The 316 stainless steel tube properties are critical for various industrial applications, characterized by its impressive mechanical strength and exceptional resistance to corrosion, particularly in harsh environments. With a tensile strength ranging from 515 to 827 MPa and a yield strength of approximately 290 MPa, this material guarantees reliable performance under stress. However, its unique advantages extend beyond these metrics, inviting exploration into its specific applications and the distinctions between various grade of stainless steel pipe. Understanding these nuances can greatly impact material selection for engineers and designers alike.

Characterized by its unique blend of elements, the chemical composition of 316 stainless steel includes a significant proportion of chromium, nickel, and molybdenum, which contribute to its enhanced corrosion resistance and overall durability.

Specifically, 316 stainless steel typically contains approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, alongside trace amounts of other elements such as carbon, manganese, and silicon.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 16.00 - 18.00 |

| Nickel (Ni) | 10.00 - 14.00 |

| Molybdenum (Mo) | 2.00 - 3.00 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

Renowned for its exceptional stainless steel tube corrosion resistance, 316 stainless steel tube properties is particularly effective in harsh environments due to its unique composition, which includes molybdenum that enhances its ability to withstand aggressive chemical exposure.

This alloy demonstrates significant resistance to pitting corrosion, a localized form of corrosion that can occur in chloride-rich environments, making it ideal for marine and chemical processing applications.

Stress corrosion cracking (SCC) is another concern in corrosive environments, but 316 stainless steel tube properties exhibits commendable resistance to this phenomenon, particularly when exposed to chlorides. Its chloride resistance is crucial for applications where exposure to saline or chlorinated water is prevalent.

To further enhance its protective qualities, surface treatments such as passivation can be employed, which improve the overall corrosion resistance by promoting the formation of a stable, inert oxide layer.

It is imperative to take into account various environmental factors, including temperature, humidity, and the presence of aggressive chemicals, as these can influence the corrosion performance of stainless steel 316.

Exhibiting excellent heat resistance, 316 stainless steel tube properties maintains its mechanical properties and structural integrity at elevated temperatures, making it suitable for applications in high-heat environments.

With a temperature limit of approximately 870°C (1600°F) in continuous service, it demonstrates commendable thermal stability. This alloy's thermal conductivity is significantly lower than that of carbon steel, allowing it to retain heat without substantial loss, which is advantageous in specific industrial applications.

One of the key attributes of 316 stainless steel tube properties is its oxidation resistance, which remains effective even under prolonged heat exposure. This resistance is particularly valuable in applications where materials are subjected to fluctuating temperatures or reactive environments, as it minimizes the risk of degradation and failure over time.

These fabrication techniques play a vital role in the versatility of 316 stainless steel tube properties across various stainless steel tube applications, including marine, chemical processing, and food industries. By adhering to industry standards and implementing effective stainless steel tube manufacturing processes, the resulting products exhibit the desired performance characteristics necessary for demanding environments.

Cold working of 316 stainless steel tube properties involves deforming the material at room temperature to enhance its mechanical properties, such as strength and hardness, while maintaining its corrosion-resistant characteristics. This process employs various cold working techniques, including rolling, bending, and drawing, which facilitate stainless steel deformation without the need for heat.

During cold working, the material experiences strain hardening, a phenomenon where dislocation density increases, leading to improved hardness and strength. This mechanical properties impact is particularly beneficial in applications requiring high strength-to-weight ratios, as it allows for the production of thinner, yet stronger components.

Hot working of 316 stainless steel tube properties involves the deformation of the material at elevated temperatures, which enhances its ductility and allows for complex shapes to be formed without cracking or excessive strain. This process is essential for applications requiring intricate designs, as it mitigates the adverse effects of strain hardening, which can occur during cold working.

The following table summarizes key considerations in the hot working of 316 stainless steel tube properties:

| Factor | Description |

|---|---|

| Temperature Range | 1000°F to 2100°F (540°C to 1150°C) |

| Tool Material | High-speed steel or carbide for durability |

| Deformation Mechanisms | Dynamic recrystallization and grain refinement |

The heat treatment of 316 stainless steel tube properties is a critical process that influences its mechanical properties and corrosion resistance, complementing the enhancements achieved during hot working. This treatment typically involves various heat treatment methods, each tailored to achieve specific outcomes. Properly executed heat treatment not only enhances the material's performance but also addresses intrinsic stresses formed during manufacturing.

Key aspects of heat treatment for 316 stainless steel tube properties include:

Temperature Effects: The heating and cooling rates greatly impact the final properties of the material, with precise control necessary to avoid unwanted phase transformation

Micro structure Changes: Elevated temperatures can alter the micro structure, affecting grain size and distribution, which in turn influences overall performance.

Hardness Improvement: Optimizing the heat treatment can lead to an increase in hardness, enhancing wear resistance and extending the material's lifespan.

Stress Relief: Heat treatment serves to mitigate residual stresses that can lead to deformation and failure in service.

Machinability of 316 stainless steel tube properties is an important consideration in manufacturing processes, as it greatly affects the efficiency and quality of machining operations. This alloy's austenitic structure presents unique challenges that require careful attention to various machining techniques and parameters. To achieve ideal results, it is essential to focus on tool selection, cutting speeds, and lubrication methods.

| Factor | Considerations |

|---|---|

| Machining Techniques | Use high-speed machining |

| Tool Selection | Carbide or high-speed steel |

| Surface Finish | Aim for a fine finish |

| Cutting Speeds | Moderate speeds preferred |

| Lubrication Methods | Employ coolant to reduce heat |

Welding 316 stainless steel requires an understanding of its unique composition and properties to guarantee strong, durable joints that can withstand corrosive environments. The successful welding of this alloy necessitates careful consideration of various factors to mitigate potential issues.

Welding Techniques: Techniques such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) are commonly employed for 316 stainless steel, providing control over heat input and minimizing distortion.

Joint Preparation: Proper joint preparation is essential to ascertain clean surfaces free from contaminants, which can adversely affect weld quality.

Filler Materials: Selecting the appropriate filler materials, typically ER316 or ER316L, is critical to achieving mechanical properties that match or exceed the base metal.

Post Weld Treatment: Implementing post weld treatment, such as passivation, enhances corrosion resistance and reduces susceptibility to common defects like pitting or cracking.

Understanding these elements not only fosters a sense of community among welders but also guarantees that the integrity of 316 stainless steel structures is maintained in demanding environments.

You may also like:

Stainless Steel Welding Issues Exploration

Mastering the Art of 201Stainless Steel Welding

| Country | Equivalent Grade |

|---|---|

| United States | ASTM/UNS S31600 |

| European Union | EN/DIN 1.4401, X5CrNiMo17-12-2 |

| Germany | DIN X5CrNiMo17-12-2 |

| United Kingdom | BS 316S31, BS 316S33 |

| France | AFNOR Z6CND17.11 |

| Japan | JIS SUS 316, JIS SUS 316L |

| China | GB 0Cr17Ni12Mo2 |

| Russia | GOST 08X17H13M2T |

| MECHANICAL PROPERTIES | METRIC | ENGLISH | COMMENTS |

| Hardness, Brinell | 146 | 146 | |

| Hardness, Knoop | 166 | 166 | Converted from Brinell hardness |

| Hardness, Rockwell B | 79 | 79 | Converted from Brinell hardness |

| Hardness, Vickers | 152 | 152 | Converted from Brinell hardness |

| Tensile Strength, Ultimate | 620 - 795 MPa | 90 - 115 ksi | |

| Tensile Strength, Yield | 206 MPa | 30000 psi | |

| Elongation at Break | 30% | 30% | |

| Modulus of Elasticity | 164 GPa | 24000 ksi |

| PHYSICAL PROPERTIES | METRIC | ENGLISH | COMMENTS |

| Density | 8 g/cc | 0.290 lb/in³ |

| ELECTRICAL PROPERTIES | METRIC | ENGLISH | COMMENTS |

| Electrical Resistivity | 7.2e-005 ohm-cm | 7.2e-005 ohm-cm |

Key electrical 316 stainless steel tube properties include:

Conductivity Factors: The electrical conductivity of 316 stainless steel is lower than that of copper or aluminum, but suitable for many applications requiring moderate conductivity.

Resistivity Measurements: The resistivity of 316 stainless steel typically ranges around 0.74 μΩ·m, influencing how efficiently electrical current can pass through the material.

Dielectric Properties: Although primarily a conductive material, 316 stainless steel tube properties exhibits dielectric behavior in certain applications, essential for insulating components within electrical assemblies.

Electrochemical Behavior: The alloy's resistance to corrosion contributes to its stability in electrochemical environments, ensuring reliable performance in diverse chemical settings while maintaining electromagnetic compatibility.

| THERMAL PROPERTIES | METRIC | ENGLISH | COMMENTS |

| CTE, linear 20°C | 17.2 µm/m-°C | 9.56 µin/in-°F | from 0-100°C |

| CTE, linear 250°C | 17.8 µm/m-°C | 9.89 µin/in-°F | at 0-315°C (32-600°F) |

| CTE, linear 500°C | 18.4 µm/m-°C | 10.2 µin/in-°F | at 0-540°C, 18.7 µm/m-C at 0-650°C |

| Specific Heat Capacity | 0.5 J/g-°C | 0.12 BTU/lb-°F | from 0-100°C (32-212°F) |

| Thermal Conductivity | 16.2 W/m-K | 112 BTU-in /hr-ft²-°F | at 100°C (212°F), 21.5 W/m-K at 500°C (930°F) |

| Melting Point | 1400 - 1420 °C | 2550 - 2590 °F | |

| Solidus | 1400 °C | 2550 °F | |

| Liquidus | 1420 °C | 2590 °F |

Widely recognized for its corrosion resistance and durability, 316 stainless steel welded pipe is utilized in a variety of applications across industries such as pharmaceuticals, food processing, and marine engineering. Its unique composition, which includes molybdenum, enhances its resistance to pitting and crevice corrosion, making it ideal for challenging environments.

Key applications of 316 stainless steel tube include:

Pharmaceutical Equipment: It is extensively used in the manufacturing of equipment due to its ability to withstand sterilization processes and maintain hygiene standards.

Food Processing: The tube is essential for food and beverage stainless steel tube application where sanitation is critical, fulfilling stringent regulatory requirements.

Marine Applications: Its resistance to saltwater corrosion makes it suitable for components in marine environments, including boat fittings and offshore structures.

Chemical Storage: The tube is ideal for storing and transporting chemicals, particularly in high temperature environments where other materials may fail.

The specifications for lengths of stainless steel tubing are critical for ensuring compatibility with various applications and adherence to industry standards. Proper understanding of stainless steel tube lengths is essential for engineers, fabricators, and end-users to achieve desired performance and structural integrity.

Key considerations for tube length specifications include:

Standard Tube Lengths: Typically available in lengths of 20 or 24 feet, these are designed for common applications and facilitate easier inventory management.

Custom Tube Lengths: Tailoring tube lengths to specific project requirements can optimize material usage and reduce waste, ensuring precise fitment in varied applications.

Length Measurement Techniques: Accurate measurement techniques are crucial for maintaining consistency and quality in manufacturing; methods such as laser measuring and caliper usage are often employed.

Application-Specific Requirements: Different industries may have unique requirements that dictate specific tube lengths, emphasizing the need for flexibility in production capabilities.

Cut end finish of stainless steel tubing is a critical aspect that influences both the aesthetic appearance and functional performance of the final product, requiring adherence to specific industry standards and application requirements.

The choice of cutting techniques plays a significant role in determining the quality of the cut end, with methods such as saw cutting, laser cutting, and plasma cutting having distinct implications for the finish types achievable.

Edge treatment is equally important, as it affects not only the visual appeal but also the safety and integrity of the tubing in various applications. Polishing methods can enhance tube aesthetics, creating a smooth and reflective surface that is desirable in many end-use environments. Techniques such as mechanical polishing, electro-polishing, and passivation are employed based on the specific requirements of the tubing application.

Roundness is a critical geometric 316 stainless steel tube properties, directly impacting its structural integrity, fluid flow characteristics, and overall performance in various applications.

Precise roundness measurement is essential to guarantee that the tubing meets the stringent demands of its intended use. The roundness tolerance defines the acceptable limits of deviation from a perfect circle, serving as a benchmark for quality assurance.

The significance of roundness in stainless steel tubing can be summarized in the following points:

Fluid Dynamics: Proper roundness minimizes turbulence, enhancing flow efficiency in piping systems

Structural Integrity: Deviations in roundness can lead to stress concentrations, increasing the risk of failure under load.

Manufacturing Consistency: Rigorous roundness testing guarantees that products meet industry specifications, promoting uniformity in production.

Application Compatibility: Roundness analysis informs engineers about how well the tubing will fit into existing systems, guaranteeing seamless integration.

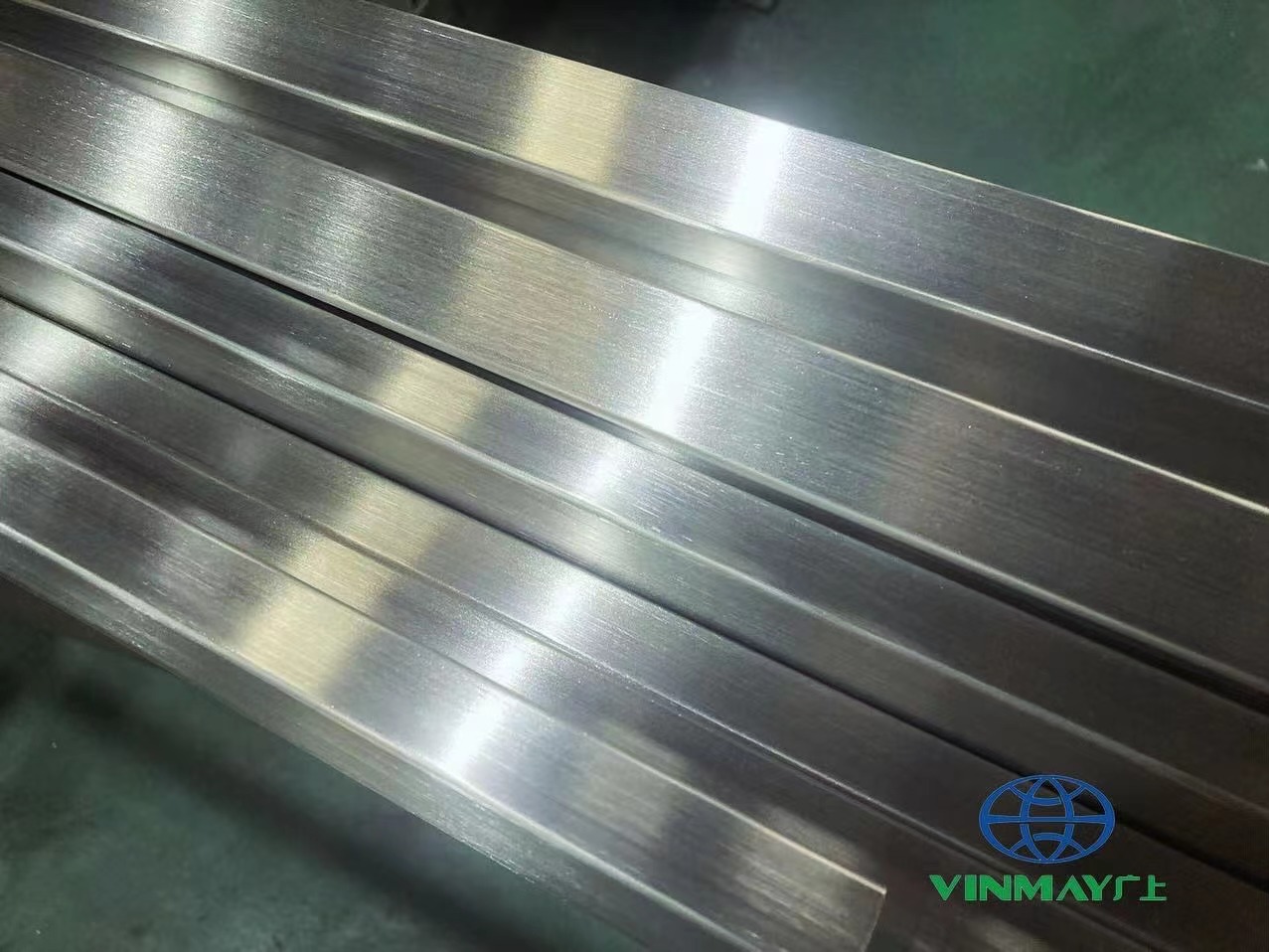

stainless s steel tube surface finish plays an essential role in the performance and longevity of stainless steel tubing, influencing factors such as corrosion resistance, aesthetic appeal, and the ability to maintain a clean internal environment for fluid transport.

Learn More:

Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

The typical outer diameter (OD) surface of a 316 stainless steel tube is generally smooth and has a high-quality finish. For 316 stainless steel tubes, common surface finishes include:

The inner diameter (ID) surface finish of 316 stainless steel tubes is crucial for applications requiring smooth and clean interiors, such as in the food, pharmaceutical, and chemical industries. Here are common finishes for the ID surface of these tubes:

The choice of finish depends on the specific requirements of the application, including the need for cleanliness, corrosion resistance, and overall surface smoothness.

ASTM A269 is suitable for general corrosion resistance and low/high-temperature service, making it versatile for various industries, including food processing, chemical, and pharmaceutical industries.

ASTM A213/ASME SA213 is primarily used in high-temperature environments, such as power plants, refineries, and other industries where boiler and superheater tubes are required.

Foshan Vinmay Stainless Steel Co.,ltd is a large -scale international enterprise which concentrates on manufacturing and selling of stainless steel welded tubes and the related fittings.

Our products are strictly produced according to a various of international standards including stainless steel welded tubes for ornamental and mechanical structure purpose (ASTM A554) ; stainless steel welded tubes for purposes heat treatment( ASTM A249); stainless steel sanitary welded tubes ( ASTM A270) and light gauge stainless steel water tube ( EN10312)

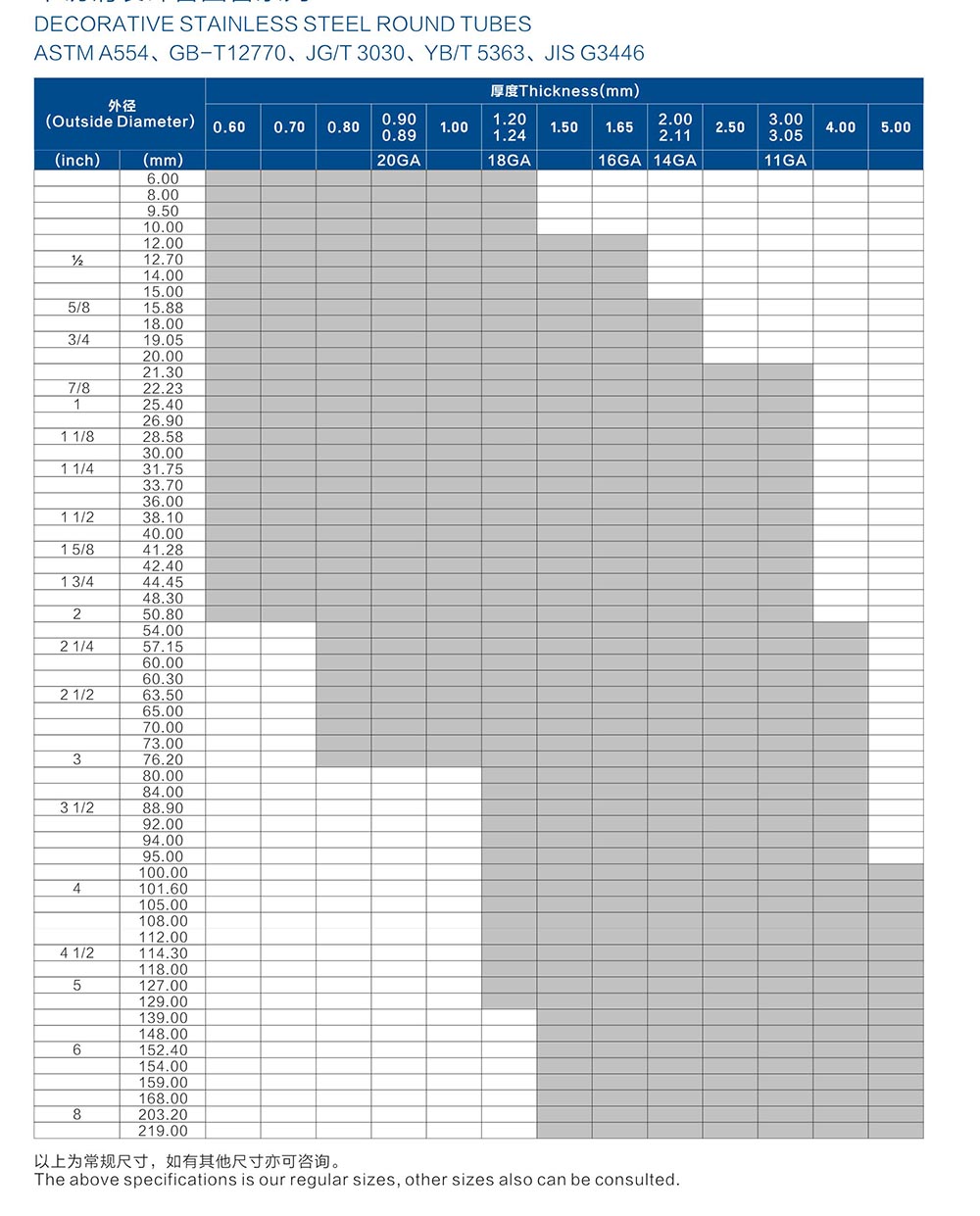

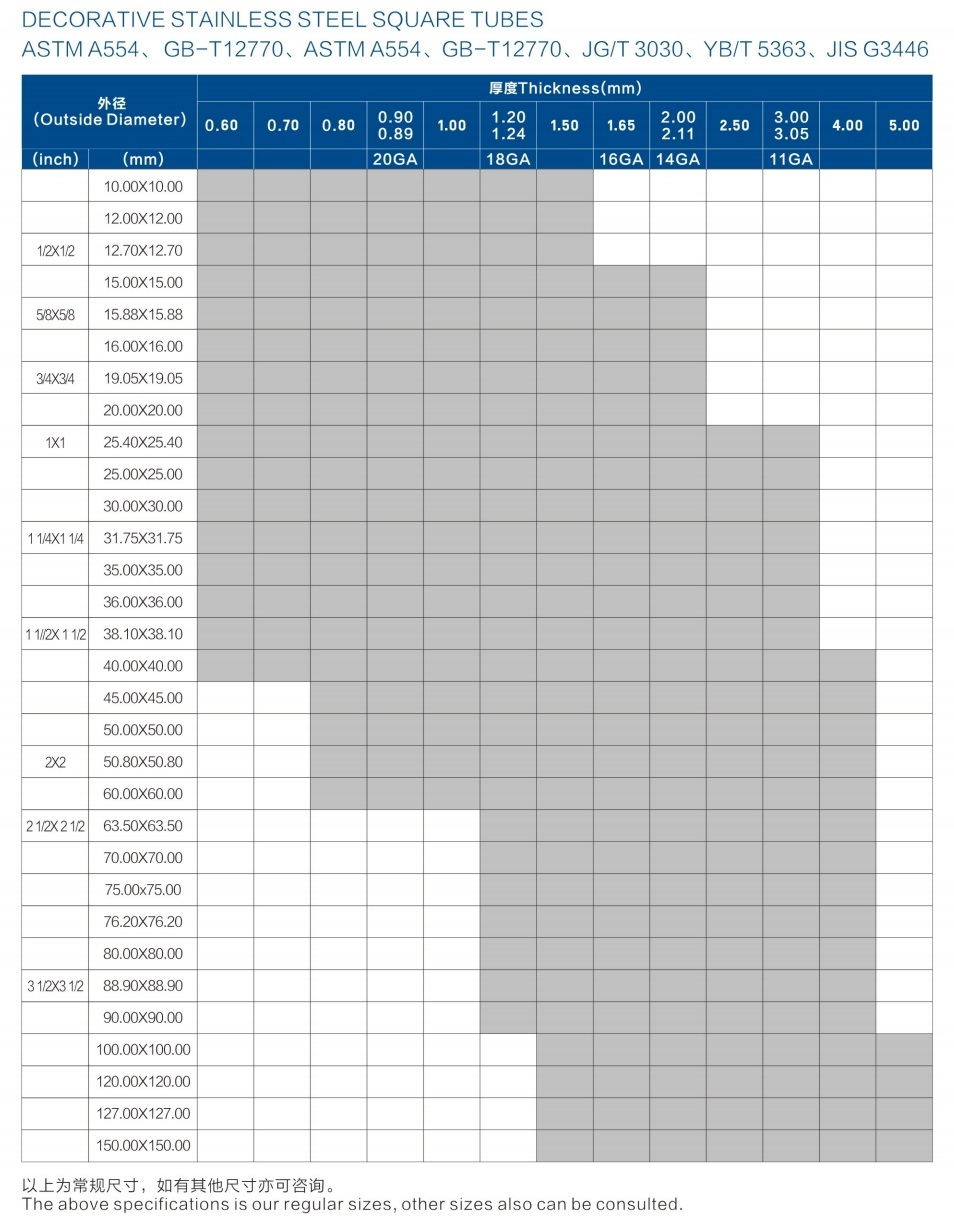

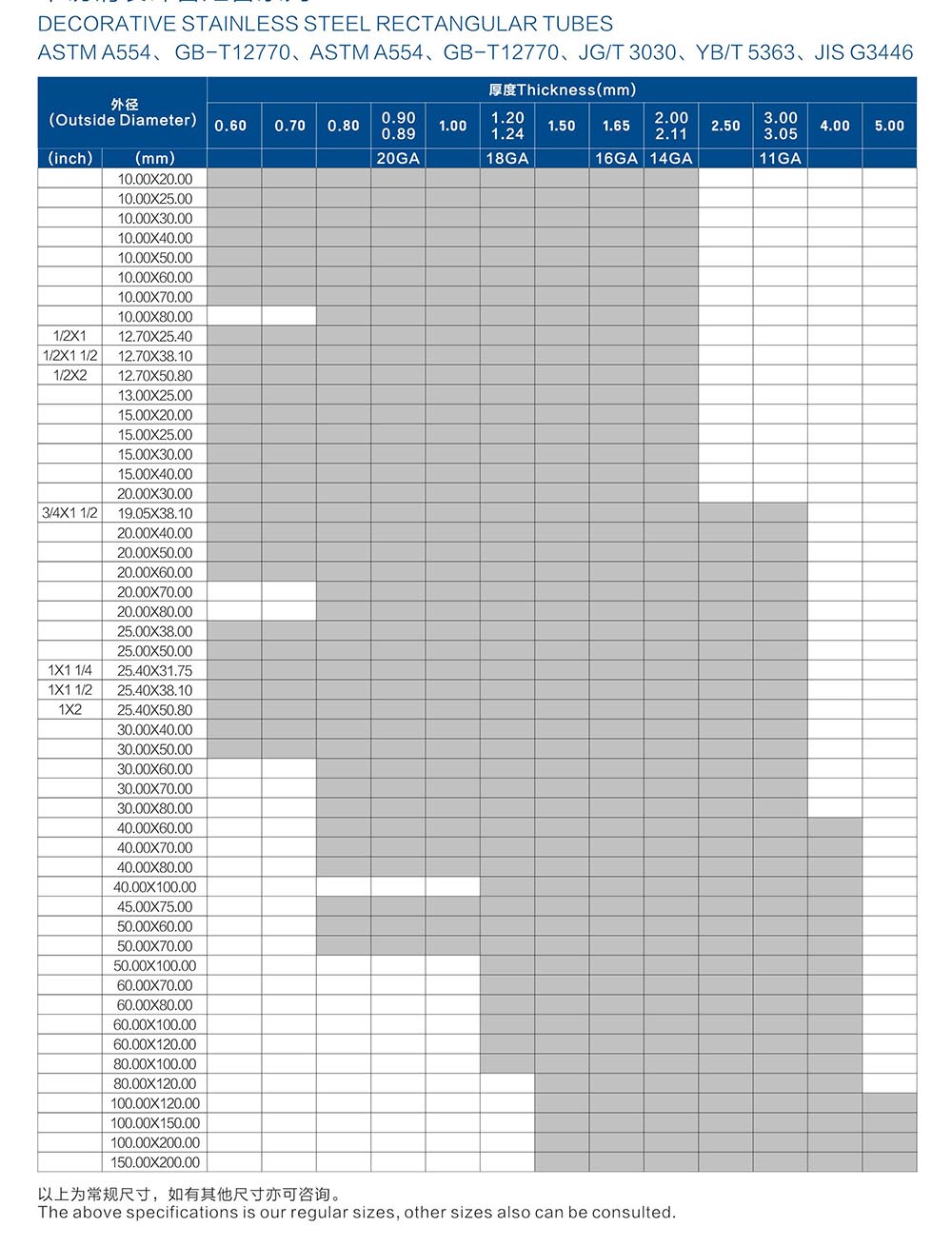

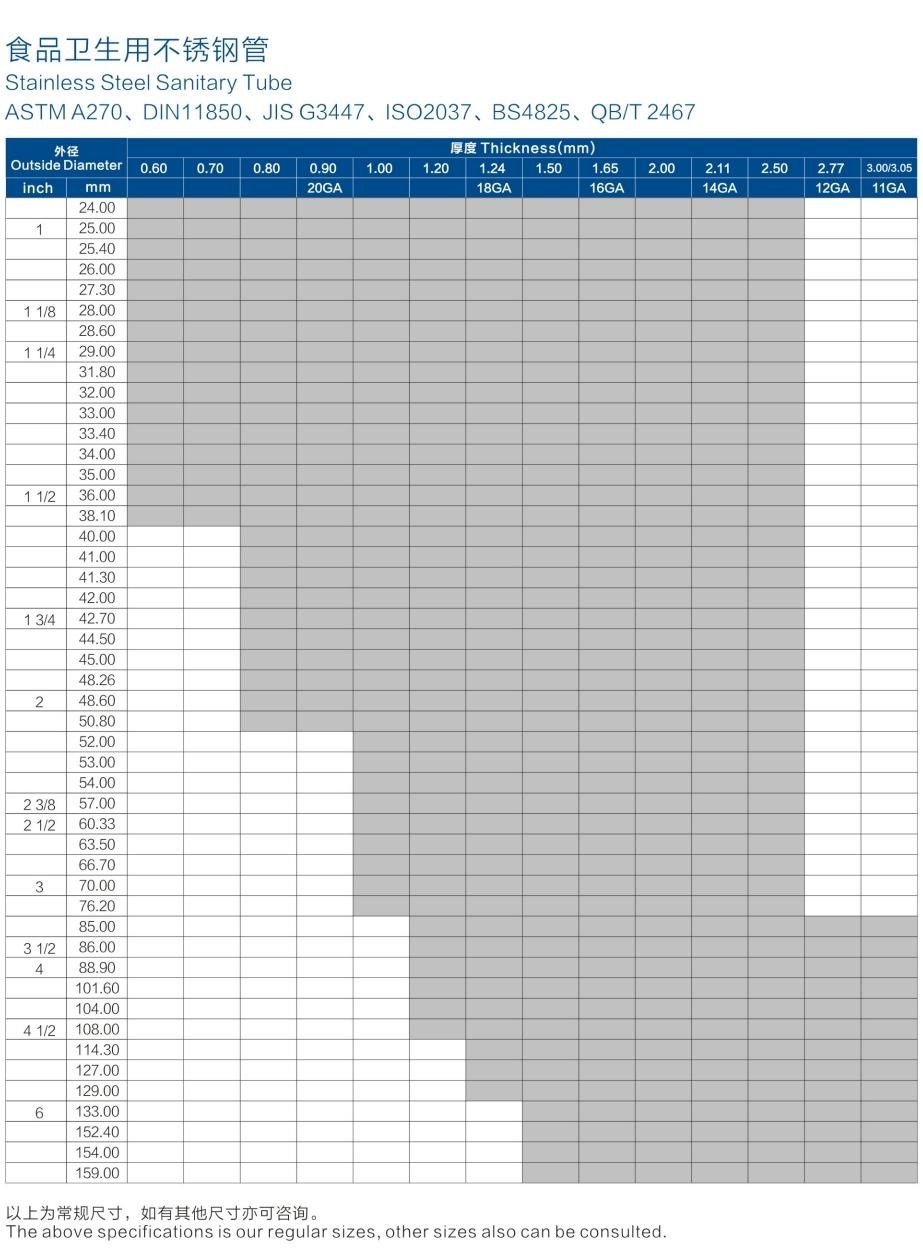

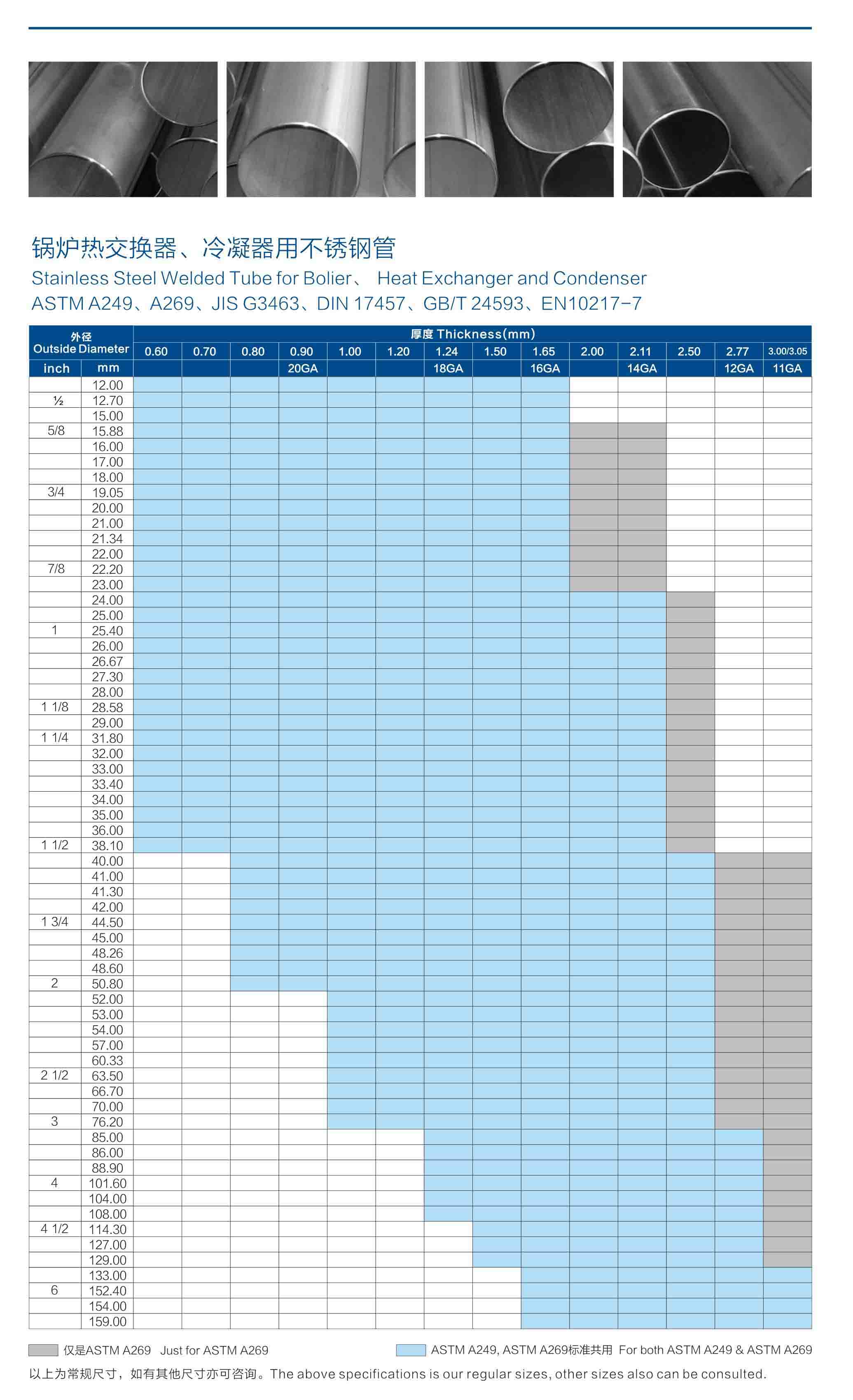

The following form are the available dimensions of 316 stainless steel tube

316 Stainless Steel Round Tube Size

316 Stainless Steel Square Tube Size

316 Stainless Steel Rectangular Tube

Read More: The Comprehensive Guide to Grade 316 Stainless Steel Structural Tube

The following factors are essential in determining the suitability of these tubes for specialized applications:

Outer Diameter (OD) Tolerances: Typically within ±0.010 inches, critical for fitting and assembly.Wall Thickness: Often maintained within ±10%, impacting strength and pressure ratings.

Length Variations: Standard lengths may have tolerances of ±1/8 inch, important for precise installations.

Straightness: Specified tolerances guarantee proper alignment in piping systems.

316L stainless steel, characterized by its low carbon content and enhanced corrosion resistance, serves as a versatile material in various industrial applications. This alloy is particularly favored for its ability to maintain strength and integrity in challenging environments, making it an essential choice in sectors such as aerospace, chemical processing, and food production.

The following points highlight the significance of L stainless steel within its category:

Stainless Steel Applications: Commonly utilized in applications requiring high corrosion resistance, such as piping systems and pressure vessels.

Stainless Steel Grades: Typically classified under grades like 304L and 316L, offering improvements in forming and welding capabilities.

Stainless Steel Advantages: Notable for its resistance to pitting and crevice corrosion, ensuring longevity and reliability.

Stainless Steel Maintenance: Requires minimal maintenance due to its inherent resistance to rust and staining, reducing lifecycle costs.

When making stainless steel comparisons, L stainless steel stands out due to its unique properties, making it a viable choice for industries where performance and durability are paramount.

Understanding these elements fosters a deeper appreciation for this essential material in modern engineering and manufacturing.

How do Ti and 316H stainless steels compare regarding high-temperature strength and corrosion resistance, particularly in demanding industrial environments?

Titanium, known for its remarkable strength-to-weight ratio and corrosion resistance, offers significant benefits in applications where weight reduction is critical. Conversely, 316H stainless steel, a high-carbon variant of the 316 grade, is engineered to withstand elevated temperatures, making it suitable for a variety of applications in chemical processing and oil and gas sectors.

When conducting an alloy comparison, 316H demonstrates superior performance in resisting pitting and crevice corrosion, particularly in chloride environments.

However, titanium excels in higher temperature effects, maintaining structural integrity where other stainless steel grades may fail. While both materials exhibit excellent resistance to oxidation, titanium's lightweight nature provides an edge in applications where weight is a concern.

The alloy designations of 316, 316L, 316Ti, and 316H stainless steel indicate variations in chemical composition and properties, tailored to meet specific industrial requirements and environmental conditions. Each grade exhibits unique alloy characteristics that influence performance metrics, mechanical behavior, and suitability for various applications.

| Uronorm | UNS | BS | En | Grade |

| 1.4401 | S31600 | 316S31 | 58H | 316 |

| 1.4404 | S31603 | 316S11 | - | 316L |

| - | S31609 | 316S51 | - | 316H |

| 1.4571 | - | 320S31 | - | 316Ti |

The primary distinctions between stainless steel 304 and 316 lie in their chemical composition, which greatly impacts their corrosion resistance and strength.

Stainless steel 316, containing molybdenum, offers enhanced resistance to chlorides and other corrosive environments compared to 304, making it suitable for marine applications.

Additionally, while 316 stainless steel tube properties generally incurs a higher cost, its durability often justifies the investment in specific applications.

When comparing corrosion resistance, stainless steel 316 exhibits superior performance over 304 due to the inclusion of molybdenum, which enhances its ability to withstand pitting and crevice corrosion in chloride environments.

The electrochemical behavior of these alloys under varying environmental factors plays an essential role in their longevity and effectiveness in specific applications.

Key differences in corrosion resistance can be summarized as follows:

Pitting Corrosion Resistance: 316's molybdenum content greatly reduces susceptibility to localized corrosion, making it ideal for marine and chemical processing industries.

Stress Corrosion Cracking: The enhanced resistance of 316 to stress corrosion cracking in harsh environments guarantees structural integrity, particularly in high-stress applications.

Surface Treatments: While both alloys can benefit from surface treatments, 316's enhanced properties can lead to improved performance under similar treatment conditions.

Environmental Factors: 316 stainless steel is better suited for environments with higher chloride concentrations, allowing for broader application ranges in corrosive settings.

These characteristics underscore the significance of selecting the appropriate stainless steel grade based on specific operational demands and environmental conditions.

Strength characteristics of stainless steel 316 typically surpass those of 304, particularly in high-temperature and stress-intensive applications, due to its enhanced alloy composition. The tensile strength of 316 is particularly higher, allowing it to endure greater loads without permanent deformation. Specifically, 316 exhibits a tensile strength range of approximately 70-80 ksi (kilopounds per square inch), compared to 304, which ranges from 70-75 ksi.

Yield strength is another crucial parameter; 316 demonstrates superior yield strength, making it more resistant to yielding under stress. This capability is essential in applications where structural integrity is paramount. Additionally, 316 stainless steel offers improved compressive strength, enabling it to withstand axial loads without failure.

Fatigue resistance is an important consideration for components subjected to cyclical loads, and 316 excels in this regard, reducing the risk of fatigue failure over time. Moreover, the impact toughness of 316 stainless steel is higher than that of 304, ensuring better performance in dynamic conditions where sudden forces may be encountered.

These properties collectively position stainless steel 316 as a preferred choice for demanding environments, fostering a sense of reliability and security among its users.

Evaluating the cost differences between stainless steel 304 and 316 reveals significant variance influenced by their respective alloy compositions and applications. Conducting a thorough cost analysis is essential for industries that prioritize both quality and budget management.

The pricing factors for these stainless steel grades are shaped by multiple elements, including:

Material Composition: Stainless steel 316 contains molybdenum, enhancing corrosion resistance, which contributes to higher manufacturing expenses.

Market Trends: Demand fluctuations and supply chain dynamics impact overall pricing, with 316 typically commanding a premium due to its superior properties.

Production Methods: The complexity of manufacturing processes for 316 often results in increased costs, reflecting its specialized applications.

Economic Impact: The long-term value of investing in 316 often outweighs initial costs, particularly in harsh environments, leading to reflections beyond immediate expenses.

The differences in properties between stainless steel 304 and 316 greatly influence their respective applications, particularly in environments requiring enhanced corrosion resistance and durability. Stainless steel 316, with its higher molybdenum content, exhibits superior resistance to chlorides and aggressive chemicals, making it the preferred choice in demanding environments.

| Application Type | Stainless Steel 304 | Stainless Steel 316 |

|---|---|---|

| Industrial Applications | Suitable for general use, less corrosion resistance | Ideal for marine and chemical industries |

| Medical Devices | Commonly used, but may corrode in some environments | Preferred for surgical instruments due to high corrosion resistance |

| Food Processing | Widely used for food handling and storage | Better suited for harsher cleaning agents and environments |

| Architectural Elements | Aesthetic appeal, moderate corrosion resistance | Used in coastal environments for longevity |

| Automotive Components | Common in non-exposed parts | Often employed in exhaust systems due to heat and corrosion resistance |

These distinctions underscore the importance of selecting the appropriate stainless steel grade based on specific application requirements, ensuring reliability and longevity in various sectors.

You may also like:

What Is the Difference Between 201 and 304 Stainless Steel?

The corrosion resistance of 316 stainless steel is superior in marine applications due to its enhanced resistance to chemical exposure and reduced pitting susceptibility, often complemented by surface treatments to further improve performance in aggressive environments.

The typical lifespan of 316 stainless steel in harsh environments, such as marine applications, can exceed 20 years, contingent upon factors like chemical exposure, wear resistance, temperature fluctuations, and diligent maintenance practices to mitigate corrosion.

Effective cleaning methods for 316 stainless steel tubes involve selecting appropriate cleaning solutions that guarantee chemical compatibility. Proper surface preparation and regular maintenance tips enhance performance in industrial applications, prolonging lifespan and maintaining structural integrity.

No, 316 stainless steel is typically considered non-magnetic. Among non-magnetic steels, it is often described as the "most non-magnetic" due to its high nickel content. The austenitic phase of 316 stainless steel is inherently non-magnetic, but magnetism can be introduced through extensive welding or machining processes. Cold working may cause the austenite to transform into ferrite or martensite, both of which exhibit slight magnetic properties. The steel’s carbon content influences its potential for martensitic transformation, impacting its magnetic properties. Overall, 316 stainless steel is recognized for its non-magnetic characteristics, although some magnetic changes may occur under certain conditions.

Yes, 316 stainless steel is classified as food-grade. It is commonly used in food processing and handling equipment, such as cookware, utensils, and food storage containers. Its high corrosion resistance makes it suitable for contact with food, as it resists the acids and chemicals commonly found in food and beverages.

To summarize, 316 stainless steel tube properties, including high tensile and yield strengths, along with superior corrosion resistance, ductility, fatigue resistance, and impact toughness.

These characteristics make them suitable for a wide range of demanding industrial applications, particularly in environments prone to pitting and stress.

The material's versatility is further enhanced by various alloy designations, enabling tailored solutions for specific operational requirements.

Overall, 316 stainless steel remains a critical choice for reliable and durable structural components.