China's stainless steel tube industry has emerged as a pivotal player on the global stage, driven by robust government support, cutting-edge technology, and a wealth of essential raw materials. These factors have enabled Chinese manufacturers to produce high-quality seamless and welded tubes that are critical to various sectors such as petrochemicals, aerospace, and automotive. As we explore the intricacies of this thriving industry, one cannot ignore the precision and adherence to international standards that set Chinese stainless steel tubes apart. What are the key considerations for buyers looking to source these tubes from China?

As the world's largest producer and consumer of stainless steel, China's stainless steel tube and pipe industry has experienced remarkable growth over the past few decades. This expansion has been driven by several pivotal factors, including government support, technological advancements, and burgeoning domestic demand. The result is a robust industry that caters to diverse industrial and consumer needs, solidifying China's position as a global force in the stainless steel tube market.

China stainless steel tube manufacturers benefit greatly from the abundant reserves of essential raw materials like nickel and chromium. This steady supply not only ensures cost-effective production but also enables these manufacturers to meet stringent international standards.

With over 50% of global stainless steel production attributed to China, the stainless steel tube China market has become a cornerstone of the global supply chain.

The government's strategic policies and incentives further bolster the industry's capabilities, encouraging research, innovation, and production efficiency. By investing in state-of-the-art equipment and technology, Chinese companies enhance their output and quality, meeting the high demands of both domestic and international markets. Consequently, the stainless steel tube and pipe sector in China continues to thrive, maintaining its competitive edge in the global arena.

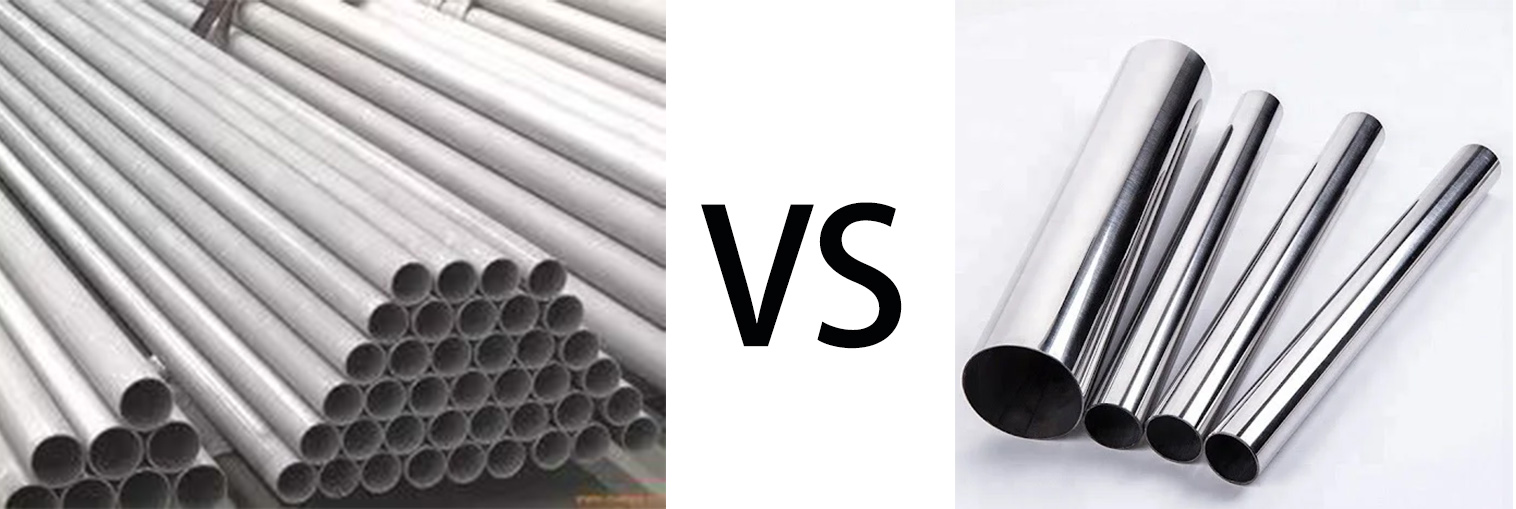

The classification of stainless steel tubes encompasses both seamless and welded varieties, each offering distinct advantages.

Seamless stainless steel tubes, produced through extrusion or rotary piercing, provide superior strength and uniformity, making them ideal for high-pressure applications.

Conversely, welded stainless steel tubes, fabricated by joining steel strips or coils, offer cost-efficiency and versatility, suitable for a wide range of industrial uses.

Seamless stainless steel tubes, recognized for their superior strength and uniformity, are essential components in various high-performance applications. These tubes are produced without a seam, resulting in enhanced mechanical properties and the ability to withstand extreme environments. In the context of steel tube production in China, leading China stainless steel tube manufacturers leverage advanced technology and abundant raw materials to produce seamless stainless steel tubes that meet stringent international standards.

Seamless stainless steel tubes are utilized across diverse industries, including petrochemical, aerospace, and automotive sectors, where reliability and performance are paramount. The absence of welds in these tubes minimizes the risk of failure under high pressure and temperature conditions, making them ideal for critical applications.

| Reduced risk of failure under high-stress | Benefit |

|---|---|

| No Welds | Reduced risk of failure under high stress |

| Superior Strength | Enhanced mechanical properties |

| Uniformity | Consistent performance across applications |

China's capacity for producing high-quality seamless stainless steel tubes is bolstered by technological advancements and cost-effective production processes. This has positioned Chinese manufacturers at the forefront of the global market, providing reliable and high-performance solutions that meet the demands of various high-stakes industries.

Welded stainless steel tubes, a crucial component in numerous industrial applications, are manufactured by welding together rolled strips of stainless steel. This method is favored for its cost efficiency and versatility, making it a mainstay for stainless steel tube manufacturers and suppliers in China.

The production process of welded stainless steel tubes involves several meticulous steps:

These welded stainless steel tubes are essential in sectors such as construction, automotive, and chemical processing due to their exceptional strength and corrosion resistance. With China leading the global market, the expertise of China stainless steel tube manufacturers guarantees the production of high-quality, reliable welded stainless steel tubes, meeting stringent international standards and catering to diverse industrial needs.

If you're looking for durable and cost-effective welded stainless steel tubes, look no further than Vinmay. Contact us today to learn more about our products and how we can meet your specific industrial needs!

Building upon the importance of welded stainless steel tubes in various industrial applications, it's imperative to compare them with their seamless counterparts to understand their distinct advantages and applications.

Seamless stainless steel tubes are produced through an extrusion process, involving no welding or joints, which results in a uniform structure. This method enhances their strength and corrosion resistance, making them ideal for high-pressure and high-temperature environments such as petrochemical and aerospace industries.

Conversely, welded stainless steel tubes are fabricated by rolling stainless steel strips and welding the seam longitudinally. Modern advancements in stainless steel tube fabrication, including laser and TIG welding, have greatly improved the quality and reliability of welded tubes. These tubes are generally more cost-effective and are widely used in applications where pressure requirements are moderate, such as in the construction, automotive, and decorative industries.

When selecting between seamless and welded stainless steel tubes, considerations such as mechanical properties, cost, and specific application requirements must be meticulously analyzed. The choice directly impacts the performance and longevity of the application, underscoring the necessity for an informed decision-making process.

The manufacturing process of China stainless steel tubes encompasses both seamless and welded methodologies, each with distinct technical procedures. Seamless tubes are typically produced through piercing, gun drilling, or extrusion, followed by cold forming techniques like cold drawing and cold pilgering to achieve precise dimensions.

In contrast, welded tubes involve processing coils through rollers to form the desired shape, followed by welding, conditioning, and sizing, ensuring structural integrity and surface finish.

Given the critical role of seamless stainless steel tubes in various high-demand industries, understanding their manufacturing process reveals the sophistication and precision involved. As a prominent China stainless steel tube supplier, the SS pipe manufacturer in China meticulously follows advanced methodologies to maintain quality and durability.

These seamless stainless steel tubes undergo rigorous heat treatments, such as annealing, to enhance ductility and structural integrity, ensuring they meet stringent industry standards.

Manufacturing welded stainless steel tubes in China involves a thorough process that starts with high-quality stainless steel sheets or coils. The initial step entails forming these raw materials into a tubular shape, achieved either longitudinally or helically, depending on the desired weld type.

For longitudinally welded tubes, china stainless steel pipe manufacturers employ methods like Electric Resistance Welding (ERW) and Fusion Welding, wherein the edges are fused together. In contrast, spiral welded tubes are created by helically welding a continuous strip of steel, typically used for larger diameters.

Post-welding, the seams undergo stringent inspection and treatment to ensure structural integrity and a smooth surface finish. This process includes techniques such as annealing and pickling, which relieve stress and remove oxide layers, respectively. Adherence to stainless steel pipe welding standards during this phase is crucial to ensure the safety and reliability of the final product.

Advanced steel tube China manufacturers may further enhance the tubes through optional cold rolling, improving dimensional accuracy and surface finish.

The final steps include a thorough inspection to meet international standards, followed by surface finishing processes like polishing and passivation. The detailed attention to quality and precision allows Chinese manufacturers to produce welded stainless steel tubes that cater to diverse industrial and consumer needs, maintaining their competitive edge in the global market.

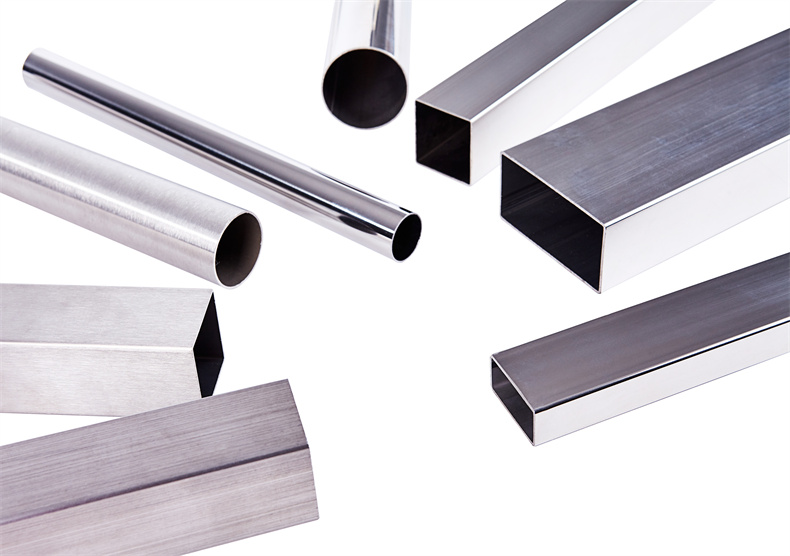

The classification of stainless steel tubes can be systematically categorized by their shape and material composition. Shape classifications include round, square, rectangular, and oval tubes, each serving distinct industrial applications.

Material composition classifications encompass austenitic, ferritic, martensitic, and duplex stainless steel grades, such as 304, 316, and 2205, each offering unique properties and performance characteristics.

In the realm of stainless steel tube categorizations, shapes play a crucial role in determining their applications and functionality. The geometric arrangement of stainless steel tubes influences not only their mechanical properties but also their suitability for specific industrial purposes. Here's an accurate breakdown of the primary shapes:

Each shape provides distinct advantages, enabling manufacturers to tailor their products to meet specific industrial requirements, thus ensuring efficient performance and reliability. At Vinmay, we offer a wide range of stainless steel tube shapes to suit your needs. Now explore our offerings and find the perfect solution for your applications!

Stainless steel tubes, classified by material composition, provide a broad spectrum of properties tailored for precise industrial applications. The major classifications include austenitic, ferritic, martensitic, and duplex stainless steels, each exhibiting unique characteristics suited for specific uses.

Austenitic stainless steels, such as grades 304 and 316, are renowned for their high corrosion resistance, making them ideal for environments exposed to corrosive elements. These grades are frequently employed in chemical processing, food and beverage industries, and marine applications.

Ferritic stainless steels, including grades 409 and 430, offer moderate corrosion resistance at a lower cost. These materials are often used in automotive exhaust systems and domestic appliances where cost-effectiveness and adequate performance are required.

Martensitic stainless steels, exemplified by grade 410, possess high hardness and strength, making them suitable for industrial tools and machinery components that demand durability and wear resistance.

Duplex stainless steels, such as grade 2205, combine the benefits of both austenitic and ferritic structures. They provide superior strength and stress corrosion resistance, tailored for applications in the oil and gas industry, and chemical processing.

Each classification offers distinct advantages, ensuring that Chinese stainless steel tubes meet diverse industrial needs while maintaining stringent quality standards.

Related Articles: Different Stainless Steel Tube Material

Adherence to international standards is crucial for the production of high-quality stainless steel tubes, guaranteeing compatibility and reliability across diverse applications. In the global market, several key standards guide the manufacturing processes and material specifications for stainless steel tubes. These standards guarantee that products meet stringent quality criteria, facilitating their use in various industries.

Compliance with these standards, along with EN (European Norms), GB (Guobiao standards from China), and BS (British Standards), ensures that stainless steel tubes produced in China meet global benchmarks for quality and performance, making them suitable for international markets.

Chinese manufacturers' dedication to excellence is highlighted by their adherence to a range of internationally recognized certifications. These certifications include BV (Bureau Veritas), IBR (Indian Boiler Regulations), ISO (International Organization for Standardization), RoHS (Restriction of Hazardous Substances), and SGS (Société Générale de Surveillance). Such certifications validate the manufacturers' compliance with strict quality, safety, and environmental standards required by global markets.

BV certification ensures that stainless steel tubes meet thorough quality and safety criteria, essential for applications in critical industries.

IBR certification, specific to the Indian market, signifies conformity to boiler regulations, guaranteeing high standards in pressure equipment.

The widespread ISO certifications affirm adherence to international quality management systems, boosting credibility and operational efficiency.

RoHS compliance indicates that the products are free from harmful substances, demonstrating a commitment to environmental sustainability and human health.

SGS certification, a globally recognized benchmark for inspection, verification, testing, and certification, further emphasizes the manufacturers' commitment to quality assurance.

Stainless steel tubes are essential to a multitude of industries due to their durability, corrosion resistance, and versatility. In industrial applications, they are vital for chemical processing and oil refining, while in construction and architecture, they provide structural strength and aesthetic appeal. Additionally, the food and beverage industry, as well as the automotive and transportation sectors, rely on stainless steel tubes for their hygienic properties and mechanical robustness.

The application of stainless steel tubes in industrial sectors is vast and multifaceted, driven by their superior properties and adaptability. These tubes are integral to numerous high-demand industries due to their corrosion resistance, durability, and strength-to-weight ratio.

Key industrial applications include:

These applications underscore the critical role of stainless steel tubes in maintaining operational efficiency and safety across various industrial domains.

In the domain of construction and architecture, architecture stainless steel tubes are essential for both their aesthetic appeal and structural integrity. These tubes, available in various grades such as 304, 316, and 2205, deliver unmatched durability and corrosion resistance, vital for long-term applications. Their versatility is evident in their use for structural supports, decorative elements, handrails, and modern architectural designs.

Technical advantages include high tensile strength and seamless or welded manufacturing processes, complying with standards like ASTM, ASME, and EN. This guarantees that the stainless steel tubes maintain structural stability under diverse environmental conditions. Surface treatments such as annealing, pickling, and polishing further enhance their performance and visual appeal, making them ideal for high-end architectural projects.

The precise dimensions (OD x WT x Length) allow for customized applications, meeting the specific requirements of complex construction projects. For example, round, square, and rectangular tubes can be used in frameworks, while oval tubes find applications in decorative elements.

China's robust production capabilities, supported by advanced technology and abundant raw materials, guarantee a consistent supply of high-quality architecture stainless steel tubes, meeting both domestic and international construction demands efficiently.

Within the food and beverage industry, the utilization of sanitary-grade stainless steel tubes is paramount for ensuring product quality and safety. These types of sanitary tubes offer superior corrosion resistance, ease of cleaning, and durability, making them ideal for applications where hygiene is critical.

Sanitary-grade stainless steel tubes are extensively employed in:

The technical specifications of these tubes often conform to stringent standards such as ASTM, ASME, and EN, ensuring their suitability for demanding environments. With precise dimensions and rigorous quality control, these tubes are designed to meet the highest industry requirements.

Automotive and transportation sectors heavily depend on stainless steel tubes for their superior strength, corrosion resistance, and longevity. These tubes are essential components in exhaust systems, fuel lines, and vehicle chassis. The exceptional mechanical properties of stainless steel make it an ideal material for these applications, ensuring longevity and performance even under challenging operating conditions.

In exhaust systems, stainless steel tubes withstand high temperatures and corrosive gases, enhancing the durability of the system. For fuel lines, the material's resistance to corrosion prevents contamination and secures the integrity of the fuel delivery system. Additionally, stainless steel's structural strength is vital for chassis components, providing a reliable and robust framework for vehicles.

Precision manufacturing techniques, including seamless and welded processes, allow for the production of tubes that meet strict automotive standards. Adherence to ASTM, ASME, and EN standards guarantees these tubes perform dependably in various automotive applications. The use of grades such as 304, 316, and 2205 further optimizes the tubes for specific requirements, balancing cost and performance.

Chinese manufacturers, benefiting from advanced production facilities and abundant raw materials, are well-positioned to supply high-quality stainless steel tubes, meeting global demand and contributing to the advancement of automotive technologies.

Dominance in the stainless steel sector is exemplified by several leading manufacturers in China, whose technical expertise and extensive production capabilities establish global standards. These manufacturers have established themselves through a combination of advanced production methods, strict quality control, and all-encompassing service offerings.

Vinmay is a leading stainless steel tube manufacturer specializing in high-quality stainless steel welded pipes and tubes. Known for its precision and advanced techniques, Vinmay adheres to rigorous industry standards while providing products widely used in construction, water supply, and other industrial applications. By consistently focusing on sustainability and innovation, we strive to enhance our competitiveness in the global stainless steel market.

Renowned for its wide product range, Zhejiang Huaye specializes in both seamless and welded stainless steel tubes. Their state-of-the-art facilities guarantee compliance with ASTM, ASME, and other international standards.

Plumberstar excels in producing high-quality stainless steel tubes and related fittings. With a focus on precision and durability, their products are widely utilized in plumbing and industrial applications.

This manufacturer is celebrated for its innovative approach in manufacturing stainless steel tubes. Foshan SHS integrates modern production processes to deliver products with exceptional corrosion resistance and mechanical properties.

As a significant player in the sector, Shandong Taigang showcases a strong portfolio of stainless steel tubes, utilizing advanced technology to meet varied industrial requirements. Their dedication to quality is evident in their stringent testing procedures and certifications.

These stainless steel tube manufacturers not only serve domestic demand but also play a vital role in global supply chains, highlighting China's crucial position in the stainless steel sector.

Considering the purchase of stainless steel tubes from China requires a careful evaluation of multiple essential factors to guarantee excellent quality and cost-effectiveness.

First, assess the material specifications, including grade (e.g., 304, 316, 316L), dimensions (OD, WT, Length), and compliance with international standards such as ASTM, ASME, EN, or DIN. Ensuring these parameters align with your application requirements is vital.

Secondly, evaluate the manufacturing process, distinguishing between seamless and welded tubes, as each offers different advantages in terms of strength and suitability for applications. Surface treatments like annealing, pickling, and polishing should also be considered to meet specific aesthetic and functional needs.

Supplier reliability is another critical factor. Verify certifications such as ISO, PED, and AEO, which indicate adherence to strict quality control protocols. Additionally, review the supplier's production capacity, including the number of stainless steel tube workshops and forming lines, to guarantee they can meet your volume and delivery timeline requirements.

Lastly, consider logistical aspects like lead times and shipping reliability. Efficient supply chain management and expedited delivery options enhance overall satisfaction and market responsiveness. By meticulously analyzing these factors, buyers can secure high-quality, cost-effective stainless steel tubes from China.

Selecting Vinmay as your stainless steel tube supplier offers a multitude of advantages grounded in our extensive industry expertise and commitment to quality. With over 15 years of experience, Vinmay specializes in manufacturing premium stainless steel welded tubes, catering to a wide array of industries from water supply to food and chemicals. Our product range adheres to international standards such as ASTM, EN, DIN, and AS, ensuring compliance and reliability.

Here are the key reasons to choose Vinmay:

Vinmay's technical proficiency and unwavering quality standards make us a dependable partner in the wholesale stainless steel tube industry.

Stainless steel tubes are commonly utilized in household applications for plumbing systems, kitchen appliances, heating elements, and structural supports. Their corrosion resistance, durability, and aesthetic appeal make them ideal for both functional and decorative purposes.

See Also - Stainless Steel Tube for Heat Exchanger

Vinmay promotes environmental sustainability through advanced waste management systems, energy-efficient production technologies, and rigorous adherence to environmental regulations. Continuous monitoring and optimization of resource utilization further strengthen their commitment to minimizing ecological impact while maintaining high-quality standards.

"An ounce of prevention is worth a pound of cure." Implement routine inspections, clean using gentle agents, and avoid exposure to corrosive environments. Regular maintenance guarantees peak performance and longevity of stainless steel tubes, minimizing unexpected failures.

Vinmay offers multiple shipping options for international orders, including air freight, sea freight, and express delivery. Each method guarantees secure packaging, timely dispatch, and real-time tracking to meet stringent customer requirements and international standards.

Vinmay, serving over 400 clients globally, offers custom-sized stainless steel tubes to meet unique project specifications. Their advanced production capabilities and strict quality controls guarantee precision and compliance with ASTM, EN, DIN, and AS standards.