You might not realize that 316L welded stainless steel pipe is specifically designed to withstand harsh chemical environments, making it a preferred choice in industries like pharmaceuticals and food processing.

Its unique low-carbon composition plays a crucial role during welding, preventing common issues that can compromise integrity. Understanding the nuances of its properties and production can reveal why it's often the go-to material for demanding applications. What you discover next could change how you approach material selection in your projects.

316L stainless steel is a low-carbon version of 316 stainless steel, specifically designed to enhance corrosion resistance, particularly in environments exposed to chlorides and acids. Its alloy composition typically includes chromium, nickel, and molybdenum, ensuring heightened durability against aggressive substances.

When you consider welding techniques, 316L's low carbon content minimizes the risk of carbide precipitation, making it ideal for welded structures that require high integrity. This grade is particularly advantageous in environments like coastal areas or chemical processing facilities, where exposure to saltwater or harsh chemicals is common.

Surface finishes play a critical role in furthering its corrosion resistance; a polished finish can enhance both aesthetics and protective qualities. Moreover, various fabrication methods—such as machining and forming—are compatible with 316L, allowing you to mold it to your specific needs.

Ultimately, the selection of 316L stainless steel reflects a commitment to quality and longevity, ensuring that your projects stand the test of time while maintaining safety and hygiene standards. Whether in medical equipment, food processing, or marine applications, 316L offers reliable performance in demanding environments.

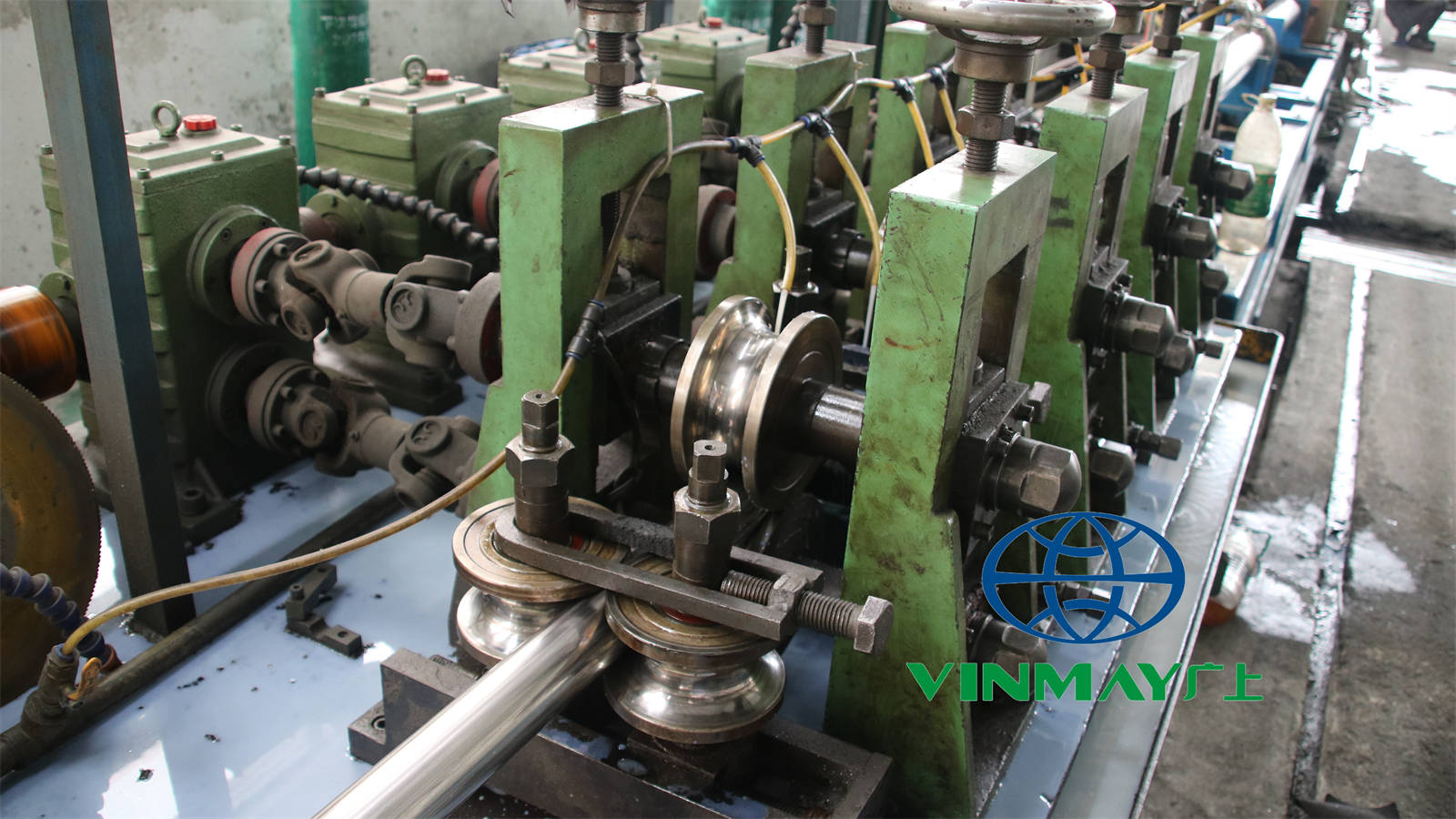

To understand the production process of 316 welded stainless steel pipe, you need to consider three critical stages: material preparation, welding, and polishing.

You'll start with meticulous preparation of the stainless steel, followed by the application of orbital TIG welding, which ensures a strong and precise joint.

The production process of welded stainless steel pipes involves meticulous material preparation that ensures optimal performance and durability in demanding environments.

You'll begin with careful material sourcing, selecting high-grade 316 stainless steel, known for its superior corrosion resistance.

After obtaining the materials, the next step is surface treatment. This process involves cleaning and finishing the steel to remove any contaminants that could compromise the integrity of the weld.

Following surface preparation, you'll employ precise fabrication processes. This includes cutting the steel into the required lengths and shaping it to desired specifications. Once the pieces are ready, you'll need to consider various welding techniques to ensure strong and reliable joints.

Finally, rigorous quality assurance measures are implemented. This involves inspections and testing to verify that every pipe meets the necessary standards before it's approved for use in critical applications.

Here's a quick summary of key aspects:

Material sourcing of high-grade 316 stainless steel.

Effective surface treatment for optimal cleanliness.

Stringent quality assurance to ensure reliability.

Orbital TIG welding is a highly precise method used for joining 316L stainless steel, ensuring strong, consistent welds essential for applications in demanding environments. This welding technique utilizes a rotating electrode to create uniform welds, crucial for maintaining weld quality in critical applications.

You'll focus on joint design, ensuring it accommodates the thermal expansion and contraction that occurs during the welding process. Proper heat treatment before and after welding is vital to prevent issues such as distortion or hardening. Maintaining optimal heat input minimizes the risk of weld defects, ensuring the integrity of the final product.

After completion, post weld inspection becomes essential. This step allows you to assess the welds for any imperfections, ensuring they meet stringent industry standards.

After ensuring the integrity of welds through meticulous inspection, polishing becomes a vital step in the production process of 316 welded stainless steel pipes, enhancing both aesthetics and corrosion resistance.

You'll find that effective polishing techniques can significantly impact the final surface finishes, which are crucial for various applications.

Using appropriate abrasive materials, you can achieve a smooth and reflective surface that minimizes impurities and enhances durability.

Additionally, buffing methods can further refine the finish, providing a polished look that meets industry standards.

To ensure optimal results, consider the following:

Polishing techniques: Choose between mechanical or chemical methods based on your requirements.

Surface finishes: Aim for a finish level that aligns with the intended application and environment.

Buffing methods: Implement rotary or orbital buffing to achieve desired aesthetics.

Equipment maintenance: Regularly maintain polishing equipment to ensure consistent performance and quality.

Learn More:

When considering 316L welded stainless steel pipe, you'll find its versatility spans multiple industries, including chemical processing and water treatment.

It excels in pulp and paper applications due to its resistance to corrosive substances, while also meeting the stringent hygiene requirements of the medical sector.

Additionally, its durability makes it a reliable choice in automotive manufacturing, ensuring longevity and performance under demanding conditions.

chemical containers, pressure vessels, and industrial equipment

woven or welded screens for water filtration

used in paper machines to avoid iron contamination.

threaded fasteners, springs, and furnace parts

medical equipment and orthopedic implants

dental implants, orthodontic appliances, and various dental instruments

semiconductor manufacturing equipment and cleanroom environments

food preparation surfaces, equipment, and appliances

aircraft structures, fasteners, turbine blades, and exhaust systems

304 and 316 stainless steel are both durable and resistant to corrosion, but 316 has superior protection, especially in harsh environments like saltwater or chemical exposure. The main difference is that 316 contains molybdenum, which makes it more resistant to corrosion and pitting, particularly in chloride-rich environments. While 304 is ideal for general use in kitchen equipment, food processing, and architecture, 316 is better suited for marine, chemical, or pharmaceutical applications where extra corrosion resistance is needed.

In terms of strength, 316 is slightly stronger than 304, with better resistance to high temperatures and stress. Both steels are non-magnetic in their annealed state, though they can become magnetic when cold-worked. The downside of 316 is that it tends to be more expensive than 304, due to the added molybdenum. Ultimately, the choice between 304 and 316 depends on the specific environmental conditions and budget of your project.

When comparing 316 vs. 316L stainless steel, the key difference lies in their carbon content and the resulting impact on their weldability, corrosion resistance, and high-temperature performance.

316 stainless steel stands out for its exceptional corrosion resistance, particularly in harsh environments, making it an ideal choice for applications ranging from medical equipment to marine components. Its unique composition enhances its resistance to chlorides and acids, providing reliability in demanding settings.

Here's a brief comparison of 316 stainless steel and its key attributes:

| Property | 316 Stainless Steel | 316L Stainless Steel | 304 Stainless Steel |

|---|---|---|---|

| Corrosion Resistance | Excellent | Excellent | Good |

| Ideal for Medical Use | Yes | Yes | No |

| Foodservice Applications | Yes | Yes | Yes |

| Coastal Durability | High | High | Moderate |

When you choose 316 stainless steel, you're ensuring longevity and performance in applications exposed to cleaning agents and the elements. Its superior resistance makes it perfect for foodservice applications, where hygiene is paramount. Moreover, its durability in coastal environments means it can withstand saltwater exposure without compromising integrity. Ultimately, selecting 316 stainless steel means investing in quality and reliability for your projects.

You may also like:

What Is the Difference Between 201 and 304 Stainless Steel?

Selecting the right stainless steel grade for process piping is crucial to ensure optimal performance and longevity in various industrial applications. You'll want to assess the environment where the piping will operate, focusing on pipe corrosion potential and material compatibility with transported substances. For instance, if you're dealing with aggressive chemicals, opting for a grade like 316L is advisable due to its superior resistance to corrosion.

Conduct a thorough cost analysis that weighs higher initial costs against long-term savings from reduced maintenance and replacement. Design considerations should also take into account pressure, temperature, and flow rates, as these factors can influence the appropriate stainless steel selection.

When it comes to installation techniques, ensure that your method aligns with the chosen material's specifications to prevent future issues. By carefully evaluating these elements, you can enhance not just performance but also safety in your process piping systems.

Ultimately, understanding the unique requirements of your application will help you make informed decisions, fostering a sense of belonging in a community focused on quality and reliability.

Blog Series:

The Comprehensive Guide to Grade 316 Stainless Steel Structural Tube

316 Stainless Steel Tube Mechanical Properties Introduction

316 Stainless Steel Tube Properties: Key Insights for Engineers and Designers

In summary, 316L welded stainless steel pipe stands as a sturdy sentinel against corrosion, making it a top choice for industries that navigate harsh environments.

Its unique properties and advanced production techniques ensure not just reliability but also cost efficiency over time.

When you choose 316L, you're not just selecting a material; you're investing in durability and performance that withstands the test of time, much like a well-crafted ship braving the stormy seas.