Like a steel fortress, stainless steel tubes offer strength and stability to a variety of applications. Renowned for its corrosion resistance and durability, stainless steel tube material is a reliable choice for many industries.

Stainless steel tube material is made from an alloy of iron and chromium, known for its durability and high resistance to corrosion. It is a popular choice in construction, automotive, medical , aerospace ,food industry and other industries due to its corrosion resistance, durability, and affordability. Stainless steel tube material comes in various grades, such as 201 ,304, 316 etc.

In this article, we will cover the various grades of stainless steel tube material as well as the different types of stainless steel tubes available. With this information, readers will gain an in-depth understanding of why stainless steel tube is a preferred material for many applications. And they will have an understanding of how to identify the right stainless steel tube material for their needs and where it should be used.

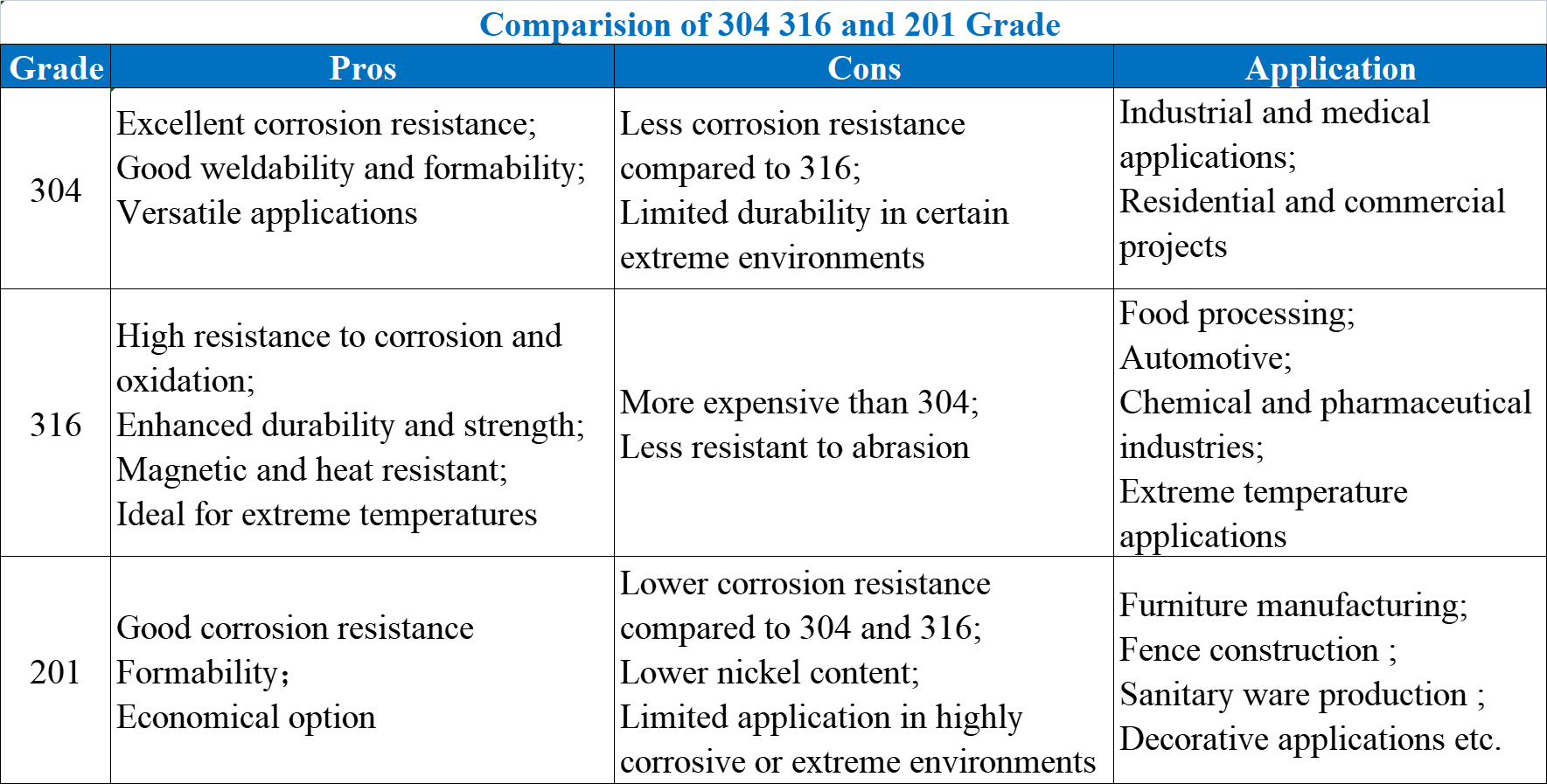

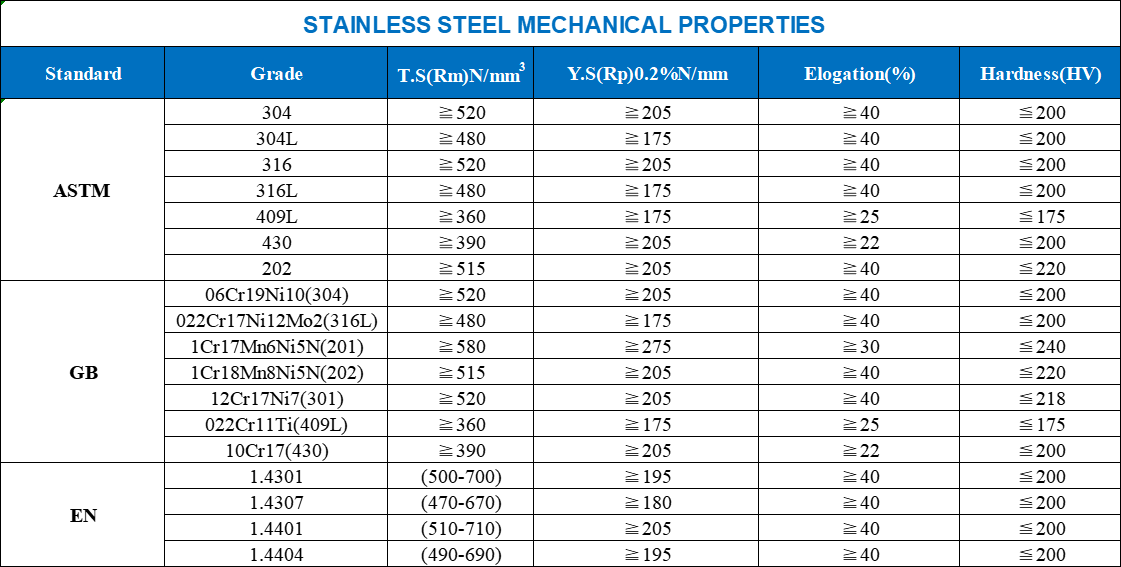

Stainless steel tubing is categorized into various grades, each with distinct properties and applications.

The 300 series, particularly grades T304 and T316, are known for their excellent corrosion resistance.

In contrast, the 400 series, exemplified by grade 410, offers enhanced strength and hardness.

Additionally, the 400 series, represented by grade 430, and precipitation hardening options, such as 201 stainless steel, further expand the range of material choices tailored for specific industrial requirements.

304 stainless steel is the most widely used austenitic stainless steel grade. It contains 18-20% chromium and 8-10.5% nickel. The properties of 304 stainless steel tube material are well-suited to many applications. Its resistance to corrosion and oxidation make it a popular choice for industrial and medical applications, as well as residential and commercial projects.

Learn More:

The Life Expectancy of 304 Stainless Steel

304 Stainless Steel Tube- Every thing you need to Know

This grades contain 16-18% chromium, 10-14% nickel, and 2-3% molybdenum.This metal is highly sought after for its resistance to corrosion and oxidation, making it an ideal choice for a variety of applications.

316 Stainless steel tube material offers an array of advantages, such as its durability, strength, and aesthetic appeal. It is non-magnetic and heat resistant, making it suitable for a variety of industries, including food processing, automotive, chemical, and pharmaceutical.

Additionally, stainless steel tube material is resistant to extreme temperatures, making it a great choice for applications requiring extreme temperatures.

Learn More:

316 Stainless Steel Tube Properties: Key Insights for Engineers and Designers

The Life Expectancy of 316 Stainless Steel

Differences Between 316 and 316L Welded Stainless Steel Pipe

201 stainless steel is an austenitic chromium-nickel-manganese stainless steel alloy. This grade normally contain 16-18% chromium , 3.5%-5.5% nickel .

It is also known for their high levels of chromium and nickel content, providing excellent corrosion resistance and formability. his makes them ideal for use in a variety of industries, including :furiture , fence, sanitary ware , etc.

You may also like:

Will 201 stainless steel rust?

Mastering the Art of 201Stainless Steel Welding

Martensitic stainless steel grade 410 offers a unique combination of moderate corrosion resistance and high strength, making it suitable for applications requiring both durability and the ability to withstand wear and tear. This grade exhibits distinct martensitic properties, characterized by its ability to be hardened through heat treatment processes, which enhance its mechanical strength.

The corrosion resistance of grade 410 is adequate for many environments, but it is not as robust as that of austenitic grades. Consequently, it is often recommended for use in applications where exposure to corrosive elements is limited. The mechanical strength of 410 makes it ideal for manufacturing components such as cutlery, valves, and pump shafts.

Welding techniques for martensitic stainless steel require careful consideration due to its susceptibility to cracking. Preheating and post-weld heat treatment are often necessary to mitigate this risk and guarantee structural integrity.

In contrast to the 400 series martensitic stainless steels, the 430 grade ferritic stainless steel offers improved corrosion resistance and is particularly well-suited for applications where aesthetic appearance and moderate strength are required.

The ferritic properties of grade 430, characterized by its high chromium content, enhance its ability to withstand corrosive environments, making it a popular choice for various applications, including automotive trim, kitchen appliances, and architectural panels.

The corrosion resistance of 430 stainless steel is notable; it performs well in mildly corrosive media, although it may not be suitable for aggressive environments. Additionally, its thermal conductivity is superior compared to other stainless steel grades, which can be advantageous in applications requiring efficient heat transfer.

Weldability factors for grade 430 are moderate; while it can be welded using standard techniques, proper precautions and pre-heating are recommended to mitigate the risk of weld cracking.

An applications overview indicates that this grade is favored in the food processing industry and decorative applications due to its aesthetic appeal, making it a versatile choice in both functional and visual contexts.

Precipitation hardening stainless steel grades, such as 17-4 PH and 15-5 PH, are engineered to achieve high strength and excellent corrosion resistance through a controlled heat treatment process.

The unique stainless steel properties of these grades arise from the precipitation of finely dispersed particles that enhance mechanical strength without greatly compromising ductility.

The heat treatment process typically involves solution annealing followed by aging, which allows for the precipitation of specific alloying elements such as copper and niobium. This precipitation hardening mechanism is vital for achieving ideal performance in demanding applications.

For instance, 17-4 PH exhibits a yield strength of up to 100 ksi (690 MPa) after appropriate aging, making it suitable for aerospace and marine environments.

In addition to superior mechanical strength, these precipitation-hardened grades offer remarkable corrosion resistance, surpassing that of standard stainless steel grades in many environments.

This combination of high strength and corrosion resistance makes them ideal for applications in industries such as oil and gas, chemical processing, and aerospace, where reliability and performance are paramount.

Therefore, understanding the heat treatment process and its impact on stainless steel properties is essential for selecting the appropriate grade for specific applications.

When comparing various stainless steel materials, 316 stainless steel stands out due to its enhanced corrosion resistance and suitability for harsh environments. This alloy, which contains molybdenum, offers improved protection against pitting and crevice corrosion, making it ideal for marine and chemical processing applications.

With regard to mechanical properties, 316 stainless steel exhibits excellent tensile strength and ductility, which are critical for structural integrity in challenging conditions.

A cost comparison between 316 stainless steel and other grades, such as 304, reveals that while 316 tends to be more expensive due to its alloying elements, the long-term benefits of durability and reduced maintenance costs can justify the investment.

Fabrication techniques for 316 stainless steel are versatile, including welding, bending, and machining, allowing it to be tailored for various industry applications, such as pharmaceuticals, food processing, and oil and gas.

Ultimately, when selecting materials for specific applications, the superior corrosion resistance and mechanical properties of 316 stainless steel make it a preferred choice despite its higher initial cost, underscoring its value in demanding environments.

Learn More:

The most common standards include ASTM A312, ASTM A554, and EN 10217, each specifying key characteristics such as mechanical strength, dimensional tolerances, and surface finishes that are essential for performance.

| Standard | Key Features | Applications |

|---|---|---|

| ASTM A312 | Seamless and welded tubes, high corrosion resistance | Oil and gas, chemical processing |

| ASTM A554 | Decorative and structural tubing, specified surface finishes | Architectural applications |

| EN 10217 | Welded tubes for pressure purposes, enhanced mechanical properties | Power generation, construction |

These stainless steel tube standards facilitate the selection of the appropriate stainless steel tube for specific applications, ensuring that the final product exhibits excellent corrosion resistance and superior performance under various operational conditions. Adhering to these standards also simplifies the integration of different components within projects, allowing for seamless interoperability.

This stainless steel pipe variety is crafted from solid chromium, nickel-chromium combination, or a fusion of chromium and nickel.

Categories of stainless steel pressure pipes encompass seamless and welded versions, electric fusion-welded pipes for high-pressure uses, large-diameter welded pipes for corrosive or high-heat scenarios, as well as both ferritic and austenitic stainless steel pipes, available in seamless and welded forms.

Pressure pipes and tubes are used to transport fluids such as water, gas, and oil .

The welded versions of pressure pipes and tubes are classified according to the American Society for Testing and Materials (ASTM) A249, A269, and A270 standards.

ASTM A249/ A269 standard stainess steel tube apply in heat exchanger, condenser , bolier , etc and ASTM A270 stainless steel tube apply in food industry, beer industry , comestics industry, chemical fiber industry etc. These industries will use stainless steel grades 304, 304L, 316Lfor production.

Stainless Steel Mechanical pipes and tubes are mainly used in building construction , furniture , railing and fence system, machine production etc.

This kind of stainless steel tube can be manipulated to exhibit a diverse range of cross-sectional shapes, including stainless steel square tube and stainless steel rectangular tube, in addition to the conventional round tubing design.

Generally, mechanical tubing applications make use of ASTM A511 and A554 grades. Grades 304/304L and 316/316L, 201 as well as ferritic stainless steel tubes in grade 430, are frequently applied in this ine above industry.

Aircraft tubing is a type of stainless steel tube material often used in aircraft components. Its composition and strength make it an advantageous choice, as it resists corrosion, retains its strength at elevated temperatures, and can be formed into a variety of shapes. The material is also lightweight and strong, making it an ideal choice for aircraft components.

In addition, the material is easy to machine and weld, allowing for precise fabrication. Understanding the properties of stainless steel aircraft tubing is essential to making the best choice for aircraft components. Thus, determining which stainless tube material is best for aircraft tubing is essential.

The ideal material should possess sufficient strength, be corrosion resistant, easy to fabricate, and lightweight. 316 stainless steel has the best balance of these properties, so is the most suitable choice for aircraft tubing.

Stainless steel tubes are a popular choice for a variety of applications due to their strength and durability. The selection of the grade of stainless steel tube material is determined by the application and cost. 304 stainless steel tube material are well-suited to many applications. 201 is the least expensive and has a higher manganese content. 316 stainless steel is in a higher resistance to corrosion and greater durability and it is more expensive.

stainless steel tubes are applied in various applications. Pressure pipes come in seamless and welded forms, transporting fluids like water and oil. 304 304L and 316stainless steel tube material are often apply in pressure pipes . Mechanical tubes find use in construction and machines, with shapes like square and rectangular. 201 304 and 316 ,430 stainless steel tube material are often apply in mechanical pipes and tube. Aircraft tubing, known for corrosion resistance and strength at high temperatures, is lightweight and easily fabricated. Grade 316 stainless steel is commonly chosen for aircraft tubing due to its balanced properties.

At Vinmay Stainless Steel, we take pride in glboally providing reliable stainless steel welded tube for construction and equipment industries . If you are looking for high quality stainless steel welded tubes or have any questions. please don't hesitate to reach out to us. We are here to assist you and provide the information you need. Contact us today for all your ss tube requirements.