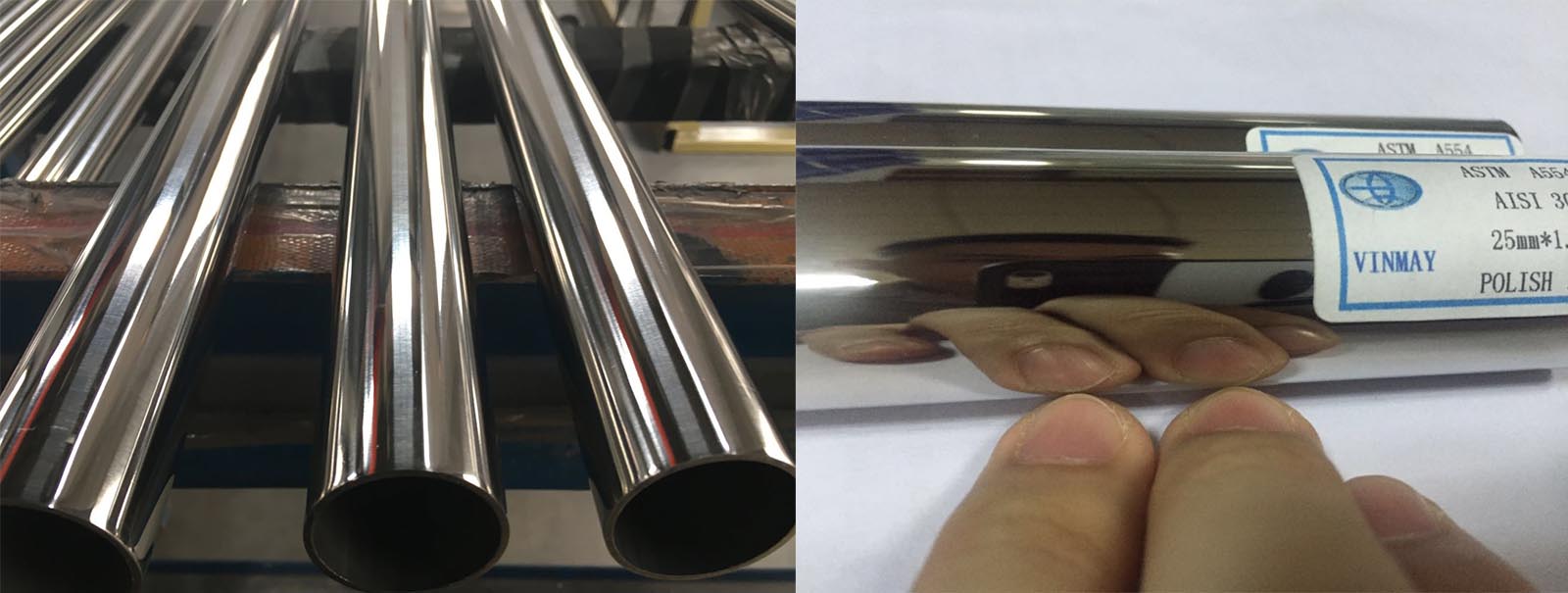

Discover the durability and elegance of our stainless steel welded round tube in mirror finish, available in a range of grades including 201, 304, 304L, 316L, and 430 stainless steel. Polished to a sleek, reflective surface, this mirror finishstainless steel round tube is perfect for diverse architectural, decorative, and industrial applications. Designed to resist corrosion and enhance your projects with a refined look, it’s ideal for marine projects, interior design, restaurants, store fixtures, handrails, and more. With an interior weld seam, this tube delivers both strength and style for any high-quality project.

| Material | 201/ 304 /304L/316L/430 | |||

| Certificate | ISO / AEO/ MTC/PED | |||

| Size | 6mm-219mm | |||

| Surface | Mill Finish, Mirror Finish, Satin Finish (MF,180G,320G,400G,600G) | |||

| Thickness | 0.6mm-5.0mm | |||

| Lenght | 5.8 M,6M,20 Feet or Customized | |||

| Delivery Time | 30 days for a container quantity | |||

| Payment Terms | T/T, LC, Cash, etc. Normally 30% by T/T in advance, balance to be paid before shipment. | |||

| Packing | Each tube will be packed in a plastic bag, then several tubes will be packed in hollow plate or weaving bags. | |||

| Application | Apply in handrails, furniture, sanitary ware, display shelves, sanitary ware, machinery equipment | |||

Our mirror finish stainless steel round tubes elevate projects with their sleek, reflective surface. Perfect for handrails, furniture, store displays, and marine applications, these tubes offer durability and a polished, modern aesthetic. Ideal for architectural designs and interior decor, they bring both strength and style to any project.

Both 304 and 316 stainless steel are excellent choices, but they each have unique properties that make them ideal for different environments.

304 Stainless Steel Welded Round Tube: This is the most commonly used stainless steel grade, known for its corrosion resistance, ease of maintenance, and versatility. It’s a great option for interior applications, such as furniture, store fixtures, and architectural designs where exposure to chemicals or saltwater is minimal. The mirror finish enhances its aesthetic appeal, providing a polished, modern look for various decorative uses.

316 Stainless Steel Welded Round Tube: If your project will be exposed to more harsh environments, such as marine applications or areas with high chemical or saltwater exposure, the 316 stainless steel welded round tube offers superior corrosion resistance. This makes it the preferred choice for outdoor installations, coastal projects, or industries like marine, chemical processing, and medical. The mirror finish not only adds elegance but also offers lasting durability in challenging conditions.

When deciding between 304 and 316, consider your project’s environmental conditions, such as exposure to salt, chemicals, or high temperatures, to choose the most suitable material.

Check out our detailed blog post to gain a deeper understanding of the differences between 304 and 316 stainless steel.

Foshan Vinmay Stainless Steel Co., Ltd. is a large-scale international enterprisewhich concentrates on producting stainless steel welded tubes and the related fittings. As a key partner for global stainless steel welded tube distributors, Vinmay serves the top importer of ss welded tube all over the world. We are committed to assisting our customers in becoming the top distributor in their country or worldwide.