This guide explores stainless steel tube surface finishes, detailing their types, properties, and applications.

It also explains the tools used to achieve specific finishes and the impact of surface roughness.

Additionally, this guide discusses brushing, buffing, and other specialized finishes.

Understanding the different stainless steel surface finish types is essential for selecting the right material for your project. With this guide, you will be able to make informed decisions when selecting the surface finish for your stainless steel tube.

A stainless steel surface finish refers to the texture or appearance of the material's surface after it has been processed. While stainless steel itself is known for its durability and corrosion resistance, different surface finishes can be applied to enhance its look and performance. These finishes not only affect the aesthetic appeal but also play a significant role in the material’s functionality in various environments.

The surface finish can impact several key characteristics, such as:

Choosing the right surface finish is crucial for ensuring the stainless steel product performs well and looks its best in its intended application. For instance, a brushed finish may be ideal for kitchen appliances, while a mirror finish could be the perfect choice for decorative or high-end design applications. Understanding these finishes helps in selecting the most appropriate option for both aesthetic and practical needs.

Mill finishes represent the most basic surface treatment for steel, which may require further processing and range from No. 0 Finish HRA to No. 2BA Finish.

Hot-rolled finishes are usually dark and dull, while cold-rolled finishes are smoother.

We often use heat treatment and pickling to enhance surface quality.

No. 0 Finish HRA is the basic stainless steel flat product surface finish, which is hot rolled to the required thickness and then annealed. This finish doesn’t fully develop the corrosion-resistant film on stainless steel, making it unsuitable for most general applications. It has limited applications in high-temperature heat-resisting applications.

The HRA finish is more affordable than other mill finishes but offers lower corrosion resistance and is harder to clean. In comparison to polished finishes, it has lower reflectivity and corrosion resistance. The HRA finish is a good choice for applications that require a slightly rougher surface and more affordable cost.

Building on the No. 0 Finish HRA, the No. 1 Mill Finish is a basic stainless steel surface achieved through hot rolling to the desired thickness, followed by annealing. It offers corrosion resistance benefits and is suitable for industrial applications.

Surface roughness is slightly higher than other stainless steel finishes like No. 2D and No. 2B. When choosing between the No. 1 finish and other mill finishes, consider factors like aesthetics, surface roughness, and corrosion resistance. Grinding marks can affect the appearance and functionality of the No. 1 finish.

No. 2D Finish (Mill Finish) is a dull, matte finish achieved through cold rolling, annealing, pickling, and passivating. Commonly used in industrial applications, this finish withstands rough handling well and offers slightly better corrosion resistance than other mill finishes.

The main benefits of the 2D finish are its cost-effectiveness and durability. However, regular cleaning is essential, and any damage should be promptly repaired to maintain its appearance.

It is important to note that 2D finish is not as smooth and reflective as other finishes such as No. 2B and No. 3. This can be an advantage for some applications as it reduces glare.

The choice of finish depends on the application and the desired aesthetic. It is useful to compare the 2D finish to other finishes to find the most suitable option. With this in mind, the next section will discuss the No. 2B finish.

No 2B finish is a semi-reflective finish achieved through cold rolling, annealing, pickling, and passivating. Thanks to its increased reflectivity, this finish is ideal for deep drawing operations and can be polished more easily than a 2D finish.

Advantages include good corrosion resistance and durability, making it ideal for cookware, control panels, kitchen equipment, pharmaceutical equipment, flatware, and pool liners. However, it requires more maintenance and careful cleaning to retain its appearance.

Use a mild detergent to clean the surface, and then rinse thoroughly with warm water. To keep the finish intact, dry the surface immediately after cleaning.

Read More: Uneviling the Versatility of 201 2B Stainless Steel

The No. 2BA finish, also known as Bright Annealed (BA) finish, is a smooth, highly reflective surface achieved through cold rolling and bright annealing in a controlled atmosphere. This process prevents oxidation, resulting in a clean, mirror-like finish with excellent corrosion resistance.

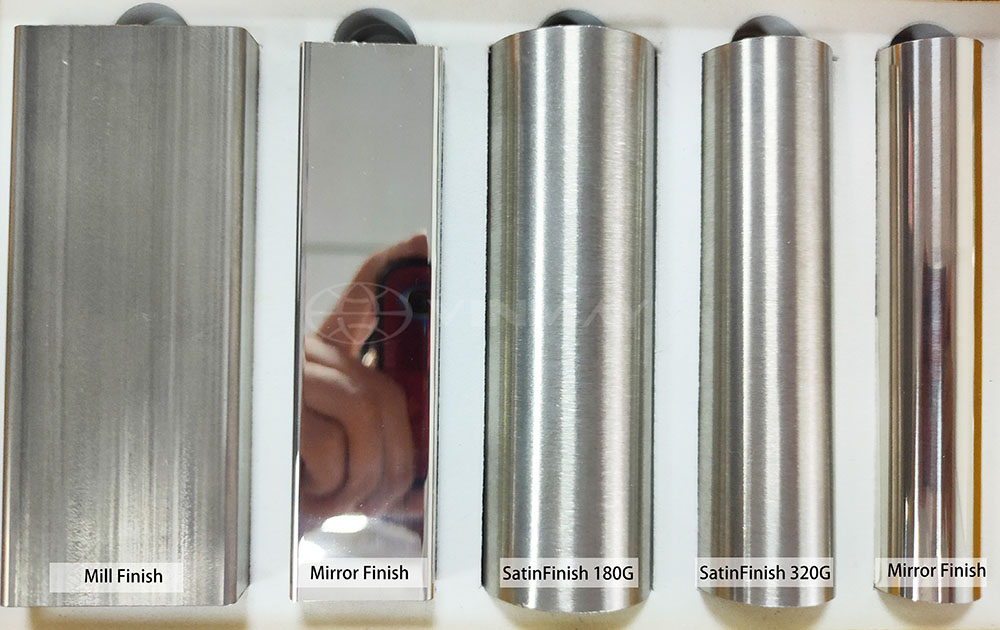

Polished stainless steel finishes can range from No. 3 to No. 8, depending on the desired quality and type of material being worked with.

No. 3 finishes are coarse, while No. 8 finishes are more mirror-like.

The size of the grit used in the polishing process will determine the result.

No. 3 finish is a ground unidirectional finish used as an intermediate surface. It is obtained through 80-100 grit abrasive and is suitable for further polishing operations to achieve a finer finish.

The unidirectional pattern, grit size, and fabrication requirements must be considered when determining this finish. It is a good choice for components that require rough handling and intermediate surfaces.

No. 3 finish is also economical and can be used to meet many fabrication requirements.

The No. 4 finish is a brushed, satin-like surface achieved by polishing with fine abrasive belts or brushes. This creates a muted appearance with fine lines, offering a balance between aesthetics and functionality. While widely used in decorative and industrial applications, it has lower corrosion resistance compared to smoother finishes, requiring regular maintenance.

The No. 6 finish is a soft satin, non-directional surface created by mechanically polishing with fine abrasives. It has lower surface roughness than the No. 4 finish, making it more corrosion-resistant while maintaining a subtle, textured appearance. This finish is often used as an intermediate step before further polishing or coating.

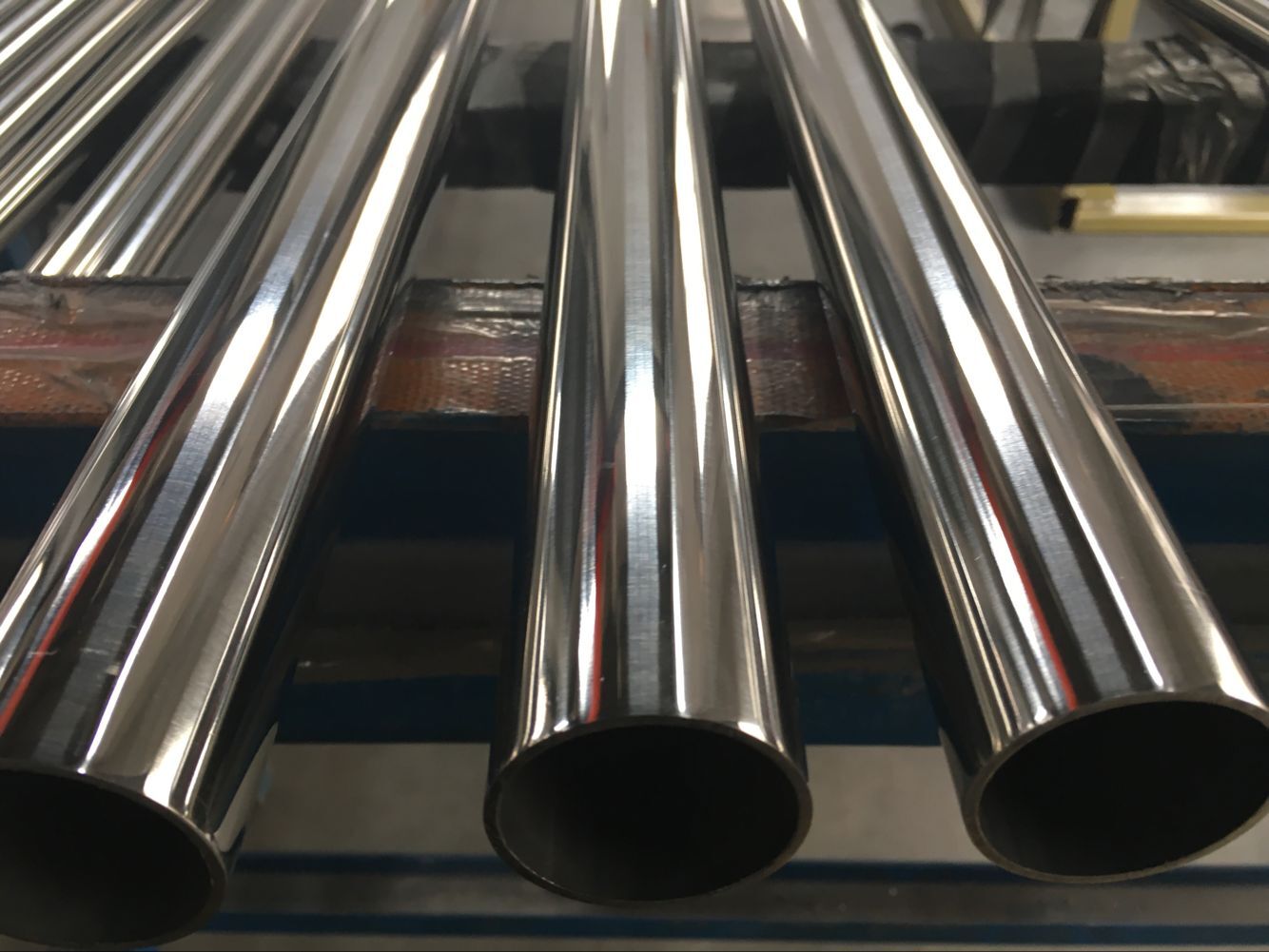

The No. 7 finish is a highly reflective, polished surface created through buffing with progressively finer abrasives and buffing compounds. While it achieves a mirror-like shine, some grit lines from the initial surface may remain, giving it a slightly rougher texture compared to a No. 8 finish.

The No. 8 finish is a true mirror-like surface, achieved by buffing with fine abrasives and polishing compounds until the surface is completely smooth and free of imperfections. It offers high image clarity, exceptional reflectivity, and superior corrosion resistance, making it ideal for aesthetic and functional applications.

Proper maintenance and cleaning are required to prevent scratches and maintain reflectivity.

See Also - How to Polish Stainless Steel Pipe

Unveiling the Excellent of Polished Stainless Steel Square Tubing

A Brushed or Grained Finish is achieved through the use of a polishing belt which creates a coarser finish than the satin polish. This finish has an approximate grit of 240 and is recommended for tubing and metal components post-fabrication.

The benefits of this finish include its affordability, as well as its ability to reduce glare. It is used in applications such as handrails, railings, and outdoor furniture, as well as in automotive and marine applications. Maintenance of this finish is relatively easy with a simple cleaning routine.

When comparing this finish to the No. 8 mirror finish, the grained or brushed finish has less corrosion resistance and is harder to clean. However, it is still more affordable and provides a unique aesthetic. One limitation of this finish is that it can have visible traces of the underlying surface finish if the surface is too coarse.

Satin Finish is a refined, smooth surface finish achieved through polishing with a 120-180 grit abrasive belt. It is widely used across a range of industries, particularly for food-grade steels, due to its corrosion resistance and ease of cleaning.

Here are some notable features of the satin finish:

Overall, the satin finish is a popular choice for its combination of affordability and corrosion resistance.

With its non-reflective, low-luster treatment, matte finish is a popular choice for industrial applications. It is not used for its aesthetic appeal but is a cost-effective option.

A matte finish is achieved by passing the stainless steel through a special roller to create a smooth, less pitted surface. Then it is descaled in an acid solution and polished for additional smoothness.

It is often used for chemical and pharmaceutical equipment due to its resistance to corrosion and surface smoothness. Matte finish is also extremely durable and can withstand high temperatures, making it an ideal choice for applications that require regular cleaning and maintenance.

This finish is also easy to maintain, as it does not require any special coatings or treatments. With its cost-effectiveness and corrosion resistance, matte finish is an ideal choice for a variety of industrial applications.

Although less common than other finishes, TR finish is a temper-rolled finish produced when an annealed surface is cold-rolled to obtain mechanical properties. It is used for a variety of applications, such as cutlery, cookware, and fuel tanks, and provides several advantages. Compared to other finishes, TR finish has better corrosion resistance, superior formability, and better strength properties. It is also widely used in manufacturing industries, such as automotive, marine, and aerospace, where its superior mechanical properties are desired.

To achieve a TR finish on stainless steel, it is important to use the correct cold rolling process and anneal the surface to obtain the desired mechanical properties. In addition, the correct grade of stainless steel must be selected to ensure the best results. With these key considerations in mind, TR finish can be used to provide superior performance and longevity in a variety of applications.

Sandblasting is an abrasive surface finishing technique commonly used to roughen a surface or create a dull, matte finish. It is achieved by placing the parts in a sandblast cabinet and exposing them to a stream of sand or grit at high speeds through a machine nozzle. A variety of sand or grits, such as silica carbide or aluminum oxide, are available in sizes from 60 grit to 120 grit.

| Applications | Benefits |

|---|---|

| Surface Preparation | Abrasion Resistant |

| Paint Removal | Cost-Efficient |

| Rust Removal | Easy to Use |

Sandblasting is commonly used for various applications, such as surface preparation, paint removal, and rust removal. It offers numerous benefits, including abrasion resistance and cost-efficiency. It is also relatively easy to use with the right techniques and equipment.

When using sandblasting, it is important to select the correct grit size for the desired surface finish. The level of roughness can be adjusted by changing the grit size or the blasting pressure. It is also important to use the right techniques and equipment to ensure a consistent and even finish.

Building on the advantages of sandblasting, electro-polished finishes provide an even higher level of corrosion resistance and cleanliness. Electrolytic polishing is a process that involves submerging the metal into a tank and running a current between a cathode and anode with the tubes in between. This removes a small layer from the surface, leaving it highly polished and clean.

Benefits of electro-polished finishes include:

These finishes are ideal for applications that require precision, hygiene, and biocompatibility.

Pickle finish stainless steel refers to a type of surface finish achieved through a chemical cleaning process that removes oxides, scales, and other impurities from the steel. This process, called "pickling," uses a strong acidic solution, typically nitric acid or a mixture of nitric and hydrofluoric acid, to clean the surface of the stainless steel after it has been hot-rolled or welded.

The pickling process involves submerging the stainless steel in a bath of acid, which dissolves surface impurities and oxides formed during the manufacturing process. It helps to:

This process can be followed by a neutralizing wash to stop the action of the acid, and sometimes a passivation treatment is applied afterward to further enhance corrosion resistance.

Stainless steel surface finishes are standardized under different systems worldwide, with ASTM (American Society for Testing and Materials) and EN (European Norms) being two of the most widely recognized standards. While both classifications define finish types, they use different naming conventions and sometimes slight variations in processing methods.

In the ASTM system, finishes are labeled with numbers such as No. 1, 2B, No. 4, and No. 8, each representing a different level of smoothness and reflectivity. For example, No. 4 finish (a brushed surface) is commonly used in architectural and kitchen applications, while No. 8 mirror finish is used in decorative applications.

The EN system (EN 10088-2), used in Europe, categorizes finishes with designations like 1D, 2B, 2J, and 2R. A 1D finish in EN is similar to ASTM’s No. 1, while a 2R finish (Bright Annealed) corresponds to the BA finish in ASTM.

The table below provides a comparison of ASTM and EN stainless steel finishes to help in selecting the right finish for your application.

| ASTM Finish | EN (EN 10088-2) Equivalent | Processing Method | Surface Characteristics | Typical Applications |

|---|---|---|---|---|

| No. 1 | 1D | Hot rolled, annealed, pickled | Rough, dull, non-reflective | Industrial tanks, structural components, heat exchangers |

| 2D | 2D | Cold rolled, annealed, pickled | Smooth, matte, low reflectivity | Automotive, chemical tanks, deep drawing applications |

| 2B | 2B | Cold rolled, light skin pass | Smooth, slightly reflective | Kitchen appliances, chemical tanks, medical equipment |

| BA (Bright Annealed) | 2R | Bright annealed in controlled atmosphere | Very smooth, highly reflective | Kitchenware, food processing, pharmaceutical and medical equipment |

| No. 3 | 2G | Coarse ground with 80–100 grit | Uniform scratches, moderate reflectivity | Kitchen equipment, brewery tanks, industrial use |

| No. 4 (Brushed) | 2J | Brushed with 150–180 grit | Satin finish with fine linear grain | Elevators, architectural panels, appliances, decorative applications |

| No. 6 | N/A | Polished with 240 grit | Dull satin, smoother than No. 4 | Architectural applications, food processing, kitchen surfaces |

| No. 7 | N/A | Polished with 320 grit | High-gloss, near-mirror, some polishing lines visible | Interior design, luxury furniture, high-end decor |

| No. 8 (Mirror Finish) | N/A | Multi-stage polishing and buffing | Mirror-like, highly reflective | Luxury interiors, automotive trim, signage |

Though surface roughness may not be the most discussed feature of stainless steel, its importance cannot be overstated. Surface roughness measurements measure the texture of a manufactured surface and are typically given in microinches or micrometers. Ra (average roughness) and Rz (mean roughness depth) are the two most commonly used parameters, and their values can vary significantly depending on the type of stainless steel finish. The impact of surface roughness on durability and performance must be closely considered and controlled.

The surface roughness of stainless steel can be compared with that of other metals. The range of values for stainless steel is typically between 0.1 and 0.5 micrometers, depending on the type of finish. This is generally much smoother than other metals such as aluminum or steel, which can range from 0.6 to 1.6 micrometers.

| Metals | Ra (µm) | Rz (µm) |

|---|---|---|

| Stainless Steel | 0.1 - 0.5 | 0.2 - 1.0 |

| Aluminum | 0.6 - 1.6 | 1.2 - 3.2 |

| Steel | 0.6 - 1.6 | 1.2 - 3.2 |

Surface roughness control is essential for stainless steel surfaces to maintain corrosion resistance and performance. Finer abrasives are used to polish the stainless steel surface and higher-end finishes (such as No. 8) can provide a true mirror finish. Different finishes can also affect the surface roughness, with brushed finishes having the same code (2J) as dull polished finishes. Careful consideration of the surface roughness must be taken when selecting the appropriate finish for a stainless steel application.

Choosing the right stainless steel finish depends on various factors such as the intended application, aesthetic preferences, and maintenance requirements. Here’s a guide to help you select the best finish for your project:

By understanding the requirements of your project, you can confidently choose the finish that best balances aesthetics, durability, and functionality.

Mill finishes are created without pickling or passivation, while polished finishes are achieved through satinizing, sanding, blasting, and other processes. Polished finishes offer a smoother and brighter look while providing improved corrosion resistance.

The roughness of stainless steel can impact its performance in several ways. Smooth surfaces offer better corrosion resistance and temperature tolerance, while rougher surfaces can affect stress strength, paint adhesion, and alloy selection. Proper selection of the right grade and finish is critical to ensure optimal performance.

Brushing and buffing are mechanical processes used to improve the appearance of stainless steel surfaces. Brushing uses a fine abrasive action whereas buffing uses cotton or felt-based media. Sanding, pickling, grinding, acid-etching, anodizing, and coating are different processes than brushing and buffing.

The temper rolled finish offers many benefits, including improved heat treatment, electrolytic cleaning, satin finish, passivation treatment, and mechanical polishing. This finish gives the stainless steel increased strength and a superior surface while providing excellent control over the surface's properties.

Sandblasting uses abrasives to roughen the surface of the steel while electro-polishing etches the surface with an electric current. Oxide coating, pickling acid, and chemical etching are also used to etch the surface. Bead blasting is also used to remove surface contaminants.

Blog Series:

In conclusion, stainless steel tube surface finishes come in a variety of types, each with its unique properties and uses.

While these stainless steel surface finish types offer many benefits, it is important to understand the different tools and techniques used to achieve them.

Choosing the right stainless steel surface finish not only improves durability but also impacts maintenance requirements. By taking the time to properly consider each option, one can ensure that the stainless steel surface finish chosen is the right one for the job.

Just like a jigsaw puzzle, the right pieces must be selected to complete the perfect picture.