In the domain of stainless steel finishes, the 2B and No. 4 finishes stand out due to their distinctive properties and applications. The 2B finish, achieved through cold rolling, presents a smooth, slightly reflective surface. In contrast, the No. 4 finish, characterized by a dull, linear appearance, results from mechanical polishing. Each finish serves unique purposes, offering excellent corrosion resistance. Understanding these differences is essential for selecting the appropriate finish for specific applications.

Stainless steel finishes refer to the surface appearance and texture resulting from specific manufacturing processes. These finishes are standardized and classified according to systems established by organizations like ASTM (American Society for Testing and Materials) and EN (European Standards).

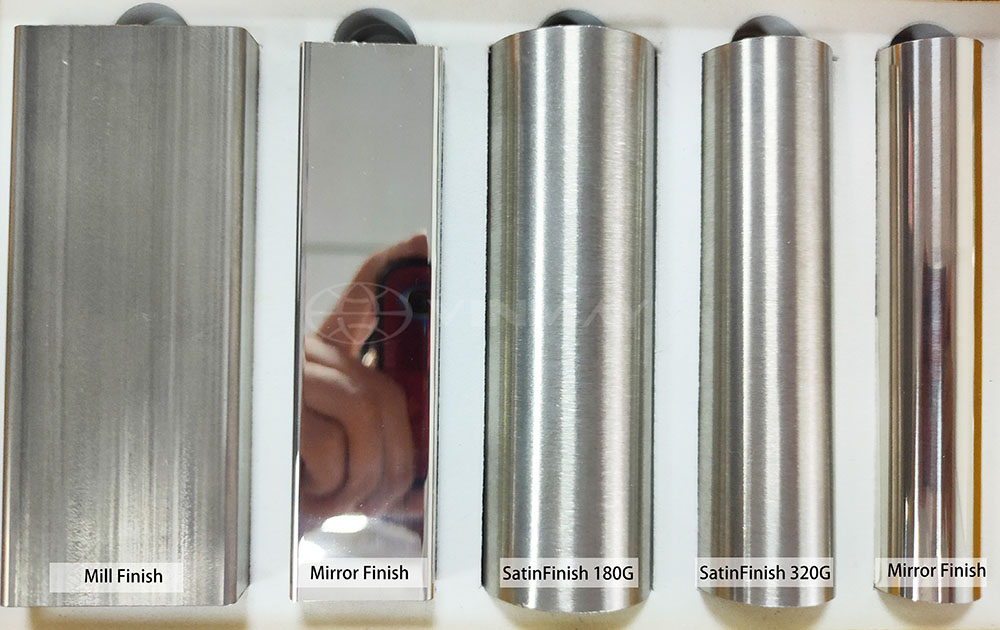

Finishes range from rough, dull surfaces (like No. 1) to highly reflective, mirror-like appearances (like BA or No. 8). Where 2B and No. 4 finishes fall on this spectrum is important to understand:

The finish you choose affects not just how your stainless steel looks, but also how it performs under various conditions, how easily it can be cleaned, and ultimately, how much it costs. This makes the 2B finish vs 4 finish decision an important consideration for any project involving stainless steel components.

In the domain of stainless steel finishes, 2B finish stands out for its practicality and widespread application in industrial and non-cosmetic contexts. This finish is achieved through a series of precise cold rolling techniques followed by heat treatment, pickling, and pinching processes. It results in a slightly reflective, cloudy mirror-like surface.

The 2 B finish facilitates stainless steel properties such as enhanced corrosion resistance and uniformity, making it ideal for grades such as 201, 301, 304, 304L, and 316L. Surface treatment methods guarantee the finish's durability factors are optimized for use in bakeware, flatware, and industrial equipment.

While aesthetic considerations are minimal, the 2B finish offers sufficient appeal for functional applications, balancing performance with practicality.

The No. 4 finish is one of the most widely used stainless steel finishes, known for its satin-like, linear appearance. Created through mechanical polishing with fine abrasive belts, it features short, parallel lines that give the surface a uniform, non-reflective texture.

This finish strikes a balance between aesthetic appeal and practical performance, making it a go-to choice for high-touch, high-traffic applications such as handrails, kitchen sinks, and commercial work surfaces.

Thanks to its consistent grain, minor scratches can be easily repaired using light abrasive pads, making it a low-maintenance and durable option in environments where both form and function matter.

| Key Aspect | Detail |

|---|---|

| Surface Appearance | Dull, linear grain with a soft sheen |

| Handrails, sinks, prep tables, and appliances | Handrails, sinks, prep tables, appliances |

| Maintenance Benefit | Easy to clean; minor damage is repairable |

The No. 4 finish is ideal for projects that demand clean visuals, resilience, and ease of upkeep—a favorite across architectural, commercial, and industrial settings.

The 2B and No. 4 finishes present distinct visual characteristics, with the 2B finish offering a slightly reflective, cloudy mirror-like appearance, while the No. 4 finish features a duller, linear grain pattern.

Regarding performance metrics, both finishes offer excellent corrosion resistance, though the production processes differ, with 2B achieved through cold rolling and No. 4 through mechanical polishing.

Cost considerations also vary, as the No. 4 finish may incur additional expenses due to its more intricate production process and maintenance requirements.

Stainless steel finishes, such as 2B and #4, exhibit distinct visual characteristics that cater to different functional and aesthetic applications.

The 2B finish offers a slightly reflective, cloudy mirror-like appearance, while the #4 finish features a dull, grained look with short, parallel lines. This variation in visual appeal influences aesthetic preferences and durability factors in selection.

2B is produced by cold rolling, heat treatment, pickling, and pinching, requiring minimal maintenance, ideal for industrial use. In contrast, the #4 finish utilizes mechanical polishing with fine abrasive belts, necessitating protective measures against scratches.

Maintenance requirements for #4 include re-graining for light scratches. These manufacturing techniques highlight the importance of controlled processes to achieve desired finishes for specific applications.

Considering the distinct visual characteristics previously discussed, understanding the performance metrics of 2B and No. 4 finishes becomes imperative for selecting the appropriate finish for specific applications. A detailed durability analysis reveals nuanced distinctions between these two finishes.

When comparing the corrosion resistance of No. 4 and 2B finishes on stainless steel, it is essential to take into account the distinct surface characteristics that influence their performance in various environments.

The 2B finish, with its smooth, slightly reflective surface, generally provides superior corrosion resistance due to minimal surface imperfections, which reduce crevice corrosion potential.

In contrast, the No. 4 finish, characterized by its grained appearance, may require more diligent maintenance practices to prevent corrosion, especially in aggressive environments where surface treatments are less protective.

Stainless steel alloys used in both finishes play a vital role, as higher chromium content enhances resistance.

Environmental factors, such as humidity and exposure to harsh chemicals, further dictate the longevity and preservation of these finishes.

While both the 2B and No. 4 finishes serve distinct purposes in the stainless steel industry, their production processes highlight critical differences in efficiency and resource utilization.

The 2B finish employs production techniques such as cold rolling, annealing, and pickling, leading to high material efficiency and reduced environmental impact due to minimal material removal.

Analyzing the production processes of 2B and No. 4 finishes highlights their distinct material efficiencies and environmental impacts, setting the stage to evaluate their cost implications.

Cost factors for 2B finish, being less labor-intensive, generally align with lower pricing trends, making it preferable under budget constraints. Conversely, the No. 4 finish requires extensive mechanical polishing, elevating its expense analysis due to labor and material consumption.

Value assessment becomes vital when considering aesthetic requirements against functional utility. While 2B finish offers cost efficiency for industrial applications, No. 4 finish justifies higher expenses with its visual appeal in consumer-facing products.

Understanding these pricing trends provides stakeholders with control over material selection, aligning financial and project objectives with precision.

In the domain of stainless steel applications, the choice between 2B and #4 finishes greatly influences both function and aesthetic appeal. Precision-driven decisions are essential for professionals seeking specific outcomes.

Selecting the appropriate stainless steel finish is a decision that directly impacts both the functional and aesthetic outcomes of a project.

The finish selection criteria should consider aesthetic preferences, where the reflective 2B finish might suit industrial settings, whereas the #4 finish, with its distinct grain, is ideal for visible surfaces.

Maintenance requirements play a significant role; the #4 finish allows for re-graining to repair light scratches, providing longevity in high-traffic areas.

Adhering to industry standards guarantees compatibility and quality, influencing the choice between the finishes.

In addition, evaluating the environmental impact of each finish, including production processes and material longevity, supports sustainable decision-making.

A precise evaluation confirms the stainless steel finish aligns with project-specific demands and environmental considerations.

Scratch repair techniques for a #4 finish involve using light-grit finishing pads to re-grain the surface. Polishing options include professional services for deeper scratches. Maintenance tips emphasize protective coatings during fabrication to prevent further damage.

In the digital age, PVC coating for 2B finish isn't necessary during fabrication due to the finish's durability and non-cosmetic applications. 2B finish advantages include its robust aesthetics and practical applications, negating the PVC coating benefits.

The 2B finish's suitability for kitchen appliances hinges on its corrosion resistance, enhancing material durability. While its surface texture provides functional benefits, aesthetic considerations may favor other finishes due to its less refined appearance in visible kitchen settings.

Maintaining a #4 finish involves regular cleaning to preserve its durability and longevity. Protecting #4 finish from scratches is essential, with PVC coatings during fabrication and using light-grit pads to repair minor abrasions, ensuring the best appearance.

The manufacturing process impacts #4 finish appearance through surface texture and material composition. Polishing techniques influence finish consistency, enhancing visual appeal. Variations in abrasive belt grit and pressure apply distinct grain patterns, ensuring desired aesthetic outcomes.

Related Articles:

In the domain of stainless steel finishes, the choice between 2B and No. 4 is akin to selecting a tailored suit versus a rugged work jacket. The 2B finish, with its smooth, reflective sheen, stands ready for the rigors of industrial environments, embodying functionality and resilience. Meanwhile, the No. 4 finish, with its subdued, linear elegance, whispers sophistication for visible applications. Each finish, a masterpiece of engineering precision, awaits its role, echoing the melody of purpose and aesthetics.

As one of China's leading manufacturers of stainless steel tubes and fittings, Vinmay specializes in producing both 2B and No. 4 finishes to exacting international standards. Our 15+ years of experience and state-of-the-art manufacturing facility ensure consistent quality and finish across all our products.

Contact Vinmay today to discuss your specific requirements for stainless steel tubes and fittings.