Stainless steel round pipe for sales present a durable and versatile solution for various industrial applications. With their corrosion-resistant properties and structural integrity, these pipes offer a reliable option for projects requiring robust materials. The availability of different stainless steel round pipe for sales grades and sizes allows for tailored selections based on specific project requirements. However, beyond their basic specifications, there are additional factors to consider when choosing the ideal stainless steel round pipe for your needs. It's essential to explore the nuances of these factors to make informed decisions that align with your project goals and budget constraints.

When considering grade of stainless steel round pipe for sales, it is essential to analyze the chemical composition and mechanical properties of each grade.

Grades such as 201, 304, 304L, 316, and 316L offer distinct characteristics that cater to various industrial applications.

Understanding the specific attributes of each grade is crucial in selecting the most suitable stainless steel round pipe for your project requirements.

Learn More:

Will 201 stainless steel rust?

Mastering the Art of 201Stainless Steel Welding

You may also like:

Can 304 stainless steel rust ?

The Life Expectancy of 304 Stainless Steel

What Is the Difference Between 201 and 304 Stainless Steel?

Read More:

The Life Expectancy of 316 Stainless Steel

| Element | 201 | 304 | 304L | 316 | 316L | 430 |

|---|---|---|---|---|---|---|

| Carbon (C) | ≤ 0.15% | ≤ 0.08% | ≤ 0.03% | ≤ 0.08% | ≤ 0.03% | ≤ 0.12% |

| Manganese (Mn) | 5.5 - 7.5% | ≤ 2.0% | ≤ 2.0% | ≤ 2.0% | ≤ 2.0% | ≤ 1.0% |

| Silicon (Si) | ≤ 1.0% | ≤ 0.75% | ≤ 0.75% | ≤ 0.75% | ≤ 0.75% | ≤ 1.0% |

| Phosphorus (P) | ≤ 0.06% | ≤ 0.045% | ≤ 0.045% | ≤ 0.045% | ≤ 0.045% | ≤ 0.04% |

| Sulfur (S) | ≤ 0.03% | ≤ 0.03% | ≤ 0.03% | ≤ 0.03% | ≤ 0.03% | ≤ 0.03% |

| Chromium (Cr) | 16.0 - 18.0% | 18.0 - 20.0% | 18.0 - 20.0% | 16.0 - 18.0% | 16.0 - 18.0% | 16.0 - 18.0% |

| Nickel (Ni) | 3.5 - 5.5% | 8.0 - 10.5% | 8.0 - 12.0% | 10.0 - 14.0% | 10.0 - 14.0% | ≤ 0.75% |

| Molybdenum (Mo) | - | - | - | 2.0 - 3.0% | 2.0 - 3.0% | - |

| Nitrogen (N) | ≤ 0.25% | ≤ 0.10% | ≤ 0.10% | ≤ 0.10% | ≤ 0.10% | - |

| Copper (Cu) | 0.8 - 1.5% | - | - | - | - | - |

How does ASTM A554 define the application standards for Stainless Steel Round Pipe for sales industry?

ASTM A554 sets the guidelines for the properties, welding techniques, surface finish, polishing methods, and material compatibility of stainless steel welded round tube.

Here are the key aspects outlined by ASTM A554:

The ASTM A270 standard delineates the sanitary requirements and specifications for stainless steel round pipes intended for sales within the industry. This standard emphasizes the importance of surface finish in ensuring the cleanliness and corrosion resistance of the pipes, particularly in applications where hygiene is crucial.

Welding techniques outlined in ASTM A270 are designed to maintain the integrity of the pipe's surface, preventing contamination and ensuring structural strength. Hygienic stainless steel tube specified in this standard aim to meet the stringent requirements of industries such as food processing and pharmaceuticals, where cleanliness is paramount.

Fabrication methods compliant with ASTM A270 ensure that the pipes are manufactured in a way that upholds their sanitary properties and dimensional accuracy. Additionally, cleaning procedures recommended by this standard are essential for maintaining the hygienic integrity of stainless steel round pipes, prolonging their service life and ensuring optimal performance in sanitary applications.

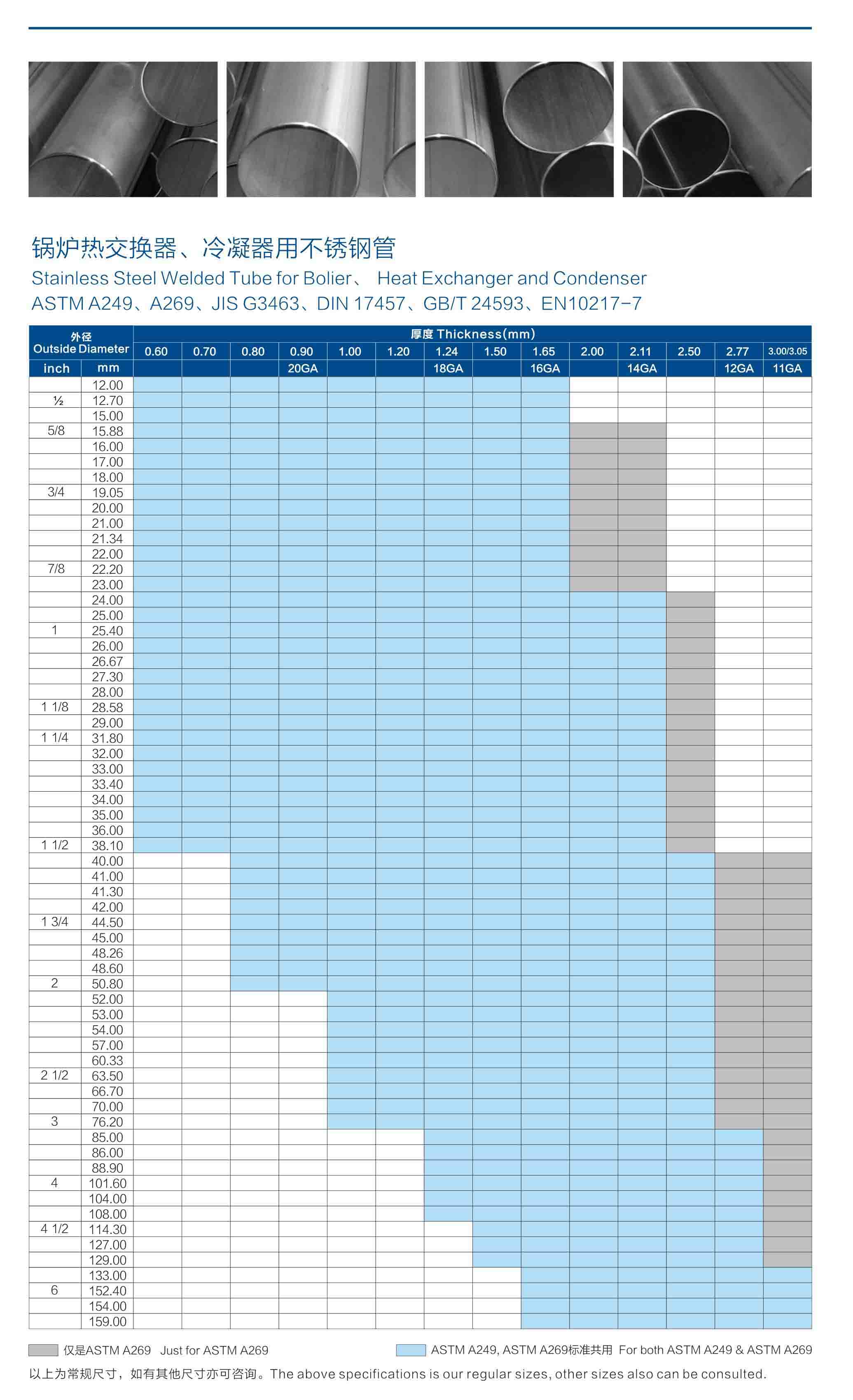

ASTM A249 is a standard specification established by ASTM International that covers welded austenitic steel boiler, superheater, heat-exchanger, and condenser tubes. These tubes are intended for high-temperature and general corrosion service. The specification outlines the requirements for the chemical composition, mechanical properties, dimensions, and surface finish of the tubes to ensure their suitability for these demanding applications.

Key points of ASTM A249 include:

ASTM A249 ensures that the tubes produced under this standard are reliable and capable of performing in the harsh environments they are designed for.

ASTM A269 is a standard specification developed by ASTM International that covers seamless and welded austenitic stainless steel tubing for general corrosion-resisting and low- or high-temperature service. This specification is widely used in industries that require high corrosion resistance and the ability to withstand various temperature ranges.

Key points of ASTM A269 include:

ASTM A269 ensures that stainless steel tubing produced under this standard is reliable and capable of performing in environments requiring high resistance to corrosion and varying temperatures.

EN 10312 is a European standard specification for welded stainless steel tubes used for the conveyance of aqueous liquids, including stainless steel water tube system. The specification details the requirements for the chemical composition, mechanical properties, dimensions, and surface quality of the tubes to ensure their suitability for plumbing and water distribution systems.

Key points of EN 10312 include:

EN 10312 ensures that the welded stainless steel tubes produced under this standard are reliable, safe, and suitable for use in water distribution and plumbing applications.

You may also like:

Stainless steel round pipe for sales exhibit excellent workability characteristics, making them easy to weld with appropriate equipment.

Alongside this weldability, they offer moderate cutting, forming, and machining abilities, providing flexibility in stainless steel tube fabrication processes.

Furthermore, these pipes possess favorable mechanical properties that contribute to their overall durability and structural integrity.

Achieving strong and durable welds with stainless steel round pipes requires specialized equipment and expertise due to the material's workability characteristics. When considering stainless steel round pipe for sales, it is essential to understand the following:

Welding Techniques: Proper welding techniques such as TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding are commonly used to join stainless steel round pipes effectively.

Joint Strength: The strength of the weld joints in stainless steel pipes is crucial for ensuring structural integrity and longevity.

Welding Equipment: Specialized welding equipment like high-quality electrodes, shielding gas, and welding machines designed for stainless steel are necessary for optimal results.

Welding Challenges: Challenges such as heat distortion, chromium carbide precipitation, and proper back purging must be addressed when welding stainless steel pipes.

Welding Applications: Stainless steel round pipes find applications in various industries, including food processing, chemical containers, architectural paneling, and more, highlighting the importance of mastering welding techniques for different purposes.

Learn More:

Stainless Steel Pipe Welding Standards: Key Guidelines

When working with stainless steel round pipes, the process of cutting can be characterized as moderate in terms of workability, requiring specific tools and methods to achieve precise results. Precision cutting is essential when working with stainless steel pipes to ensure accuracy in dimensions and a clean finish. Cutting techniques such as sawing, plasma cutting, or water jet cutting are commonly used for stainless steel round pipe for sales, each offering its own advantages in terms of speed, accuracy, and cost-effectiveness.

Tool selection plays a crucial role in achieving precise cuts on stainless steel pipes. Tools like band saws with bi-metal blades, plasma cutters with fine nozzles, or water jet cutters are commonly used for cutting stainless steel pipes. It is important to select the appropriate tool based on the pipe's thickness and the desired cut quality.

Safety measures must be strictly adhered to when cutting stainless steel pipes to prevent accidents and ensure a secure working environment. Proper protective gear such as gloves, goggles, and hearing protection should be worn at all times. Additionally, proper ventilation to remove fumes generated during cutting is essential to maintain a safe workspace.

Despite the advantages of stainless steel, cutting poses challenges due to its hardness and toughness. The material's tendency to work-harden during cutting can lead to increased tool wear and potential deformation of the pipe. Hence, proper cutting techniques, tool selection, and adherence to safety measures are crucial to overcoming these challenges and achieving precise cuts on stainless steel round pipes.

Forming and machining stainless steel round pipe for sales requires specialized equipment and precise techniques to achieve accurate results. When working with stainless steel pipes, several key considerations come into play:

Addressing these aspects is essential to overcome fabrication challenges and ensure the quality and functionality of stainless steel round pipes in various applications.

You may also like:

How to Weld Stainless Steel Tubing Like a Pro

Working with stainless steel round pipe for sales requires an understanding of their mechanical properties, particularly in terms of workability for forming and machining processes. Stainless steel exhibits excellent temperature resistance, making it suitable for applications where exposure to high heat is common.

The surface finish of stainless steel round pipe for sale is typically smooth and aesthetically pleasing, enhancing their overall appearance in various industries. In terms of mechanical properties, stainless steel pipes offer high impact strength, ensuring durability in demanding environments. Additionally, their flexibility allows for easier shaping and manipulation during manufacturing processes.

Stainless steel round pipe for sale also possess good thermal conductivity and electrical conductivity, making them suitable for applications requiring heat transfer or electrical conduction. Moreover, stainless steel pipes exhibit a balance between hardness and toughness, providing both strength and resilience.

Understanding the pressure rating of stainless steel pipes is essential to ensure they are used within safe operating limits. Proper surface treatment can further enhance the corrosion resistance and longevity of stainless steel round pipes.

Foshan Vinmay Stainless Steel Co.,ltd is large-scale international enterprise which concentrates on producing stainless steel welded tubes and the related fittings. With the large-scale production capacity , advanced equipments and technology , a professional sales and management team the good credit guarantee, Vinmay has been offering high quality and value added products and service to our clients all over the world.

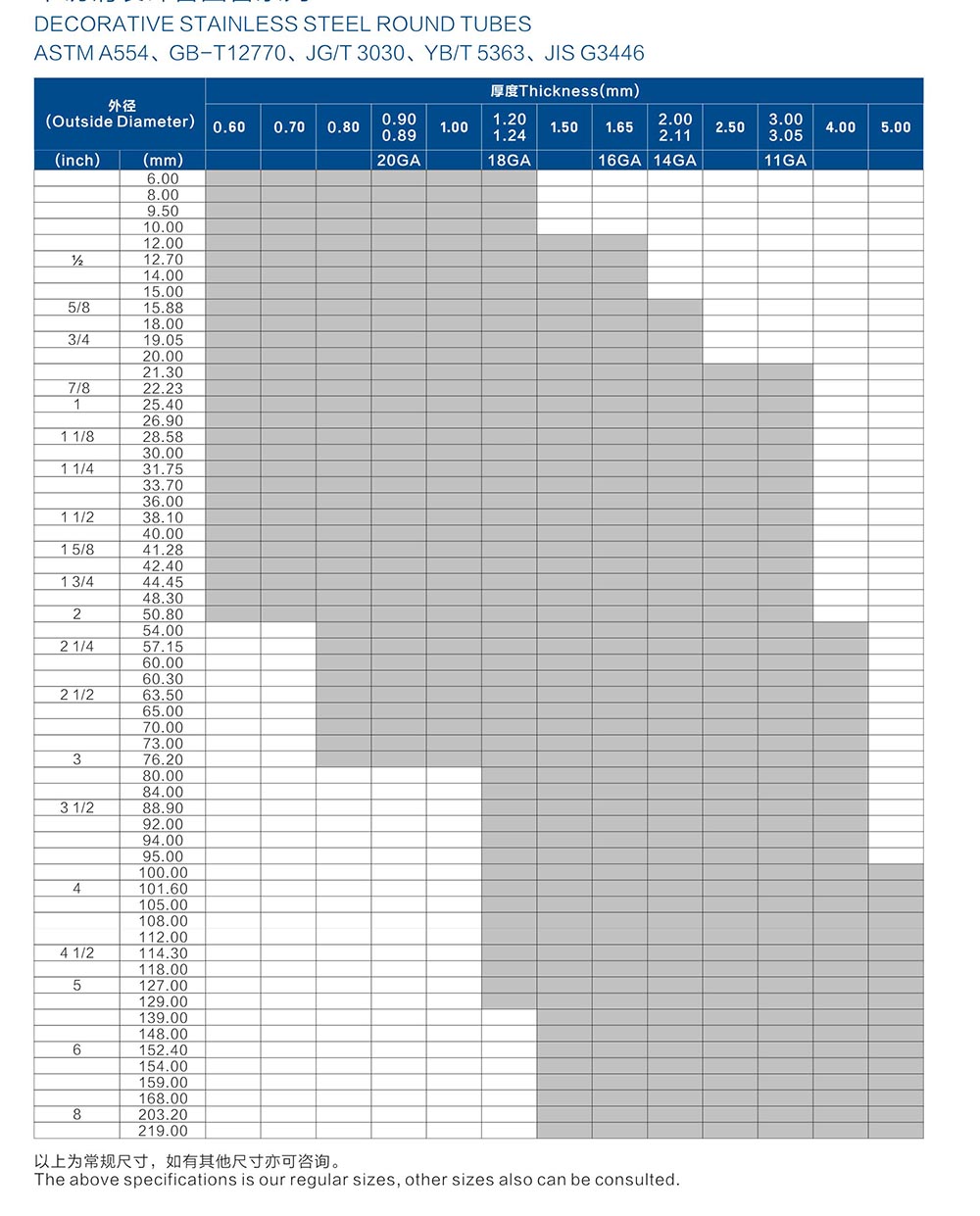

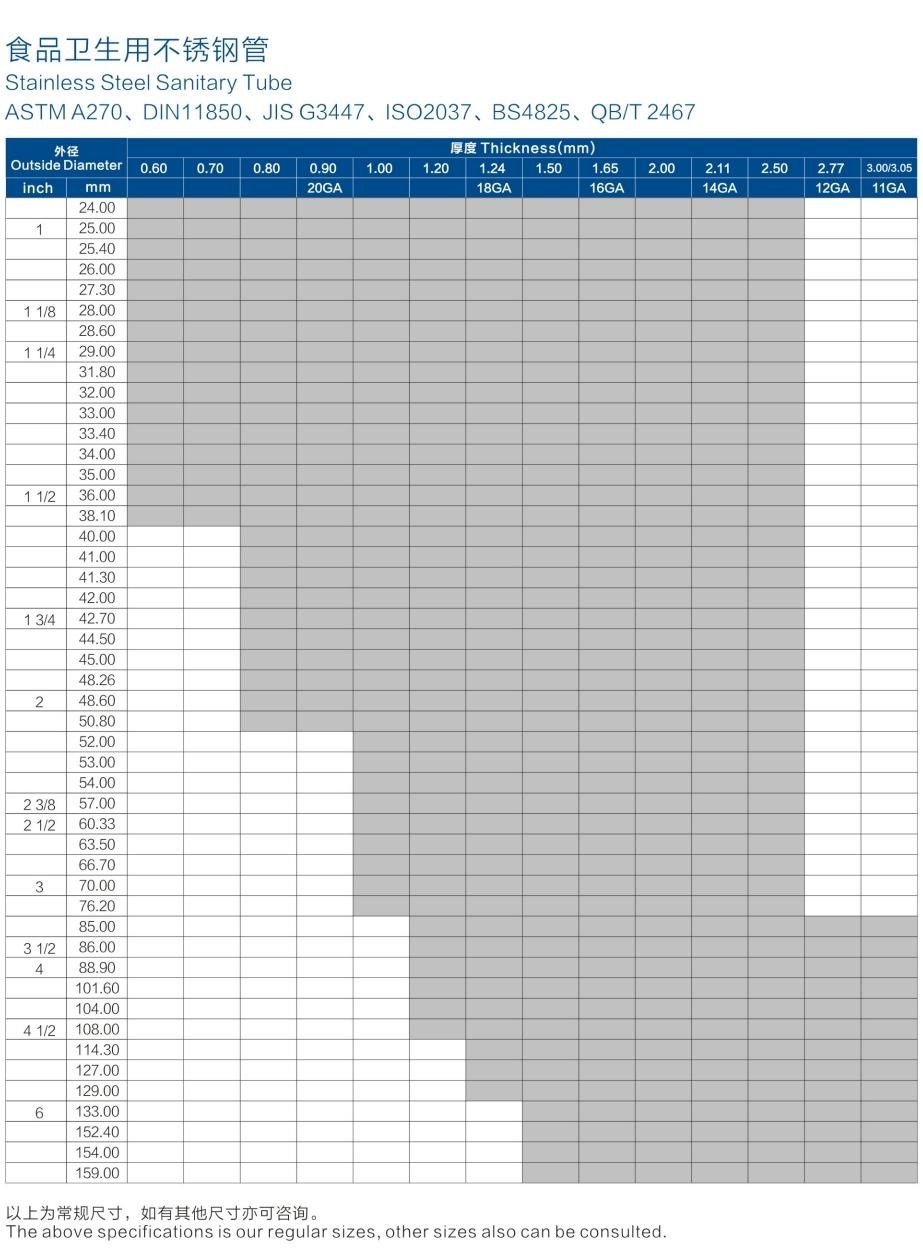

Our products are strictly produced according to multiple international stainless steel tube standards including stainless steel welded tubes for ornamental and mechanical structure purposes ( ASTM A554/EN10296-2); stainless steel welded tubes for boiler, heat exchanger and condenser ( ASTM A249, EN10217-7); stainless steel sanitary welded tubes ( ASTM A270 , DIN11850) and light gauge stainless steel water tubes ( EN10312). The following size list are our available stainless steel round pipe size

Read More:

A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

The stainless steel round pipe price for sales is influenced by various factors such as grade, size, and market demand. When considering the cost of stainless steel round pipes, it is essential to conduct a pricing comparison across different suppliers to ensure a competitive rate. Market trends play a significant role in determining the price fluctuations of stainless steel round pipes, with industry insights providing valuable information on when to make purchasing decisions.

Customer reviews can also offer insights into the price-to-quality ratio of stainless steel round pipes from specific suppliers.

To help save costs when purchasing stainless steel round pipes, consider buying in bulk or opting for standard sizes that are readily available in the market. Additionally, exploring cost-saving tips such as negotiating prices with suppliers based on market conditions can lead to more economical purchases.

Stainless steel round pipe for sales offer exceptional corrosion resistance, durability, and a visually appealing finish, making them suitable for various applications.

However, they come with drawbacks such as high costs, heavyweight, and the need for specialized tools for welding.

It is essential for project planners to carefully weigh these advantages and disadvantages to determine the suitability of stainless steel pipes for their specific needs.

Stainless steel pipes offer numerous advantages, including high corrosion resistance, exceptional durability, an appealing appearance, impressive strength, and the benefit of being 100% recyclable.

These qualities make stainless steel pipes a reliable choice for various applications where longevity, aesthetics, and environmental considerations are paramount.

The combination of these characteristics positions stainless steel pipes as a versatile and sustainable solution in the construction and industrial sectors.

Exhibiting exceptional resistance to corrosion, stainless steel round pipe stands out as a premier choice for various industrial applications.

The remarkable durability of stainless steel pipes is a key attribute that sets them apart in various industrial and commercial applications. Durability testing confirms their longevity benefits, requiring minimal maintenance.

Their impact on the environment is positive due to recyclability and long lifespan, contributing to sustainable practices.

Although stainless steel pipes may have a higher initial cost, their longevity and low maintenance needs make them cost-effective in the long run.

An inherent characteristic of stainless steel pipes is their aesthetically pleasing finish, making them a desirable choice for various applications in industries where appearance is a key consideration.

Demonstrating exceptional strength, stainless steel pipes offer a reliable solution for various industrial applications requiring robust materials. Their high corrosion resistance, durability factors, and weight considerations make them ideal for demanding environments.

Additionally, stainless steel pipes are known for their excellent welding techniques, ensuring strong and secure connections.

Furthermore, their recyclability benefits contribute to sustainable practices, making them a preferred choice for many industries.

With stainless steel pipes being 100% recyclable, they offer a sustainable solution for various industrial applications.

Recycling benefits: Reduces waste and promotes environmental responsibility.

Sustainable practices: Contributes to eco-friendly manufacturing processes.

Environmental impact: Positively affects carbon footprint reduction.

Longevity advantages: Ensures durable and long-lasting infrastructure.

Stainless steel pipes exhibit drawbacks such as high cost, heavy weight, difficulty in welding, and the necessity for special tools to work with them. These factors can impact the overall project budget, installation process, and maintenance requirements.

Understanding these limitations is crucial for making informed decisions regarding the use of stainless steel pipes in various applications.

The elevated cost of stainless steel round pipe for sales can pose a significant financial consideration for projects requiring this material.

Careful expense evaluation is crucial when deciding on the use of stainless steel pipes, as their higher cost compared to alternative materials can impact the overall project budget significantly.

Considering the financial implications of using stainless steel pipes is essential to ensure that the project remains within budget constraints and does not incur unexpected costs.

Comparing the prices of stainless steel round pipe for sales with other available materials can help project managers make informed decisions based on both cost and quality considerations.

In addition to the initial purchase cost, factors such as maintenance expenses and longevity should be taken into account when weighing the financial implications of using stainless steel pipes in a project.

The substantial weight of stainless steel round pipe for sales can present logistical challenges during transportation and installation processes. Proper weight distribution is crucial to prevent handling challenges.

Transport considerations must account for the heavy weight, while installation methods require structural support to manage the pipe's mass effectively.

Careful planning and adherence to guidelines are essential to ensuring the safe and efficient handling of stainless steel pipes.

The challenge of welding stainless steel round pipe for sales can arise due to their unique composition and characteristics.

Stainless steel's properties, such as high thermal conductivity and low thermal expansion, pose challenges during welding. These properties can lead to issues like distortion, cracking, and poor weld quality if not managed correctly.

Specialized welding techniques, such as using low heat input and controlling inter pass temperatures, are crucial for welding stainless steel pipes. Employing proper filler materials and ensuring adequate shielding gas coverage are also essential techniques to achieve high-quality welds.

The selection of appropriate welding equipment, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welders with pulsing capabilities, is vital for welding stainless steel pipes. Quality equipment helps in maintaining precise control over the welding parameters and achieving desired weld characteristics.

Safety precautions, including wearing appropriate personal protective equipment (PPE) like gloves, helmets, and safety glasses, are essential when welding stainless steel. Adequate ventilation in the welding area and following established safety protocols minimize the risks associated with welding stainless steel.

Welding stainless steel requires specialized knowledge and equipment due to its properties. Ensuring proper techniques, safety measures, and seeking expert advice are essential for successful welding. Understanding these challenges helps in finding effective welding solutions.

Specialized equipment is necessary for working with stainless steel round pipe for sales due to their unique properties and composition.

Tool selection, welding challenges, equipment needs, tooling requirements, and accessory compatibility are crucial considerations.

Welding stainless steel pipes can be challenging due to their high melting point and potential for distortion.

Using the right tools and equipment is essential to ensure proper fabrication and long-term performance.

When comparing carbon steel tubes and stainless steel pipes, several key points must be considered.

The chemical composition of the materials significantly impacts their corrosion resistance and durability.

Additionally, factors such as cost, maintenance requirements, mechanical properties, application fields, and aesthetic differences play crucial roles in determining the most suitable option for a specific project.

In comparing the chemical composition of carbon steel tubes to stainless steel pipes, a notable distinction lies in the presence of chromium in stainless steel, which enhances its corrosion resistance properties.

Stainless steel typically contains a minimum of 10.5% chromium, whereas carbon steel lacks this element, making it more susceptible to corrosion.

Other elements present in stainless steel, such as nickel and molybdenum, contribute to its superior material properties, including increased strength and durability.

Additionally, stainless steel's composition allows for effective heat treatment techniques that can further enhance its mechanical characteristics compared to carbon steel.

When it comes to welding techniques, stainless steel requires specific procedures due to its chemical composition to maintain its corrosion resistance after welding.

Comparing the cost and maintenance aspects between carbon steel tubes and stainless steel pipes reveals significant differences in financial investment and care requirements. In terms of cost analysis, stainless steel pipes are initially more expensive than carbon steel tubes due to the higher cost of the raw material and manufacturing process. However, stainless steel pipes offer longevity benefits, requiring less frequent replacements and maintenance, which can offset the initial higher cost over time.

When it comes to maintenance, stainless steel round pipe for sales require less care compared to carbon steel tubes. Stainless steel has high corrosion resistance, reducing the need for constant inspections and repairs. Additionally, proper cleaning and using compatible fittings can help maintain the appearance and functionality of stainless steel pipes.

Below is a comparison table highlighting the key differences between carbon steel tubes and stainless steel pipes:

| Aspect | Carbon Steel Tubes | Stainless Steel Pipes |

|---|---|---|

| Cost | Lower initial cost | Higher initial cost |

| Maintenance | Higher maintenance | Lower maintenance |

| Longevity | Shorter lifespan | Longer lifespan |

A fundamental distinction in mechanical properties exists between carbon steel tubes and stainless steel pipes, impacting their performance in various applications. When considering the mechanical properties of these materials, several key factors come into play:

Stainless steel pipes and carbon steel tubes each find distinct applications in various industries due to their unique mechanical properties and performance characteristics.

Stainless steel pipes are commonly used in industrial applications such as chemical processing, oil and gas refineries, and power plants due to their high corrosion resistance and durability. In construction projects, stainless steel pipes are favored for their strength and aesthetic appeal, often seen in architectural structures and building facades. The marine industry extensively utilizes stainless steel pipes for their ability to withstand harsh sea environments and resist corrosion.

On the other hand, carbon steel tubes are prevalent in the automotive sector for their strength and cost-effectiveness, used in manufacturing vehicle frames and exhaust systems. In agricultural machinery, carbon steel tubes are chosen for their durability and ability to handle heavy loads in equipment like tractors and harvesters.

Understanding the specific requirements of each industry helps in selecting the most suitable material for optimal performance and longevity.

When comparing a carbon steel tube to a stainless steel pipe, the appearance can significantly differ due to various factors. Here are key elements to consider:

The corrosion resistance of carbon steel tubes differs significantly from that of stainless steel pipes. Stainless steel pipes exhibit superior corrosion resistance compared to carbon steel tubes due to the presence of chromium that forms a protective layer of chromium oxide on the surface. This layer acts as a barrier against corrosion, making stainless steel pipes ideal for applications where corrosion is a concern. When selecting between carbon steel tubes and stainless steel pipes, it's essential to consider the project's environmental conditions, budget, and required durability. Stainless steel pipes offer various surface finish options, including brushed, mirror, or satin finishes, enhancing their aesthetic appeal and corrosion resistance. Maintenance considerations for stainless steel pipes include regular inspections, prompt repairs for any damage, and proper cleaning to maintain their appearance. Industries such as food processing, chemical containers, and heat exchangers commonly utilize stainless steel pipes due to their excellent corrosion resistance and durability.

| Corrosion Resistance | Material Selection Tips | Surface Finish Options |

|---|---|---|

| Superior in Stainless Steel Pipes | Consider environmental conditions, budget, and durability requirements | Brushed, mirror, or satin finishes for enhanced aesthetic appeal |

| Inferior in Carbon Steel Tubes | Evaluate project needs carefully | - |

| - | Consult with experts for guidance | - |

| - | Explore alternative materials if needed | - |

| - | Consider long-term maintenance requirements | - |

Considering the differing wear resistance properties between carbon steel tubes and stainless steel pipes is crucial for selecting the most suitable material for applications where durability against wear is a significant factor. Here is a comparison between the two materials:

For maintenance tips and extended durability, regular inspections for wear, prompt repairs, and following manufacturer guidelines are essential. By understanding these factors, you can make an informed decision when choosing between carbon steel tubes and stainless steel pipes.

Comparison of the prices between carbon steel tubes and stainless steel pipes reveals significant variations influenced by material quality and production processes. When considering budget considerations, market analysis, price negotiation, and sales strategies, understanding the pricing differences is crucial for making informed decisions. Carbon steel tubes generally have a lower upfront cost compared to stainless steel pipes due to the differences in material composition and manufacturing techniques. However, stainless steel pipes offer higher corrosion resistance and durability, which may result in long-term cost savings despite the initial higher price.

| Carbon Steel Tubes | Stainless Steel Pipes | |

|---|---|---|

| Price | Lower | Higher |

| Durability | Moderate | High |

| Corrosion Resistance | Lower | Excellent |

When evaluating the ductility of carbon steel tubes and stainless steel pipes, it is evident that these materials exhibit distinct mechanical properties that play a significant role in their respective applications.

These differences in ductility, tensile strength, impact resistance, and surface finish between carbon steel tubes and stainless steel pipes must be carefully considered when selecting the appropriate material for specific projects to ensure optimal performance and longevity.

You may also like:

Copper VS Stainless Steel Pipe Which one is right for you ?

In conclusion, stainless steel round pipes offer a durable and versatile solution for various projects. The grade, standard, workability, size, and price of stainless steel pipes should be carefully considered to ensure optimal performance.

While stainless steel pipes have advantages such as corrosion resistance and high strength, they also have disadvantages such as higher cost compared to carbon steel tubes.

Ultimately, selecting the right stainless steel pipe for sales requires thorough evaluation of project requirements and cost-effectiveness.