Welding stainless steel tubing demands precision and expertise to achieve flawless results. From meticulous heat control to the selection of the right welding equipment, each step plays a vital role in the welding process. Mastering welding techniques like Gas Tungsten Arc Welding (GTAW) is essential for consistent quality, but there's more to the process than meets the eye. Understanding the challenges of welding thin stainless steel tubing and incorporating safety measures are just a few aspects that contribute to successful welds. So, how does one navigate through these intricacies to create impeccable welds on stainless steel tubing?

Stainless steel tubing plays a pivotal role across diverse industries, owing to its exceptional properties and versatility. Let's delve into the fundamentals of stainless steel tubing, exploring its composition, types, and key characteristics.

Stainless steel tubing is primarily composed of iron, chromium, nickel, and other alloying elements. The addition of chromium creates a passive oxide layer on the surface, providing resistance to corrosion and oxidation. Nickel enhances the material's ductility and toughness, making it suitable for various applications.

There are several types of stainless steel tubing, categorized based on their microstructure and properties:

See Also - Stainless Steel Pipe vs Galvanized

Stainless steel welded tubes are available in various shapes to suit different applications and design requirements:

By understanding the composition, types, and shapes of stainless steel tubing, you can select the most appropriate tubing for your project, ensuring both functionality and aesthetic appeal.

Related Article:

Stainless steel tubing exhibits several key characteristics that make it a preferred choice in various industries:

Understanding the composition, types, and key characteristics of stainless steel tubing lays the foundation for selecting the right stainless steel tube material for specific applications. Whether it's structural support in construction or fluid transport in the chemical industry, stainless steel tubing continues to prove its mettle across diverse sectors.

Recommended:

Selecting the appropriate welding equipment is crucial for achieving the best results when working with stainless steel welded tubes. High-quality welding machines and accessories ensure consistent and strong welds. When selecting equipment for stainless steel tube welding, it is imperative to prioritize precision, durability, and compatibility with the chosen welding processes.

Choosing the right stainless steel tubing welding equipment is essential for achieving superior weld quality. High-quality equipment not only enhances precision but also contributes to the overall durability and reliability of the welded joints. By investing in advanced equipment that is specifically designed for stainless steel welding processes, welders can ensure consistent and high-quality results in their welding projects.

To ensure high-quality welds, stainless steel tubing must be properly handled and prepared. Here's a streamlined checklist to get it ready for welding:

Following these steps helps set the stage for strong, clean welds and a smooth fabrication process.

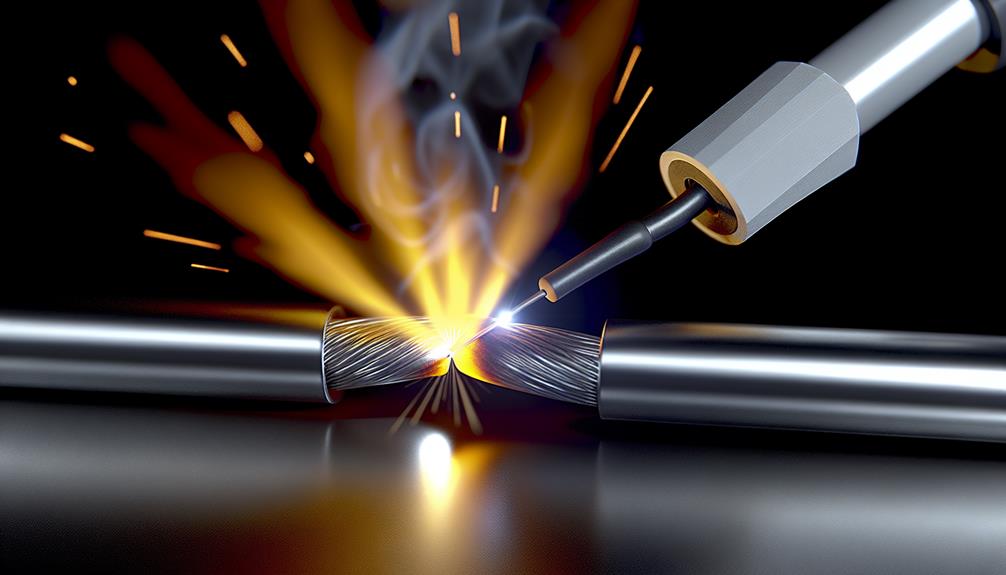

Welding stainless steel tubing requires precision, skill, and an understanding of the material's unique properties. Whether you're fabricating structural components or creating intricate assemblies, mastering welding techniques is essential for achieving strong, durable joints. Let's explore some key considerations and techniques for welding stainless steel tubing effectively.

Before diving into welding, it's crucial to consider several factors that can influence the welding process and the quality of the final weld:

TIG welding, also known as GTAW (Gas Tungsten Arc Welding), is a popular method for welding stainless steel tubing due to its precision and control. Here's a brief overview of the TIG welding process:

Related: The Difference of Stainless Steel Pipe TIG Welding and HF Welding

MIG welding, or GMAW (Gas Metal Arc Welding), is another commonly used method for welding stainless steel tubing, particularly for thicker materials or high-volume production. Here's a brief overview of the MIG welding process:

Regardless of the welding method used, adhering to best practices can help ensure successful welds and minimize the risk of defects:

Mastering welding techniques for stainless steel tubing requires practice, patience, and attention to detail. By understanding the unique properties of stainless steel and employing appropriate welding methods and best practices, you can achieve high-quality welds that meet the stringent requirements of your applications.

Recommended:

Achieving high-quality welds is paramount when working with stainless steel tubing, as weld integrity directly impacts the performance, durability, and safety of the final product. To ensure weld quality, it's essential to implement effective quality control measures and adhere to established welding standards and procedures. Let's explore some key strategies for ensuring weld quality when welding stainless steel tubing.

Before initiating the welding process, conduct a thorough inspection of the stainless steel tubing and the joint to be welded. Check for any defects, imperfections, or surface contaminants that could compromise weld quality, such as rust, scale, or oil residues. Ensure proper fit-up and alignment of the tubing components to minimize gaps and inconsistencies along the joint.

Establishing optimal welding parameters is critical for achieving high-quality welds in stainless steel tubing. Factors such as welding method, welding current, voltage, travel speed, and shielding gas flow rate should be carefully controlled and adjusted according to the specific requirements of the application and the characteristics of the stainless steel material being welded. Refer to welding procedure specifications (WPS) and qualified welding procedures to ensure proper parameter selection and adherence to industry standards.

Recommended: Stainless Steel Pipe Welding Procedure Specification

The quality and composition of the shielding gas used during welding have a significant impact on weld quality and integrity, particularly in stainless steel applications. Ensure that the shielding gas supply is free from impurities and contaminants that could cause weld defects such as porosity, oxidation, or metallurgical changes. Monitor gas flow rates, purity levels, and gas coverage to maintain an inert atmosphere around the weld pool and prevent atmospheric contamination.

After completing the welding process, perform post-weld inspection and testing to verify the quality and integrity of the welds. Visual inspection can detect surface irregularities, discontinuities, and defects such as cracks, undercut, or lack of fusion. Non-destructive testing methods such as ultrasonic testing (UT), radiographic testing (RT), or dye penetrant testing (PT) may be employed to detect internal flaws or discontinuities that are not visible to the naked eye. Conduct mechanical testing, such as tensile testing or bend testing, to assess the mechanical properties and strength of the welded joints.

Maintaining comprehensive documentation and traceability throughout the welding process is essential for quality assurance and regulatory compliance. Document welding procedure qualifications (WPQ), welding procedure specifications (WPS), welder qualifications, inspection records, and any deviations or corrective actions taken during the welding process. Ensure proper identification and labeling of welded components to facilitate traceability and quality control throughout the product lifecycle.

Continuously evaluate and improve welding processes, procedures, and techniques to enhance weld quality, productivity, and efficiency. Collect and analyze data on weld performance, defect rates, and process parameters to identify areas for optimization and implement corrective actions as necessary. Invest in training and professional development programs to empower welders with the knowledge, skills, and resources needed to consistently produce high-quality welds.

Ensuring weld quality in stainless steel tubing requires a systematic approach, attention to detail, and a commitment to continuous improvement.

Welding stainless steel tubing can sometimes present challenges, leading to various issues that affect weld quality and integrity. Understanding common welding problems and their root causes is essential for effective troubleshooting and corrective action. Let's explore some of the most prevalent issues encountered when welding stainless steel tubing and strategies for resolving them. Below is a table summarizing common issues and their troubleshooting methods:

| Welding Issue | Causes | Solutions |

|---|---|---|

| Porosity | - Contaminated shielding gas - Improper cleaning of weld area - Inadequate gas coverage | - Thoroughly clean weld area - Use high-quality shielding gas - Optimize gas flow rates and coverage |

| Cracking | - High residual stress - Sensitization of stainless steel - Inadequate filler metal or welding technique | - Control heat input - Perform post-weld heat treatment - Select appropriate filler metals |

| Lack of Fusion | - Inadequate welding heat input or travel speed - Insufficient joint preparation - Improper welding technique | - Increase heat input or reduce travel speed - Clean and prepare joint surfaces - Adjust welding parameters and technique |

| Distortion | - Non-uniform heating and cooling - Inadequate clamping or fixturing - Excessive heat input or improper technique | - Proper clamping and fixturing - Control heat input and welding parameters - Use proper welding sequence and technique |

| Surface Discoloration | - Excessive heat or prolonged welding duration - Inadequate shielding gas coverage - Contamination of welding environment | - Optimize welding parameters - Ensure adequate shielding gas - Thoroughly clean and degrease weld area |

Upon encountering thin stainless steel tube welding, welders face specific challenges due to the material's low thermal conductivity and susceptibility to warping during the welding process.

GTAW provides controlled heat input, minimizing distortions and burn-through, crucial for thin stainless steel welding. Orbital welding simplifies the process, ensuring uniform welds around the tube circumference without interruptions.

Utilizing back purge welding techniques is essential for ensuring optimal shielding and preventing contamination during the welding process. Back purging removes contaminants and provides backing during welding, shielding the back side of the weld to prevent heavy oxides. In open-root pipe welding, the risk of sugaring increases without back purging. To protect the weld, purge dams, vent holes, and tape are commonly used. However, the modified short-circuit Gas Metal Arc Welding (GMAW) process offers a solution by eliminating the need for back purging, saving time and costs. This advancement in welding technology enhances productivity, efficiency, and ease of use, making it a valuable technique for welding stainless steel tubing.

| Back Purge Welding Benefits | Description |

|---|---|

| Optimal Shielding | Ensures protection of the back side of the weld. |

| Contamination Prevention | Prevents the formation of heavy oxides and sugaring risks. |

| Cost and Time Savings | Eliminates the need for back purging, saving resources. |

Safety is paramount when welding stainless steel tubing. Here are key safety measures to prioritize:

By following these safety guidelines, you can create a secure working environment for welding stainless steel tubing.

To prevent discoloration on stainless steel tubing during welding, control heat input, utilize proper shielding gases, and consider using anti-oxidation compounds. Employing precise techniques and maintaining cleanliness can help achieve a uniform, corrosion-resistant finish.

To prevent distortion when welding thin stainless steel tubes, meticulous heat management is imperative. Employ strategies like preheating, controlled heat input with Gas Tungsten Arc Welding (GTAW), and welding in quarters to mitigate warping. Precision in heat control ensures distortion-free welds.

A recommended post-welding treatment for stainless steel tubing involves passivation, a process that enhances corrosion resistance by removing contaminants and forming a protective oxide layer. Passivation ensures the tubing's longevity and maintains its quality.

To ensure consistent weld penetration on stainless steel tubing, meticulous control of heat input and welding parameters is imperative. Employ advanced techniques like pulse welding or modified short-circuit processes for precise penetration and optimal weld quality.

To prevent contamination during stainless steel tube welding, meticulous attention to cleanliness is paramount. Utilize dedicated tools, ensure work surfaces are free of debris, and adhere to strict protocols for handling materials. Contamination control is essential for high-quality welds.

In conclusion, mastering the art of welding stainless steel tubing requires precision, skill, and attention to detail. By prioritizing proper heat management, selecting the right equipment, and mastering welding techniques, one can achieve high-quality and durable connections.

Remember, patience and practice are key to overcoming common welding issues and challenges. So, keep calm and weld on with finesse and expertise!

For premium stainless steel welded tube solutions crafted with precision and excellence, turn to Vinmay, the trusted stainless steel tubing manufacturer known for its commitment to quality and innovation. Enhance your projects with Vinmay's top-notch products and expertise. Contact Vinmay today and elevate your stainless steel tubing experience!

Read More: How to Weld Stainless Steel Tubing Like a Pro