Sanitary pipes are specialized conduits for transporting fluids in sterile environments, crucial for industries with strict hygiene standards. They are designed to prevent contamination, ensuring product integrity and compliance with hygiene regulations. Made from materials like stainless steel, aluminum, plastic, titanium, or glass, they offer durability, corrosion resistance, and ease of cleaning. These pipes adhere to stringent standards set by organizations like the FDA and ASME and come in different sizes and materials to suit various needs. Further details on materials, applications, and differences compared to tubes can provide a deeper understanding of their functionality.

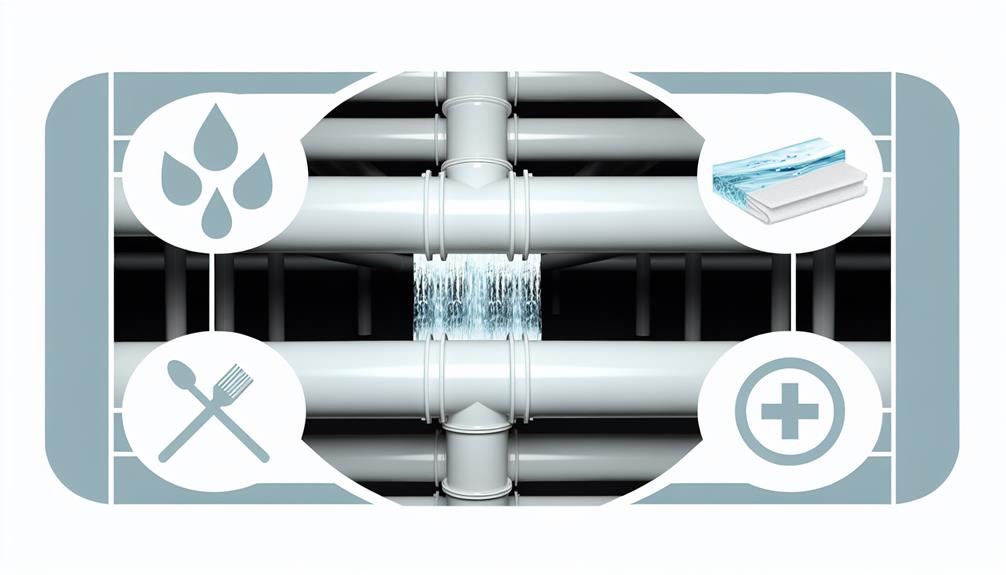

Sanitary piping, also known as sanitary pipe, refers to a specialized system of piping designed for the safe and hygienic transportation of fluids in industries such as pharmaceuticals, food processing, and biotechnology. The design of sanitary pipes is crucial to prevent contamination and ensure product purity.

These pipes are constructed to meet stringent hygiene standards, often featuring smooth surfaces with minimal crevices where bacteria could accumulate. The materials used in sanitary pipe design are typically stainless steel, which is known for its corrosion resistance, durability, and ease of cleaning. Other materials like plastic, such as PVC or PTFE, may also be used based on the specific requirements of the industry.

Sanitary pipes are engineered to maintain the integrity of the transported fluids while minimizing the risk of contamination, making them essential components in industries where product quality and safety are paramount. Proper installation and maintenance of sanitary piping systems are vital to ensure compliance with regulatory standards and the efficient operation of manufacturing processes.

Materials used in sanitary pipe manufacturing play a crucial role in ensuring the durability, cleanliness, and safety of the piping systems. Stainless steel, known for its corrosion resistance and ease of cleaning, remains a popular choice for sanitary tubing.

Other materials like aluminum, plastic, titanium, and glass each have unique properties that manufacturers consider when selecting the most suitable material for specific applications.

Stainless steel, being renowned for its durability and resistance to corrosion, is the predominant material utilized in the manufacturing of sanitary tubing, with Stainless Steel 304 emerging as the most prevalent grade.

Stainless steel's qualities make it an ideal choice for sanitary tubing, particularly in industries where hygiene and product purity are paramount. Learn more about the benefits of hygienic stainless steel tubes in our in-depth guide.

Aluminum is a lightweight material commonly considered for use in sanitary pipe manufacturing due to its ease of handling, but its susceptibility to cracking and warping over time, coupled with limited resistance to corrosion and damage, necessitates frequent replacement.

While aluminum's lightweight nature makes it easy to work with during installation, its structural integrity can be compromised over time due to its tendency to crack and warp under stress. Moreover, aluminum pipes are prone to corrosion, reducing their lifespan and requiring regular maintenance.

Manufacturers opting for aluminum in sanitary pipe systems must factor in these limitations, ensuring proper upkeep and timely replacements to maintain the efficiency and functionality of the piping infrastructure.

For those seeking a durable and corrosion-resistant option in sanitary pipe manufacturing, the use of high-quality plastic components remains a viable choice. While plastic was once a popular material for designing sanitary pipe hangers and supports, its usage has declined. This shift is primarily due to the stringent regulations set forth by the FDA regarding the determination of plastics and rubbers as food-grade materials.

These regulations classify such materials as indirect food additives, necessitating careful consideration of their application in sanitary piping systems. Despite these considerations, plastic still offers advantages such as resistance to corrosion and durability, making it a suitable option for certain sanitary pipe manufacturing needs. Proper adherence to regulations and quality standards is crucial when utilizing plastic components in sanitary pipe systems.

Best For Industries requiring durable and corrosion-resistant options in sanitary pipe manufacturing.

Pros:

Cons:

Incorporating titanium into sanitary pipe manufacturing processes enhances corrosion resistance and strength, albeit typically at a higher cost compared to other materials. When considering the use of titanium in sanitary pipe production, several key points should be noted:

Glass is a material utilized in sanitary pipe manufacturing due to its cleanliness and transparency, although its susceptibility to breakage poses challenges in certain applications.

While glass offers easy cleaning and visibility within machinery, concerns about breakage limit its widespread use, especially in industries like food and beverage production.

When considering glass for tubing, piping, or sanitary pipe hangers, rigorous testing is necessary to ensure its durability and resistance to breakage under specific conditions.

Manufacturers must carefully evaluate the risk of breakage and determine if the benefits of using glass in sanitary pipes outweigh the potential drawbacks, such as the need for robust quality control measures to prevent failures in operation.

Copper is a commonly utilized material in sanitary pipe manufacturing due to its excellent corrosion resistance and durability.

These characteristics make copper an ideal choice for sanitary pipe applications where reliability and cleanliness are paramount. If you're considering the best material for your project, learn more about the differences between copper and stainless steel pipes in our blog post on Copper vs. Stainless steel Pipe.

Sanitary pipes are commonly utilized in a variety of industries, including pharmaceutical, food processing, and biotechnology, due to their hygienic design and smooth surfaces that facilitate easy cleaning and maintenance.

In the pharmaceutical industry, sanitary pipes are crucial for ensuring the integrity of the drug manufacturing process by preventing contamination and maintaining a sterile environment. Food processing plants rely on sanitary pipes to meet strict hygiene standards and prevent the growth of harmful bacteria, ensuring the safety of the food products. In biotechnology, where precision and cleanliness are paramount, sanitary pipes play a vital role in maintaining the purity of sensitive biological processes.

Moreover, sanitary pipes find applications in the dairy industry to transport milk and dairy products without compromising their quality. They are also used in cosmetic manufacturing to ensure the purity of the products. Overall, the use of sanitary pipes across these industries underscores the importance of maintaining sanitary conditions and preventing contamination in critical processes.

Utilizing sanitary pipes in industrial applications offers numerous advantages, ranging from ensuring product integrity to facilitating stringent hygiene standards.

Adherence to established sanitary standards and regulations is paramount in industries utilizing sanitary pipes to uphold hygiene and product integrity. These standards, set by organizations like the Food and Drug Administration (FDA) and the American Society of Mechanical Engineers (ASME), dictate the materials, design, installation, and maintenance requirements for sanitary piping systems.

Sanitary standards ensure that the materials used in the construction of sanitary pipes are non-toxic, corrosion-resistant, and suitable for the intended application. They also specify guidelines for proper cleaning and sanitation procedures to prevent contamination and bacterial growth. Regular inspections and testing are typically mandated to verify compliance with these standards.

Regulations surrounding sanitary pipes also address issues such as proper labeling, documentation, and traceability of materials used. In the food and pharmaceutical industries, where sanitary pipes are commonly employed, any deviation from these standards can lead to severe consequences, including product contamination, regulatory fines, and damage to reputation. Therefore, strict adherence to sanitary standards and regulations is essential to ensure the safety and quality of products transported through sanitary piping systems.

Recommended: Common Issues and Solutions for Sanitary Stainless Steel Tube Systems

The distinctions between pipe, tube, and sanitary tube lie in their structural characteristics and intended applications within industrial settings.

1. Pipe:

2. Tube:

3. Sanitary Tube:

Explore the differences between stainless steel pipe and tube to understand their unique characteristics and applications.

Yes, sanitary pipes are commonly used in food processing industries due to their design that minimizes contamination risks. These pipes are made of materials that meet strict sanitary standards and can withstand rigorous cleaning processes.

Sanitary pipes are typically constructed with corrosion-resistant materials like stainless steel. These materials act as a shield, much like a suit of armor, protecting the pipes from rust and corrosion, ensuring durability and longevity in food processing environments.

The maximum pressure rating for sanitary pipes varies depending on the material and intended application. Typically, stainless steel sanitary pipes can handle pressures up to 150 psi. It is crucial to consult specific industry standards and guidelines for accurate pressure ratings.

Installation of sanitary pipes necessitates adherence to specific techniques such as proper alignment, support, and sealing to ensure optimal performance and prevent leaks or contamination. Special considerations should be made for connection methods and material compatibility.

Specific cleaning requirements for sanitary pipes are crucial to maintain hygiene and prevent blockages. Regular flushing with hot water and specialized cleaning agents is necessary. Scheduled inspections for buildup and proper disposal of waste are essential.

Blog Series:

In conclusion, the sanitary pipe plays a crucial role in various industries due to its hygienic design and materials used in manufacturing. It meets strict sanitary standards and regulations to ensure safety and efficiency in applications such as food processing, pharmaceuticals, and water treatment.

Understanding the differences between pipe, tube, and sanitary tube is essential for selecting the right product for specific requirements. Overall, the sanitary pipe is a vital component in maintaining cleanliness and quality in industrial processes.