Stainless steel welded square pipe embodies a versatile and robust metal conduit commonly utilized in various industrial applications. This type of pipe is constructed from alloyed iron, nickel, and chromium, making it a corrosion-resistant material with superior strength and durability.

The square shape of the pipe provides extra structural stability, making it suitable for applications requiring rigidity. Stainless steel square pipes are known for their high heat and corrosion resistance, superior formability, and fabrication properties. They also exhibit good weld-ability characteristics and ductility, allowing for bending without damage.

Due to these properties, stainless steel welded square pipes find wide applications in ornamental and structural projects, outdoor elements like fencing and railings, automotive parts, and the kitchenware industry.

They are commonly used to create countertops, shelves, and architectural components. The benefits of using stainless steel square pipes include high strength and durability for heavy-duty applications, resistance to corrosion and high temperatures, ease of welding and shaping, low maintenance requirements, and long-lasting performance without needing frequent repairs.

With their high heat and corrosion resistance, stainless steel square pipes demonstrate exceptional durability and versatility in various industrial applications. These pipes possess a unique set of properties that make them highly desirable for a wide range of uses. Below is a table outlining the key properties of stainless steel square pipes:

| Property | Description |

|---|---|

| High Heat Resistance | Able to withstand high temperatures without deforming |

| Corrosion Resistance | Resistant to rust and corrosion even in harsh environments |

| Formability | Easy to shape and mold into desired configurations |

| Weld-ability | Exhibits good welding characteristics for joining sections |

| Ductility | Can be bent without breaking or losing structural integrity |

Stainless steel welded square pipes are known for their longevity when properly maintained, making them a cost-effective choice for many applications. Their ability to resist heat, corrosion, and deformation, coupled with their ease of fabrication, makes them an ideal material for projects requiring strength and durability.

Commonly utilized in a variety of industries, stainless steel square tubes find widespread application in diverse structural and decorative projects. These versatile components offer a range of benefits that make them a popular choice for various applications.

Some common applications of stainless steel square welded pipe include:

Structural Projects: Stainless steel square tubes are commonly used in the construction industry for structural purposes due to their superior strength and durability.

Decorative Elements: These tubes are also popular in decorative projects, such as architectural components and ornamental designs, where their sleek appearance adds a modern touch.

Industrial Equipment: In industrial settings, stainless steel square tubes are found in machinery, automotive parts, and kitchenware due to their resistance to corrosion and high temperatures.

Recommended:

Mastering Fabrications Techniques for Stainless Steel Square Tubings

316 stainless steel requires minimal maintenance but should be cleaned regularly to maintain its appearance and prevent any potential corrosion. Routine cleaning with soap and water or a mild detergent is typically sufficient.

In summary, 316 stainless steel is an excellent choice for applications requiring enhanced corrosion resistance, particularly in chloride-rich environments or where contact with harsh chemicals is common. Its superior durability and resistance make it a preferred material in many critical and demanding industries.

An important aspect to take into account when discussing stainless steel square tubes is the finish they possess after the manufacturing process, known as the 'Mill Finish.' This finish is the untreated and unfinished surface that results from the initial production stages, leaving the metal with a dull appearance.

Key points to note about the Mill Finish include:

The Mill Finish is a practical choice for projects where the focus is on functionality rather than a polished appearance.

A popular finishing option for stainless steel square tubes is the Satin Finish, known for its smooth and elegant surface texture. This finish is achieved by brushing the stainless steel with abrasive materials, creating a soft, matte appearance that reduces glare and fingerprints.

The Satin Finish provides a sophisticated look while maintaining the natural luster of stainless steel. It is often chosen for applications where a more subdued aesthetic is desired, such as architectural elements, furniture, and kitchen fixtures. This finish also offers some level of scratch resistance, making it suitable for high-traffic areas.

The Satin Finish adds a touch of modern elegance to stainless steel square tube products, enhancing their visual appeal and versatility.

The Satin Finish, a popular choice for stainless steel square tubes, offers a smooth and elegant surface texture.

Turning our attention to the Mirror Finish, another exquisite option known for its reflective and shiny appearance.

The Mirror Finish provides a brilliant and polished look that enhances the aesthetics of the stainless steel square tube.

This finish is achieved through a series of polishing processes that create a mirror-like surface, perfect for applications where visual appeal is essential.

The reflective nature of the Mirror Finish can also help in creating a sense of space and light in various structural and decorative projects.

You may also like:

Comprehensive Guide to Stainless Steel Tube Surface Finishes

Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

Foshan Vinmay Stainless Steel Company provide high qulity ornamental stainless steel welded square pipes with ASTM A554 standard. Please contact Vinmay if you have interesting in our products. Free sample can be provided today!

| Material | 201/ 304 /304L/316L/430 | |||

| Certificate | ISO / AEO/ MTC/PED | |||

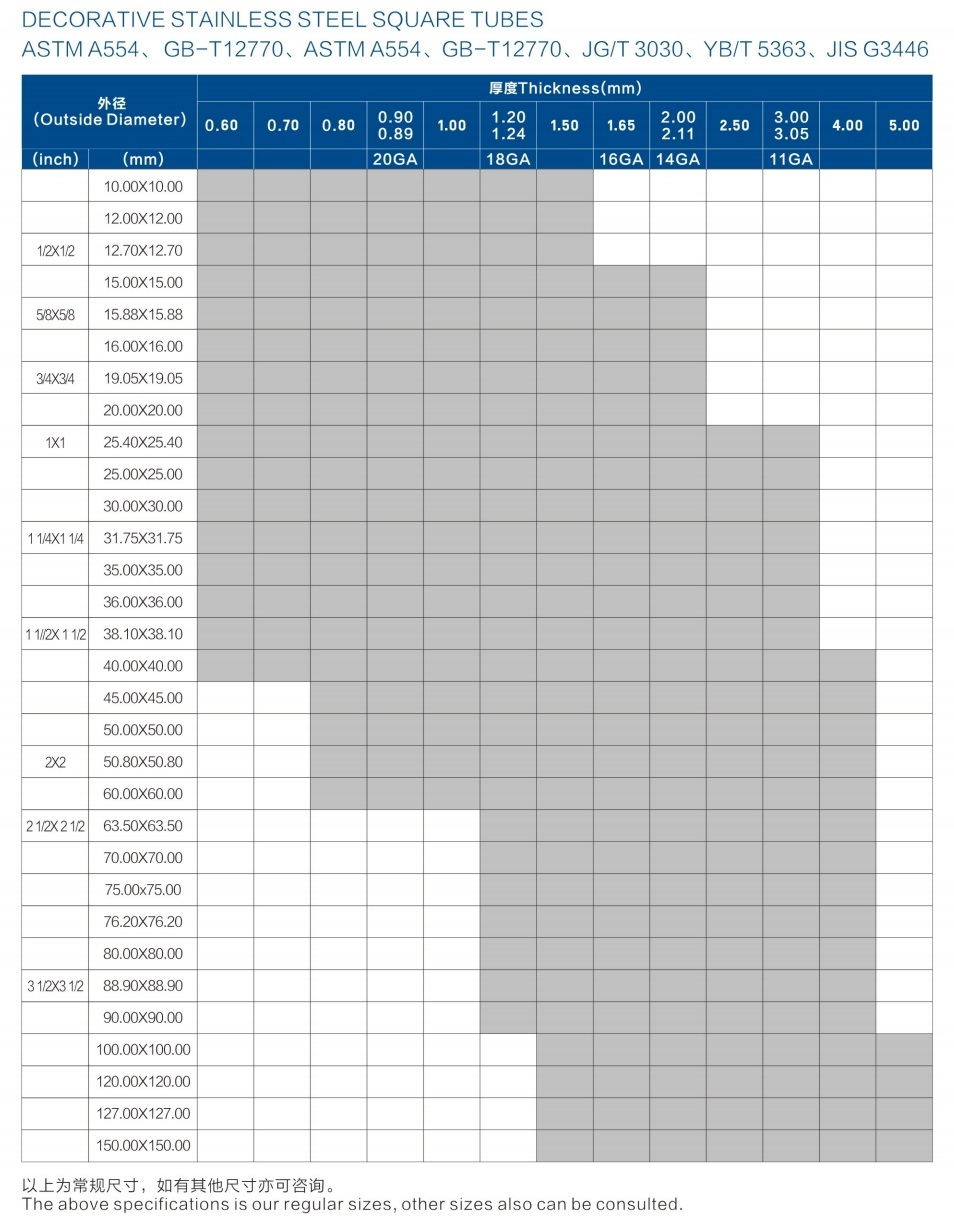

| Size | 10x10mm-150x150mm | |||

| Surface | Mill Finish, Mirror Finish, Satin Finish (MF,180G,320G,400G,600G) | |||

| Thickness | 0.6mm-5.0mm | |||

| Length | 5.8 M,6M,20 Feet or Customized | |||

| Processing | Welding, bright annealing, inside bead removing, pickling | |||

| Delivery Time | 30 days for a container quantity | |||

| Payment Terms | T/T, LC, Cash, etc. Normally 30% by T/T in advance, balance to be paid before shipment. | |||

| Packing | Each tube will be packed in a plastic bag, then several tubes will be packed in hollow plates or weaving bags. | |||

| Application | Apply in handrails, furniture, sanitary ware, display shelf, sanitary ware, machinery equipment | |||

Stainless steel square tubing is typically measured in the following ways:

Outside Dimensions (OD): The outside dimensions refer to the width of the tubing on each side. For square tubing, this is usually given as a single measurement, representing the width of one side of the square.

Wall Thickness (WT): This is the thickness of the tube's walls. It is an important measurement because it affects the tubing's strength and weight. Wall thickness is often measured in millimeters or inches.

Length: The overall length of the tubing is measured from one end to the other. This can be specified in feet, meters, inches, or centimeters, depending on the application and regional measurement standards.

For instance, a stainless steel square tube may be specified as 2" x 2" x 0.125" x 12':

Stainless steel square tubing measurements adhere to certain standards, such as ASTM (American Society for Testing and Materials) specifications. These standards ensure consistency and reliability in the measurements and quality of the tubing.

By considering these measurements, you can accurately specify and source the correct stainless steel square tubing for your need.

When distinguishing between pipe and tube in industrial applications, understanding their unique characteristics is essential for precise selection and best performance. Pipes and tubes may seem similar, but they serve different purposes based on their design and function.

Here are key differences to take into account:

Shape: Pipes are typically round with uniform wall thickness, designed for the transfer of fluids or gases under pressure. Tubes, on the other hand, can be round, square, or rectangular and are often used for structural applications due to their shape variations.

Manufacturing Process: Pipes are manufactured to specific industry standards such as ASTM or DIN and are produced to withstand high pressure. Tubes are generally produced to more precise dimensions and tolerances, often with tighter wall thickness control.

End Use: Pipes are commonly used for conveying fluids or gases, while tubes are frequently utilized in structural applications like construction, architecture, and machinery where strength and durability are essential.

Learn More :

Differences Between Stainless Steel Pipe and Tube

The Top-Rated Stainless Steel Square Tube Manufacturers

Understanding Stainless Steel Square Tubing Dimensions

The Ultimate Guide to Calculating Stainless Steel Square Tube Weight

To sum up, stainless steel welded square pipes offer exceptional strength, corrosion resistance, and durability for various applications. With different alloys and finishes available, they can be customized to meet specific project requirements.

The question remains: How can the versatility and reliability of stainless steel square pipes benefit your next structural or industrial project?