Stainless steel 304 (18/8, EN 1.4301) contains 180% Cr and 80.5% Ni with low C. It offers about 505 MPa tensile strength, 215 MPa yield, ~40% elongation, and a 193 GPa modulus. It has good formability, weldability, and general corrosion resistance, with caution in warm chlorides and above 60°C for SCC. It resists oxidation up to ~870°C. Common uses include food processing, sanitary tubing, piping, and heat exchangers, with 304L/304H variants addressing welds and high temperatures. More insights follow.

Stainless steel 304 is an austenitic 8/8alloy (EN 1.4301, UNS S30400) known for balanced corrosion resistance, formability, and weldability. Its variants 304L (low carbon for welds) and 304H (higher carbon for high-temperature strength)—address sensitization and elevated-temperature needs. These attributes make 304 the most widely used stainless grade across food equipment, appliances, and general-purpose fabrications. It is widely used in kitchenware due to its food-grade safety and ease of sanitation. It commonly contains 18% chromium and 8% nickel, which underpin its superior corrosion resistance and broad applicability. In comparison, grade 316 includes molybdenum for enhanced corrosion resistance, particularly in marine environments.

Additionally, 304’s durability and corrosion resistance make it a reliable choice for structural tubing in construction, automotive, and manufacturing applications. For welded tubing, 304 is commonly supplied to ASTM A554 requirements for mechanical and structural uses.

Ubiquitous in industry and everyday products, Grade 304 is an austenitic stainless steel defined by approximately 18% chromium and 8% nickel, often called 18/8. It offers excellent welding characteristics, accommodating TIG and MIG processes with strong, distortion-controlled joints. Its corrosion resistance and high tensile strength make it a durable, low-maintenance choice for diverse applications.

Recognized as UNS S30400 and EN 1.4301, it delivers reliable corrosion resistance, formability, and ductility. The stainless steel 304 composition supports excellent fabrication and consistent performance across food processing equipment, piping, heat exchangers, and fasteners. For environments with chlorides or aggressive media, consider upgrading to 316 stainless due to its molybdenum-enhanced corrosion resistance.

Users seeking predictable outcomes value the mechanical properties of 304 stainless steel, including stainless steel 304 tensile strength suitable for structural and sanitary applications.

This versatility extends to ASTM A554 conforming 304 stainless steel rectangular tubes, which offer excellent corrosion resistance, formability, and weldability for structural and fabrication applications.

Although grouped under the same 300-series family, 304, 304L, and 304H differ primarily in carbon content, which drives their weldability and high-temperature performance.

Standard 304 balances formability and strength; 304L (.03% C) minimizes carbide precipitation during welding and is preferred for critical welds or thick sections; 304H (0.04.10% C) delivers higher creep and tensile strength above 500°C. For reference, square tubes commonly follow ASTM A554, a standard also applied to 316 stainless steel mechanical tubing.

Compared with 304, 316 typically offers superior resistance to chloride-induced attack due to its molybdenum content, enhancing durability in marine applications. Additionally, 316’s higher yield strength and toughness support demanding service where impact and stress corrosion are concerns. As an added benefit from the 300-series family, 316 demonstrates strong high temperature resistance suitable for heat exchangers and boiler parts.

For design control, the typical yield strength of 304 stainless steel is approximately 205 MPa, with a similar baseline yield for 304L and elevated high-temperature strength for 304H.

Stainless steel 304 density is approximately 7.93.00 g/cm³, consistent across all three.

Selection should reference stainless steel 304 material specification frameworks (e.g., ASTM A240/A240M) and any dual certification requirements ensuring compliance for both 304 and 304L where applicable.

Compared with 304, grade 316 includes molybdenum for improved chloride resistance, making it preferable in marine environments and chemical processing applications.

Versatility defines 304, the austenitic grade that combines corrosion resistance, formability, and cost efficiency better than most alternatives. It is frequently supplied to ASTM A269 standards for general service round tubing across industries. Building on this, 316 tubes for sanitary and heat-exchanger service are often produced to ASTM A270 specifications for compliance in food and pharmaceutical applications. 316 rectangular tubes also offer excellent weldability and customizable surface finishes for application-specific aesthetics and performance.

Its 18/8 chemistry balances performance and price, delivering reliable fabrication, weldability, and broad availability.

For decision-makers seeking predictable behavior, the stainless steel 304 modulus of elasticity (about 193 GPa) provides stiffness for dimensional control, while 304 stainless steel hardness (around HRB 70 in annealed condition) maintains ductility for deep drawing.

Controlled 304 stainless steel thermal conductivity (~16 W/m·K) aids welding and machining heat management. In applications where higher chloride resistance is required, manufacturers may recommend upgrading to 316 stainless tubes produced to ASTM A312 or A269 standards.

Compared to 316L, 304 offers strong general corrosion resistance but lacks the molybdenum-enhanced protection of 316L stainless in aggressive chloride environments.

The chemical makeup of 304 stainless steel, per ASTM A240, typically includes 18.00.0% Cr, 8.00.5% Ni, up to 0.08% C, up to 2.00% Mn, up to 0.75% Si, up to 0.045% P, and up to 0.030% S, with Fe as the balance. 304 is the most widely used austenitic grade, valued for its versatility and cost-effectiveness compared to 316 stainless.

Compared to 201 stainless steel, 304 offers superior corrosion resistance due to its higher nickel content and more robust passive oxide layer. As part of quality assurance, manufacturers often verify composition and properties through ASTM testing, ensuring compliance and reliability. In contrast, 201 stainless uses higher manganese and lower nickel to achieve cost savings while maintaining good corrosion resistance.

Chromium establishes the passive oxide layer for corrosion resistance, while nickel stabilizes the austenitic structure and improves toughness.

Carbon, manganese, silicon, phosphorus, and sulfur are tightly controlled to balance strength, weldability, formability, and machinability.

In selecting 304 for specific applications, understanding the SAE and ASTM grading systems helps ensure compliance and appropriate material selection across industries.

At the heart of 304 stainless steel, chromium (180%) forms a passive oxide film that delivers primary corrosion resistance, while nickel (80.5%) stabilizes the austenitic structure for toughness and ductility. In regulated environments, adherence to ASTM standards ensures consistent mechanical properties and surface finish suitable for hygienic service.

Additionally, in applications where welding is critical, insights from 316L’s success in minimizing carbide precipitation highlight the importance of weldability and post-weld integrity for dependable performance. Medical stainless steel tubing often leverages 304 for its biocompatibility and clean surface finish, supporting sterile, safety-critical use.

Compared with stainless steel 304 vs 316, 316’s molybdenum boosts chloride pitting resistance; 304 relies on precise control of supporting elements. Stainless steel 304 is widely used in sanitary tubing for food, beverage, pharmaceutical, and biotechnology applications due to its smooth surface and corrosion resistance.

These alloying choices also enable excellent weldability and make 304 suitable for sanitary tubes used in food and medical applications.

Although exact melt practices vary by producer, ASTM A240 defines tight composition ranges for 304 that anchor its 18-8 profile: chromium 18.00.0% and nickel 8.00.5%, with carbon limited to a maximum of 0.08%. Typical limits also govern Mn, Si, P, S, and N to preserve austenite stability, weldability, and corrosion resistance. Buyers should specify 304L when carbon must not exceed 0.03% and confirm nickel allowances where dual certification is expected.

In sanitary tubing contexts, ASTM A270 highlights cleanliness, surface finish, and strength criteria relevant to 304/304L, including minimum tensile strength of 70 ksi and inspection methods like non-destructive testing. For long service in aggressive environments, regular maintenance and avoidance of abrasive cleaners support the alloy’s corrosion resistance as outlined in sustainability and longevity practices. Additionally, compared with 304/304L, the molybdenum-bearing 316L tubing is often chosen in chloride-rich environments for superior pitting and crevice corrosion resistance.

In applications where dimensional control and surface finish are critical, ASTM A554 sets standards for mechanical tubing used in architectural and automotive uses.

Solution annealing at a minimum of 1900°F followed by rapid cooling is commonly employed to optimize 304/304L’s corrosion resistance and mechanical properties in accordance with standardized heat treatment practices.

| Element | ASTM A240 304 | Control note |

|---|---|---|

| Cr | 18.00.0% | Guarantees passivity |

| Ni | 8.00.5% | Austenite stabilizer |

| C | .08% | Limits sensitization |

| Mn/Si/P/S | Mn .00%; Si .75%; P .045%; S .030% | Process cleanliness |

These ranges target consistent performance across heats; verify mill test reports to ascertain compliance for regulated service.

In service and in test, stainless steel 304 exhibits a balanced combination of strength, ductility, and toughness that suits demanding applications. These properties make it a reliable choice for industrial use where corrosion resistance and mechanical stability are critical. Its recyclability and durability also support environmental sustainability, contributing to long-term cost efficiency in water and infrastructure projects. Accurate descriptions in piping should include OD, WT, length, and material grade to ensure compliance with ASTM standards. The choice of a reputable manufacturer is crucial for quality assurance in tubing applications, aligning with the global growth of the stainless steel market and the importance of corrosion resistance.

Its austenitic matrix delivers predictable plasticity, stable work-hardening, and reliable impact performance, even at subzero temperatures.

Typical minimum mechanical values allow confident design margins: ultimate tensile strength around 505 MPa, yield strength near 215 MPa (0.2% offset), and elongation of 405%.

Stiffness is governed by a Young’s modulus of 19300 GPa with a shear modulus near 86 GPa, supporting deflection control and joint integrity.

Typical hardness sits around 70 HRB (23 HB), enabling machinability planning and wear expectations.

Additionally, 304’s corrosion resistance, especially compared to other stainless grades like 316 and 409, supports longevity in demanding tube manufacturing and industrial applications.

Beyond its corrosion resistance, 304 stainless steel is defined by stable physical and thermal metrics that guide design and processing. Designers can rely on a density of 8.00 g/cm3 for accurate mass models and a melting point near 1450 °C for process windows. Thermal conductivity of 16.2 W/m·K and a coefficient of thermal expansion of 17.2×10 /K inform heat flow and distortion control. An elastic modulus of 193 GPa supports stiffness targets, while electrical resistivity of 0.72×10 Ω·m aids in Joule heating estimates. The alloy remains non-magnetic and ductile, simplifying fixturing and forming.

For projects using tubing, aligning with ASTM standards like A213, A269, and ISO 1127 supports compatibility, uniform sizing, and safety across global applications. Additionally, knowledge of ASTM A554 standards and typical finishes like mirror or satin helps align 304 design choices with established specifications for stainless steel square tubing. For welded round tubing applications, selecting grades per A269/A270 helps ensure appropriate surface quality, bead control, and corrosion performance across heat exchangers, sanitary lines, and condensers.

To ensure proper selection for sanitary, structural, and high-temperature service, reference ASTM specifications such as A270 for sanitary tubing, A554 for structural use, and A312 for high-temperature and corrosive environments. Among these, ASTM A312 commonly covers seamless austenitic stainless steel tubes in grades like 304 and 316, supporting consistent quality and global interoperability.

| Property | Value | Use |

|---|---|---|

| Density | 8.00 g/cm3 | Mass/weighting |

| Modulus of Elasticity | 193 GPa | Stiffness sizing |

| Electrical Resistivity | 0.72×10 Ω·m | Heating calculations |

| Thermal Conductivity | 16.2 W/m·K | Thermal modeling |

| CTE | 17.2×10 /K | Tolerance management |

Stable physical and thermal behavior sets the stage for how 304 stainless steel handles aggressive environments and heat. In controlled service, its chromium-rich passive film delivers broad corrosion resistance, yet operators must mitigate chloride risk and temperature-driven degradation to preserve margins. Regular inspection and maintenance help identify early signs of deterioration and preserve performance by preventing pitting corrosion from progressing. Incorporating routine cleaning with non-chloride cleaners and applying protective coatings can further preserve the passive layer and reduce rust risk in service. Compared with galvanized steel, 304’s self-healing passive film offers superior corrosion resistance and longer service life in harsh environments. For severe saltwater exposure, specifying 316 stainless with molybdenum improves resistance to pitting and crevice corrosion relative to 304.

Chromium-rich passivity grants broad resistance, but manage chlorides and heat to protect performance.

Alloy selection (304, 304L, 304H) should align with temperature regime and corrosion risks.

In harsh, chloride-rich environments, regular cleaning, use of protective coatings, and design choices that minimize crevices help prevent rust and extend service life, reflecting the importance of corrosion prevention practices.

Although renowned for corrosion resistance, 304 stainless steel is equally defined by its forgiving fabrication window: the austenitic 18/8 matrix delivers excellent formability, clean weldability, and predictable cold-work response. It draws, bends, and spins into deep and complex geometries with low fracture risk, supporting consistent toolpaths and repeatability.

Welding is straightforward with or without filler; distortion control improves with proper heat input and rapid post-weld cooling to preserve corrosion performance. Machining is serviceable but demands control: it work-hardens rapidly, so sharp tools, light yet deep cuts, moderated speeds, and effective flood coolants reduce glazing and tool wear.

Strength cannot be increased by heat treatment; cold working provides the only strengthening route, with full-hard condition maximizing strength. For hot working, heat to 1149-1260°C and cool rapidly. For cutting and joining 304 tubing, using appropriate techniques such as carbide-tipped saws and TIG/MIG welding enhances precision and minimizes defects, aligning with best practices for stainless steel fabrication.

A brief comparison positions 304 against 316 and 430 in corrosion resistance, strength, and formability.

Relative to 316, 304 offers lower molybdenum-free corrosion resistance but similar strength and easier availability; compared with 430, 304 provides higher toughness, better corrosion performance, and austenitic non-magnetic behavior.

These contrasts guide grade selection for chloride-rich environments and cost-sensitive applications.

When comparing 304 to 316 stainless steel, the defining difference is 316’s addition of 2.0.5% molybdenum, which elevates corrosion resistance—especially in chlorides and marine environments—at a higher cost.

Both are austenitic, nonmagnetic in annealed condition, and only mildly responsive after cold work. Selection hinges on environment, lifecycle cost, and compliance.

1) Composition: 304 contains 17.59.5% Cr and 8.00.5% Ni; 316 contains 16.58.5% Cr, 10.03.0% Ni, and 2.0.5% Mo. The Mo drives chloride pitting resistance.

2) Corrosion control: 316 is favored for coastal, chemical, and marine exposure; 304 suits benign or intermittently cleaned settings.

3) Cost control: Molybdenum content typically makes 316 pricier; 304 minimizes upfront spend.

4) Application control: 304 fits appliances, food equipment, and hardware; 316 fits coastal panels, boat fittings, lab and process equipment, and medical uses.

Building on the 304 vs. 316 comparison, 304 and 430 differ more fundamentally in cost, magnetism, composition, and forming performance.

Type 304 includes 80.5% nickel and 17.59.5% chromium; 430 uses 16.08.0% chromium and no nickel. Nickel drives price and enhances corrosion resistance and formability, so 304 costs more but tolerates harsher media and deeper draws.

Magnetism provides a quick screen: 430, a ferritic grade, is strongly magnetic; 304, an austenitic grade, is generally non-magnetic but becomes magnetic after cold work, especially at cut edges.

For fabrication control, 304 presses and draws reliably; 430 is more prone to cracking during deep forming.

Selection guidance: choose 304 for aggressive environments or complex shapes; choose 430 for lower-cost, short-term, or mildly corrosive service.

Although selected for its balanced mix of corrosion resistance, formability, and strength, stainless steel 304 sees broad use across industries: kitchen equipment and appliances, food processing and handling systems, architectural fixtures and construction components, automotive and transportation hardware, plumbing and water treatment systems, chemical and petrochemical equipment, and general-purpose fasteners.

Its 18/8 composition supports deep draw sinks, hygienic surfaces, and easily cleaned finishes while maintaining toughness from low to moderately high temperatures. For chloride-rich or marine exposure, 316 is typically chosen; otherwise 304 offers a cost-effective, controllable baseline.

Beyond typical applications, specifying stainless steel 304 correctly requires citing recognized material standards and certifications that govern composition, product forms, and performance.

Control begins with designating UNS S30400 (EN 1.4301) or low-carbon S30403 (EN 1.4307). For flat-rolled plate and sheet, ASTM A240/A240M and EN 10088 define chemistry, tolerances, and mechanical minima.

Bar and shapes align to ASTM A276/A479 and EN 10088-3; seamless and welded pipe/tube follow ASTM A312/A269/A249 and EN 10216-5/10217-7. Pressure equipment compliance typically references ASME Section II and Section VIII, with material test reports confirming “Nor “Hstamps where applicable.

Quality assurance relies on mill MTCs per EN 10204 3.1/3.2, heat identification, and traceable lot control.

Dual certification (304/304L) is common, enabling weldability without sacrificing specified strength limits.

They identify 304 by verifying grade stamps or certificates, performing a magnet test (weakly magnetic after cold work), applying a copper sulfate test (no copper deposit), checking Moly presence absent via spot test, and confirming density and spark test characteristics.

Electropolished or fine 2B/BA finishes are preferred; lower Ra (<0.5 µm) minimizes biofilm. They resist corrosion, clean rapidly, and endure CIP/SIP. Avoid rough-brushed finishes. Specify passivation, full weld polishing, and crevice-free design to maintain hygienic control.

304 typically prices 100% below 316, with the gap widening when nickel and molybdenum surge. Over time, both track global alloy surcharges; 316’s molybdenum premium adds volatility. Buyers hedge via contracts, dual-qualification, and substitution strategies.

He schedules quarterly inspections, immediate chloride removal, and biannual passivation; contrasts daily cleaning with weekly lubrication, mandates prompt repair of scratches, and annual risk assessments. He controls environment: avoid stagnant chlorides, limit heat, guarantee drainage. Documentation and training enforce consistency, maximizing service life.

Yes. 304 stainless steel is fully recyclable without inherent property degradation; composition can be restored via controlled remelting and alloying. Closed-loop segregation, certified scrap streams, and melt chemistry verification guarantee consistent corrosion resistance, mechanical properties, and surface finish across cycles.

Vinmay is your trusted source for certified 304/304L stainless steel welded tubes and handrail fittings, produced under globally recognized standards including ASTM A270/A249/A269/A554, EN10357/EN10217-7, and DIN11850.

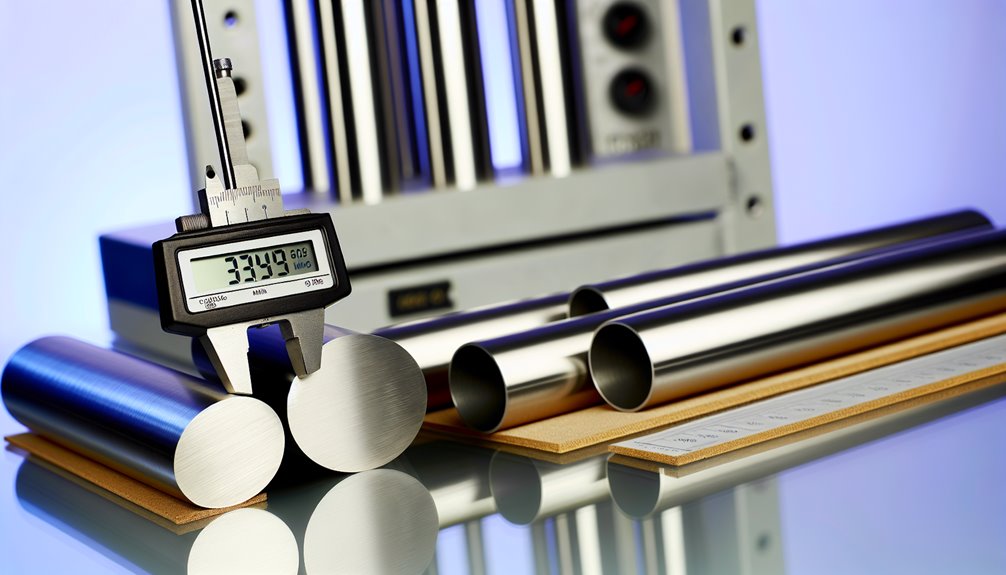

We supply sanitary, construction, water, and heat-treatment tubing, as well as matching handrail fittings, available in 201, 304, 304L, and 316L grades. Each batch is verified through video inspections, free samples, and comprehensive measurement toolsets to ensure dimensional accuracy and material conformity prior to purchase.

Our products meet ASTM/EN/DIN certifications, covering construction, sanitary, and process applications.

📧 Contact: marketing@vinssco.com

📍 Address: No. 6 Jingang Rd, Foshan, China