requiring strength and durability.

Steel material efficiency reflects in their minimal environmental impact, promoting sustainable use in construction and manufacturing sectors.

Distinguishing between steel pipes and steel tubes is crucial for industrial applications, as each offers unique dimensions, tolerances, and mechanical properties tailored to specific uses. Steel tubes, in particular, are integral to various steel tube applications, ranging from structural frameworks to tubular structures. The benefits of stainless steel, including corrosion resistance and strength, enhance the utility and longevity of these components. Advanced tube fabrication techniques allow for precise customization, essential in metal framework design. Understanding these differences not only ensures the optimal selection of materials but also fosters a sense of belonging among professionals who appreciate the technical nuances of their craft.

| Feature | Steel Pipes | Steel Tubes |

|---|---|---|

| Applications | Fluid transport | Structural support |

| Fabrication | Welded/Seamless | Precision techniques |

| Benefits | Durability | Customization |

| Design Consideration | Diameter-based | Shape & Strength |

Discover more :

Differences Between Stainless Steel Pipe and Tube

The A554 specification pertains to stainless steel welded tube used primarily for structural and ornamental purposes. This standard ensures that the rectangular tube stainless steel are made from alloys like 304/304L and 316/316L, providing them with superior corrosion resistance and the ability to withstand diverse environmental conditions.

These tubes are characterized by their dimensional accuracy, surface finish options ranging from mill finish to a highly polished appearance, and mechanical properties that make them suitable for a wide array of applications in construction and design.

ASTM A554 rectangular tube stainless steel is characterized by its welded construction, offering a combination of aesthetic appeal and structural integrity for diverse applications. This specification facilitates a sense of belonging among professionals who value technical excellence and precision in their structural projects.

Specifications comparison: ASTM A554 sets the standards for weld integrity and finish quality.

Material composition: Predominantly consists of 201/304/304l or 316/316L alloy, ensuring durability.

You may also like :What Is the Difference Between 201 and 304 Stainless Steel?

Corrosion resistance: High resistance to environmental and chemical degradation.

Welding capabilities: Optimized for efficient welding, allowing for seamless integration into structures.

Structural applications: Ideal for support structures, architectural accents, and various industrial uses.

These features underscore the technical, precise, and analytical considerations integral to selecting A554 stainless steel rectangular tubes for sophisticated applications.

Beyond the widely utilized 304 and 304L grades, the rectangular tube stainless steel market also offers 316 and 316L grades, catering to more demanding environments.

The 316 grade, with its enhanced molybdenum content, provides superior corrosion resistance, particularly in chloride-exposed conditions, making it ideal for marine applications.

In contrast, the 316L variant, due to its lower carbon content, offers better weldability and is preferred in welded structures where post-weld annealing is not feasible.

Exploring rectangular tube stainless steel reveals a diversity of grades beyond 304/304L, each tailored to specific industrial requirements and applications. These alternative grades offer varying levels of:

You may also like:

Exploring the Versatility and Durability of 304 Stainless Steel Round Tubing: A Comprehensive Guide

Mastering 304 Stainless Steel Square Tubing: Complete Guide

Several grades of rectangular tube stainless steel , aside from the commonly used 304/304L, are engineered to meet specific industry needs, offering variations in corrosion resistance, weldability, structural integrity, and design flexibility.

These materials are selected based on a strength comparison to ensure optimal performance in demanding environments. Advanced welding techniques allow for seamless integration into complex structures, providing enhanced material efficiency without compromising on durability.

Customizable options in sizing and finishing cater to unique project requirements, ensuring a perfect fit for applications ranging from architectural to industrial. The selection of a particular grade often involves a careful analysis of its corrosion resistance properties, ensuring long-term reliability and maintenance ease.

Through such versatile offerings, rectangular tube stainless steel continues to be a cornerstone in design and construction, embodying a blend of aesthetic appeal and functional excellence.

While 304/304L rectangular tube stainless steel is prevalent in various applications, the industry also offers a diverse range of other grades designed to meet specific requirements and challenges. These grades differ in properties such as corrosion resistance, offering enhanced durability in harsh environments.

Some grades also facilitate better welding characteristics for complex constructions. Additionally, there are variations in surface finishes available to match aesthetic and functional needs. These rectangular tube stainless steel grades are engineered to support varying loads in structural applications, providing different load-bearing capacities.

Moreover, customization options allow for tailored dimensions and shapes to fit unique project specifications. This variety ensures that regardless of the specific demands of a project, there is a stainless steel rectangular tube grade that can meet those needs with precision.

This enhances the sense of belonging and satisfaction among professionals in the field, knowing they have access to a comprehensive range of stainless steel options to choose from.

Apart from the widely utilized 304/304L grade, the industry offers a plethora of alternative rectangular tube stainless steel grades designed to fulfill distinct specifications and environmental challenges. These alternatives not only provide superior corrosion resistance but also cater to various welding techniques, surface finishes, custom fabrication options, and load-bearing capacities, ensuring a sense of belonging and achievement for professionals seeking optimal performance and durability in their projects.

| Grade | Key Feature | Application |

|---|---|---|

| 316/316L | Enhanced corrosion resistance | Marine, chemical |

| 310 | High-temperature resilience | Heat exchangers |

| 410 | Good strength and wear resistance | Structural supports |

| 2205 | Exceptional strength and durability | Load-bearing structures |

| 430 | Aesthetic appeal with moderate resistance | Architectural trim |

Discover More:

The Ultimate Guide to Grade of Stainless Steel Pipe

Type of Different Stainless Steel Tube Material

Transitioning from a focus on stainless steel, it is pertinent to explore alternative materials in rectangular tubing. Such materials include 6063 T52 Aluminum and Mild Steel. These alloys offer distinct mechanical properties and cost advantages, making them suitable for a variety of applications where stainless steel may not be the optimal choice.

Analyzing their characteristics and applications will provide a comprehensive understanding of their role in structural and design projects.

The 3 T52 Aluminum Rectangular Tube offers a lightweight yet strong alternative to traditional steel tubing, suitable for a variety of structural and aesthetic applications. This aluminum alloy excels in environments where both the strength-to-weight ratio and resistance to corrosion are of paramount importance. Emphasizing its utility, consider the following:

This tubing is a testament to the innovative use of aluminum in overcoming traditional material limitations.

Mild steel, known for its versatility and welding ability, represents a foundational material in the array of tubing alloys used across numerous industries. Esteemed for its excellent mild steel properties, this material underpins many steel fabrication techniques, offering unparalleled adaptability in steel structural design.

Its inherent steel material efficiency not only ensures robust performance but also contributes significantly to sustainable practices, notably through steel recycling advantages. This synergy between practicality and sustainability positions mild steel as an indispensable component within engineering and construction realms.

Moreover, its capacity to be reshaped and reinforced through various processes underscores its pivotal role in advancing technological and architectural innovations, making it a quintessential choice for professionals seeking reliability and environmental stewardship in their projects.

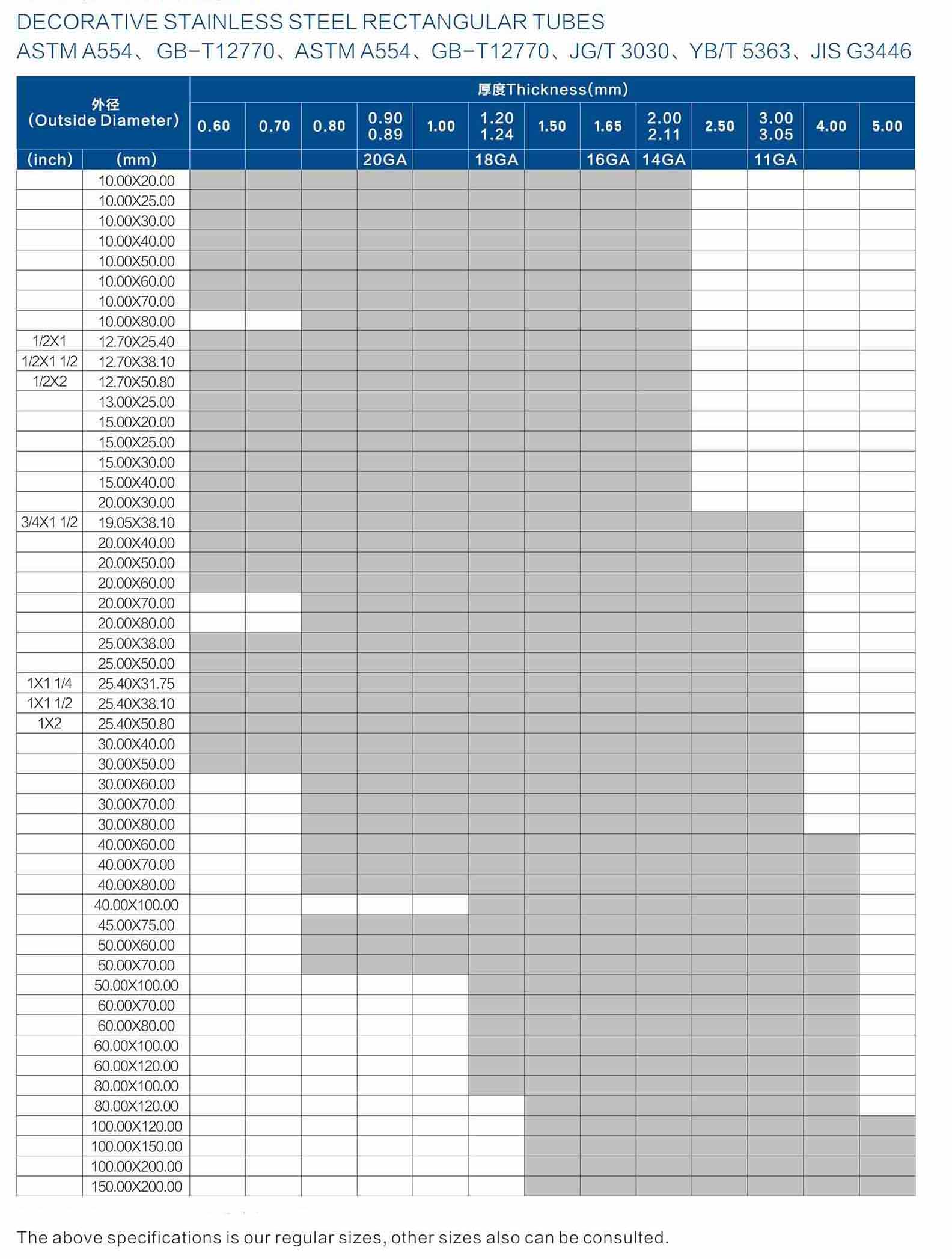

Within the context of stainless steel rectangular tube standard sizes are defined by specific dimensions that include wall thicknesses, diameters, and lengths, alongside the tolerances permitted for each. These parameters are critical for ensuring the tubing meets the rigorous requirements of structural applications, offering a balance between strength, durability, and workability.

The adherence to ASTM A554 specifications further ensures that these stainless steel products meet consistent quality standards, suitable for a wide range of industrial, architectural, and structural applications.

Regarding wall thicknesses, stainless steel rectangular tubes are manufactured in a variety of standard sizes, each tailored to meet specific structural and aesthetic requirements. The diversity in wall thicknesses not only provides structural versatility but also enhances the product's ability to cater to diverse applications and design preferences.

Thickness variations impact the tube's strength and weight, making selection crucial for project specifications.

Welding techniques vary, with thicker walls requiring more advanced methods to ensure strength and durability.

Corrosion resistance is influenced by wall thickness, affecting longevity in different environments.

Surface finishes can be applied differently across wall thicknesses, enhancing aesthetics and resistance.

Customization options allow for tailored solutions, accommodating unique project needs while considering wall thickness constraints.

The standard sizes of stainless steel rectangular tubes are determined by their outer dimensions, including both width and height, rather than a singular measurement of diameter, catering to a wide range of structural and design requirements. These dimensions allow for a variety of diameter variations, ensuring that each application can benefit from the unique mechanical properties of stainless steel, including its excellent corrosion resistance and superior welding capabilities.

The customization options available for these tubes further enhance their appeal, allowing for a precise fit in specialized projects. By leveraging the inherent strength and durability of stainless steel, manufacturers can offer products that meet specific structural needs while maintaining the aesthetic and functional qualities desired by their clients.

Standard sizes of stainless steel rectangular tubes also encompass a variety of lengths, ranging from 2ft to 20ft, to accommodate diverse structural and design demands efficiently. This versatility ensures that users can find the optimal length for their specific project requirements, enhancing both the functionality and aesthetics of the finished structure.

These aspects collectively ensure that stainless steel rectangular tubes can be efficiently and effectively utilized in a wide range of applications, meeting the needs of a community seeking reliable and durable materials.

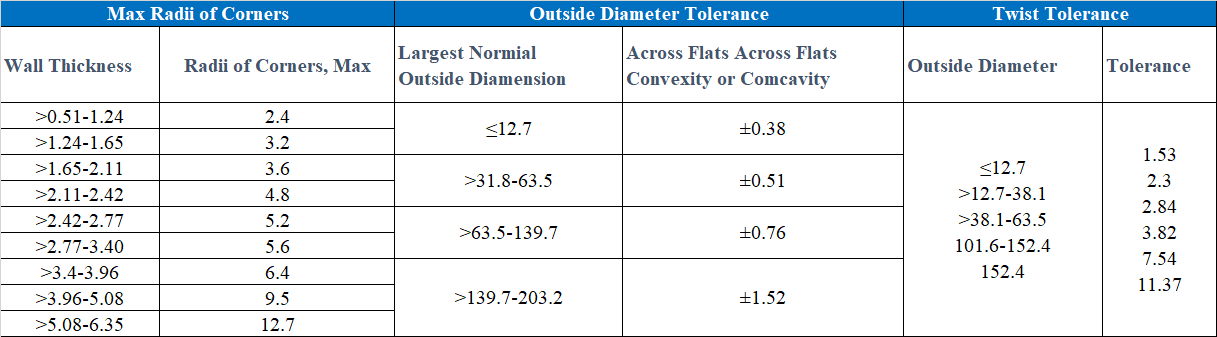

In the realm of stainless steel rectangular tube production, tolerance levels are meticulously defined to ensure uniformity across all standard sizes and applications. Tolerance analysis is a critical aspect, guiding the precision of manufacturing techniques to meet exacting standards.

These standards are not only pivotal for ensuring dimensional accuracy but also significantly impact welding considerations, where precise tolerances can affect the ease and quality of welds. Additionally, adherence to strict tolerances plays a crucial role in enhancing corrosion resistance, as uniform wall thicknesses contribute to the material's ability to withstand environmental challenges.

Lastly, surface finishing techniques, critical for the aesthetic and functional qualities of the final product, rely heavily on established tolerance criteria to achieve the desired finish and texture.

The following tables show the thickness tolerances, outside diameter tolerances and twist tolerances for stainless steel rectangular tubing

Learn More:

304 Stainless Steel Rectangular Tube Size: Unveiling Industrial Precision

A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

Rectangular tube stainless steel is available in a range of surface finishes, each tailored to specific application requirements and aesthetic preferences.

Polished rectangular tubing offers a reflective surface that is often sought after for its visual appeal in architectural and decorative uses, while a mill finish provides a basic, untreated appearance suitable for structural applications where aesthetics are less critical.

Additionally, satin and brushed polished finishes offer a middle ground, balancing aesthetic appeal with practicality in environments where glare reduction and minor scratch resistance are desired.

Polished rectangular tubing, often chosen for its aesthetic appeal, offers a sleek surface finish that enhances the appearance and corrosion resistance of stainless steel rectangular tubes. This enhancement is crucial for applications where both functionality and visual appeal are priorities. The polished surface not only contributes to the tube's aesthetic but also improves its resistance to environmental factors that might cause corrosion.

You may also like:

Exploring the World of Polished Stainless Steel Round Tubes

Unveiling the Excellent of Polished Stainless Steel Square Tubing

Unlike its polished counterpart, a mill finish on rectangular tube stainless steel is characterized by an unpolished surface that retains the appearance of the steel as it comes off the mill, providing a functional and cost-effective option for structural applications where aesthetics are less critical.

| Feature | Benefit |

|---|---|

| Surface Finish | Enhances corrosion resistance |

| Welding Techniques | Improves structural integrity |

| Corrosion Resistance | Extends the lifespan in harsh environments |

| Structural Integrity | Ensures reliability and safety |

| Customization Options | Meets specific project requirements |

This approach prioritizes practicality, focusing on essential attributes like corrosion resistance and structural integrity, which are critical for ensuring durability and safety in industrial and construction applications.

Moving beyond the practicality of mill finish, satin finish stainless steel rectangular tubes offer an aesthetically pleasing surface that combines a visually appealing look with enhanced corrosion resistance. This finish is achieved through specific fabrication methods that not only improve its appearance but also bolster its usability in various structural applications.

Surface finishes play a crucial role in the material's durability and aesthetic appeal. Welding techniques must be carefully selected to preserve the integrity of the satin finish. Enhanced corrosion resistance contributes to the material's longevity. Fabrication methods are tailored to maintain the quality of the satin finish. Ideal for diverse structural applications where both strength and appearance are important.

This approach ensures a balance between form and function, making satin finish tubes a preferred choice for discerning projects.

Brushed polished stainless steel tubes offer a unique combination of aesthetic appeal and functional benefits, characterized by their uniform matte finish that reduces the appearance of fingerprints and marks.

| Feature | Brushed Finish | Mirror Polish |

|---|---|---|

| Aesthetic Appeal | Subtle, refined | High gloss, reflective |

| Surface Texture | Uniform, directional matte | Smooth, no visible grain |

| Maintenance | Lower visibility of smudges | Requires regular cleaning |

| Application | Ideal for high-traffic areas | Suited for decorative purposes |

This table highlights the distinct characteristics between brushed finish and mirror polish, emphasizing the importance of selecting the appropriate finishing technique based on the desired aesthetic appeal, maintenance requirements, and application. Brushed polished tubes seamlessly blend functionality with style, making them a preferred choice for those prioritizing both appearance and practicality.

Learn More:

Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

Rectangular tube stainless steel is integral to various sectors, prominently including construction and architecture, where its robustness and corrosion resistance are paramount for structural applications.

Its utility extends to outdoor frameworks and structures, benefiting from its durability against environmental stressors, and marine applications, where its resistance to seawater corrosion is crucial.

Additionally, its versatility is showcased in a range of other applications, underscoring its adaptability and reliability in diverse operational conditions.

In the realms of construction and architecture, rectangular tube stainless steel are esteemed for their unparalleled strength, versatility, and aesthetic flexibility, making them indispensable components in building frameworks, structural supports, and decorative installations.

These elements underscore the pivotal role of stainless steel rectangular tubes in modern construction and architecture, merging form with function to meet both aesthetic and structural demands.

Building upon the foundational role of stainless steel rectangular tubes in construction and architecture, their applications extend significantly into structural uses where their unique properties are capitalized upon for enhanced performance and reliability.

These tubes offer exceptional corrosion resistance, crucial in environments prone to chemical exposure or moisture. Advanced welding techniques enable secure joints, essential for maintaining structural integrity under stress. The remarkable load-bearing capacity of these tubes supports heavy structures without compromise.

Customization options allow for tailored solutions, meeting specific design requirements while optimizing material efficiency. This efficiency ensures that projects utilize resources effectively, reducing waste and promoting sustainability in construction practices.

Together, these attributes make rectangular tube stainless steel indispensable in modern structural applications, blending strength, durability, and adaptability.

Stainless steel's exceptional durability and corrosion resistance make it an ideal choice for outdoor frameworks and structures, leveraging rectangular tube stainless steel designs for their strength and versatility. This material's superior qualities support a wide array of outdoor applications, offering:

These attributes make rectangular tube stainless steel a preferred material for constructing durable, efficient, and visually appealing outdoor frameworks and structures, echoing a sense of belonging and permanence in the spaces we inhabit and utilize.

Considering the exceptional durability and corrosion resistance of stainless steel for outdoor frameworks, its application extends naturally to marine and seawater environments where these properties are indispensable. The material's inherent seawater resistance and structural durability make it an ideal choice for maritime constructions. Welding applications benefit from stainless steel's compatibility, ensuring robust assembly of marine structures. Additionally, its workability allows for efficient customization in demanding marine conditions.

| Feature | Benefit |

|---|---|

| Marine Corrosion Resistance | Prolongs structure lifespan |

| Structural Durability | Withstands harsh marine conditions |

| Welding Applications | Ensures strong structural connections |

| Material Workability | Facilitates customization |

| Seawater Resistance | Reduces maintenance needs |

These properties collectively enhance the reliability and longevity of marine and seawater applications, fostering a sense of belonging among professionals who rely on the highest standards of material performance.

Learn More :

Custom Stainless Steel Tube for Every Application

The mechanical properties of rectangular tube stainless steel, notably its workability, play a crucial role in its applicability across various industries. Factors such as tensile strength, yield strength, and elongation percentage directly influence the tube's performance under stress and its ability to be shaped, welded, and machined.

Understanding these properties is essential for engineers and fabricators to optimize the material's use in structural applications, ensuring durability and reliability.

The mechanical properties of stainless steel tubes, such as 304/304L grade, significantly influence their workability in various applications, including flaring, flattening, flanging, and bending.

These properties are determined by the material's inherent tensile strength, yield strength, and elongation capacity, which are critical for assessing the tube's ability to withstand mechanical processing without compromising structural integrity.

Understanding these mechanical properties is essential for optimizing the selection and application of stainless steel tubes in construction, fabrication, and repair projects, ensuring both performance and durability.

Understanding the flaring properties of stainless steel tubes is critical for assessing their adaptability in precision applications and complex assemblies.

Flaring applications: Enhances fitting and joining capabilities.

Welding techniques: Determines compatibility with various welding methods.

Corrosion resistance: Preserved during the flaring process.

Forming methods: Influences the choice of flaring techniques.

Mechanical properties: Maintains structural integrity post-flaring.

Evaluating the flattening properties of stainless steel tubes is essential for gauging their adaptability in fabrication and assembly processes. Tube flattening reflects on material properties, influencing corrosion resistance and determining the efficacy of welding techniques.

This characteristic directly impacts the load-bearing capacity of the tubes, making it a critical factor in the design and engineering phases of construction and manufacturing applications. Precision in assessment ensures optimal performance and structural integrity.

Analyzing the flange properties of stainless steel tubes reveals insights into their mechanical workability, crucial for applications requiring precise fabrication and assembly.

These characteristics underscore the material's suitability for diverse and demanding applications.

The bending properties of stainless steel tubes, particularly those of the 304 grade, play a critical role in their workability for various structural and fabrication applications. Effective bending techniques enhance strength and design flexibility, while welding considerations ensure durability.

Corrosion resistance minimizes maintenance, customization options enhance aesthetics, and superior load-bearing capacity offers unparalleled design flexibility. These aspects together underscore the material's robustness and adaptability in demanding environments.

The utilization of rectangular tube stainless steel presents a myriad of benefits spanning structural integrity to environmental sustainability. Its unique shape affords exceptional strength and load-bearing capabilities, making it indispensable in various structural applications including construction and industrial manufacturing.

Furthermore, its adaptability in fabrication processes, coupled with inherent cost-effectiveness and minimal environmental impact, underscores its value in modern engineering and design solutions.

Rectangular tube stainless steel, known for their exceptional strength and load-bearing capacity, offer significant structural advantages in various applications. These advantages make rectangular tube stainless steel a preferred choice for professionals seeking reliable and robust construction materials.

The benefits include:

These attributes underscore the importance of rectangular tubes in modern construction, offering a blend of strength, versatility, and value.

Building upon the structural advantages highlighted earlier, the versatility of rectangular tube stainless steel further extends its applicability across a wide array of industries and projects, offering unique benefits in terms of design flexibility and ease of integration. Its adoption furnishes cost-effective solutions while upholding environmental benefits and structural integrity.

| Feature | Benefit |

|---|---|

| Versatile Applications | Adaptable to diverse industrial needs |

| Design Flexibility | Allows for innovative architectural uses |

| Cost-Effective Solutions | Reduces overall project expenses |

| Environmental Benefits | Supports sustainable construction practices |

| Structural Integrity | Ensures longevity and reliability |

This adaptability not only fosters a sense of belonging among professionals across various sectors but also champions the innovative and efficient use of materials in construction and manufacturing.

Due to its unique shape, rectangular tube stainless steel offers significant advantages in terms of ease of fabrication, making it a preferred choice for engineers and designers.

Fabrication Techniques: Adaptability to various sophisticated fabrication techniques allows for the creation of complex structures.

Welding Methods: Compatibility with multiple welding methods ensures strong joints and enhances the product's structural integrity.

Surface Finishes: Availability in a range of surface finishes to meet aesthetic and functional requirements.

Corrosion Resistance: High corrosion resistance protects the integrity of structures in harsh environments.

Structural Integrity: The rectangular shape contributes significantly to the strength and durability of the fabricated structure.

These characteristics collectively make stainless steel rectangular tubing an excellent material for projects that demand precision, strength, and long-term reliability.

Exploring the economic advantages of using stainless steel rectangular tubing, it is evident that this material offers significant cost savings in both construction and maintenance phases. The inherent durability benefits of stainless steel contribute to a longer lifespan of structures, mitigating the need for frequent replacements and repairs.

This, coupled with design flexibility, allows for the creation of cost-efficient, aesthetically pleasing, and robust architectural and structural components. Moreover, the material efficiency of stainless steel rectangular tubes ensures minimal waste during production, translating into direct cost savings.

The combination of these factors - durability, design flexibility, and material efficiency - underscores the cost-effectiveness of stainless steel rectangular tubing, making it a prudent choice for a wide array of applications.

The environmental sustainability of rectangular tube stainless steel is significantly enhanced by its recyclability and energy-efficient manufacturing processes. This aligns with the growing demand for sustainable solutions and eco-friendly initiatives that significantly reduce the environmental impact of industrial activities.

Rectangular tube stainless steel exhibits exceptional temperature working properties, making it suitable for applications requiring durability under varying thermal conditions. Its temperature resistance and low thermal expansion ensure structural integrity across a broad spectrum of temperatures. The material's heat conductivity is optimal for processes demanding quick thermal response, while its suitability for cryogenic applications underscores its versatility. Moreover, its remarkable thermal stability enhances longevity and performance reliability in challenging environments.

| Property | Benefit | Application |

|---|---|---|

| Temperature Resistance | Maintains strength at high temperatures | High-temperature environments |

| Thermal Expansion | Minimal expansion under heat | Precision assemblies |

| Thermal Stability | Consistent properties across temperatures | Cryogenic applications |

These features position rectangular tube stainless steel as a material of choice for those valuing reliability, precision, and thermal resilience.

Stainless steel tubes can endure high temperatures, with limits dependent on alloy selection, design flexibility, and thermal expansion considerations. Application-specific standards and temperature measurement techniques are crucial for ensuring structural integrity in various environments.

Welding techniques, such as proper heat input control and welding atmosphere selection, play critical roles in preserving corrosion resistance and structural integrity. Oxidation prevention and meticulous post-weld cleaning further ensure optimal performance of welded components.

To enhance durability in marine environments, specific treatments such as surface preparation, application of protective layers, and electroplating methods using corrosion inhibitors are recommended. Salt spray testing can verify the effectiveness of these treatments.

Cold working processes induce grain refinement and work hardening in metals, increasing the elastic limit and tensile strength. Conversely, annealing effects can reverse these changes, reducing tensile strength but improving ductility and workability.

Recycling materials mitigates resource depletion, reduces ecosystem disruption, and minimizes energy consumption. Compared to alternatives, stainless steel's recyclability notably lessens pollution generation and wildlife impact, offering a sustainable choice for informed communities seeking responsible material use.

Foshan Vinmay Stainless Steel Co.,ltd is a large-scale international enterprise which concentrates on producing stainless steel welded tubes and the related fittings. We provide high quality stainless steel rectangular tube for handrail , furniture , building and construction etc. Size range from 10x20-150x200mm. And the thickness range from 0.6mm-5.0mm. Contact us today for the free samples.

Blog Series:

Unveiling the Strength and Versatility: A Comprehensive Guide to Stainless Steel Round Tubes

The Comprehensive Guide of Stainless Steel Welded Round Tube

In conclusion, rectangular tube stainless steel, particularly of the 304 grade, serves as an essential material in diverse industrial and architectural applications due to its robustness, corrosion resistance, versatility, and compliance with ASTM A554 standards.

Its mechanical properties, including significant tensile strength and Brinell hardness, along with its workability encompassing welding and machining, make it suitable for demanding environments.

The material's distinct advantages, such as durability and aesthetic appeal, underscore its importance in modern engineering and construction projects.