Understanding the 304 stainless steel rectangular tube size goes beyond mere measurements; it defines the very essence of its functionality within structural frameworks. The interplay between size, strength, and application intricacies requires a meticulous approach to guarantee peak performance. As we explore the world of stainless steel tubing, investigating the nuances of size specifications reveals a domain where precision meets purpose. Stay tuned to uncover the significance of these dimensions in shaping the backbone of industrial advancements.

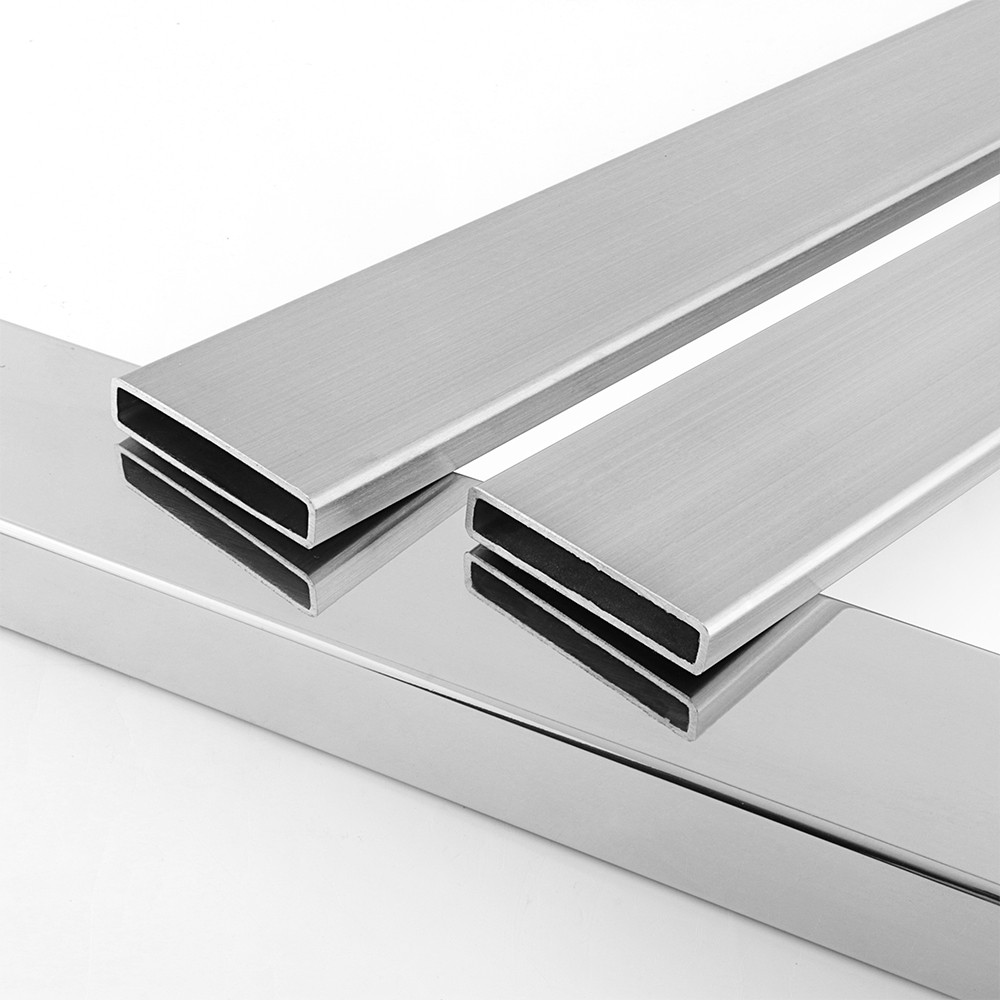

The specifications of 304 stainless steel rectangular tubes encompass important details such as the chemical composition, providing insight into the material's elemental makeup.

Mechanical information is essential for understanding the tube's strength, durability, and performance characteristics under different conditions.

Additionally, applications and workability considerations offer valuable guidance on where and how this specific stainless steel tube can be effectively utilized.

In the composition of 304 stainless steel tubes, the chemical specifications play a crucial role in determining the material's properties and performance characteristics. A thorough chemical composition analysis is essential for accurate material properties evaluation, corrosion resistance testing, surface finish assessment, and welding compatibility review. To highlight this importance, consider the following content:

These key elements contribute significantly to the overall quality and characteristics of the 304 stainless steel rectangular tube, impacting its strength, corrosion resistance, and stainless steel pipe welding standards.

You may also like:

The Life Expectancy of 304 Stainless Steel - VINMAY

The mechanical properties of 304 stainless steel tubing can vary depending on factors such as the manufacturing process, heat treatment, and specific dimensions of the tube. However, here are some typical mechanical properties for annealed 304 stainless steel tubing:

These values may vary slightly depending on the diameter and wall thickness of the tube, as well as the specific standards or specifications being followed. Additionally, stainless steel can exhibit different mechanical properties depending on factors such as temperature and strain rate. For applications requiring specific mechanical properties, it's essential to consult the relevant stainless steel tube standards or specifications or consult with the stainless steel tubing manufacturer.

304 stainless steel rectangular tube size have a wide range of applications due to their excellent corrosion resistance, durability, and versatility. Some common applications include:

Construction: Used in the construction industry for structural components, such as handrails, support beams, and frames for buildings, bridges, and other structures.

Tubes for Construction: Often used in architectural designs for decorative elements like trim, facades, and railing systems due to its aesthetic appeal and resistance to corrosion in outdoor environments.

Piping Systems: Suitable for piping systems in industries such as food processing, pharmaceuticals, chemical processing, and water treatment due to its resistance to corrosion and ability to withstand high temperatures.

Tubes for Automotive: Utilized in automotive applications such as exhaust systems, structural components, and decorative trim due to its resistance to corrosion and high temperatures.

Tubes for Furniture: Used in the manufacturing of furniture frames, legs, and supports due to its strength, durability, and aesthetic appeal.

Medical Equipment: Used in the fabrication of medical equipment and devices due to its sanitary properties, resistance to corrosion from bodily fluids, and ease of sterilization.

Tubes for Food Processing Equipment: Commonly used in the production of food processing equipment, kitchen appliances, and utensils due to its corrosion resistance and ease of cleaning.

Tubes for Heat Exchangers: Suitable for heat exchangers in various industries due to its resistance to corrosion and ability to withstand high temperatures.

Oil and Gas: Utilized in the oil and gas industry for applications such as pipelines, drilling equipment, and storage tanks due to its corrosion resistance and ability to withstand harsh environmental conditions.

Aerospace: Used in aerospace applications for components requiring high strength, corrosion resistance, and lightweight properties.

These are just a few examples, but the versatility of 304 stainless steel rectangular tube size makes them suitable for a wide range of industrial, commercial, and residential applications.

The workability of the 304 stainless steel rectangular tube size is characterized by its precise dimensions and structural integrity, ensuring excellent performance in various fabrication processes. Workability advantages of this material include its customization options, allowing manufacturers to tailor the tube to specific project requirements.

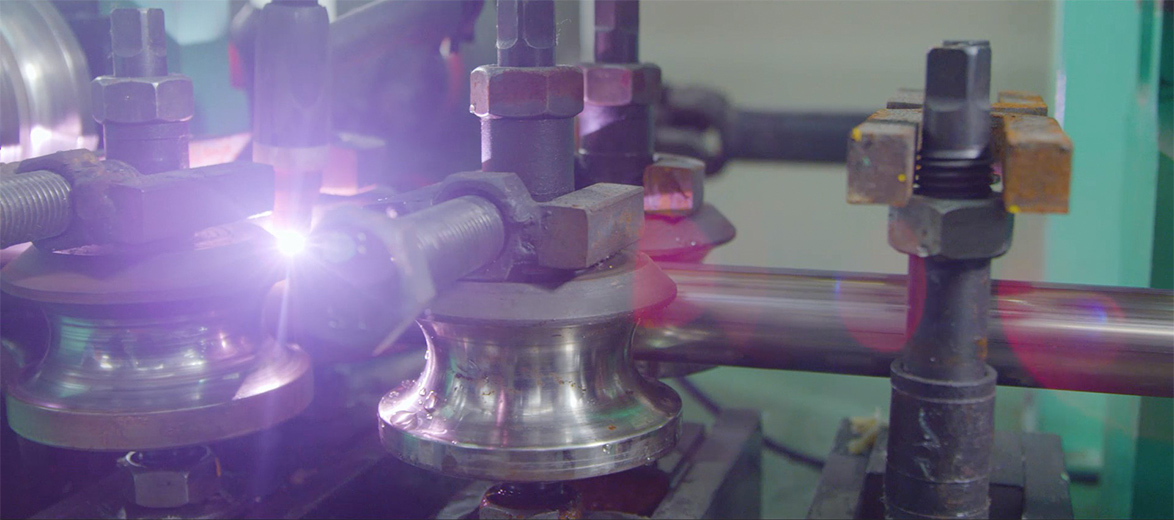

Fabrication techniques such as cutting, welding(TIG Welding, HF Welding), and bending are easily achievable due to the material's properties, enhancing its versatility in different applications. Welding considerations are essential when working with 304 stainless steel rectangular tube size, requiring proper techniques to maintain its corrosion resistance and structural strength.

Material compatibility is an important factor to keep in mind, ensuring that the 304 stainless steel rectangular tube size meets the requirements of the intended use and functions effectively within the given system.

Rectangular tube stainless steel offers significant advantages when it comes to strength and durability, making it a preferred choice for applications requiring robust support. Additionally, its cost-effectiveness and stability provide efficient solutions for various construction and industrial projects.

The corrosion resistance and recyclability further enhance its appeal as a sustainable and reliable material for structural applications.

In the domain of structural tubing, the strength and durability of rectangular tubes stand out as paramount attributes. When considering rectangular structural tubing, several key benefits contribute to its appeal:

Material properties: Rectangular tubes are often made from strong materials like stainless steel, providing excellent structural integrity.

Design considerations: The shape and construction of rectangular tubes offer increased strength and stability compared to round tubes.

Structural applications: Rectangular tubing is commonly used in various industries for its ability to support heavy loads and withstand external forces.

Welding techniques: Rectangular tubes can be easily welded using different techniques, ensuring secure and durable connections

These factors collectively make rectangular structural tubing a preferred choice for applications requiring robustness and reliability.

Cost-effectiveness plays a pivotal role in the utilization of rectangular structural tubing due to its efficient material use and cost-saving benefits in building and industrial operations. Rectangular tubing offers significant cost savings through its material efficiency, allowing for the fabrication of structures with reduced material waste. Additionally, the availability of custom lengths guarantees dimensional accuracy, optimizing the use of materials and reducing excess costs. The versatility of rectangular tubing in fabrication options enables tailored solutions for various projects, further enhancing cost-effectiveness. Below is a table highlighting the key cost-effective benefits of rectangular structural tubing:

| Cost-Effective Benefits | Description |

|---|---|

| Cost Savings | Efficient material use and reduced waste |

| Material Efficiency | Custom lengths for dimensional accuracy |

| Fabrication Options | Versatile for tailored solutions |

| Custom Lengths | Optimizing material use and reducing excess costs |

| Dimensional Accuracy | Ensuring precise fit and minimizing material waste |

When considering the structural integrity of rectangular tubing, its shape and construction provide inherent stability and strength for various industrial and building applications. Rectangular structural tubing offers numerous benefits due to its design and composition:

Structural Integrity: The shape enhances stability and load-bearing capacity.

Load Capacity: Rectangular tubing can withstand heavier loads compared to round tubes.

Material Composition: High-quality materials guarantee strength and durability.

Welding Techniques: Welding methods tailored for rectangular tubes enhance structural cohesion and integrity.

These factors, coupled with precise dimensional accuracy, make rectangular structural tubing a reliable choice for a wide range of projects requiring stability and strength.

Enhancing the longevity and reliability of rectangular structural tubing, its corrosion resistance properties guarantee durability in various industrial and building applications. The surface finish, welding techniques, material properties, surface treatment, and longevity factors play vital roles in ensuring the resistance to corrosion, discoloration, and rust.

The surface finish protects against environmental elements, while appropriate welding techniques maintain the material's integrity. Material properties such as stainless steel composition enhance the tubing's ability to withstand corrosive environments. Surface treatments like passivation further fortify the tubing's resilience.

Considering these factors collectively contributes to the overall longevity and durability of the rectangular structural tubing, making it an ideal choice for diverse industries.

Considering the durability and reliability of rectangular structural tubing in various applications, an important aspect to highlight is its recyclability, which contributes to sustainability and environmental consciousness in industrial and construction sectors.

Recycling benefits include reducing waste and conserving resources by reusing materials. Sustainability advantages are achieved through eco-friendly solutions that lessen the environmental impact of manufacturing processes. By utilizing rectangular tubing made from reusable materials, industries can contribute positively to a greener future.

Incorporating recyclable materials not only aids in preserving natural resources but also promotes a circular economy model where products are reused efficiently, minimizing waste and promoting environmental stewardship.

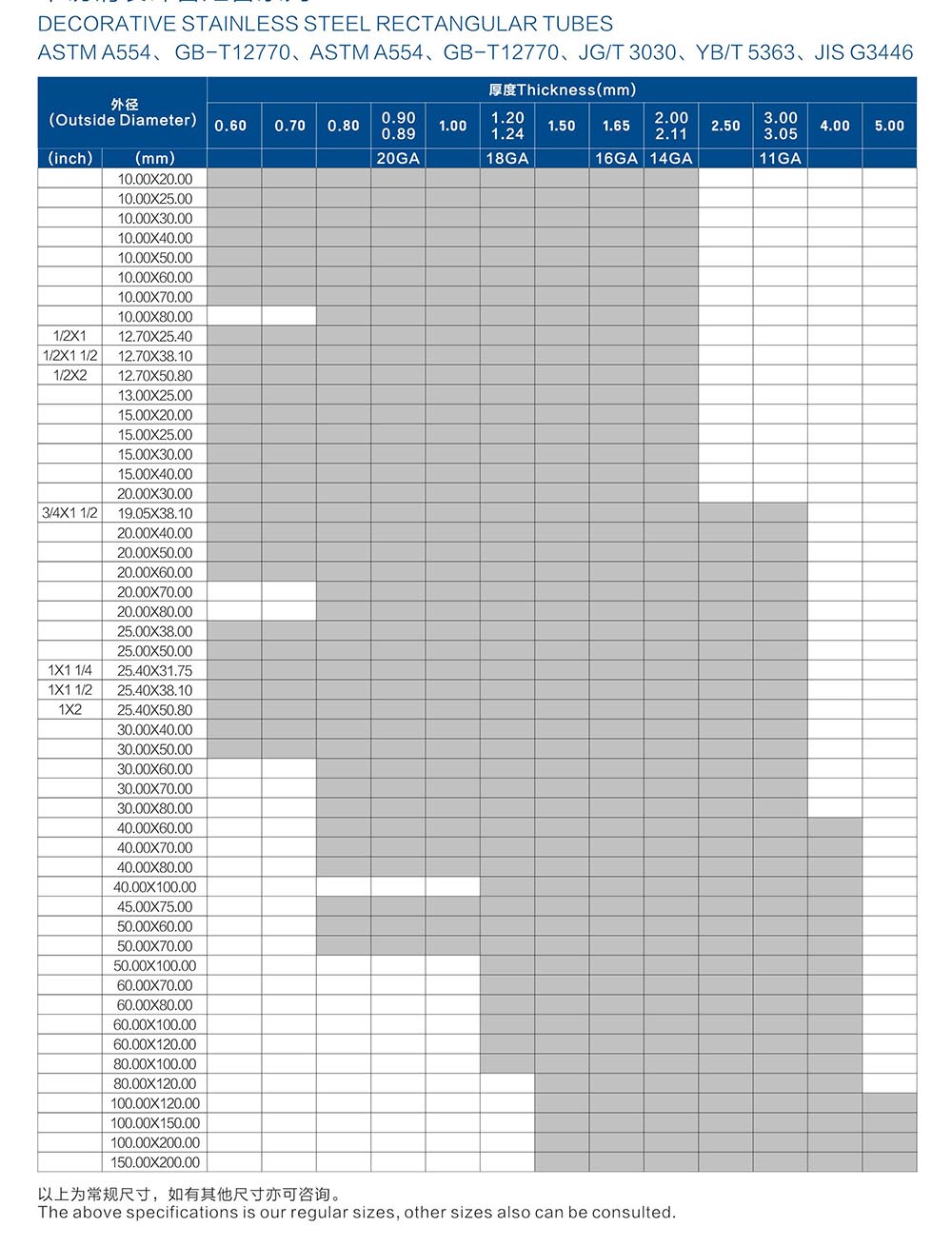

When purchasing 304 stainless steel rectangular tube size, understanding key dimensions like Outside Diameter (OD) and Inside Diameter (ID) is essential.The OD influences tubing fit, compatibility with connectors, strength, and performance. The ID affects flow rate, compatibility with fittings, and precise fluid flow applications.

A thorough understanding of these aspects guarantees accurate selection and effective use of stainless steel tubing across various sectors, including aerospace, automotive, medical, and manufacturing industries.

The outside diameter (OD) of 304 stainless steel rectangular tube size is a critical factor that influences the fit, function, and performance of the tubing.

Understanding the importance of the OD in relation to compatibility with connectors and its impact on strength is essential for selecting the right tubing for specific applications.

Additionally, the option for customization of the OD allows stainless steel pipe manufacturers to tailor tubing to meet unique requirements and enhance overall system functionality.

Considering the importance of precise measurements, the Outside Diameter (OD) plays a significant role in determining the compatibility and functionality of stainless steel tubing dimensions. The OD influences tubing fit, compatibility with connectors, strength, and performance.

Importance of size: Essential for proper fit

Dimensional accuracy: Guarantees precise measurements

Material compatibility: Influences connector fit

Functional fit: Impacts overall performance

Given the significance of precise measurements in determining compatibility and functionality, the customization of the outside diameter (OD) for 304 stainless steel rectangular tube size plays an essential role in meeting specific application requirements.

Manufacturers offer custom fabrication services allowing for tailored dimensions to meet unique applications, enhancing compatibility and functionality. Customized OD sizes guarantee the tubing fits connectors properly and can withstand intended applications, optimizing durability and workability.

The outside diameter (OD) of stainless steel tubing greatly influences its strength and performance in various industrial applications.

Impact analysis on strength evaluation

OD performance comparison in different scenarios

Best-fit OD for enhanced performance

Strength evaluation based on varying OD sizes

The inside diameter (ID) of stainless steel tubing plays a crucial role in determining flow rate and compatibility with fittings, especially in applications requiring precise fluid flow.

Understanding the impact of ID on tubing fit into systems is essential for ensuring peak performance. Factors such as wall thickness, alongside ID, must be carefully considered to meet the specific requirements of various applications.

Wall thickness in 304 stainless steel rectangular tube size plays a critical role in determining the mechanical properties and performance of the stainless steel tube material.

In 304 stainless steel rectangular tube size, the significance of wall thickness lies in its direct influence on the mechanical properties and performance of the material, particularly in applications where precision and reliability are paramount. Thicker walls impact material strength, fluid compatibility, system fit, and precise flow. Balancing these factors is essential for selecting the appropriate thickness to guarantee peak performance and functionality.

| Thickness Impact | Material Strength | Fluid Compatibility |

|---|---|---|

| System Fit | Precise Flow |

When considering the impact of wall thickness on weight in stainless steel tubing dimensions, it is important to analyze its direct correlation with material density and overall structural integrity.

Thicker walls result in increased weight due to the higher material density, affecting the overall performance and manufacturing process of the tubing.

The choice of wall thickness greatly influences the bending and welding processes of stainless steel tubing. It affects structural integrity and performance outcomes, impacting material properties, bending requirements, and forming considerations important for structural applications.

Proper selection is vital to guarantee excellent performance and functionality of the tubing within various structural applications. It is crucial to consider the impact on performance and overall structural integrity.

The selection of a thin-walled tube for an application is influenced by factors such as working pressure, installation method, and environmental conditions.

Structural Strength: Adequate for specific applications.

Material Efficiency: Efficient material usage.

Cost Savings: Reduced material costs.

Performance Impact: Enhances functionality with appropriate strength.

In applications where robust structural integrity and resistance to high pressures are paramount, heavy wall tubing is specified to guarantee reliable performance and longevity.

The benefits of thick walls include increased strength, enhanced durability, and the ability to withstand demanding working conditions.

These factors are essential for meeting application requirements, ensuring top strength considerations, and enhancing overall performance factors for critical operations.

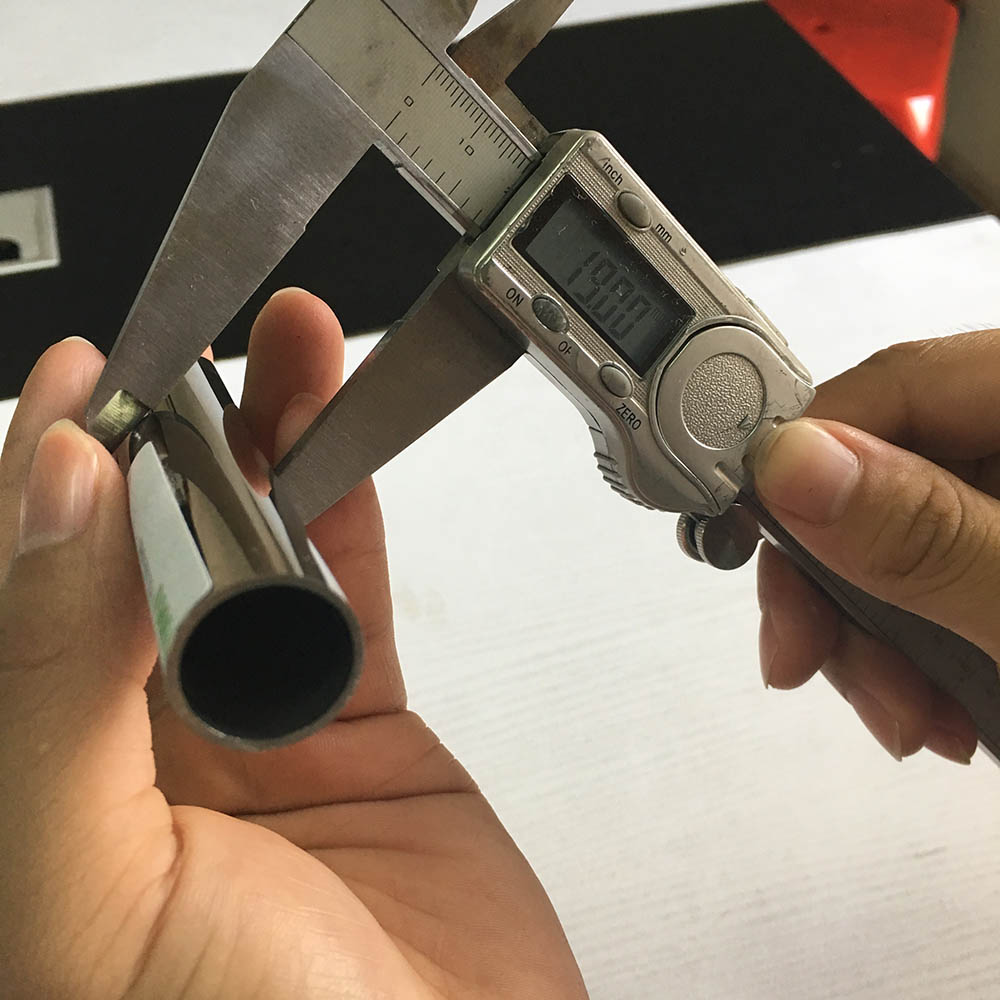

When considering stainless steel tubing, understanding how the inside diameter (ID) is measured is essential for precise fluid flow applications and compatibility with fittings. The inside diameter plays a significant role in determining the tubing fit into systems and its overall performance.

It is essential to grasp the importance of the inside diameter alongside other factors when selecting stainless steel tubing for various applications.

Measuring the inside diameter (ID) of stainless steel tubing involves the use of specialized tools to guarantee precise dimensions for fluid flow applications.

Calipers: Common tool for accurate measurements.

Micrometers: Provide high precision readings.

Bore Gauges: Confirms inner diameter conformity.

Optical Comparators: Allows for detailed dimensional accuracy checks.

The inside diameter of stainless steel tubing plays a vital role in determining its suitability for specific applications. It has a direct impact on fluid flow efficiency and compatibility with fittings. Precise inside diameter measurements are essential for ensuring the tubing meets system fit requirements. This ensures it functions efficiently within various applications.

Factors such as fluid flow, fittings compatibility, and precise system fit all hinge on the inside diameter selection.

To sum up, the 304 stainless steel rectangular tube size is a critical factor in determining its structural integrity and performance in various industrial applications.

By carefully considering the specifications and dimensions of the tube, one can guarantee a precise fit and compatibility for specific projects.

Custom fabrication services can further tailor solutions to meet unique 304 stainless steel rectangular tube size requirements, enhancing the overall efficiency and effectiveness of the tubing in structural applications.