When you're considering stainless steel tube materials for challenging environments, grade 316 stainless steel structural tube should be on your radar. Its corrosion resistance and strength make it a go-to choice for marine and chemical applications, and it meets ASTM A554 standards for quality. You might find its mechanical properties, like a yield strength of 30,000 psi, particularly noteworthy. Yet, there's more to this material that could influence your decision-making process. What specific applications might benefit from its unique characteristics?

Grade 316 stainless steel structural tubes are commonly produced to meet several international stainless steel tube standards. Here are some of the key standards for grade 316 stainless steel structural tubes:

These standards ensure that grade 316 stainless steel tubes meet the required mechanical properties, dimensions, stainless steel tube surface finish , and corrosion resistance for structural applications.

When considering grade 316 stainless steel structural tube, it's essential to focus on its mechanical properties, physical properties at room temperature, and chemical composition by weight.

These factors significantly influence its performance in various applications.

Understanding these technical details will help you make informed decisions regarding its use in your projects.

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | 515 MPa (74,800 psi) |

| Yield Strength (0.2% offset) | 205 MPa (29,700 psi) |

| Elongation at Break | 40% in 50 mm (2 in.) |

| Hardness (Rockwell B Scale) | Max 95 |

| Modulus of Elasticity | 193 GPa (28 x 10⁶ psi) |

| Poisson’s Ratio | 0.27-0.30 |

| Shear Modulus | 77 GPa (11.2 x 10⁶ psi) |

| Melting Point | 1371–1399°C (2500–2550°F) |

Understanding the physical properties of grade 316 stainless steel structural tube at room temperature is vital for evaluating its performance in various applications. These properties directly influence strength, durability, and suitability for specific environments. Here are key physical properties you should consider:

These physical properties highlight why 316 stainless steel is often chosen for applications requiring corrosion resistance and strength, such as in marine environments or chemical processing.

| Element | Percentage (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 16.00 - 18.00 |

| Nickel (Ni) | 10.00 - 14.00 |

| Molybdenum (Mo) | 2.00 - 3.00 |

| Nitrogen (N) | ≤ 0.10 |

| Iron (Fe) | Balance |

When choosing a grade 316 stainless steel structural tube, you'll encounter various shapes, including round, rectangular, and square options.

Each configuration offers unique benefits tailored to specific applications and structural requirements.

Understanding these distinctions can help you select the most suitable tube for your project needs.

A 316 stainless steel round tube is a popular choice for various industrial applications due to its excellent corrosion resistance, strength, and durability. It is made from 316-grade stainless steel, which is an austenitic steel that contains a higher amount of nickel and molybdenum compared to 304 stainless steel. These elements provide enhanced resistance to chlorides, acids, and saltwater, making 316 stainless steel ideal for harsh environments.

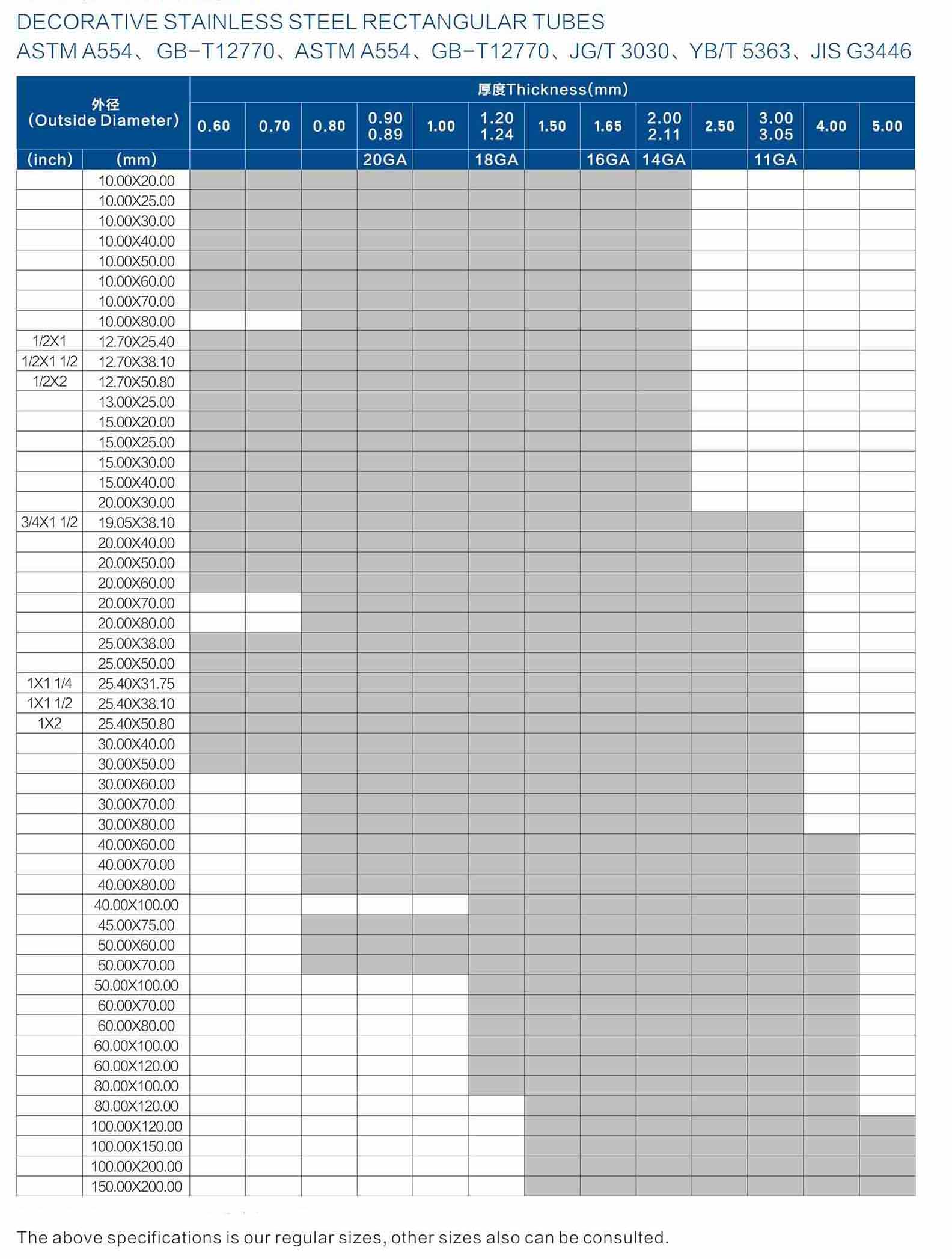

A 316 stainless steel rectangular tube is widely used in industries that require both structural strength and corrosion resistance. Like the round tube, the rectangular tube made from 316-grade stainless steel offers superior performance in challenging environments, thanks to its higher levels of molybdenum and nickel.

When selecting rectangular tubes, consider the dimensions and wall thickness according to your specific requirements. The standard finishes, such as mill finish or polished, enhance aesthetic appeal while maintaining durability. You can also easily weld and fabricate these tubes, which simplifies the construction process.

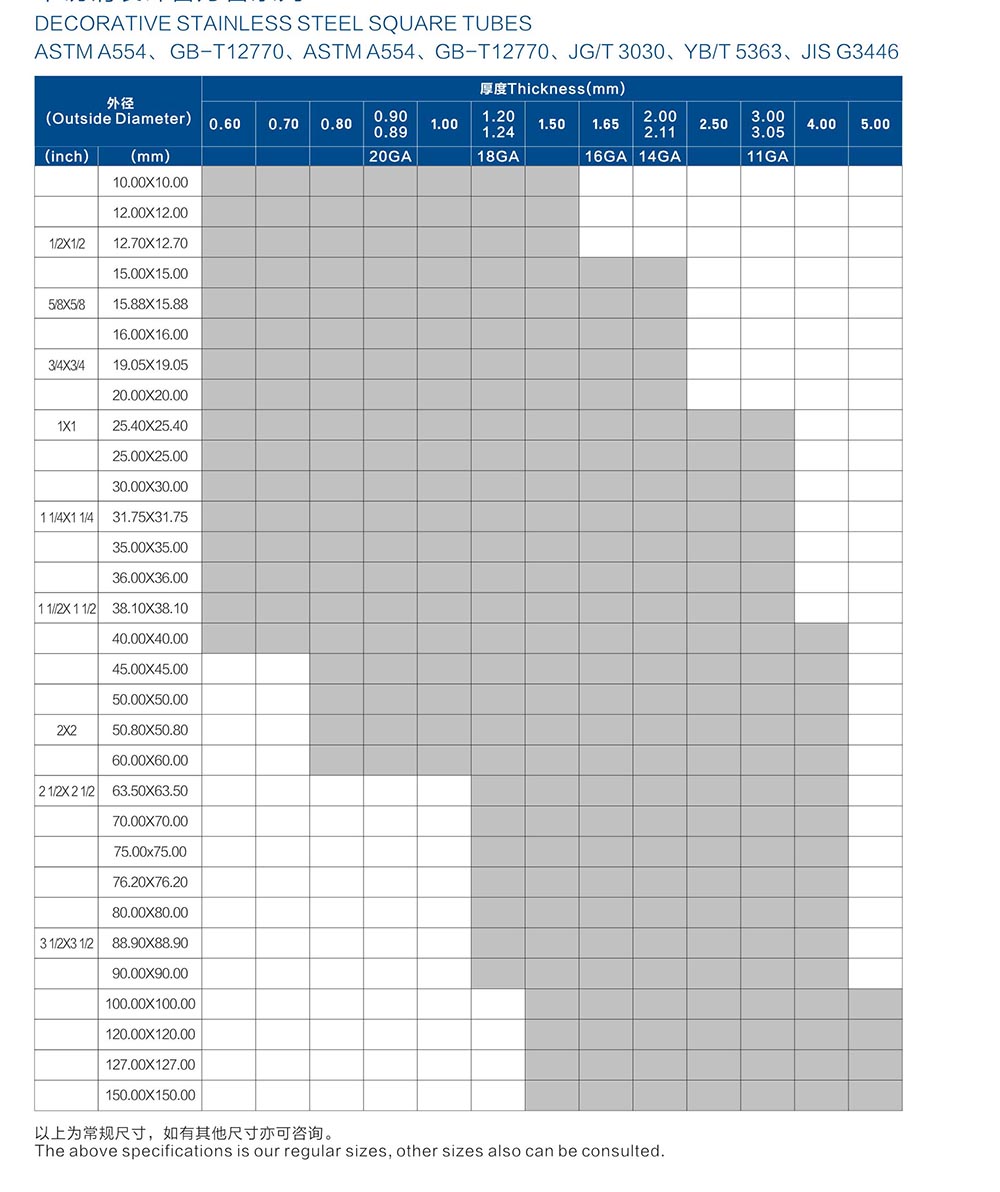

Stainless steel square tubes made from grade 316 deliver exceptional structural integrity and corrosion resistance, making them ideal for various demanding applications. Whether you're constructing marine structures or architectural frameworks, these tubes offer superior performance due to their unique properties.

Using grade 316 stainless steel square tubes can significantly enhance your project's lifespan and structural reliability. Their adaptability across various industries, including construction, marine, and chemical processing, makes them a preferred choice among engineers and architects.

You'll find that grade 316 stainless steel structural tubes are ideal for use in marine environments due to their excellent corrosion resistance. This property makes them particularly effective in applications where exposure to saltwater or high humidity is a concern.

You'll often see these tubes employed in shipbuilding, offshore oil rigs, and coastal infrastructure projects, where durability and longevity are critical.

Did you know that 316 stainless steel contains about 2-3% molybdenum? Compared to 304, it offers better corrosion resistance, particularly in chloride environments, making it ideal for marine applications and chemical processing.

Learn More : Stainless Steel Tube 304 Vs 316

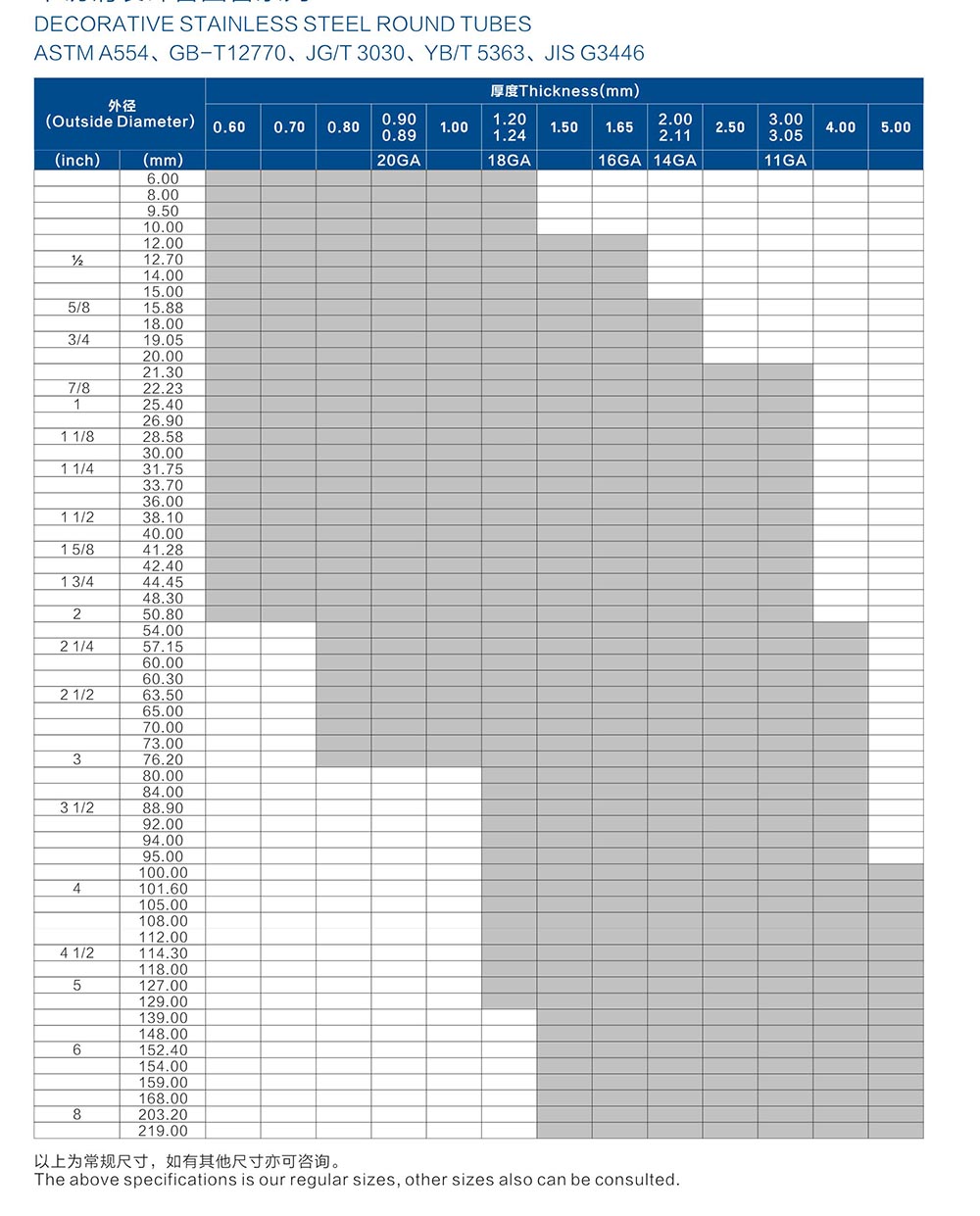

You'll find various sizes for structural tubes, typically ranging from small diameters like 1 inch to larger options up to 12 inches. Wall thicknesses usually vary between 0.065 inches and 0.250 inches, depending on the application.

You'd think saltwater's a fierce adversary, but grade 316 stainless steel stands strong! It's renowned for its exceptional resistance to saltwater corrosion, making it perfect for marine applications and environments where moisture reigns supreme.

Yes, you can weld grade 316 stainless steel easily, but you should use appropriate techniques and filler materials to maintain its corrosion resistance and mechanical properties. Proper preparation ensures optimal results and minimizes the risk of defects.

You may also like:

How to TIG Weld Stainless Steel Pipe ?

When you delve into the world of stainless steel, you'll find that grade 316 often commands a higher price due to its superior corrosion resistance. Comparatively, grades like 304 typically cost less, reflecting their differing properties.

In summary, grade 316 stainless steel structural tube stands as a robust guardian against corrosion, shining brightly in harsh environments.

Picture it gracefully supporting a sleek architectural masterpiece or enduring the relentless tides of a marine installation.

With its impressive yield and tensile strength, this tubing not only ensures safety and reliability but also enhances the aesthetic appeal of your projects.

Choosing grade 316 means investing in durability and performance, ultimately leading to lower maintenance costs and peace of mind.