316 stainless steel square tubes are widely used in various industries due to their excellent corrosion resistance, strength, and durability. This high-performance stainless steel tube grade is commonly found in applications such as marine environments, chemical processing plants and structural components. In this article, we will explore the properties, standards, sizes, surface finishes, and leading suppliers of 316 stainless steel square tubes.

316 stainless steel is primarily composed of iron, chromium, nickel, and molybdenum. The addition of molybdenum significantly enhances its resistance to corrosion, particularly in chloride-rich environments. Below is a table showcasing its chemical composition:

| Element | Composition (%) |

|---|---|

| Iron (Fe) | Balance |

| Chromium (Cr) | 16.0-18.0 |

| Nickel (Ni) | 10.0-14.0 |

| Molybdenum (Mo) | 2.0-3.0 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Carbon (C) | ≤ 0.08 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.03 |

The mechanical properties of 316 stainless steel square tubes make them suitable for high-stress applications. These properties include:

| Property | Value |

| Yield Strength | 205 MPa (30,000 psi) |

| Tensile Strength | 515 MPa (75,000 psi) |

| Elongation | 40% min |

| Hardness (Rockwell B) | 95 max |

| Density | 7.98 g/cm³ |

When comparing stainless steel 304 and 316, the primary difference lies in the addition of molybdenum in 316 stainless steel, which enhances its corrosion resistance, especially against chlorides and acids. While both grades are durable and strong, 316 is preferred in environments where exposure to harsh chemicals or saltwater is common.

316L stainless steel is a low-carbon variation of 316 stainless steel. The lower carbon content reduces the risk of carbide precipitation during welding, making it an excellent choice for applications requiring extensive welding without sacrificing corrosion resistance.

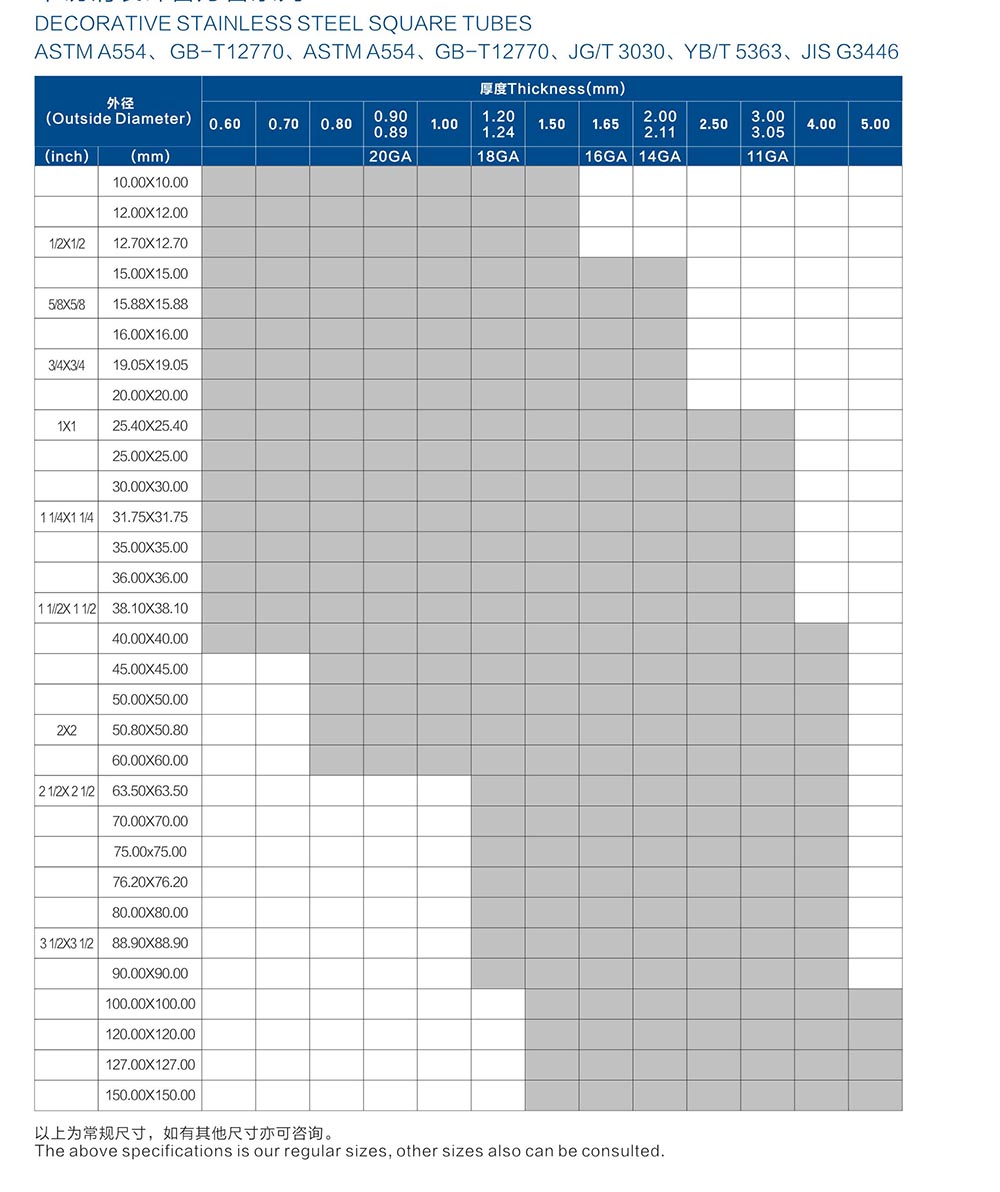

316 Stainless Steel Square Tube Size

Here’s a list of common sizes for 316 stainless steel square tubes. These sizes are typically available in various wall thicknesses, with dimensions and tolerance depending on the manufacturer.

Different surface finishes are available for 316 stainless steel square tubes, depending on their intended application. Here are some common finishes:

Finding a reliable supplier is crucial for obtaining high-quality 316 stainless steel square tubes. Below are the top 10 suppliers worldwide:

316 stainless steel square tubes are a preferred choice for applications requiring superior corrosion resistance, strength, and durability. Whether used in marine environments, food processing, or industrial applications, these tubes provide long-lasting performance. Understanding their properties, standards, sizes, surface finishes, and suppliers can help businesses and individuals make informed purchasing decisions. If you are looking for high-quality 316 stainless steel square tubes, be sure to source from a reputable supplier like Vinmay Stainless Steel, which offers premium-grade products tailored to industry needs.