The utilization of stainless steel tube for ornamental and construction applications presents a compelling intersection of durability and design. With a variety of shapes available, these tubes cater to a wide range of architectural needs, from structural integrity to aesthetic enhancement. Their inherent resistance to corrosion and low maintenance requirements make them a practical choice for long-term projects. However, the question remains: what specific factors should one consider when selecting the right type of stainless steel tube for a given application? Understanding these nuances can significantly impact project outcomes.

Stainless steel is the material of choice for ornamental tube products due to its exceptional corrosion resistance, durability, and versatility, making it ideal for both aesthetic and functional applications across various environments.

The current design trends favor stainless steel for its sleek, modern appearance, which enhances the aesthetic appeal of structures while meeting rigorous performance benefits. Its robust construction ensures longevity and minimal maintenance, addressing the growing market demand for sustainable and cost-effective materials.

When considering installation tips, it is essential to select the appropriate grade and surface finish, as these factors influence both the visual quality and functional longevity of the installation.

For instance, opting for a polished or brushed finish can not only elevate the design but also facilitate easier cleaning. Moreover, understanding the specific performance characteristics of different grades, such as 304 versus 316, can inform material selection based on environmental exposure.

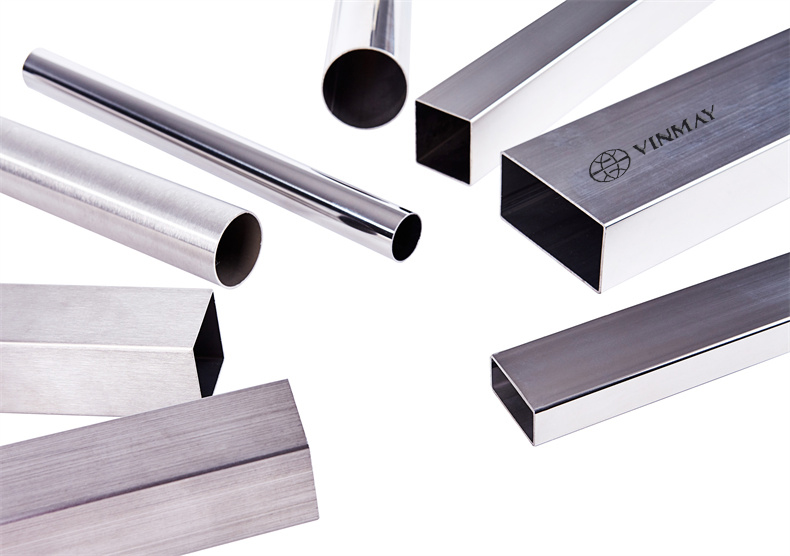

The shapes of stainless steel tubes—round, square, and rectangular—offer distinct advantages for both ornamental and construction applications.

Each shape not only influences aesthetic appeal but also affects performance and usability, necessitating careful consideration during material selection.

Understanding the specific requirements of a project is crucial in determining the most suitable tubing shape to achieve optimal results.

Round models of stainless steel tube for ornamental and construction offer significant versatility in both ornamental and construction applications, providing a robust option that balances aesthetic appeal with functional strength. The inherent design flexibility of round stainless steel tubing allows for innovative architectural solutions, making it a favored choice for handrails, supports, and decorative features.

One of the key advantages of round models is their structural integrity, which is crucial for load-bearing applications. The uniform shape distributes stress evenly, minimizing the risk of failure under load. This characteristic is particularly beneficial in environments where safety and durability are paramount, such as in public spaces and commercial buildings.

Installation techniques for stainless steel round tube are also straightforward, allowing for efficient assembly and integration into various projects. The ease of connecting round tubing to other materials enhances its usability across a range of applications, from residential to industrial.

Furthermore, round tubing's smooth surface facilitates cleaning and maintenance, ensuring longevity without the need for extensive upkeep. Overall, the combination of aesthetic appeal, design flexibility, structural integrity, and practical installation techniques positions round stainless steel tubing as an indispensable choice in modern construction and ornamental design.

Square models of stainless steel tubing provide distinct advantages in both structural integrity and aesthetic versatility, making them a favored option for various ornamental and construction applications. One of the primary square tubing benefits lies in its ability to support significant loads while maintaining a compact form factor, ideal for structural frameworks and decorative elements alike.

The use of stainless steel square tube enhances aesthetic design through clean lines and uniformity, allowing for seamless integration into modern architectural styles. Its geometric shape offers design flexibility, enabling architects and builders to create distinctive features that elevate the visual appeal of structures.

Moreover, installation techniques for square models are often straightforward, facilitating efficient assembly and reducing labor costs. The uniform dimensions of square tubing simplify connections and fittings, leading to streamlined construction processes.

Customization options are abundant, as square stainless steel tubes can be tailored to specific dimensions, finishes, and grades to meet project requirements. This adaptability ensures that square models can be utilized in a wide range of applications, from handrails to frames, providing both functional and aesthetic solutions in the realm of ornamental and construction projects.

Rectangular stainless steel tubing plays a crucial role in both ornamental and construction applications, offering enhanced structural support and design versatility compared to other shapes. This type of tubing is particularly valued for its exceptional structural integrity, allowing it to bear significant loads while maintaining stability. Its design caters to a wide array of decorative applications, from elegant railings to modern architectural features, demonstrating aesthetic versatility.

Dimensional accuracy is a key attribute of rectangular tubing, which is available in a range of sizes, typically from 0.5x1 inches to 0.5x12 inches. This precision ensures that the tubing fits seamlessly into various constructions and installations, which is essential for maintaining overall quality and safety. Additionally, the flat surfaces of rectangular tubing allow for a more extensive range of connections and mounting options, enhancing both functionality and aesthetic appeal.

Furthermore, the capacity to customize rectangular stainless steel tubing to specific project requirements further solidifies its position as a preferred choice in both decorative and structural contexts. Ultimately, the unique attributes of rectangular tubing make it an invaluable asset in today's construction and design industries.

Stainless steel ornamental tubing is extensively utilized in a variety of applications, including architectural features, safety installations, and functional components across both residential and commercial environments. Its versatility allows for integration into design aesthetics, enhancing the visual appeal of spaces while adhering to safety standards.

Common applications include handrails, grab bars, and decorative trim, where both load capacity and stability are crucial. In commercial settings, stainless steel tubing is often found in equipment such as vehicle running boards, restaurant appliances, and medical devices, emphasizing its functional benefits.

Installation techniques vary based on specific applications, ensuring that structural integrity is maintained while facilitating ease of use and maintenance. Market trends indicate a growing preference for stainless steel due to its corrosion resistance and minimal upkeep requirements, making it a cost-effective choice over time.

Additionally, advancements in finishing options allow for custom designs that meet the aesthetic and practical needs of diverse projects. Thus, stainless steel tube for ornamental and construction not only serves functional roles but also significantly contributes to the overall design language of modern architecture and infrastructure.

Stainless steel tube for ornamental and construction offers a unique combination of aesthetic appeal and structural integrity, making it an ideal choice for both decorative and functional applications in modern design.

The use of stainless steel tubing enhances design aesthetics through its sleek, polished surfaces and ability to be formed into various shapes, allowing designers to create visually striking elements.

In addition to its visual attributes, stainless steel tube for ornamental and construction provides exceptional structural integrity, ensuring that installations are robust and long-lasting. This characteristic is essential for high-traffic environments where durability is paramount.

Furthermore, the application versatility of stainless steel tube for ornamental and construction makes it suitable for a wide range of uses, from handrails to decorative frames.

Another significant advantage is maintenance ease; stainless steel requires minimal upkeep, typically only needing a wipe with warm water and mild soap to maintain its appearance.

This feature not only reduces long-term maintenance costs but also promotes sustainability by extending the lifespan of the material.

When selecting stainless steel tube for ornamental and construction , several critical factors must be evaluated, including the shape and size that align with the intended application.

The choice of material grade is essential for ensuring appropriate corrosion resistance, particularly in challenging environments.

Additionally, the finish of the tubing not only affects aesthetic appeal but also influences maintenance requirements and durability.

Selecting the appropriate shape and size of stainless steel tube for ornamental and construction is crucial for ensuring optimal performance and aesthetic appeal in various applications. The primary shapes available—round, square, and rectangular—offer significant design flexibility, allowing architects and designers to achieve desired visual effects while meeting structural requirements.

When considering tubing applications, the specific use case should guide the selection process. For instance, round tubing is often preferred for handrails due to its ergonomic design, while square or rectangular shapes may provide enhanced stability in structural applications.

Sizing is equally important; round tubes typically range from 0.5 to 6 inches, whereas square tubes can vary from 0.5 to 8 inches, and rectangular tubing sizes range from 0.5x1 inches to 0.5x12 inches.

Additionally, the choice of shape and size directly influences corrosion resistance and maintenance needs. Proper installation tips, such as ensuring secure fittings and appropriate mounting locations, can further enhance longevity and performance.

Ultimately, a thoughtful approach to selecting ornamental tubing shapes and sizes will yield both functional and aesthetic benefits in any project.

Determining the ideal grade of stainless steel tube for ornamental and construction requires a thorough understanding of the specific environmental conditions and application requirements to ensure optimal performance and durability.

A detailed grade comparison between 304/304L and 316/316L is essential, as these grades offer varying levels of corrosion resistance. The 304 series stainless steel is suitable for less aggressive environments, while the 316 series excels in chloride-rich or acidic conditions, making it preferable for swimming pool applications and coastal installations.

Consideration of the environmental impact is critical; exposure to corrosive substances could significantly diminish the lifespan of the tubing. Additionally, the aesthetic appeal of the finished product is influenced by the chosen grade, as it affects the surface finish options available and the overall visual quality.

Furthermore, understanding the associated manufacturing processes can inform decisions related to fabrication and installation. The right grade not only enhances corrosion resistance but also ensures that the ornamental tubing meets the performance standards required for both structural integrity and design.

Selecting the appropriate stainless steel grade is a balance of functionality, aesthetic requirements, and environmental resilience, thereby guaranteeing long-term satisfaction and effectiveness in various applications.

When selecting stainless steel ornamental tubing, the finish is a critical factor that influences both aesthetics and functionality.

The mill finish on stainless steel ornamental tubing serves as a foundational consideration, influencing both aesthetic appeal and the material's suitability for various applications.

Mill finish benefits include cost-effectiveness and durability, while its maintenance requires minimal effort.

Aesthetically, it offers a raw, industrial look, making it suitable for diverse environments, from architectural designs to functional structures, without compromising performance.

180 grit stainless steel refers to the level of fineness of the surface finish on stainless steel products. The grit number indicates the size of the abrasive particles used during the polishing process, with a lower number representing a coarser finish and a higher number indicating a finer finish.

600 grit stainless steel tube refers to a finer surface finish than 180 grit, often used in applications where aesthetics and corrosion resistance are important. Here are some key characteristics:

When selecting stainless steel ornamental tubing, several critical factors must be evaluated to ensure optimal performance and suitability for the intended application.

Weight plays a significant role in structural integrity and ease of installation, while environmental suitability determines the appropriate material grade to withstand specific conditions.

Additionally, cost considerations are essential for balancing budget constraints with desired quality and durability.

Weight is a critical factor to consider in the selection of stainless steel ornamental tubing, as it influences structural integrity, ease of installation, and overall performance in various applications.

Proper weight distribution and weight capacity ensure safety, while weight tolerance affects durability.

Conducting a weight comparison among different tubing options enhances weight efficiency, optimizing choice for both decorative and functional purposes.

Environmental suitability is a crucial consideration in the selection of stainless steel tube for ornamental and construction, as it directly affects the material's performance and longevity in specific applications and conditions.

Evaluating environmental impact, including recycling benefits and sustainable sourcing, is essential.

Additionally, considering the life cycle and energy efficiency of the materials ensures responsible usage, promoting durability while minimizing ecological footprints in various projects.

Evaluating the cost of stainless steel tube for ornamental and construction requires a comprehensive analysis of various factors, including material grade, shape, finish, and customization options, which collectively influence both initial investment and long-term value.

Conducting a thorough cost analysis, utilizing budgeting tips, and performing pricing comparisons are essential for value assessment, enabling informed decisions that enhance long-term savings and maximize project efficiency.

Read More:

Deciphering the Dynamics: Unraveling Stainless Steel Round Tube Prices

In conclusion, stainless steel tubes present a compelling solution for ornamental and construction applications, combining aesthetic appeal with superior durability and corrosion resistance.

Their versatility in shape and design accommodates a wide array of architectural and safety requirements.

The low maintenance and extended lifespan of stainless steel tubes contribute to sustainable practices in construction.

Consideration of specific project needs and customization options further enhances the efficacy of stainless steel tubing in meeting diverse functional and design objectives.