Choosing the right tube clamp fittings for hygienic and industrial applications requires a methodical assessment of several key factors. Material selection is vital, with 316L stainless steel often favored for its superior corrosion resistance and compliance with sanitary standards. Consider the specific fitting type, whether sanitary or industrial, and evaluate the system's pressure, temperature, and vibration conditions. Proper installation and maintenance are essential to prevent leaks and guarantee efficiency. But what more could impact your decision?

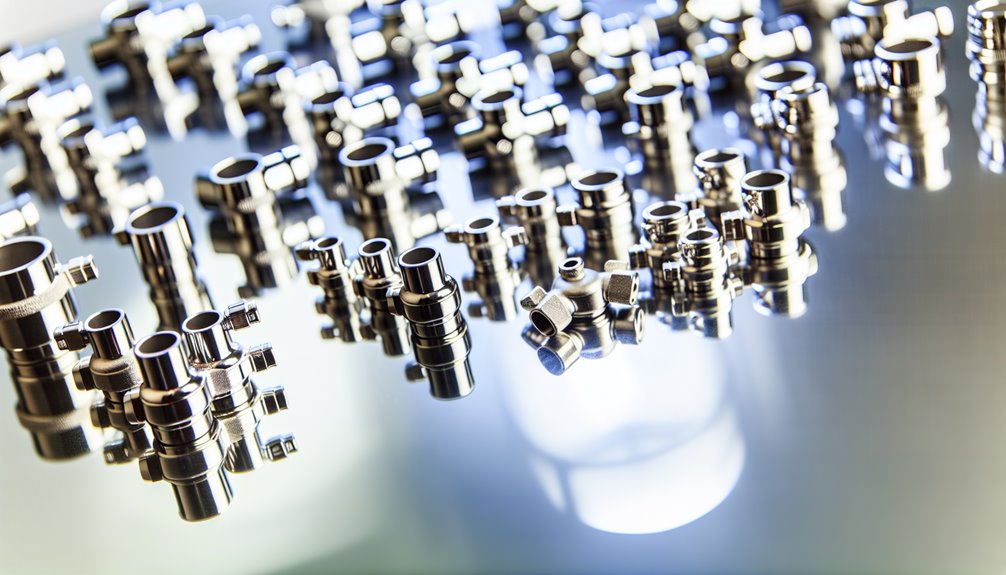

Tube clamp fittings, also known as tri-clamp fittings, are essential components in industries requiring sanitary and leak-free connections, such as food and beverage processing and biopharmaceutical manufacturing.

These fittings facilitate quick disassembly and clean-in-place (CIP) or steam-in-place (SIP) processes, ensuring hygienic tube clamp fittings maintain operational efficiency. Manufactured using stainless steel, these fittings offer superior corrosion resistance, making them ideal for maintaining cleanliness in sensitive environments. Medical-grade stainless steel tubing provides exceptional corrosion resistance, ensuring long-term durability and safety in environments involving frequent sterilization.

Quick disassembly and CIP/SIP processes ensure operational efficiency of hygienic tube clamp fittings.

Unlike threaded or welded joints, which are prone to contamination, industrial tube clamps provide superior seal integrity through precise tube fitting installation torque. The selection of appropriate diameter and wall thickness in tubing paired with these fittings ensures optimal fluid movement without pressure drops. Sanitary stainless steel pipes play a critical role in safeguarding quality and safety across various industries by ensuring reliable and hygienic transportation of liquids and gases.

Stainless steel sanitary tubes are often used in conjunction with these fittings due to their corrosion resistance and smooth surfaces, which prevent bacteria and contaminants accumulation.

The risk of CIP/SIP tube clamp fitting failures can be mitigated by regular inspections and maintenance.

Ensuring proper torque during installation is vital to prevent leaks and maintain the sanitary conditions necessary for sensitive production environments, thereby enhancing the reliability and safety of the manufacturing processes.

The selection of tube clamp fittings is influenced by the specific requirements of each application, with distinctions made between heavy-duty and standard clamps based on load-bearing capacity. Sanitary tube clamps are critical in industries such as food and pharmaceuticals, where hygiene and ease of cleaning are paramount, while industrial tube clamps are designed for environments that prioritize durability over sanitation. Adjustable tube clamps provide versatility in various configurations and are employed across diverse sectors, from construction to manufacturing, to accommodate different structural and process needs.

In selecting materials for sanitary applications, factors such as corrosion susceptibility and temperature resistance must be carefully considered to ensure reliability and compliance with industry standards. The selection of appropriate materials ensures that the fittings can withstand the same stringent standards as pharmaceutical grade stainless steel tubing. Sanitary tube fittings, made from high-quality stainless steel, are essential for hygienic piping systems, ensuring smooth flow and reliable sealing. The use of stainless steel, particularly grades like 304 and 316, provides exceptional corrosion resistance and hygiene, which is crucial for maintaining food safety. Adhering to sanitary standards is essential to prevent contamination and ensure product integrity, especially in the pharmaceutical and food processing industries where sanitation is critical.

When selecting tube clamp fittings for various applications, understanding the distinction between heavy-duty and standard options is vital. Heavy-duty tube clamps are designed for high-stress environments, offering superior support and pressure resistance, making them ideal for robust industrial settings. In contrast, standard tube clamps are suited for less demanding conditions, providing adequate functionality at a lower cost. Tri-clamp fittings selection requires consideration of tube clamp material compatibility to guarantee longevity and performance. Pressure rated tube clamps are essential for maintaining integrity under varying operational pressures, and sourcing from reputable sanitary clamp fitting suppliers guarantees quality and compliance.

Stainless steel rectangular tubes provide standardized and reliable solutions for structural needs, which can be crucial in selecting materials for various tube clamp applications. When selecting materials for marine applications, stainless steel grades such as 316/316L offer enhanced corrosion resistance, ensuring durability in harsh environments. 316 stainless steel is preferred for highly corrosive environments due to its superior resistance to chemicals and chlorides. When it comes to selecting sanitary elbows, the choice between short radius elbows and long radius options depends on installation constraints and flow requirements.

Sanitary and industrial tube clamps serve distinct functions within various applications, each offering unique benefits tailored to specific operational demands.

Sanitary clamps are vital in environments requiring stringent hygiene standards, such as food and biopharmaceutical industries. These clamps are typically made from high-grade materials like stainless steel to prevent contamination and guarantee compliance with safety regulations. Their design minimizes crevices where impurities could accumulate, thereby maintaining product integrity.

Excellent weldability is a key characteristic of 304 stainless steel, making it an ideal choice for sanitary applications where hygiene and structural integrity are paramount. Strict adherence to standards is crucial in these applications to prevent contamination and ensure safety. The exceptional corrosion resistance of 304 stainless steel enhances its suitability for such environments, ensuring long-lasting performance and reducing maintenance needs. ASTM A554 standards outline specifications ensuring high-quality tube clamps for both sanitary and industrial uses.

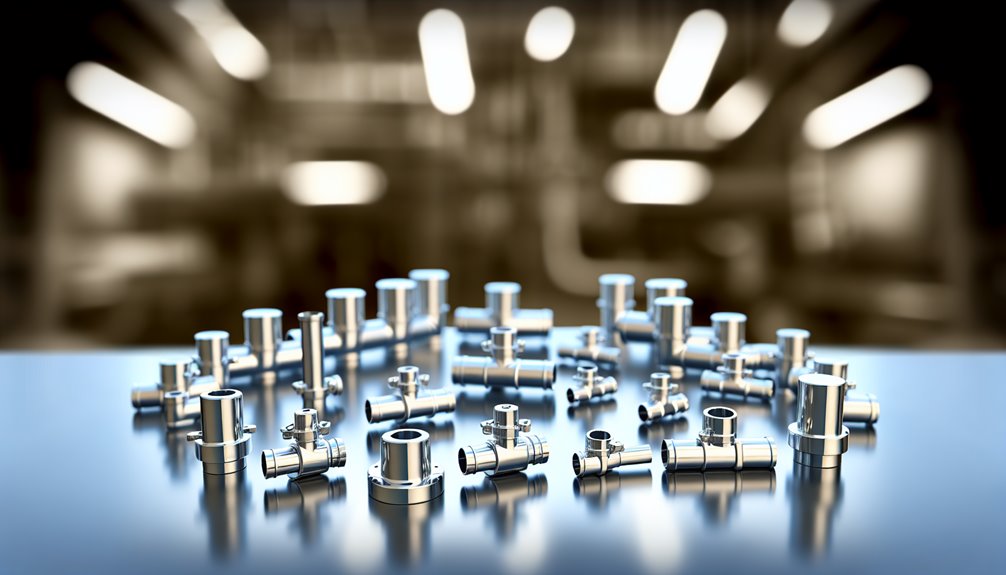

In contrast, industrial tube clamps are designed for durability and strength in robust environments. They accommodate various types of connections, such as straight couplings, elbows, tees, and reducers, to support complex piping systems.

Engineering choices, like selecting a 45° elbow over a 90° elbow in process loops, optimize flow dynamics and structural integrity.

Food grade 304 stainless steel is considered safe for food contact due to its corrosion resistance and durability, ensuring ease of sanitation.

Adjustable tube clamps, a versatile category of tube clamp fittings, are essential in numerous applications where flexibility and adaptability are paramount.

These clamps are designed to accommodate varying tubing diameters and angles, allowing for precise adjustments in dynamic environments. Engineers often face situations that require adaptability, such as incorporating a 45° elbow rather than a 90° elbow in process loops to enhance flow dynamics and reduce pressure loss. The 300 series stainless steel used in the construction of these clamps offers excellent corrosion resistance, making them suitable for diverse applications in industries like pharmaceuticals and food processing.

In addition to their adaptability, these clamps benefit from the corrosion resistance properties of stainless steel, which is critical for maintaining hygiene and longevity in demanding industrial environments. Marine-grade alloys like 316 and 316L are particularly effective in saltwater conditions due to their enhanced resistance to pitting and crevice corrosion. Stainless steel tubing is favored for its ability to maintain performance under thermal cycling and fluid exposure, ensuring reduced failure rates over time.

Adjustable clamps provide the necessary flexibility to make such modifications seamlessly. They are particularly useful in applications demanding frequent reconfiguration or maintenance, guaranteeing that processes remain efficient and uninterrupted.

Their design enables quick assembly and disassembly, minimizing downtime and enhancing operational efficiency. Selecting the correct adjustable clamp guarantees peak performance and process continuity. Stainless steel pipes offer excellent corrosion resistance, ensuring a long lifespan with minimal maintenance.

Building on the versatility offered by adjustable tube clamps, practical applications across various industries demonstrate the critical role different types of tube clamp fittings play in optimizing process efficiency. Straight couplings, elbows, tees, and reducers are pivotal in configuring fluid transport systems tailored to specific operational requirements. For instance, a 45° elbow offers reduced turbulence in process loops compared to a 90° elbow, enhancing flow efficiency in fluid dynamics applications. In the food and beverage sector, tri-clamp fittings guarantee sanitary conditions, preventing contamination. The pharmaceutical industry benefits from their sterile environment adaptability.

Each fitting type serves a distinct purpose, carefully selected based on fluid characteristics, pressure, and temperature conditions, facilitating seamless integration and superior performance in industrial processes. Stainless steel pipes, known for their exceptional corrosion resistance, further enhance the reliability of these systems by preventing material degradation. Their non-toxic nature ensures that no harmful substances leach into the fluids, maintaining water purity in the process. Seamless tubes offer structural integrity, making them ideal for high-pressure applications, which can be crucial in maintaining system stability and safety.

The widespread use of 316 stainless steel tubes in these fittings is bolstered by their superior durability and ability to withstand harsh environmental conditions, making them an industry favorite for critical applications. These tubes are produced by leading manufacturers known for their advanced production technologies and quality control, ensuring consistent and reliable performance across various uses.

Selecting the appropriate tube clamp fitting requires a careful assessment of several critical factors, including material choice, pressure and temperature limits, system vibrations, and joint stability. Each factor plays an essential role in ensuring that the fitting performs effectively under operational conditions, with material selection directly impacting corrosion resistance and durability. Additionally, compatibility with sealing methods must be evaluated to maintain system integrity and prevent leakage. When selecting fittings for dairy processing, it's important to ensure compliance with food safety regulations to maintain sanitation and hygiene standards.

It is also crucial to ensure materials meet ASTM standards to guarantee the quality and reliability of the fittings used in industrial applications. Understanding key ASTM standards such as ASTM A312 helps manufacturers and engineers select the right stainless steel tubes for high-temperature and corrosive environments, ensuring safety and performance. The ASTM A270 standard is specifically designed to meet stringent hygienic needs, making it essential for applications in food processing, pharmaceuticals, and biotechnology. Proper compliance with ASTM A249 ensures that the tubes used in these fittings meet the dimensions, tolerances, and heat treatment requirements needed for optimal performance.

Choosing the appropriate material for tube clamp fittings is a vital decision that impacts the longevity and performance of a system.

The material choice often revolves around stainless steel alloys, primarily 304 and 316L. Alloy 304 is cost-effective but can be susceptible to corrosion in certain environments. On the other hand, alloy 316L includes Molybdenum, enhancing its resistance to corrosion and making it preferable for more demanding applications. This distinction is essential when considering exposure to harsh chemicals or saline environments. A methodical evaluation of factors such as the system's environmental conditions and potential exposure levels will guide the selection.

304 stainless steel offers superior corrosion resistance and durability than 201, which is critical when deciding between these materials for industrial applications. Stainless steel grade 316 is often specified for its outstanding tensile strength and corrosion resistance, which makes it ideal for structural applications in harsh environments. Additionally, 316L stainless steel is favored in marine environments due to its superior resistance to chloride-induced corrosion. The high tensile strength and impressive corrosion resistance of 304 stainless steel make it ideal for a variety of applications in both industrial and hygienic settings.

Understanding the material properties of tube clamp fittings is integral to guaranteeing system longevity and reliability. Evaluating pressure and temperature limits is a critical component in selecting appropriate fittings.

Each material, such as stainless steel alloys 304 and 316, possesses distinct characteristics affecting its ability to withstand specific conditions. Alloy 316, for instance, offers enhanced resistance to high temperatures and pressures due to its Molybdenum content.

Analyzing these properties aids in determining the fitting's suitability for operational demands. Precise calculations of the operating environment, including maximum anticipated pressure and temperature, must be conducted. This guarantees the selected fittings maintain structural integrity under stress, preventing failures.

Ultimately, methodical analysis of these parameters secures ideal performance and extends system lifespan.

System stability is a cornerstone of efficient process operations, with vibrations posing significant challenges to tube clamp fittings. To address this, understanding the interplay between system dynamics and fitting integrity is vital. High-frequency vibrations can lead to joint fatigue, degradation, and ultimately, failure.

Selecting fittings with robust design and appropriate material properties mitigates these risks. Stainless steel alloys, known for their durability and resistance to mechanical stress, are often preferred. Additionally, guaranteeing precise alignment and secure fastening of components enhances joint stability, reducing the impact of vibrations.

Regular monitoring and maintenance further assure that fittings remain in peak condition, thereby sustaining system reliability. Consequently, a methodical approach to fitting selection and maintenance is essential for maintaining system integrity under vibrational stress.

When evaluating sealing method compatibility for tube clamp fittings, it is essential to take into account the interplay between gasket materials and the chemical and thermal conditions of the system.

Different materials, such as PTFE, O-rings, and traditional gaskets, offer varying levels of resistance to temperature fluctuations and chemical exposure. PTFE, known for its excellent chemical resistance and thermal stability, is often preferred in harsh environments.

Meanwhile, elastomeric O-rings provide effective seals in less extreme conditions. Selecting the appropriate material requires a thorough understanding of the system’s operational parameters, including pressure, temperature variations, and the types of chemicals involved.

Ensuring compatibility between the sealing material and the system conditions is critical to maintaining the integrity and reliability of the tube clamp fittings.

In selecting tube clamp fittings, the choice of material is paramount due to its direct impact on the system's longevity and reliability, especially in hygienic applications.

The use of 304 and 316L stainless steel is prevalent, each offering distinct benefits:

Corrosion Resistance: Critical in food and beverage systems to prevent material degradation and contamination.

Impact on Lifespan: Proper material selection guarantees extended lifespan and reduced maintenance costs.

These factors necessitate a precise and informed decision to guarantee peak performance and compliance with industry standards, making material selection a foundational step in the process.

Choosing the right material is just one part of ensuring the longevity and reliability of tube clamp fittings; proper installation is equally significant.

Precision in installation begins with correct torque application and precise alignment to guarantee ideal performance. Misalignment or incorrect torque can lead to leaks or system failures, undermining the effectiveness of the fittings. It is essential to meticulously follow installation guidelines to maintain seal integrity.

Implementing best practices, such as avoiding over-tightening and ensuring uniform compression of gaskets, enhances the reliability of the connection. Additionally, consideration for ease of disassembly should be integrated into the installation process, facilitating maintenance and inspection without compromising the system’s integrity.

These strategic approaches sustain fitting functionality and operational efficiency.

Numerous factors contribute to tube clamp fitting failures, requiring a methodical approach to diagnosis and prevention.

Key issues include leaks, often resulting from vibration-induced stresses or improper installation techniques. Incompatibility with system pressure ratings can also lead to failures, as clamps may not withstand the operational pressures.

Additionally, the choice of clamps plays a vital role in CIP/SIP processes; an inadequate selection can compromise cleaning efficiency and system integrity. Recognizing early warning signs is essential to mitigate failures effectively.

Failures in tube clamp fittings can have significant implications for hygienic systems, necessitating a thorough understanding of their role in maintaining cleanliness and system integrity.

Tube clamp fittings for sanitary applications must adhere to specific requirements such as smooth surfaces, drainability, and ease of disassembly. These features are essential for Clean-in-Place (CIP) and Sterilization-in-Place (SIP) compliance, ensuring that systems remain uncontaminated and efficient.

The material selection for these fittings is critical; stainless steel alloys, particularly grades 304 and 316, are preferred in food and pharmaceutical industries due to their durability and resistance to corrosion.

The choice between these materials depends on the environmental conditions and operational demands, ensuring ideal performance and longevity in maintaining hygienic standards.

When selecting tube clamp fittings for sanitary systems, adherence to established standards such as 3-A, DIN, and FDA is imperative to confirm regulatory compliance and system integrity.

Adhering to standards like 3-A, DIN, and FDA ensures regulatory compliance and system integrity for sanitary systems.

These standards guarantee the fittings meet stringent sanitary requirements and mitigate contamination risks. The importance of compliance can be distilled into several essential factors:

Choosing fittings aligned with these standards is vital for maintaining system hygiene and operational efficiency, thereby safeguarding product integrity.

Tube clamp fittings should be inspected after each production run in industries with stringent hygiene requirements. Regular inspections guarantee peak performance, identify wear or damage, and prevent contamination risks, maintaining integrity and compliance with safety standards.

Tube clamp fittings, once disassembled, can theoretically be reused, akin to resurrecting a phoenix from ashes. However, meticulous inspection for wear, residue, and gasket integrity is essential to guarantee they function without compromise in hygienic environments.

Common signs of tube clamp fitting failure include visible leaks, compromised gasket integrity, misalignment of flanged ends, and corrosion. Regular inspections and maintenance are essential to prevent contamination and guarantee peak functioning within industrial and hygienic applications.

Environmental concerns related to tube clamp fittings include potential material wastage, energy consumption during manufacturing, and the environmental impact of discarded fittings. Stainless steel options mitigate some risks due to recyclability, but careful selection remains essential for sustainability.

Sixty-seven percent of U.S. fittings sold are tri-clamp, demonstrating preference for their versatility. However, extreme temperature fluctuations can compromise gasket integrity, causing potential failures at flange connections, emphasizing the importance of material selection and regular maintenance.

In the intricate interplay of industrial innovation, choosing tube clamp fittings demands deliberate diligence. Prioritizing premium materials like 316L stainless steel guarantees enduring efficacy in sensitive settings. Selecting suitable styles—sanitary for sustenance scenarios, industrial for intense installations—safeguards system stability. Scrutinizing standards and securing seamless setup staves off structural failures. This meticulous methodology maximizes maintenance, minimizing mishaps. Ultimately, aligning attributes with application confirms an adept and advantageous arrangement, enhancing efficiency and guaranteeing enduring operational excellence.