A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

Stainless steel pipes are widely used in many industries due to their strength, durability, and corrosion resistance. Knowing the stainless steel pipe dimension chart is essential to ensure that the pipes meet the necessary requirements for a particular application.

In this comprehensive guide, we will delve into

the world of stainless steel pipes and explore the intricacies of their dimensions. Whether you're a professional in the industry or a curious homeowner, this guide will equip you with the knowledge needed to make informed decisions when working with stainless steel pipes.

Stainless Steel Pipe Dimensions Chart 3 elements

Stainless Steel pipe dimensions are an important aspect of construction and engineering projects. They are typically measured in terms of outer diameter (OD), wall thickness (WT), and pipe length.

Knowing the correct pipe size is essential for ensuring the success of a project, as it affects the pressure capacity, weight, and cost of the pipe. It is important to be aware of the various dimension standards and calculations for determining the appropriate steel pipe size.

outer diameter (OD)

Outer diameter (OD) is an important measure in the stainless steel pipe dimension chart, as it is used to determine the appropriate wall thickness for the pipe. It is represented in millimeters after the symbol, such as DN50 for a pipe with a nominal diameter of 50 mm.

Wall thickness (WT)

Wall thickness (WT) is an important measure in determining the appropriate pipe size as it affects the pressure capacity and cost per foot/meter. It is represented in millimeters after the symbol, such as DN50 for a pipe with a nominal diameter of 50 mm.

The weight class (WGT class) indicates the pipe wall thickness, which has three grades: STD (standard), XS (extra strong), and XXS (double extra strong). Thin-walled pipes were also introduced to meet cost-effective demands.

Understanding the different stainless steel pipe dimensions is essential for proper pipe installation.

Pipe length

Pipe length is typically measured in 20 ft (6 meters) or 40 ft (12 meters). It is an important factor to consider for proper pipe installation.

It is vital to determine the exact length of the pipe required to complete a project. Additionally, the wall thickness needs to be considered when selecting pipe for a specific job.

With this understanding, the correct pipe size can be determined for any project.

Dimension standards for stainless steel pipe

The dimension standards for stainless steel pipe are primarily defined by

ASTM and ASME standards.

ASTM Standards provide a basis for the dimensional requirements of stainless steel pipes. The American Society for Testing and Materials (ASTM) have established a range of standards that define the dimensions of steel pipes. These standards are applicable to all types of stainless steel pipes, including those for use in low and high pressure applications. Here is a list of some ASTM standards related to stainless steel pipes:

ASTM A312/A312M - Standard Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

ASTM A358/A358M - Standard Specification for Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe for High-Temperature Service and General Applications

ASTM A790/A790M - Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe

ASTM A269 - Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

ASTM A270 - Standard Specification for Seamless and Welded Austenitic and Ferritic/Austenitic Stainless Steel Sanitary Tubing

ASTM A554 - Standard Specification for Seamless Stainless Steel Mechanical Tubing

The American Society of Mechanical Engineers (ASME) has provided standards to describe the steel pipe dimensions. Here are some of the ASME standards related to stainless steel pipes:

ASME B36.19 - Stainless Steel Pipe: This standard covers the dimensions and tolerances for stainless steel pipes.

ASME B36.10M - Welded and Seamless Wrought Steel Pipe: While this standard primarily covers carbon steel pipes, it includes provisions for stainless steel as well. It specifies dimensions and tolerances for welded and seamless stainless steel pipes.

ASME B31.1 - Power Piping: This code section covers the design, construction, inspection, and testing of power piping systems, which may include stainless steel components such as pipes.

ASME B31.3 - Process Piping: This code section deals with the design, construction, and maintenance of piping systems used in chemical, petroleum, and other process industries, which can include stainless steel pipes.

What is the Nominal Pipe Size (NPS)?

The Nominal Pipe Size (NPS) is the standard way of describing the size of a pipe. It is an important parameter when considering the dimensions of a steel pipe. NPS is specified in inches or millimeters, and is based on the outside diameter of the pipe. It is used to differentiate between different pipe sizes, as well as between different types of pipe such as seamless, welded, or hydraulic. The relationship between NPS and pipe schedules can be found in these specifications.

The larger the NPS, the larger the diameter of the pipe. NPS is used to determine the appropriate wall thickness for a pipe of a given size. It is also used to differentiate between different pipe sizes, as well as different pipe materials, such as stainless steel. NPS is an important parameter when considering steel pipe dimensions, as it helps determine the appropriate size for a given application.

What is DN (Nominal Diameter) ?

DN (Nominal Diameter) is a standardized measurement used to describe the size of a pipe. It is represented in millimeters after the symbol, such as DN50 for a pipe with a nominal diameter of 50 mm. This is the most common way to describe the size of a pipe and is used by most piping systems. It is important to note that the outside diameter of a pipe is not always the same as the pipe number. For example, a DN50 pipe may have an outside diameter of 63.5 mm.

How to Describe Stainless Steel Pipe Dimensions and Size Correctly?

Correctly describing the size of a stainless steel pipe is essential for determining the appropriate wall thickness, as well as the cost per foot/meter. The dimensions of a stainless steel pipe include outer diameter (OD), wall thickness (WT), and length.

To accurately calculate the weight, pressure capacity, and cost per foot/meter, the correct pipe size must be determined. The pipe schedule chart in millimeters or inches provides the unit of measurement for pipe schedule and can be used to help determine the right wall thickness.

For example, a correct description for a stainless steel pipe might be: "Nominal Pipe Size (NPS): 2 inches, Outside Diameter (OD): 2.375 inches, Wall Thickness (WT): 0.154 inches, Schedule: 40, Length: 20 feet, Material Grade: 316L, Pipe Type: Seamless, End Connections: Plain Ends, ASTM Compliance: ASTM A312.

Providing accurate and detailed information about stainless steel pipe dimensions and size will help ensure that you receive the correct pipe for your project and application.

Stainless Steel Pipe Dimensions Chart of Vinmay

As a key partner for global

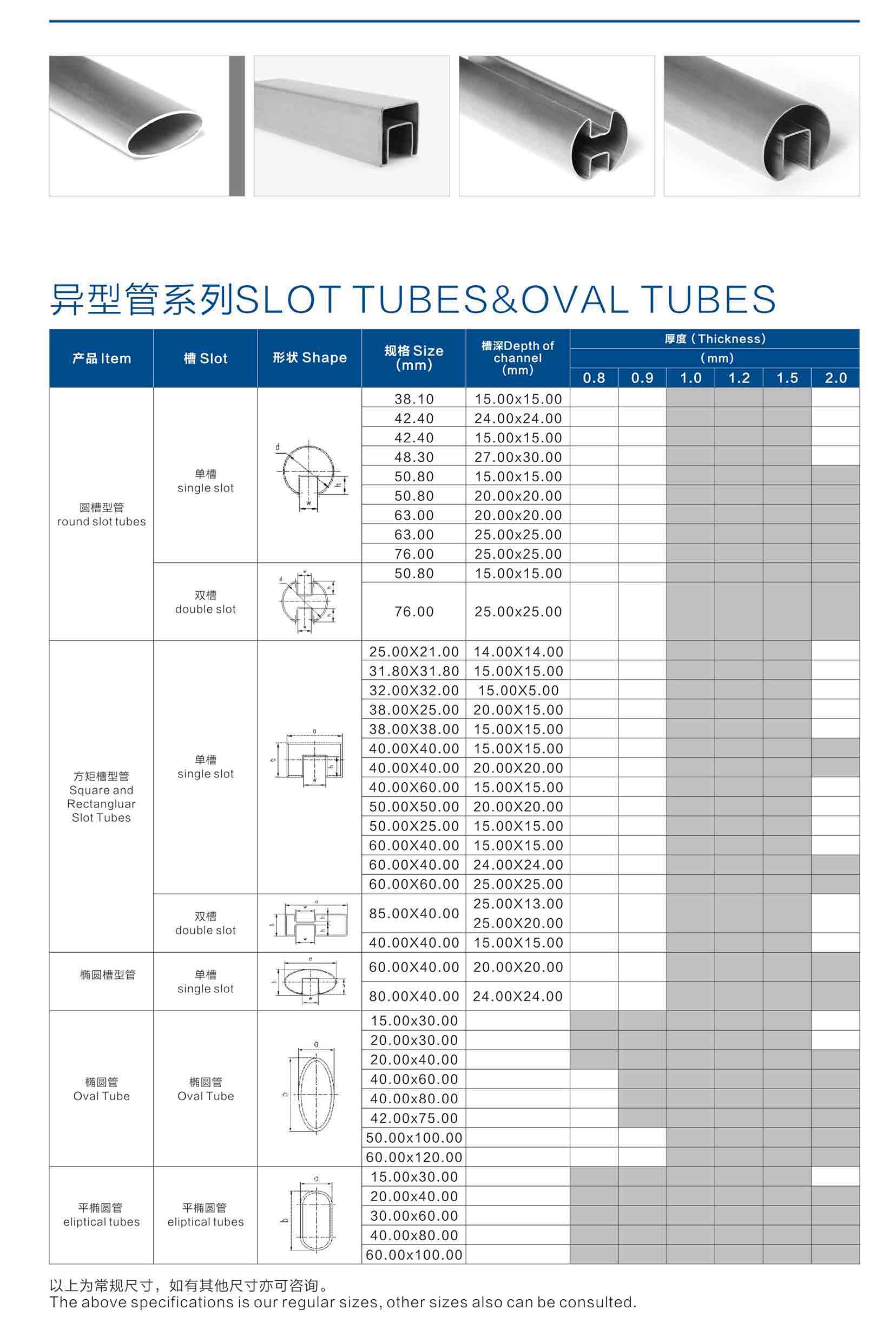

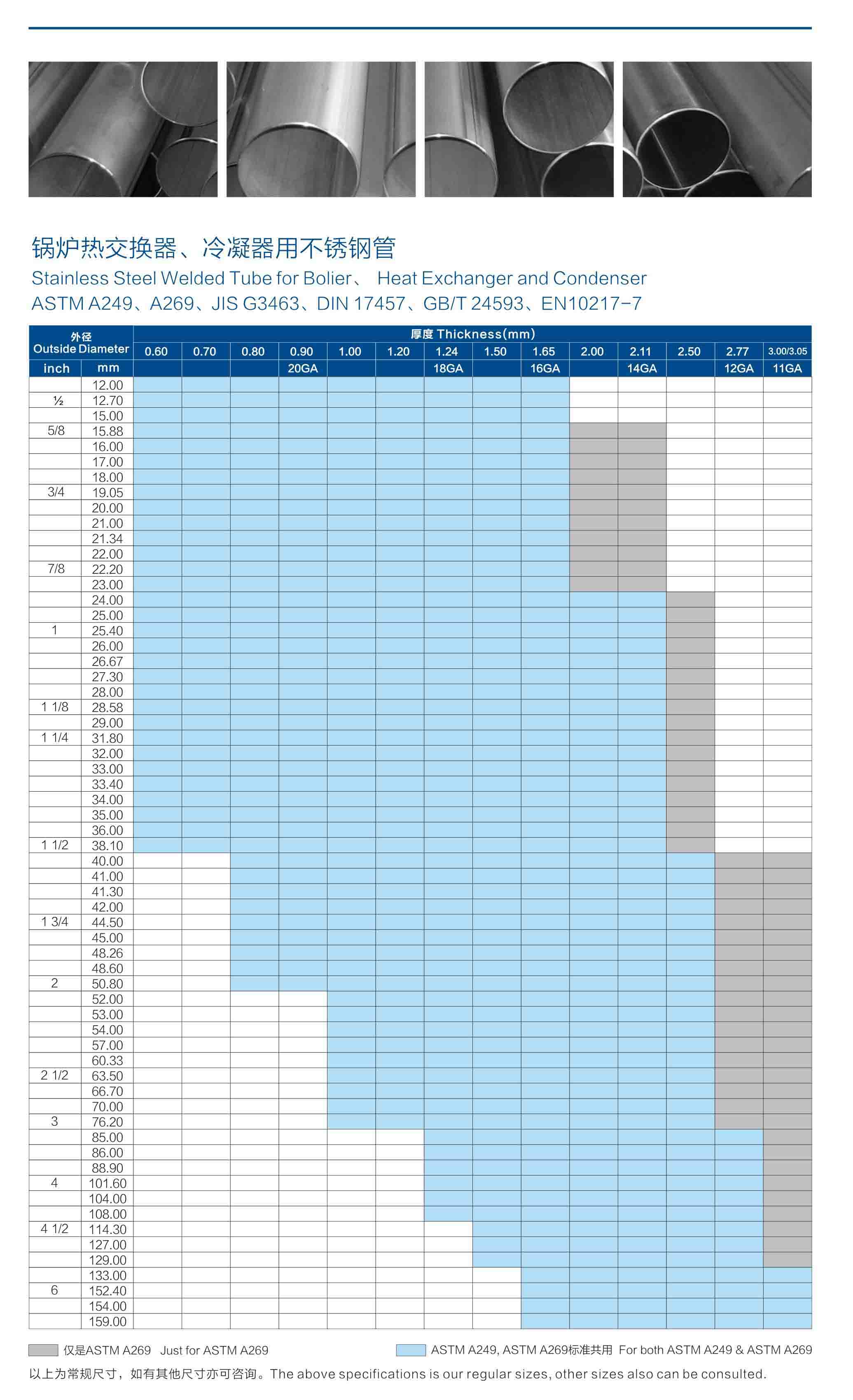

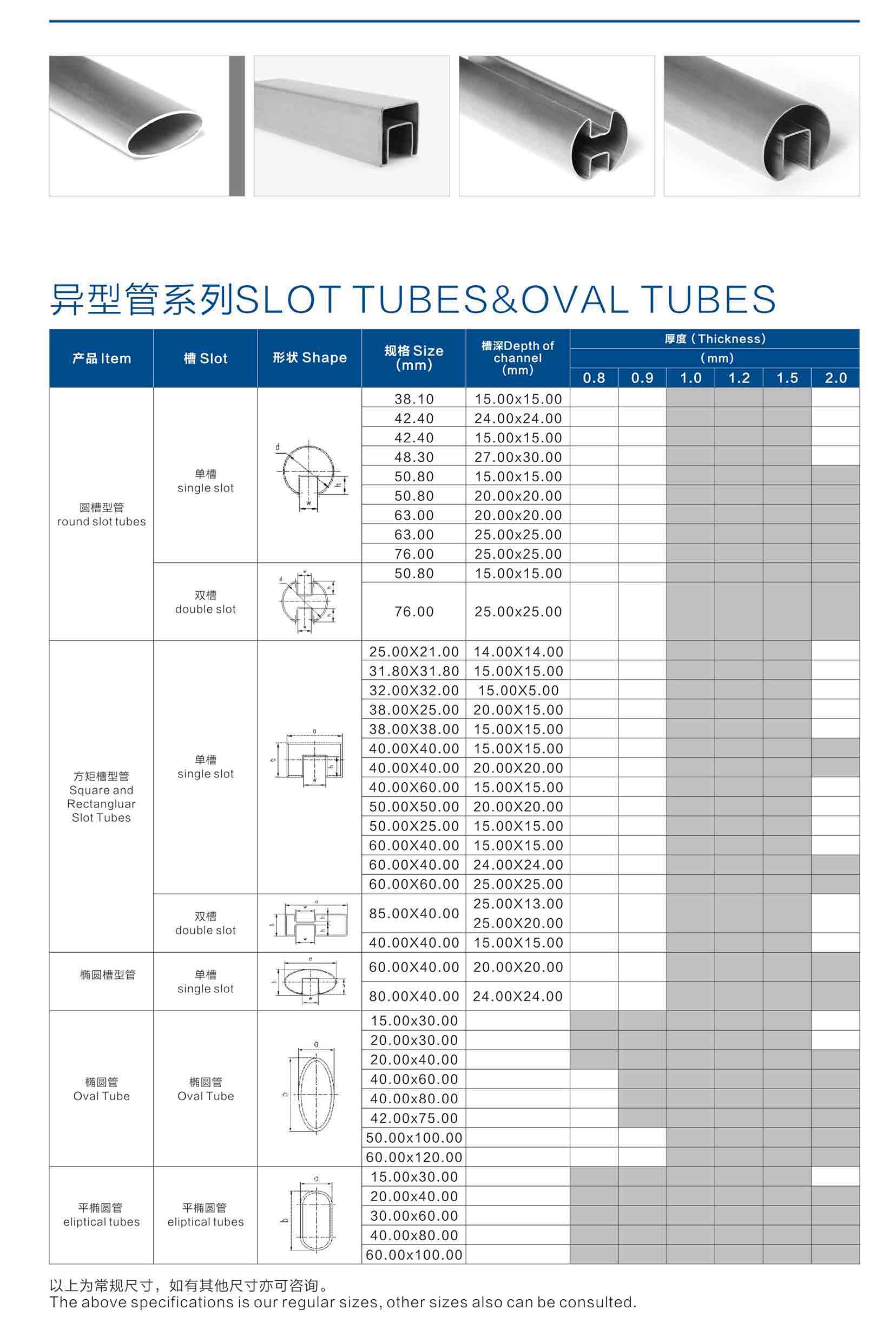

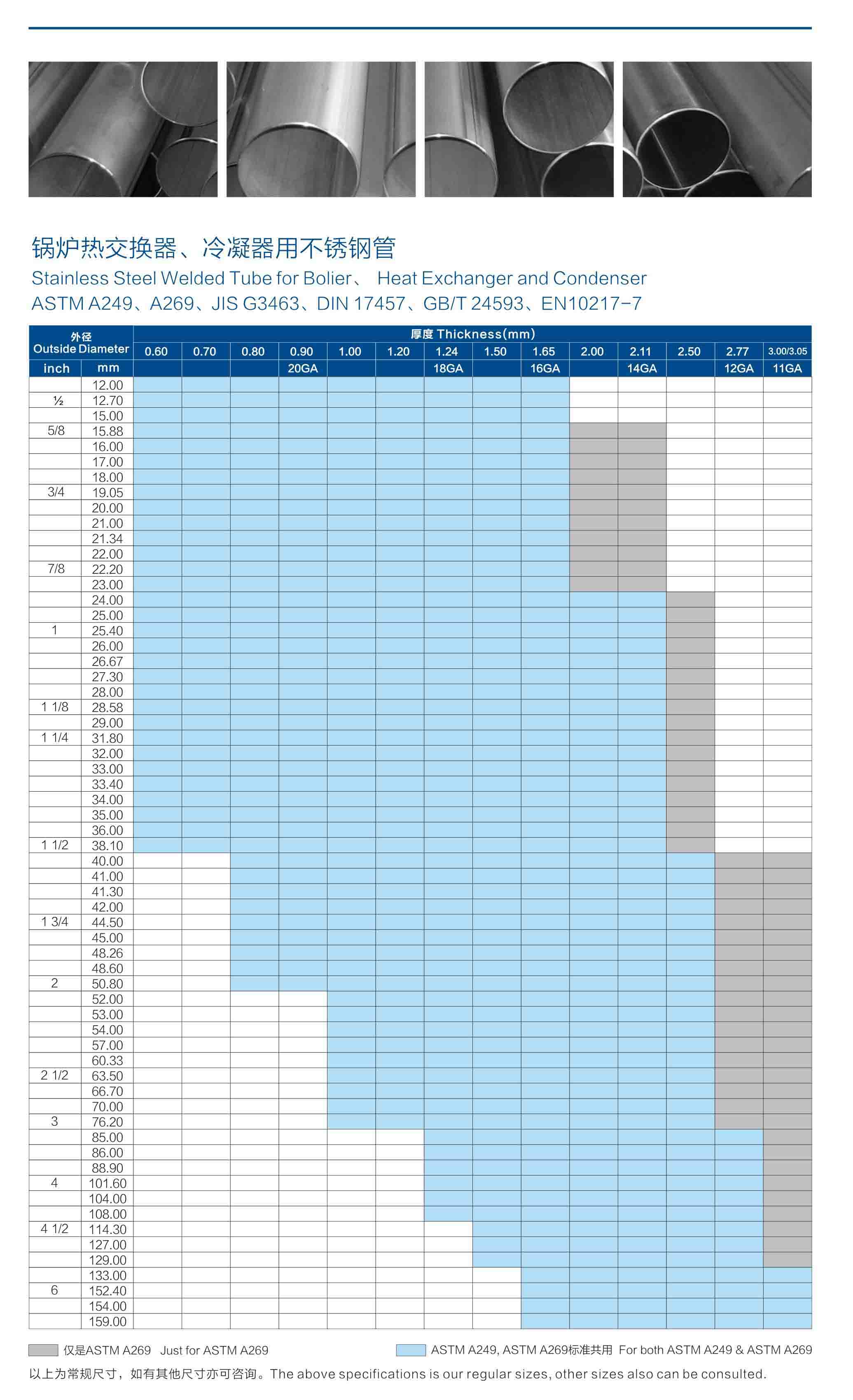

stainless steel welded pipe distributors, Vinmay serves the top importer of ss welded tube all over the world. We provide stainless steel pipe standard with ASTM A554, ASTM A270, ASTM A249, ASTM A269 etc. The follow photos are our stainless steel pipe dimensions chart.

ASTM A554 Round Stainless Steel Pipe Dimensions Chart

ASTM A554 square stainless steel pipe dimensions chart

ASTM A554 Rectangular Stainless Steel Pipe Dimensions Chart

ASTM A554 Shaped Stainless Steel Pipe Dimensions Chart

ASTM A249 Stainless Steel Pipe Dimensions Chart

ASTM A270 Stainless Steel Pipe Dimensions Chart

EN10312 Stainless Steel Pipe Dimensions Chart

Conclusion

In conclusion, it is vital to understand the stainless steel pipe dimension chart in order to select the right pipe for a

particular application. Knowing the correct pipe size, dimension standards, pipe weight class, Nominal Pipe Size, and Nominal Diameter are essential.

Additionally, knowing how to describe pipe dimensions and size correctly is important to ensure safety and cost-efficiency.

It is crucial to research the standards when selecting a steel pipe to ensure the correct product is purchased and used in the correct

application.