201 2b stainless steel is a grade known for its versatility and durability in various industries. It has been gaining attention for its unique properties. The designation '2B' often raises questions among professionals in the field, prompting a closer look at its significance in the realm of stainless steel.

Understanding the benefits of utilizing 201 2b stainless steel and its common Vinmay Applications List can shed light on why this material remains a popular choice. Stay tuned to uncover the secrets behind achieving a flawless 2B finish on stainless steel surfaces.

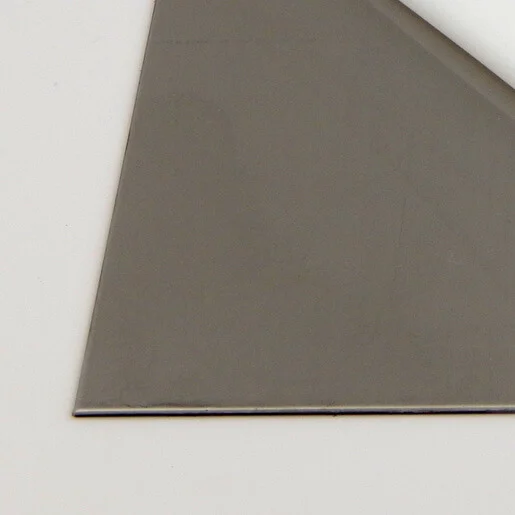

The term '2B' in stainless steel refers to a specific surface finish designation that indicates a smooth, moderately reflective surface. This surface texture is achieved during the stainless steel pipe manufacturing process by cold rolling the stainless steel sheet in coils. The 2B finish is one of the most common finishes in the industry due to its versatility and aesthetic appeal. It meets stainless steel tube standards for surface quality and is suitable for various applications where appearance and corrosion resistance are essential.

In terms of corrosion resistance, 2B stainless steel provides good protection against corrosion in mild environments. However, in more corrosive environments, proper maintenance is crucial to preserve its appearance and performance. Regular cleaning with mild detergents and non-abrasive materials can help maintain the surface finish and extend the lifespan of the material. Following these maintenance tips can ensure that the 2B stainless steel retains its smooth and reflective surface for an extended period.

Boasting enhanced manganese and nitrogen content, 201 stainless steel offers a cost-effective solution for various industrial applications. Its corrosion resistance properties make it a suitable choice for environments where exposure to moisture or chemicals is a concern. The high strength of 201 stainless steel ensures durability and reliability in demanding conditions, making it a preferred stainless steel material for structural components. Additionally, its easy maintenance requirements contribute to its appeal in industries looking to minimize upkeep costs.

Furthermore, 201 stainless steel presents a modern aesthetic, adding a sleek and contemporary look to finished products. This combination of functionality and visual appeal makes it a versatile option for a range of applications, from kitchen equipment to architectural elements. The cost-effectiveness of 201 stainless steel makes it an attractive choice for stainless steel tube manufacturers seeking to balance performance and budget considerations without compromising quality.

With its enhanced manganese and nitrogen content, 201 2b stainless steel finds widespread usage in various industrial applications due to its corrosion resistance and high strength properties. In industrial applications, this type of stainless steel is commonly used in the stainless steel tube manufacturing of equipment for chemical processing, food processing, and storage tanks.

Its resistance to corrosion makes it ideal for architectural projects such as building facades, roofing, and decorative elements. Additionally, 201 2b stainless steel is a popular choice for kitchen appliances like sinks, cookware, and countertops due to its durability and sleek appearance.

In the automotive industry, this stainless steel grade is utilized in automotive components such as exhaust systems, trim, and grills. Moreover, manufacturers rely on 201 2b stainless steel for various 201 stanless steel welding processes where a combination of strength, corrosion resistance, and affordability is required.

Its versatility and reliability make it a preferred material across a range of industries.

Achieving a 2b finish on stainless steel involves a meticulous process that focuses on refining the surface to meet specific quality standards. The process begins with thorough surface preparation, which includes removing any impurities or contaminants that could affect the final finish. Chemical cleaning is often employed to ensure a clean surface free of oils or residues. Mechanical finishing techniques such as grinding or sanding are then used to smoothen the surface further. Polishing techniques play a crucial role in achieving the desired 2b finish, imparting a consistent and smooth texture to the stainless steel.

Quality inspection is integral throughout the process to ensure that the finish meets industry standards. Inspecting the surface for any imperfections or inconsistencies is vital to guarantee a uniform 2b finish. By combining precise surface preparation, chemical cleaning, mechanical finishing, and meticulous quality inspection, stainless steel can achieve a flawless 2b finish that is both aesthetically pleasing and meets stringent quality requirements.

Like attracts like, stainless steel's magnetic properties vary. The 2B finish doesn't affect its corrosion resistance, surface appearance, strength, or welding compatibility. Understanding these properties helps in selecting the right stainless steel for specific applications.

The 2B finish in stainless steel stands out due to its superior surface smoothness, excellent chemical resistance, and distinct reflective properties. Its fabrication techniques are specialized, requiring attention to detail, and specific cleaning methods ensure its longevity.

Discover More:

Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

201 stainless steel is suitable for outdoor applications due to its decent rust resistance, corrosion protection, and durability outdoors. While not as weather-resistant as higher grades, it offers good surface aesthetics for various outdoor uses.

Common misconceptions about stainless steel include assumptions about its corrosion resistance, heat resistance, surface finish, weldability concerns, and environmental impact. These aspects often vary based on the specific grade and application, necessitating informed decision-making to avoid misunderstandings.

Learn More:

What Is the Difference Between 201 and 304 Stainless Steel?

Will 201 Stainless Steel Rust ?

Exploring the Strength and Versatility of 201 Stainless Steel Welded Pipes: A Cost-Effective Choice

When considering maintenance requirements for stainless steel, cleaning techniques, corrosion prevention, surface restoration, heat resistance, and rust removal are essential factors to maintain the material's integrity and appearance. Proper care ensures longevity and optimal performance.

In conclusion, 201 2b stainless steel offers a smooth and reflective finish, making it ideal for a variety of applications in industries such as automotive, construction, and kitchenware.

The 2B designation indicates a cold-rolled finish that is both aesthetically pleasing and corrosion-resistant.

With its versatility and durability, 201 stainless steel is a reliable choice for projects requiring a high-quality material.