304 stainless steel square tubing is an essential component in many industrial and commercial applications. This type of stainless steel steel tubing offers excellent corrosion resistance, durability, and strength, making it an ideal choice for a variety of uses. Its properties make it an ideal choice for applications in which temperature, pressure, and other environmental factors may be present.

Additionally, it can be easily fabricated and welded for complex applications. This article will provide an overview of the properties, advantages, applications, and purchasing considerations of 304 stainless steel square tubing.

304 stainless steel square tubing is a corrosion-resistant material commonly used in architectural and industrial applications. It is highly resistant to oxidation and is also non-magnetic. This type of square tubing is made from an alloy of chromium and nickel and provides excellent tensile strength when compared to other metals. It is also relatively cost-effective and can be easily welded using standard welding techniques. Its product standards are also widely accepted, making it a reliable choice for many projects.

Benefiting from a combination of strength and corrosion resistance, 304 stainless steel square tubing is an excellent choice for many applications. Its cost-effectiveness and versatility make it a popular choice for construction projects. The material is known for its impressive strength properties and can be welded using conventional welding techniques.

304 stainless steel is resistant to oxidation and is easy to clean and maintain. It is often used in the food industry pipe and other applications that require sanitary conditions. The material is also known for its strong corrosion resistance, making it an ideal choice for outdoor construction projects.

In addition, 304 stainless steel square tubing is highly resistant to heat and can withstand extreme temperatures. This makes it a popular choice for the automotive industry, where it is used to create parts and components. It is also commonly used in the manufacture of medical equipment.

The strength and corrosion resistance of 304 stainless steel square tubing makes it an ideal choice for a variety of applications. From construction projects to medical equipment, the material is a cost-effective and versatile choice.

You may also like:

The Reality of 304 Stainless Steel Surgical Grade: Pros, Cons, and Critical Considerations

With its superior strength and corrosion resistance, 304 stainless steel square tubing offers numerous advantages and benefits.

304 stainless steel square tubing is an ideal material for many applications due to its corrosion resistance, easy installation, cost savings, strength and durability, and aesthetic appeal. This makes it an ideal material for many industrial, construction, and architectural applications. Its relatively low cost, versatile formability, and attractive mirror and satin finish make it an ideal choice for many projects. Its versatility makes it suitable for a wide range of projects, from plumbing and drainage systems to exterior fixtures, furniture, and ornamental pieces.

These advantages make 304 stainless steel square tubing an ideal material for any project. It is an excellent choice for projects that require strength, durability, and aesthetic appeal. Its advantages make it an attractive option for projects both small and large. The cost savings and low maintenance make it an ideal choice for any project that requires an eye-catching finish and superior strength. Its ease of installation makes it an ideal choice for any project that requires quick installation.

The advantages and benefits of 304 stainless steel square tubing make it an ideal material for many applications. It is an excellent choice for projects that require strength, durability, and aesthetic appeal. Its cost savings, easy installation, and corrosion resistance make it an ideal choice for any project. With its many advantages and benefits, 304 stainless steel square tubing is a great choice for any project.

The next section will discuss the various applications of 304 stainless steel square tubing.

Learn More: Exploring the Advantages of Stainless Steel Square Tubing

Numerous applications benefit from the use of 304 stainless steel square tubing due to its superior strength and corrosion resistance. From automotive uses to medical equipment, industrial facilities, and kitchen appliances, the wide range of applications for this material is virtually limitless.

304 stainless steel square tubing is often used for outdoor activities as it is highly resistant to the elements.

The automotive industry utilizes 304 stainless steel square tubing for exhaust systems, brackets, and clamps. In the medical field, it is used to construct medical equipment, such as hospital beds, IV poles, and stretchers. Industrial facilities can use 304 stainless steel square tubing for conveyor systems, railings, and support frames.

Kitchen appliances, such as refrigerators, stoves, and ovens, use 304 stainless steel square tubing for the manufacture of shelves, drawers, and hoses. Additionally, it is often used to construct outdoor furniture, such as benches, tables, and chairs.

Finally, 304 stainless steel square tubing is often used in marine applications due to its high resistance to saltwater corrosion. Therefore, it is a popular choice for boat trailers, mooring cables, and other marine components.

Related Article: Applications of Stainless Steel Square Tubing Revealed

Building upon its superior strength and corrosion resistance, 304 stainless steel square tubing can also be worked into a variety of shapes and sizes using various fabrication techniques. Welding techniques, cutting methods, bending tools, forming specs, and finishing processes can all be used to create a custom-made piece that meets the exact specifications of the project.

When welding 304 stainless steel square tubing, it is important to make sure that the weld is free from any defects or cracks. It is also important to use a welding technique that is suitable for the thickness and size of the square tubing. Many welding techniques, such as TIG, MIG, and stick welding, can be used to weld 304 stainless steel square tubing.

Cutting methods for 304 stainless steel square tubing include sawing, shearing, and laser cutting. Bending tools, such as a press brake, can be used to form the tubing into a specific shape. The forming specs of the square tubing should also be taken into consideration when selecting the right bending tool.

Finally, finishing processes such as grinding, sanding, and polishing can be used to create a smooth, even surface on the tubing. It is important to apply the finishing process carefully to achieve the desired outcome.

Learn More: Mastering Fabrication Techniques for Stainless Steel Square Tubing

Once the desired shape and size of the 304 stainless steel square tubing has been achieved, it is important to take proper care and maintenance measures to ensure its longevity. This includes the selection of the right product for the job, proper installation techniques, and cleaning and corrosion prevention techniques.

When selecting the right product, the surface finish and wall thickness must be taken into account. After installation, regular cleaning is essential to prevent dirt and debris build-up, as well as corrosion. Using a soft cloth, warm water, and mild soap can help maintain the appearance and extend the life of the tubing. To reduce the risk of corrosion, coat the tubing with an appropriate sealant or paint.

With the right product selection, installation, and cleaning techniques, 304 stainless steel square tubing can last for many years. These maintenance and care tips provide a good foundation for comparison with other 300 series stainless steel grades in the subsequent section.

When comparing 304 stainless steel square tubing to other 300 series stainless steel tubing, one must consider several factors:

Here's a comparison table highlighting key properties of various types of stainless steel within the 300 series:

| Properties | 302 | 303 | 304 | 316 | 321 | 347 | 309/310 | 330 |

|---|---|---|---|---|---|---|---|---|

| Alloy Composition | Chromium: 17-19%, Nickel: 8-10% | Chromium: 17-19%, Nickel: 8-10%, Sulfur: 0.15% | Chromium: 18-20%, Nickel: 8-10.5% | Chromium: 16-18%, Nickel: 10-14%, Molybdenum: 2-3% | Chromium: 17-19%, Nickel: 9-13%, Titanium: 5xC to 0.70% | Chromium: 17-19%, Nickel: 9-13%, Niobium: 10xC to 1.0% | Chromium: 22-24%, Nickel: 12-15% | Chromium: 17-20%, Nickel: 34-37% |

| Corrosion Resistance | Good | Good | Excellent | Excellent | Good | Good | Good | Excellent |

| Strength | High | Moderate | Good | Moderate | High | High | High | High |

| Heat Resistance | Good | Good | Good | Excellent | Excellent | Excellent | Excellent | Excellent |

| Weldability | Good | Good | Excellent | Good | Good | Good | Good | Good |

| Cutting Options | Can be cut using abrasive methods | Easily machinable but can be tough on tools | Can be cut using various methods including sawing, laser, plasma | Can be cut with higher-power tools | Can be cut, but higher strength may pose challenges | Can be machined but is tougher than some austenitic stainless steels | Can be cut using plasma, water jet, laser | Can be cut using abrasive methods |

| Machining Options | Machinable but may work harden | Machinable but can be gummy and tough | Good machinability, but work-hardening can occur | Challenging due to work-hardening | Can be machined but is tougher than some austenitic stainless steel | Challenging due to work-hardening | Challenging due to work-hardening | Challenging due to work-hardening |

| Application Range | Springs, wire forms | Machined parts, shafts, valves | Various industrial applications, kitchen settings | Marine environments, chemical processing | High-temperature applications | High-temperature applications | High-temperature applications | High-temperature applications |

These additional columns on cutting options and machining characteristics provide insight into how these stainless steel alloys respond to different cutting methods and machining processes. The machinability of these alloys can significantly impact their usability in various applications and industries.

Given the range of factors to consider, what should one look for when purchasing 304 stainless steel square tubing? How to choose the suitable 304 stainless steel pipe supplier?

Cost considerations are typically a major concern, as 304 stainless steel is more expensive than other steel alloys. Wall thickness is also important to consider, as thicker walls can provide better corrosion resistance and greater strength. Additionally, welding methods should be taken into consideration when choosing the right square tubing for the job. Finally, the dimensions of the square tubing should be carefully measured to ensure it meets the desired specifications.

When it comes to cost considerations, it is important to compare the prices of multiple suppliers to ensure the best deal. Wall thickness should be determined based on the application and desired corrosion resistance. Welding methods should be chosen based on the type of welding process and the desired strength of the weld joint. Lastly, the dimensions of the tube should be considered to ensure it meets the desired specifications.

The environmental impacts of using 304 stainless steel square tubing are generally positive. It is a highly durable material that is corrosion-resistant and has a long life expectancy. Additionally, it is safe for use in many applications, and installation techniques are easy to learn.

With its superior weatherproofing and corrosion resistance, 304 stainless steel square tubing is the perfect choice for outdoor use. Installation methods, welding techniques, and price comparison must all be considered when making this decision. Control is key, and 304 stainless steel square tubing offers the perfect solution.

When it comes to cutting or joining 304 stainless steel square tubing, welding techniques, special tools, corrosion protection, weight considerations, design flexibility, and installation methods should all be taken into account. Proper techniques will ensure maximum control and longevity.

Yes, 304 stainless steel square tubing is recyclable due to its weatherproofing, corrosion resistance, welding techniques, durability testing, and installation methods. It can be easily re-purposed and is considered an environmentally friendly choice.

The cost of 304 stainless steel square tubing can vary greatly, depending on corrosion resistance, finishing options, installation tips, weight considerations, and durability benefits. Though the price tag may be daunting, the long-term cost savings and reliability of stainless steel make it worth the investment. Anachronism: Investing in stainless steel square tubing is like setting money aside for a rainy day.

Read also:

304 stainless steel square tubing is a popular choice for many projects due to its superior corrosion resistance and strength. Its excellent properties and fabrication techniques make it ideal for a wide range of applications.

With proper maintenance and care, 304 stainless steel square tubing can provide long-term durability, with some studies indicating the life expectancy 304 stainless steel of up to 200 years.

It is also one of the more affordable 300 series stainless steel grades, making it a cost-effective option for many projects.

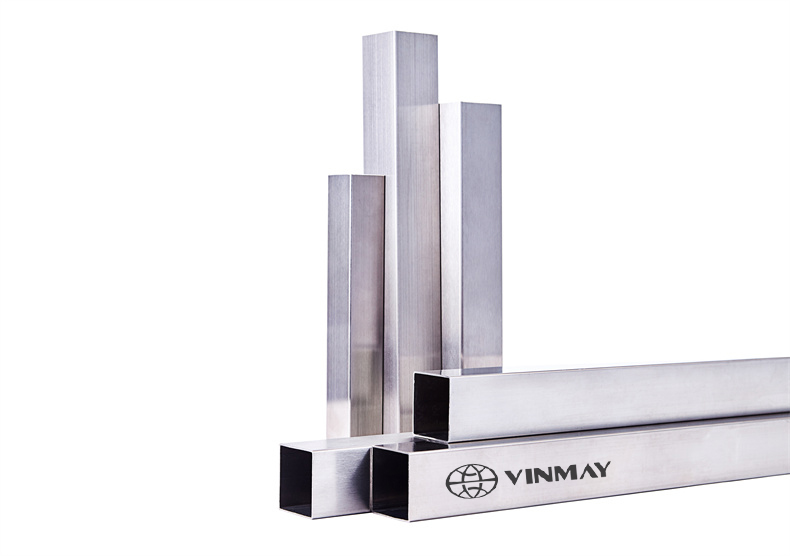

Ready to elevate your project with durable 304 stainless steel square tubing? Discover Vinmay's quality offerings and find the perfect fit for your needs. Create lasting solutions with top-notch materials that stand the test of time.