The application of 304 stainless steel welded pipe is diverse , being commonly used in machinery , architectural , chemical ,food and beverage and cryogenic industries

In machinery, it is used in components such as valves, pumps, and fasteners.

Architecturally, it is used for cladding and handrails, as well as for structural frameworks.

In chemical industries, it is used in process piping systems and heat exchangers.

In the food and beverage industry, it is used for its corrosion resistance and non-contamination properties.

Lastly, in the cryogenic industry, 304 stainless steel welded pipe is used for its strength and durability in extreme temperatures.

Workability of 304 stainless steel welded pipe is facilitated by its high corrosion resistance and excellent formability. When it comes to welding techniques, the 304 stainless steel welded pipe offers versatility. Proper joint preparation is important to guarantee strong welds, including cleaning the surfaces to be welded thoroughly.

Welding parameters, such as appropriate heat input and welding speed, play a significant role in achieving high-quality welds. Utilizing the right welding equipment, like TIG or MIG welders, is essential for a successful welding process. Additionally, observing welding safety measures, including wearing protective gear and ensuring proper ventilation in the workspace, is crucial to safeguard against potential hazards.

The ease of welding 304 stainless steel welded pipe makes it a preferred choice in various industries where efficient and reliable welding is necessary.

Facilitating efficient machining processes, the cutting workability of 304 stainless steel welded pipe is characterized by its moderate nature, offering a balance between ease of cutting and structural integrity.

Precision cutting and welding techniques are essential in ensuring clean cuts without compromising the pipe's overall strength. Custom stainless steel tubing fabrication and finishing options further enhance the versatility of 304 stainless steel welded pipe, allowing for tailored solutions to meet specific project requirements.

When working with 304 stainless steel welded pipe, adherence to industry regulations and safety precautions is paramount to prevent accidents and ensure a secure working environment.

Quality control and inspection procedures play a crucial role in maintaining the high standards expected in the industry, guaranteeing the reliability and durability of the finished products. Moreover, considering the environmental impact, sustainability initiatives are increasingly important in the production and handling of stainless steel tube materials, promoting responsible practices and reducing ecological footprints.

| Category | Description | Importance |

|---|---|---|

| Precision Cutting | Clean cuts without compromising strength | High |

| Custom Fabrication | Tailored solutions for specific needs | Medium |

| Industry Regulations | Compliance with safety standards | High |

| Sustainability | Environmental impact reduction initiatives | High |

Efficient forming processes for 304 stainless steel welded pipe demand meticulous attention to detail and adherence to precise manufacturing techniques. Welding techniques play an essential role in ensuring the integrity of the welded joints during forming operations.

Proper heat treatment is necessary to maintain the material's mechanical properties and prevent unwanted deformations. Surface finishing after forming is crucial to enhance the aesthetic appeal and improve corrosion resistance, especially in harsh environments.

Quality control measures must be implemented throughout the forming process to detect any defects or inconsistencies that could compromise the final product's performance. By carefully managing these factors, stainless steel tube manufacturers can produce 304 stainless steel welded pipes with excellent workability and structural integrity, meeting the highest industry standards.

During the machining process of 304 stainless steel welded pipe, attention to detail in tool selection and cutting parameters is vital to guarantee precise shaping and dimensional accuracy.

Utilizing the appropriate welding techniques ensures a strong and durable welded pipe. Surface finishing techniques such as polishing or grinding enhance the aesthetic appeal and corrosion resistance of the stainless steel pipe.

Precision cutting methods like laser cutting or abrasive water jet cutting are essential for achieving intricate designs and maintaining tight tolerances in metal fabrication projects.

Additionally, heat treatment techniques can be applied to the welded pipe to improve its hardness, strength, and overall performance.

The mechanical characteristics of 304 stainless steel welded pipe play a vital role in determining its suitability for various industrial applications. 304 stainless steel is renowned for its excellent corrosion resistance and attractive surface finish, making it a popular choice in industries where exposure to harsh environments is common.

The mechanical properties of 304 stainless steel welded pipe include:

Tensile Strength: 505 MPa (min)

Yield Strength (0.2% offset): 215 MPa (min)

Elongation (in 50mm): 40% (min)

Hardness:

These properties make 304 stainless steel suitable for a wide range of applications, including piping systems, food processing equipment, and architectural components, due to its balance of strength, ductility, and corrosion resistance.

ASTM A269 is a standard specification from ASTM International that outlines requirements for seamless and welded austenitic stainless steel tubing intended for general service.

Key Points of ASTM A269

Purpose: ASTM A269 covers both seamless and welded austenitic stainless steel tubing for general corrosion-resisting and low- or high-temperature service.

Grades: Includes several grades of stainless steel, commonly 304, 304L, 316, and 316L, among others, each providing different levels of corrosion resistance and mechanical properties.

Manufacturing Process: Tubing covered under this specification can be produced through seamless or welded methods, with appropriate heat treatments to ensure desired properties.

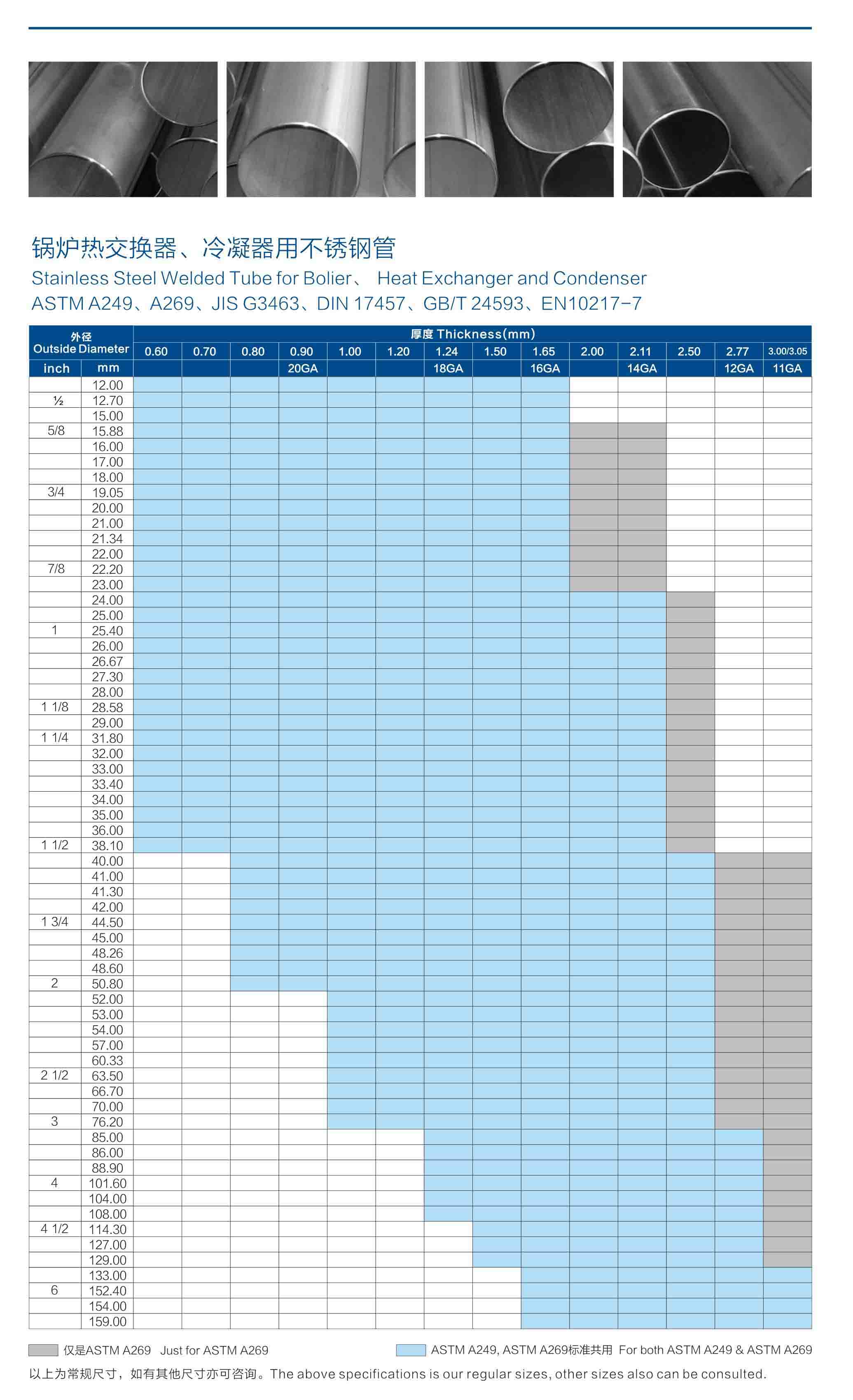

Sizes and Dimensions: Specifies the permissible dimensions, including outside diameter and wall thickness, ensuring consistent and reliable tube sizes.

Mechanical Properties: Defines the mechanical properties such as tensile strength and yield strength that the tubing must meet.

Surface Condition: Outlines the requirements for the surface condition of the tubing, which should be free from scale and have a smooth finish.

Testing: Tubing must undergo various tests, such as tension tests, flattening tests, and hydrostatic tests, to ensure it meets the required standards.

Applications: Commonly used in various industries for general service applications, including in chemical plants, food processing, oil and gas industries, and more.

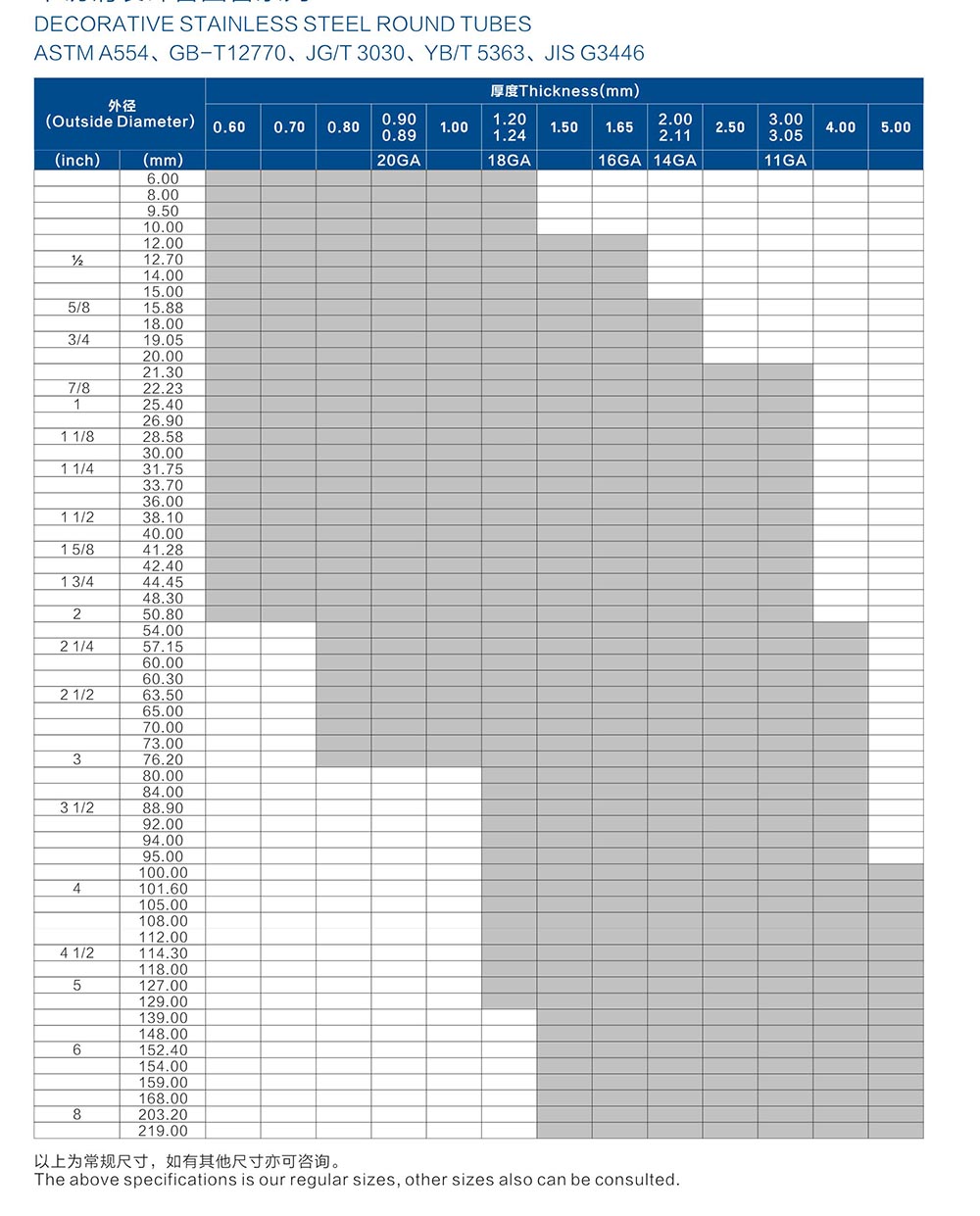

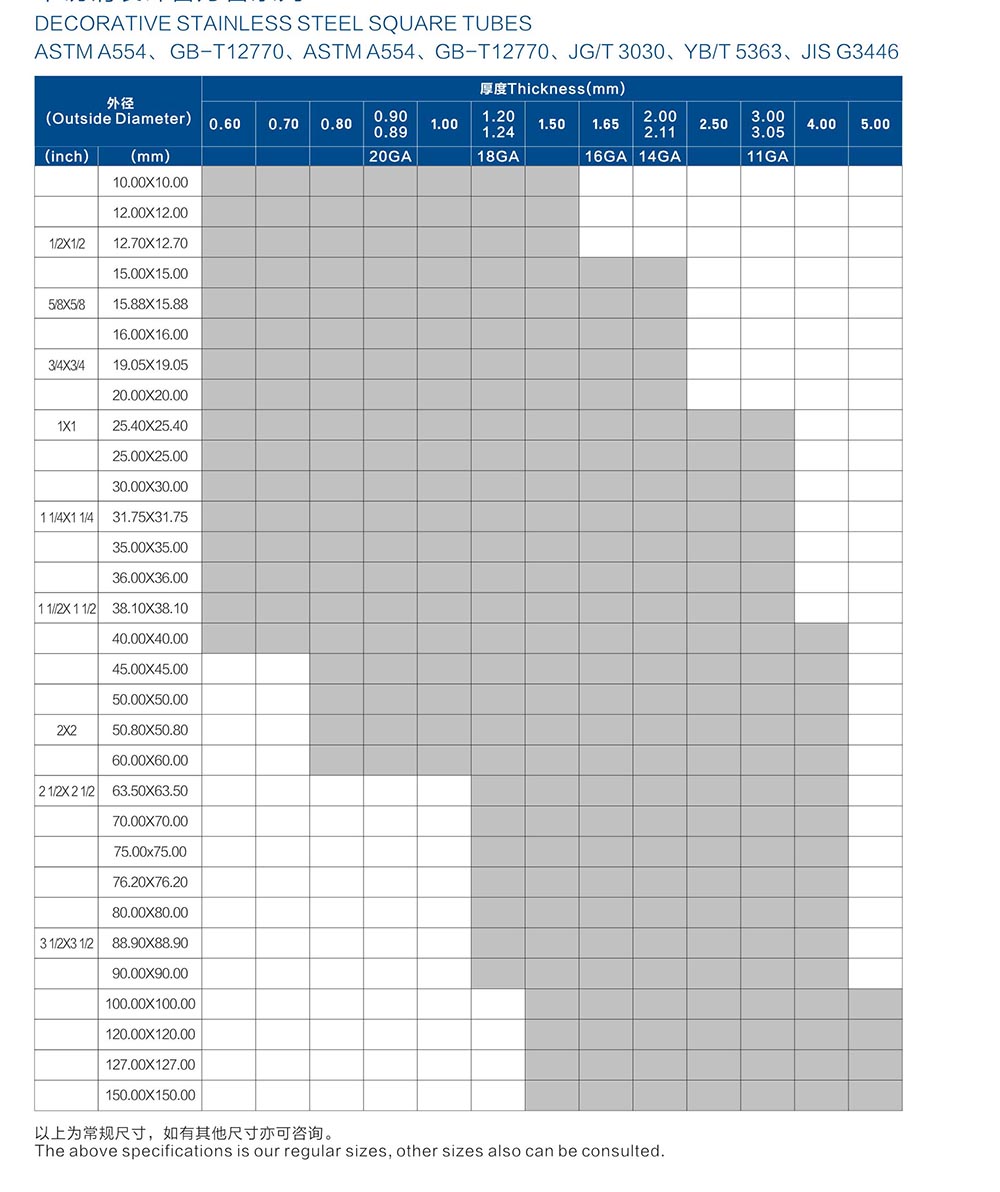

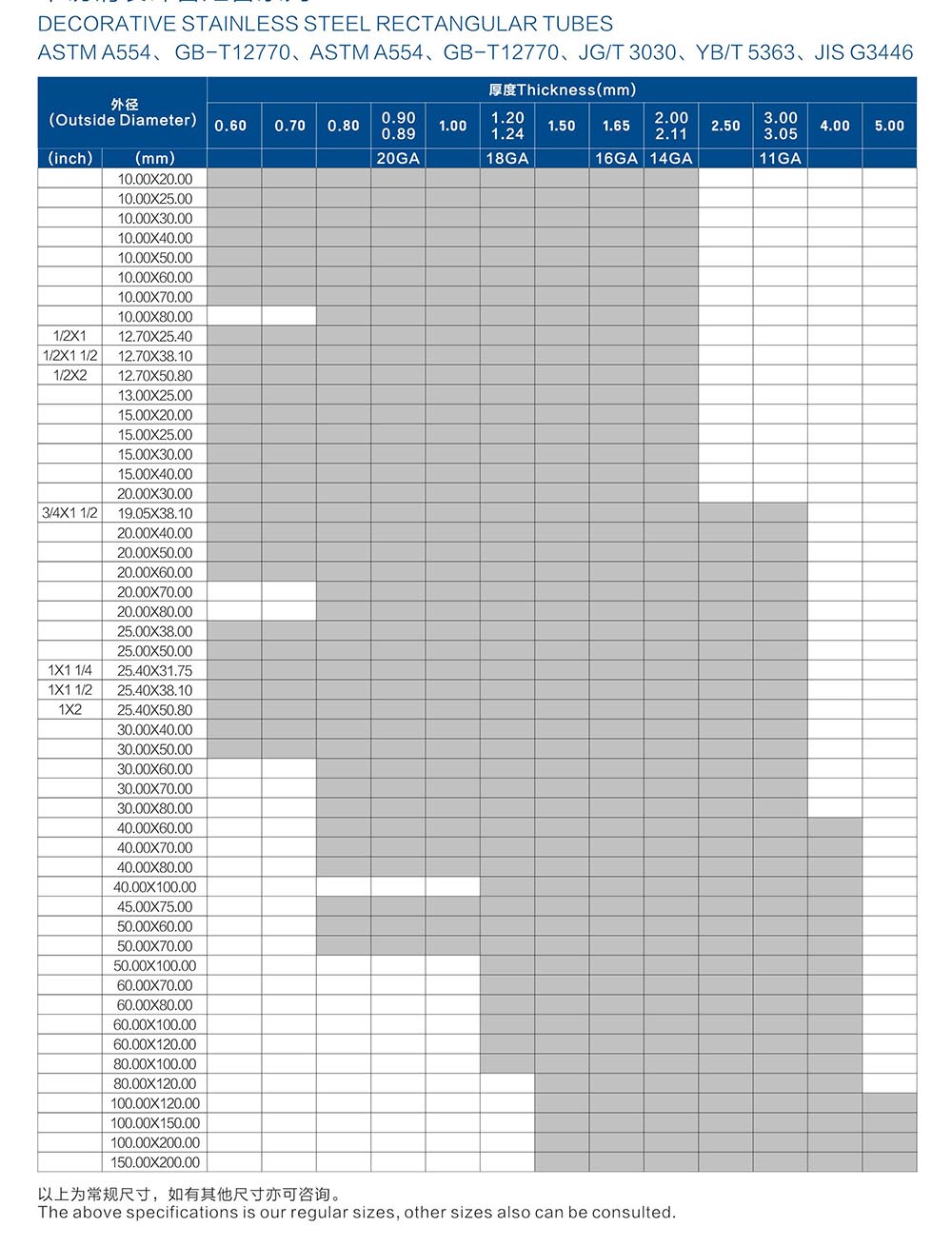

ASTM A554 is a standard specification from ASTM International for welded stainless steel mechanical tubing.

Key Points of ASTM A554

Purpose: ASTM A554 covers welded stainless steel tubing intended for mechanical and structural purposes, where appearance, mechanical properties, or corrosion resistance are important.

Grades: The standard includes several grades of stainless steel, commonly 201, 304, 316, and others, each offering different levels of corrosion resistance and mechanical properties.

Manufacturing Process: The tubing is produced by welding stainless steel strips together and may be further processed (e.g., annealing, pickling) to improve its properties.

Sizes and Dimensions: It specifies the dimensions, such as outside diameter and wall thickness, with permissible variations to ensure uniformity and quality.

Surface Finish: ASTM A554 specifies the types of surface finishes for the tubing, including polished finishes that are important for decorative applications.

Mechanical Properties: It outlines the mechanical properties such as tensile strength and yield strength that the tubing must meet.

Applications: Commonly used in architectural and ornamental applications, structural components, and various industrial uses where appearance and mechanical integrity are essential.

ASTM A312 is a standard specification from ASTM International for seamless, welded, and heavily cold worked austenitic stainless steel pipes intended for high-temperature and general corrosive service. Here's a simple explanation:

Key Points of ASTM A312

Purpose: ASTM A312 covers seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipes intended for high-temperature and general corrosive service.

Grades: The standard includes several grades of stainless steel, such as 304, 304L, 316, 316L, and others, each offering different levels of corrosion resistance and mechanical properties.

Manufacturing Process:

Sizes and Dimensions: Specifies the dimensions of the pipes, including outside diameter and wall thickness, with permissible variations to ensure uniformity and quality.

Mechanical Properties: Defines the mechanical properties such as tensile strength and yield strength that the pipes must meet.

Surface Condition: Outlines the requirements for the surface finish, ensuring the pipes are free from scale and other surface defects.

Testing: Pipes must undergo various tests, such as tension tests, flattening tests, and hydrostatic tests, to ensure they meet the required standards.

Applications: Commonly used in industries where high-temperature and corrosive conditions are prevalent, such as in chemical processing, oil and gas, power generation, and more.

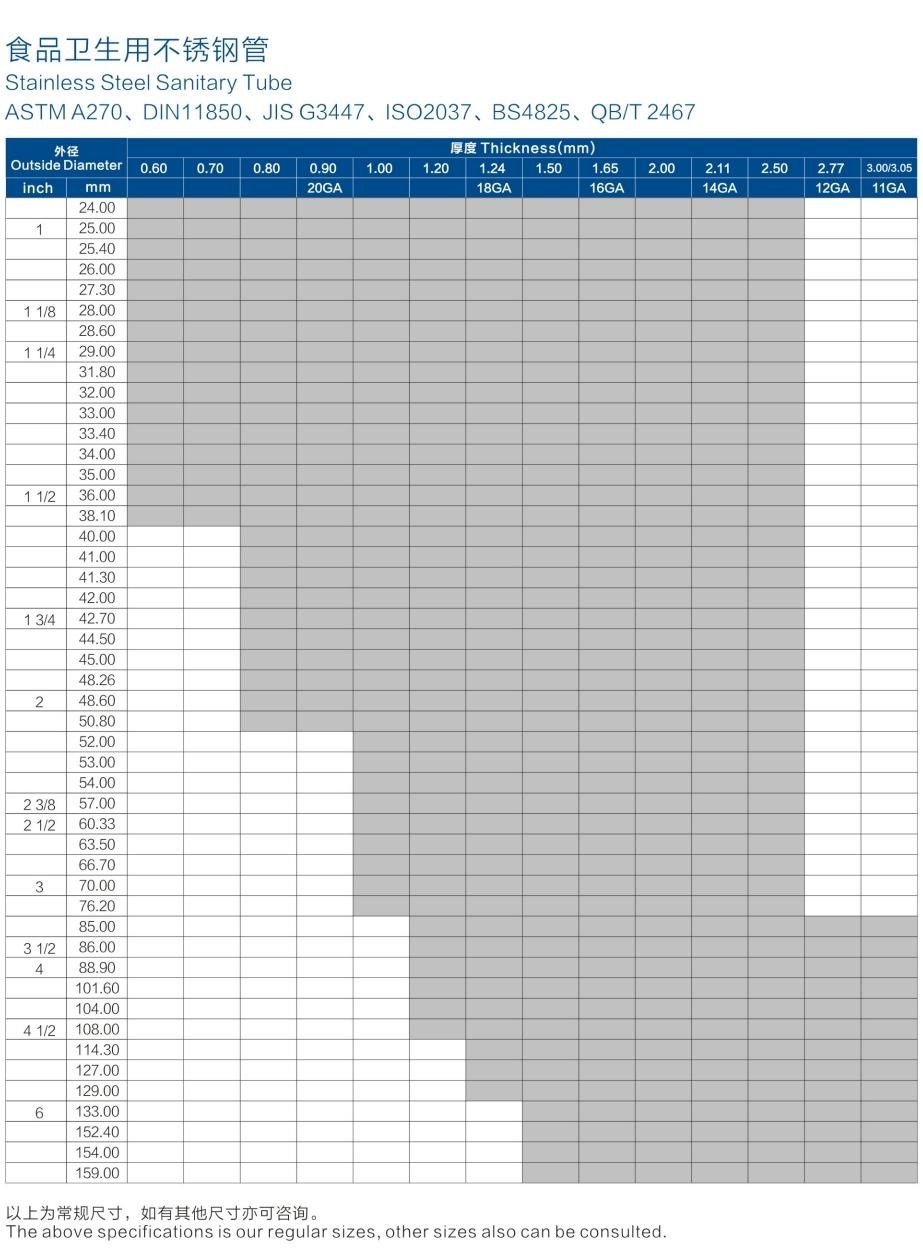

ASTM A270 is a standard specification from ASTM International for seamless and welded austenitic and ferritic/austenitic (duplex) stainless steel sanitary tubing. Here's a simple explanation:

Key Points of ASTM A270

Purpose: ASTM A270 covers seamless and welded austenitic and duplex stainless steel sanitary tubing intended for use in the dairy and food industry, as well as in the pharmaceutical industry.

Grades: Includes several grades of stainless steel, such as 304, 304L, 316, 316L, and duplex grades like 2205, each providing different levels of corrosion resistance and mechanical properties.

Manufacturing Process:

Sizes and Dimensions: Specifies the permissible dimensions, including outside diameter and wall thickness, ensuring consistent and reliable tube sizes.

Surface Finish: Outlines the requirements for the surface finish of the tubing, which must be smooth and polished to a specified level (e.g., Ra value), ensuring it is suitable for sanitary applications.

Mechanical Properties: Defines the mechanical properties such as tensile strength and yield strength that the tubing must meet.

Testing: Tubing must undergo various tests, such as tension tests, flattening tests, and hydrostatic tests, as well as specific tests for surface finish quality.

Applications: Commonly used in the dairy, food, and pharmaceutical industries where sanitary conditions are critical, as well as in other industries requiring high levels of cleanliness and corrosion resistance.

Moreover, A249 addresses the surface finish requirements, ensuring a smooth and consistent appearance that meets industry standards.

304 and 316 stainless steel are both popular grades of stainless steel, however, there are important distinctions between them.

On a chemical level, 304 stainless steel contains 18% chromium and 8% nickel while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. This difference in chemical composition gives 316 stainless steel superior corrosion resistance compared to 304 stainless steel.

Price-wise, 316 stainless steel is usually more expensive than 304 stainless steel. However, this difference in stainless steel price is usually minimal and the cost of corrosion prevention must also be taken into account.

In terms of usage, 304 stainless steel is typically used for kitchen sinks, medical equipment, and architectural applications while 316 stainless steel is often used for chemical processing equipment, marine applications, and in the food and beverage industry.

You may also like:

The Ultimate Guide to 316 Stainless Steel Welded Pipes

What is the difference between 201 and 304 stainless steel?

304 stainless steel welded pipe is the most popular product in Foshan Vinmay Stainless Steel Co.,ltd. Vinmay's 304 stainless steel pipe stands out from the competition due to its superior raw material, thickness and outer diameter, outer surface, welded line, and mechanical properties.

Raw Material

Analysis of raw materials used for the production of stainless steel welded pipes is essential. Vinmay's commitment to high-quality raw materials ensures that their 304 stainless steel welded pipes are reliable and durable.

All of the raw material in Vinmay are from TISCO, BAOSTEEL, TSINGSHAN and other high quality steel supply refining furnace materials, which can make sure a high stability and corrosion resistance to all of our products. In addition, we can provide the quality inspection report of raw materials.

Thickness and Outer Diameter

Stainless steel welded pipes are produced according to international stainles steel tube standards of tolerance, and have a wide range of thickness and outer diameter variations. This makes them ideal for use in fittings assemblies, as they are easy to work with and have a reliable degree of accuracy.

This allows for the construction of complex, interdependent parts and structures in a safe and efficient manner.

You may also like:

A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

Outer Surface

The outer surface of a stainless steel welded pipe is of great importance. All of the stainless steel welded pipe from Vinmay are Free from press point, scratches, black spot. And the mirror finish of 600 grit stainless steel pipe are close to Taiwanese and Italian producers, what’s more the outside welded lines of our stainless steel welded pipe are invisible

Welded Line

Welded lines are a critical component of stainless steel pipes, requiring precision in their execution. Fully T.I.G welding is used to ensure that the weld bead has a maximum height of 0.2mm, which enables the pipe to be easily bent to the desired shape.

Mechanical Properties

Flaring, flattening and flange testings allow us to follow standards: EN 10217-7, EN 10312, DIN11850(EN10357) , ASTM 249/269 and 270

Pipe Inner Surface

The inner surface of welded stainless steel pipe is of great importance to the overall quality of the pipe. All of the pipe from Vinmay are Removing the inside bead of the welded area reduces the roughness of the surface below 1.6 Ra. With further polishing of the inside surface, the roughness can be further decreased to a range of 0.4-0.8 Ra. And what’s more All of our tubes are in100% inside cleaning ( ultrasonic wave and wipe)

In the field of materials engineering, understanding the temperature limits of 304 stainless steel welded pipes is vital. It's important to take into account their corrosion resistance, thermal expansion tendencies, mechanical properties, and welding procedures to guarantee peak performance.

When considering high-pressure systems, it is essential to assess corrosion resistance, material composition, and pressure ratings. Factors such as strength, durability, welding techniques, and cost effectiveness play a vital role in determining suitability.

Are there specific welding techniques required for 304 stainless steel welded pipe? Achieving a strong weld involves selecting appropriate welding methods, ensuring proper heat treatment, optimizing joint design, choosing suitable filler materials, and executing thorough post-weld cleaning procedures.