Polished stainless steel round tubes have become a quintessential component in various industries, owing to their durability, corrosion resistance, and aesthetic appeal. Among the myriad options available, polished stainless steel round tubes stand out for their sleek finish and versatility. In this guide, we delve into the world of polished stainless steel welded round tubes, exploring different finishes, grades, and specifications.

The term "satin finish" indicates a smooth, semi-reflective surface texture achieved by sanding or brushing the stainless steel. This finish is less reflective than a polished finish but still offers an attractive appearance. It can hide fingerprints, scratches, and other imperfections better than a polished surface.

A 180 grit finish on a stainless steel round tube would typically result in a satin or brushed appearance. This finish is often used in applications where a moderate level of smoothness and aesthetics is desired, such as architectural elements, decorative fixtures, or furniture components. It provides a balance between surface texture and reflectivity, offering a visually appealing appearance while still maintaining some resistance to fingerprints and scratches.

A "240 grit stainless steel round tube" refers to a polished stainless steel round tube that has been finished using abrasives with a 240-grit size. Grit size is a measure of the size of the abrasive particles used in the finishing process. In this case, 240 grit indicates that the surface of the stainless steel tube has been sanded or polished with abrasives that have 240 grit particles.

A 240 grit finish results in a smoother surface compared to lower grit finishes. It provides a finer texture and higher level of polish, making it suitable for applications where a more refined appearance is desired. The surface of a stainless steel tube with a 240 grit finish would have a satin or brushed appearance with fewer visible scratches and a moderate level of reflectivity.

Stainless steel round tubes with a 240 grit finish are commonly used in various industries and applications, including architectural design, interior decoration, furniture manufacturing, and food processing equipment. This finish offers a balance between aesthetics and practicality, providing a visually appealing surface while still maintaining some resistance to fingerprints, scratches, and corrosion.

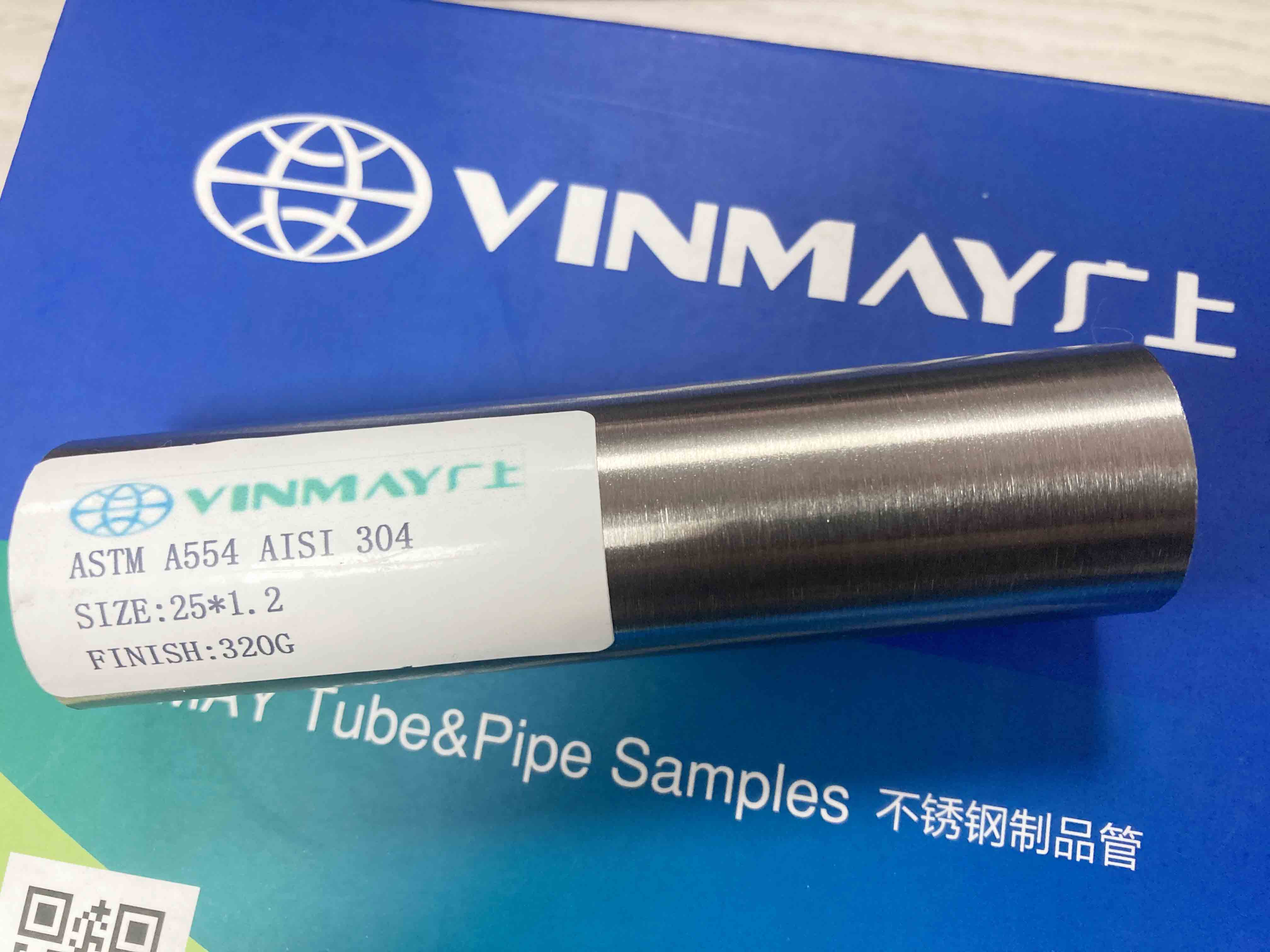

A 320 grit finish offers an even smoother surface compared to coarser grit finishes. It results in a fine texture and a higher level of polish, making it ideal for applications where a more refined and aesthetically pleasing appearance is desired. The surface of a stainless steel tube with a 320 grit finish would typically exhibit a satin or brushed appearance with minimal visible scratches and a relatively high level of reflectivity.

A mirror finish stainless steel round tube is characterized by a highly reflective surface achieved through polishing with fine abrasives like 600 or 800 grit.

The mirror finish enhances the aesthetic appeal of the stainless steel tube, making it suitable for decorative applications where a sleek and polished appearance is desired.

This finish also provides added corrosion resistance, contributing to the durability and longevity of the stainless steel round tube.

A 600 grit finish is a relatively smooth finish, often used in applications where appearance matters, such as architectural or decorative projects. It provides a fine, polished appearance but is not as mirror-like as higher grit finishes.

Stainless steel round tubes are commonly used in various industries including construction, automotive, aerospace, and manufacturing due to their corrosion resistance, strength, and versatility.

A stainless steel round tube with an 800 grit finish refers to a higher level of surface smoothness compared to a 600 grit finish

The "grit" number indicates the size of the abrasive particles used in the finishing process. A higher grit number corresponds to smaller abrasive particles and a smoother finish. Therefore, an 800 grit finish would result in a finer, more polished appearance compared to a 600 grit finish.

Stainless steel round tubes with an 800 grit finish are often used in applications where a very smooth and aesthetically pleasing surface is desired. This could include applications in industries such as pharmaceuticals, food processing, dairy, and certain architectural or decorative projects where a high-end finish is required.

As with other stainless steel tubing, when purchasing or specifying an 800 grit stainless steel round tube, you would typically provide the dimensions (outer diameter, wall thickness, and length) along with the desired finish. These tubes can be sourced from specialized metal suppliers or manufacturers who offer custom fabrication services.

A hairline finish on a stainless steel round tube refers to a surface finish that exhibits very fine parallel lines, giving it a subtle, brushed appearance. This finish is achieved by brushing the surface of the stainless steel with abrasive materials. The result is a finish that is smoother than a standard mill finish but not as reflective as a polished finish.

Hairline finishes are commonly used in architectural applications, interior design, furniture, and appliances where a modern and elegant appearance is desired. The fine lines of the hairline finish can help mask minor scratches and imperfections while providing a sleek and sophisticated look.

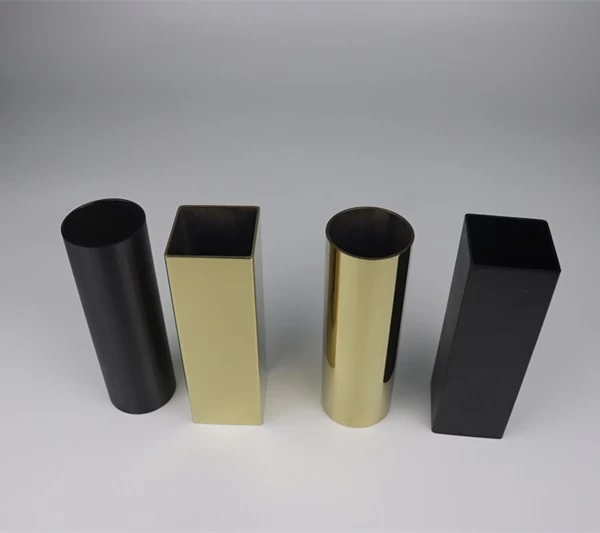

A color finish polished stainless steel round tube offers a distinctive visual appeal and protective coating, enhancing both aesthetics and durability in various applications. These tubes come in a wide range of color options, allowing for custom stainless steel tube to suit specific design requirements. The surface finish on color-finished stainless steel round tubes can vary from matte to glossy, providing versatility in design possibilities. Custom lengths are also available, enabling precise handrail fitting for individual project needs.

In terms of durability features, color finish stainless steel round tubes exhibit excellent wear and corrosion resistance, making them suitable for both indoor and outdoor applications. The protective color finish not only enhances the appearance but also adds a layer of protection against environmental elements, ensuring long-term performance. The design possibilities with color finish stainless steel round tubes are vast, offering a modern and sleek aesthetic that can elevate the overall look of architectural or decorative elements.

Related Blogs:

Comprehensive Guide to Stainless Steel Tube Surface Finishes

Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

The specifications of Polished Stainless Steel Round Tube include standard types and grades, which commonly adhere to ASTM standards like A554 for welded tubes.

Additionally, the size range of these round tubes varies, offering options in outside diameter, wall thickness, and lengths ranging from 4ft to 20ft or custom cut sizes.

Understanding the stainless steel tube standard classifications and available dimensions is crucial for selecting the appropriate Polished Stainless Steel Round Tube to meet specific project requirements.

This standard is widely used in industries where stainless steel tubing is required for structural or decorative applications.

ASTM A270 is a specification developed by the American Society for Testing and Materials (ASTM) that covers seamless and welded stainless steel tube intended for use in the dairy and food industry and other hygienic applications. The standard outlines requirements for materials, dimensions, mechanical properties, surface finishes, and testing procedures for stainless steel sanitary tubes.roperties meet stringent industry standards for durability and performance.

These are austenitic stainless steels, which are non-magnetic and have excellent corrosion resistance. Common grades include:

These are martensitic stainless steels, magnetic and less corrosion-resistant compared to the 300 series. Common grades include:

This can range from as small as 1/16 inch (1.5875 millimeters) to as large as 12 inches (304.8 millimeters) or more, depending on the stainless steel welded tube manufacturer and the specific needs of the project.

The wall thickness of stainless steel round tubes can vary greatly depending on the application and the required strength. It can range from very thin walls, such as 0.010 inches (0.254 millimeters) for instrumentation tubing, to thicker walls, such as 1 inch (25.4 millimeters) or more for structural or heavy-duty applications.

Providing a versatile range of stainless steel pipe dimensions, the Polished Stainless Steel Round Tube is available in various lengths to accommodate diverse industrial requirements.

Down the size list of Vinmay

You may also like:

A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

The Ins and Outs of Sanitary Stainless Steel Tube Sizes

The mechanical properties of polished stainless round tubes are crucial indicators of their structural integrity and performance. Tensile strength, yield point, elongation, shearing strength, and Brinell hardness are key parameters that define the material's ability to withstand various forces and loads.

Understanding these properties is essential for selecting the appropriate tube for specific applications.

The polished stainless round tube exhibits a Tensile Strength of 85,800 psi, showcasing its capability to withstand high levels of tensile force before yielding.

Tensile Strength Comparison: Compared to other materials, this stainless steel tube offers a superior tensile strength, ensuring reliable performance in demanding applications.

Impact Testing: The high tensile strength makes it suitable for applications requiring resistance to impact loads and dynamic forces.

Microstructure Analysis: The microstructure of the tube contributes to its impressive tensile strength, showcasing a well-balanced composition for enhanced mechanical properties.

Heat Treatment Effects: Proper heat treatment can further enhance the tensile strength of the stainless steel tube, providing opportunities for tailored mechanical properties.

Impressive mechanical properties extend beyond tensile strength in the polished stainless round tube, notably exemplified by its Yield Point measurement of 34,000 psi. Yield point analysis reveals the stress level at which the material transitions from elastic to plastic deformation, indicating its ability to withstand deformation without permanent damage. Ductility evaluation of polished stainless round tubes shows their capacity to deform under tensile stress before fracturing, contributing to their formability in various applications. When compared to other materials, the stainless round tube's yield point signifies its strength and resilience under loading conditions. Understanding the significance of the yield point is crucial for designing structures that require a balance between strength and deformability. Various testing techniques, such as tension testing, are employed to determine the yield point accurately.

| Yield Point (psi) | Ductility | Material Strength |

|---|---|---|

| 34,000 | High | Superior |

Exhibiting a crucial mechanical characteristic, the elongation of the polished stainless round tube measures 60% in 2, showcasing its capacity to deform before fracturing under tensile stress.

This ductile elongation property highlights the material flexibility and formability characteristics of the tube.

The tensile elongation of 60% emphasizes its stretching properties, allowing for significant deformation before failure.

This elongation percentage signifies the tube's ability to withstand external forces and reshape without breaking easily.

The elongation value plays a vital role in applications requiring durability and resilience to bending or shaping processes.

With a shearing strength of 11,500 psi, the polished stainless round tube demonstrates notable resistance to forces applied parallel to its surface. This mechanical property is crucial for ensuring the structural integrity of the tube, as it determines the maximum force the material can withstand before undergoing shearing failure. By conducting a strength analysis that includes shearing strength, engineers can assess the tube's ability to withstand various types of loads and forces, contributing to the overall safety and reliability of the structure. Understanding the force distribution within the material is essential for designing and optimizing applications where shearing forces are prevalent.

| Shearing Strength | 11,500 psi |

|---|---|

| Material Property | Shear Resistance |

| Strength Analysis | Structural Integrity |

The Brinell Hardness, a crucial mechanical property, provides insight into the resistance of the polished stainless round tube to indentation and wear, complementing the tube's shearing strength for a comprehensive evaluation of its structural robustness.

When considering the material properties of the tube, the Brinell Hardness of 170 indicates a high level of hardness and resistance to penetration, which is essential for applications requiring durability. It plays a significant role in determining the tube's ability to withstand abrasive forces and maintain its shape over time.

Considering its exceptional corrosion resistance and durability, polished stainless steel round tubes are suitable for outdoor applications. They offer a blend of aesthetics and design, requiring minimal maintenance and cleaning. Their strength-to-weight ratio and long-term cost-effectiveness make them a reliable choice.

When considering high temperatures, limitations of materials must be acknowledged. Corrosion resistance in stainless steel offers benefits in varied environments. Heat resistance properties contribute to durability. Surface finish maintenance is crucial for longevity. Mechanical strength provides advantages in structural applications.

Surface cleanliness, corrosion resistance, and hygienic properties are crucial in food-grade applications. Polished stainless steel round tubes offer excellent resistance to corrosion, a smooth surface for cleanliness, and strong mechanical properties, ensuring both functionality and aesthetics.

When considering welding techniques on stainless steel round tubes, it is crucial to implement proper procedures to avoid affecting the finish. Surface protection, finishing options, and metal fabrication play vital roles in maintaining heat and corrosion resistance. Careful welding considerations and surface maintenance are essential for preserving the tube's integrity.

Brushed finish stainless steel round tubes typically feature a satin-like surface texture, lower reflectivity levels, and hide scratches well. They require less maintenance compared to polished finishes, offering a more industrial aesthetic while maintaining durability.

Deciphering the Dynamics: Unraveling Stainless Steel Round Tube Prices

A Comprehensive Guide to Top Stainless Steel Round Tube Suppliers Worldwide

Foshan Vinmay Stainless Steel Co.,ltd is the manufacturer of stainless steel round tube for building and construction, food industry , water supply system. if you are interested in stainless steel round tube . Please feel free to contact us.

In conclusion, the Polished Stainless Round Tube offers exceptional durability and performance in industrial applications.

With its 304 welded construction and ASTM A554 certification, this tube is a reliable choice for projects requiring high strength and corrosion resistance.

One interesting statistic to note is that it boasts a tensile strength of up to 90,000 psi.

Overall, the Polished Stainless Round Tube is a versatile and reliable component that meets the demands of various engineering projects.