When you consider the demands of industrial applications, ASTM A249 stainless steel tubes stand out for their exceptional properties. You might find that the specific grades, like 304 and 316, offer distinct advantages in terms of durability and corrosion resistance. Understanding the nuances of their size range and testing protocols can be crucial for ensuring reliability in your projects. But what exactly do these standards entail, and how do they compare to other specifications like ASTM A269? Exploring these aspects can reveal essential insights for your next undertaking.

| Grade | UNS Design | Composition, % | ||||||||||||||

| C | Mn | P | S | Si | Cr | Ni | Mb | Ti | Nb | N | Cu | Ce | B | Al | ||

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | . . . | . . . | . . . | . . . | . . . | ||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–13 | . . . | . . . | . . . | . . . | . . . | . . . | ||

| TP304H | S30409 | 0.04 – 0.1 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | . . . | . . . | . . . | . . . | . . . | . . . | ||

| TP310S | S31008 | 0.08 | 2 | 0.045 | 0.03 | 1 | 24.0- 26 | 19.0- 22 | 0.8 | . . . | . . . | . . . | . . . | . . . | ||

| TP310H | S31009 | 0.04 – 0.1 | 2 | 0.045 | 0.03 | 1 | 24.0–26 | 19.0–22 | . . . | . . . | . . . | . . . | . . . | |||

| TP310H | S31035 | 0.04 – 0.1 | 0.6 | 0.025 | 0.015 | 0.4 | 21.5–23.5 | 23.5–26.5 | . . . | . . . | 0.40- 0.6 | 0.20- 0.3 | 2.5- 3.5 | . . . | 0.002- 0.008 | |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | . . . | . . . | . . . | . . . | . . . | ||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | . . . | . . . | . . . | . . . | . . . | ||

| TP316H | S31609 | 0.04 – 0.1 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | . . . | . . . | . . . | . . . | . . . | ||

| TP317 | S31700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 11.0–15 | 3.0–4 | . . . | . . . | . . . | . . . | . . . | ||

| TP317L | S31703 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 11.0–15 | 3.0–4 | . . . | . . . | . . . | . . . | . . . | ||

| TP321 | S32100 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–12 | . . . | Ti 5 × (C+N) min, 0.70 max | . . . | 0.1 | . . . | . . . | ||

| TP321H | S32109 | 0.04 – 0.1 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–12 | . . . | 4(C+N) min; 0.70 max | . . . | 0.1 | . . . | . . . | ||

| TP321H | S32654 | 0.02 | 2.0-4 | 0.03 | 0.005 | 0.5 | 24.0–25 | 21.0–23 | 7.0-8 | . . . | . . . | 0.45- 0.55 | 0.30-0.6 | . . . | ||

| TP321H | S33228 | 0.04 – 0.08 | 1 | 0.02 | 0.015 | 0.3 | 26.0–28 | 31.0–33 | . . . | . . . | 0.60- 1 | . . . | . . . | 0.05 – 0.1 | 0.025 | |

| TP321H | S34565 | 0.03 | 5.0-7 | 0.03 | 0.01 | 1 | 23.0–25 | 16.0–18 | 4.0-5 | . . . | 0.1 | 0.40- 0.6 | . . . | . . . | ||

| TP347 | S34700 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . | See Spec | . . . | . . . | . . . | ||

| TP347H | S34709 | 0.04 – 0.1 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–13 | . . . | . . . | See Spec | . . . | . . . | . . . | ||

| TP348 | S34800 | 0.08 | 2 | 0.045 | 0.030 | 1 | 17.0–19 | 9.0–13 | . . . | . . . | . . . | . . . | . . . | . . . | Co 0.20, Ta 0.10 | |

| TP348H | S34809 | 0.04-0.10 | 2 | 0.045 | 0.030 | 1 | 17.0–19.0 | 9.0–13 | . . . | . . . | . . . | . . . | . . . | . . . | . . . | Co 0.20, Ta 0.10 |

You may also like:

The Ultimate Guide to Grade of Stainless Steel Pipe

Type of Different Stainless Steel Tube Material

Each finish serves different purposes, depending on the specific application, aesthetic requirements, and exposure to corrosive environments.

You may also like: Comprehensive Guide to Stainless Steel Tube Surface Finishes

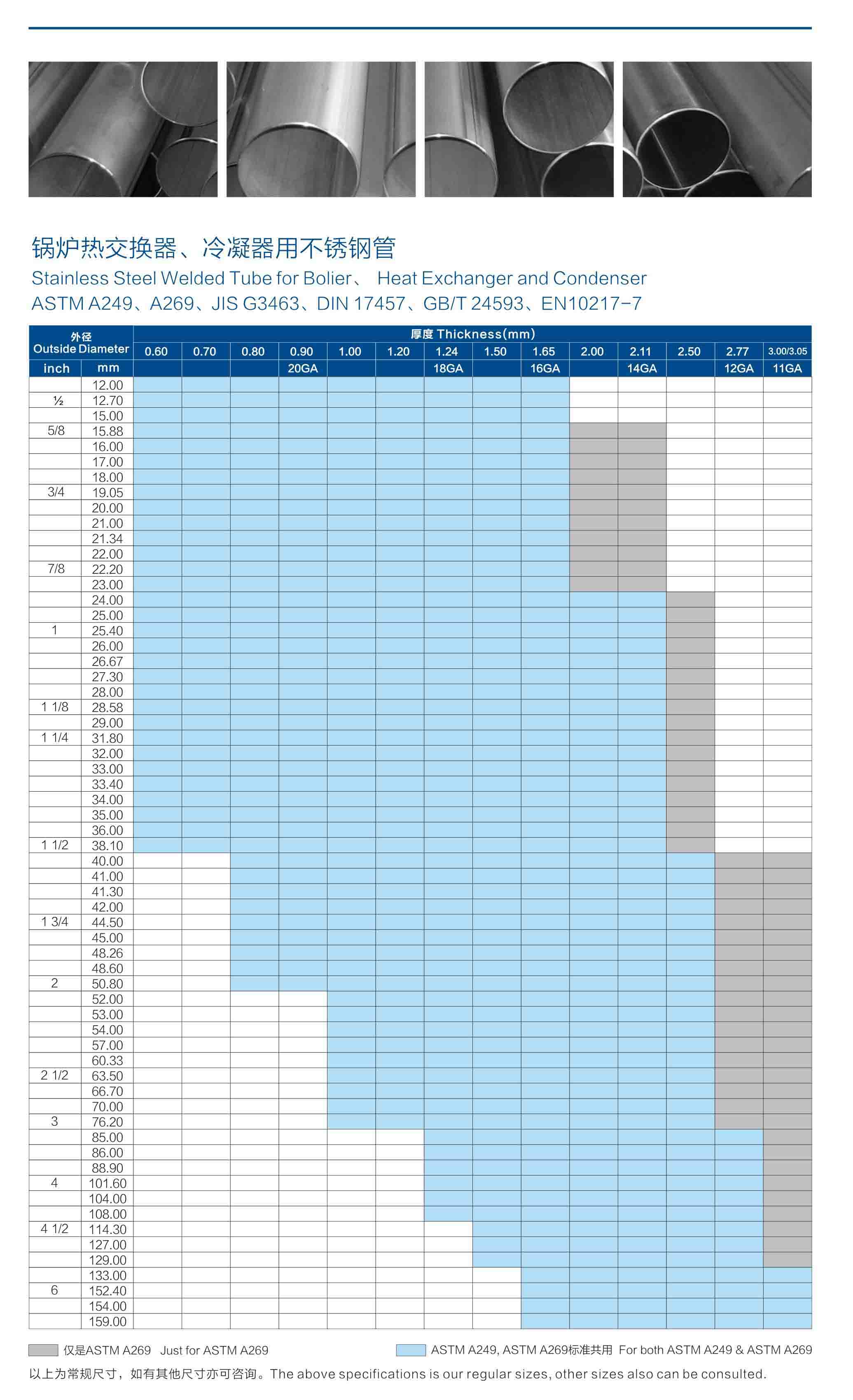

ASTM A249 stainless steel tube is specified with an outside diameter (OD) that ranges from 1/8 in. [3.2 mm] to 12 in. [304.8 mm], allowing for versatility in various applications. This range supports diverse ASTM A249 applications, including heat exchangers and boilers, where efficient heat transfer is crucial.

| OD Range | Applications | Efficiency Factors |

|---|---|---|

| 1/8 in. [3.2 mm] | Laboratory equipment | Compact heat exchangers |

| 1 in. [25.4 mm] | Food processing | Enhanced flow rates |

| 3 in. [76.2 mm] | Power generation | Optimal thermal conductivity |

| 12 in. [304.8 mm] | Industrial systems | High-pressure performance |

Wall thickness in ASTM A249 stainless steel tube ranges from 0.015 in. [0.4 mm] to 0.320 in. [8.1 mm], ensuring suitability for various applications that require specific pressure and structural integrity.

Understanding wall thickness advantages can significantly impact your choice of tubing, as thicker walls provide enhanced strength and resistance to high pressures, while thinner walls may offer improved flexibility and reduced weight.

Complying with wall thickness standards is essential for ensuring that the tubing can withstand the demands of its intended environment. You'll find that wall thickness measurements vary across different grades, which allows for tailored solutions based on application-specific requirements.

Moreover, wall thickness variations can affect thermal conductivity, corrosion resistance, and overall performance. When selecting tubing, consider how these variations may influence your project's success.

Choosing the right OD optimizes heat exchanger efficiency, making it essential for engineers and designers to understand these specifications.

Heat Exchangers

ASTM A249 tubes are widely used in heat exchangers due to their ability to withstand high temperatures and resist corrosion, making them ideal for transferring heat in chemical, petrochemical, and power plants.

Boilers

The high-temperature resistance of ASTM A249 stainless steel tubes makes them a suitable material for boiler tubing in industries such as power generation, where boilers operate under extreme heat and pressure.

Condenser Tubes

Used in steam condensers, these tubes play a key role in converting steam back into water in industrial applications like power plants and refrigeration units.

Evaporators

In systems where liquids are evaporated at high temperatures, like in desalination plants, ASTM A249 tubes are favored due to their thermal conductivity and resistance to scaling and fouling.

Superheaters

ASTM A249 stainless steel tubes are utilized in superheaters in power generation systems, where they help increase the temperature of steam beyond its boiling point, maximizing efficiency.

Food Processing Equipment

Given the cleanliness and corrosion resistance of stainless steel, ASTM A249 tubes are often used in heat exchangers within food processing plants, particularly where hygiene and cleanability are paramount.

Pharmaceutical and Chemical Processing

In pharmaceutical and chemical industries, these tubes are used in equipment like heat exchangers and reactors where purity and resistance to contamination are critical.

Water Treatment Systems

ASTM A249 tubes are also used in desalination plants and water treatment systems, especially where high corrosion resistance is needed due to exposure to saline or chemically treated water.

Automotive Industry

In the automotive sector, these tubes are sometimes used in exhaust systems, fuel lines, and other applications where high temperature and corrosion resistance are required.

Oil and Gas

In the oil and gas industry, ASTM A249 stainless steel tubes find use in pipelines, heat exchangers, and other critical equipment exposed to harsh, corrosive environments.

You may also like: Top Stainless Steel Pipe Applications in Various Industries

The tolerances for the diameter, thickness, and length of ASTM A249 stainless steel tubes are defined by the ASTM A249 specification, which covers welded tubes intended for heat exchanger, condenser, and similar heat transfer applications. Here are the standard tolerances:

Heat treatment for ASTM A249 stainless steel tubes is crucial, as it ensures optimal mechanical properties and enhances corrosion resistance through a solution treatment process at a minimum temperature of 1900°F (1040°C). This process is fundamental in maintaining the austenitic properties of the steel, which is essential for its performance in demanding applications.

| Grade | UNS Designation | Heat Treat Type | Austenitizing/ Solutioning Temperature, min or range °F [°C] | Cooling Media | ASTM Grain Size No. B |

| TP304 | S30400 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP304L | S30403 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP304H | S30409 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | 7 |

| TP309S | S30908 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP309H | S30909 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | 7 |

| TP310S | S31008 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP310H | S31009 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | 7 |

| TP316 | S31600 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP316L | S31603 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP316H | S31609 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | 7 |

| TP317 | S31700 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP317L | S31703 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP321 | S32100 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP321H | S32109 | Solution treatment | cold worked:2000[1100] hot rolled: 2050 [1120]H | water or another rapid cool | 7 |

| TP347 | S34700 | Solution treatment | 1900 °F [1040 °C] | water or another rapid cool | . . . |

| TP347H | S34709 | Solution treatment | 2000°F [1100] | water or another rapid cool | 7 |

| Grade | UNS | Tensile Strength, Min ksi [MPa] | Yield strength, min ksi [MPa] | Elongation in 2 in. or 50 mm, min, %A, B | Hardness, Max | |

| Designation | Brinell/Vickers | Rockwell | ||||

| TP304 | S30400 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP304L | S30403 | 70 [485] | 25 [170] | 35 | 192HBW/200Hv | 90HB |

| TP304H | S30409 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP304N | S30415 | 80 [550] | 35 [240] | 35 | 192HBW/200Hv | 90HB |

| TP310S | S31008 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP310H | S31009 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP316 | S31600 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP316L | S31603 | 70 [485] | 25 [170] | 35 | 192HBW/200Hv | 90HB |

| TP316H | S31609 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP316Ti | S31635 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP317 | S31700 | 75 [515] | 30 [205] | 34 | 192HBW/200Hv | 90HB |

| TP317L | S31703 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP321 | S32100 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP321H | S32109 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP347 | S34700 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

| TP347H | S34709 | 75 [515] | 30 [205] | 35 | 192HBW/200Hv | 90HB |

Conducting a flattening test on ASTM A249 stainless steel tubes assesses their ability to withstand deformation without cracking, ensuring structural integrity for critical applications.

This standardized evaluation is crucial for quality control in material evaluation, validating the strength and durability of the tubing.

Here is a brief overview of flattening test procedure

Preparation: Select a representative sample from the production batch and verify its dimensions.

Testing Equipment: Utilize hydraulic or mechanical presses configured to apply a controlled and uniformly across the tube.

Flattening Process: Gradually apply force to tube until a specified deformation is a achieved, ensuring the tube remains free from cracks or imperfections.

Evaluation: Inspect the deformed tube for any visible cracks or signs of failure to confirm compliance with ASTM standards.

These flattening test methods provide essential data for ensuring that each tube meets the rigorous demands of its intended applications.

These flattening test methods provide essential data for ensuring that each tube meets the rigorous demands of its intended applications.

A flange test evaluates the structural integrity of ASTM A249 stainless steel tubes by assessing their ability to withstand pressure and prevent leaks at the joint connections. This test is crucial for ensuring flange integrity, as it directly impacts the reliability and safety of applications in boilers, heat exchangers, and condensers.

The test significance lies in its role as a quality assurance measure, verifying that the tubes meet stringent manufacturing standards. During the test, samples are subjected to various pressures, simulating real-world conditions to evaluate their performance under stress. Any failure indicates potential weaknesses in the tube or the joint, prompting further investigation and rectification.

Incorporating this testing process into your quality control protocols not only ensures compliance with ASTM standards but also enhances your overall product reliability. Regular performance evaluation through flange testing helps maintain a commitment to excellence, fostering trust among clients and stakeholders.

The reverse-bend test evaluates the ductility and strength of ASTM A249 stainless steel tubes by subjecting them to a bending stress that simulates operational conditions. This test is crucial for ensuring tube integrity and verifying material performance under stress, thus playing a significant role in quality assurance.

Hydrostatic and nondestructive electric tests ensure the structural integrity of ASTM A249 stainless steel tube by detecting leaks and material defects that could compromise performance under pressure. These testing methods play a critical role in quality assurance, confirming that each tube meets stringent standards for safety and reliability.

During hydrostatic testing, you'll fill the tubes with water and pressurize them to check for leaks. This method effectively reveals any weaknesses in the material, ensuring tube integrity under operational conditions.

Contrastingly, electric testing employs electromagnetic techniques to assess the condition of the tube without causing any damage.

Both methods are essential in different contexts; hydrostatic testing is often favored for its straightforward approach, while electric testing can be more efficient for production lines due to its rapid execution.

Incorporating these testing methods into your quality control processes not only enhances the durability of the stainless steel tubes but also fosters confidence among users. By adhering to ASTM A249 standards and implementing rigorous testing protocols, you ensure that your products remain durable and reliable, meeting industry demands for high-performance applications.

These flattening test methods provide essential data for ensuring that each tube meets the rigorous demands of its intended applications.

Microstructure Examination: Conducting a detailed examination helps reveal the grain boundary effects that influence the material’s integrity.

Grain Refinement: Implementing grain refinement techniques can lead to improved mechanical properties, making the material more durable under stress.

Heat Treatment Influence: Understanding how heat treatment affects grain size is essential, improper treatment can lead to undesirable grain coarsening.

ASTM Standards Compliance: Adhering to ASTM standards, particularly E112, provides reliable methods for determining average grain size, ensuring standardized quality.

Learn More:

Stainless Steel Tube Test: Essential Methods for Ensuring Reliability and Performance

Determining grain size in stainless steel tubes is crucial for assessing their mechanical properties and overall performance, as finer grains typically enhance strength and corrosion resistance.

Through grain size analysis, you can evaluate the grain structure and its implications for material performance. Here are four key aspects to consider:

Markings on ASTM A249 stainless steel tubes must clearly indicate the grade, size, and heat number to ensure traceability and compliance with industry standards. Following established marking standards is crucial for effective tube identification. Each marking should be legible and permanently affixed to the tube, providing essential information that supports quality assurance and regulatory compliance.

You'll find that the heat number offers a direct link to the manufacturing process, facilitating traceability practices that many industries require. By adhering to these marking standards, you not only enhance the reliability of your products but also align with best practices in stainless steel tube manufacturing.

Incorporating the appropriate details in your markings can significantly reduce the risk of errors during installation and maintenance. It's vital that all stakeholders, from manufacturers to end-users, understand the importance of these markings for operational integrity.

Ultimately, you're contributing to a culture of accountability and safety in your work environment, reinforcing the collective commitment to high-quality standards and fostering a sense of belonging within the industry.

ASTM A262 provides essential guidelines for assessing intergranular attack susceptibility in austenitic stainless steels, ensuring their reliability in critical applications. By implementing A262 testing, you can determine the material's resistance to degradation, which is crucial for long-lasting performance. The significance of A262 standards lies in their ability to predict how well materials will withstand harsh environments.

The ASTM A480/A480M standard outlines the general requirements for flat-rolled stainless steels, ensuring consistency in chemical composition, mechanical properties, and surface conditions across various applications. This standard is particularly relevant for you if you're involved in ASTM A249 applications, as it complements the specifications for welded stainless steel tubes used in heat exchangers and other critical systems.

By adhering to ASTM A480/A480M, manufacturers can guarantee essential stainless steel properties such as corrosion resistance and durability, which are vital for enhancing heat exchanger efficiency. The standard specifies requirements for surface finish, which directly impacts the manufacturing processes and overall performance of the tubes.

A1016/A1016M specifies the requirements for ferritic and austenitic alloy steels, ensuring that materials used in high-temperature applications meet stringent performance standards. By adhering to this standard, you can guarantee that your components will withstand the demands of various environments.

Understanding these elements helps you navigate the complexities of ASTM A1016 while ensuring that your projects meet industry standards.

Utilizing E112 provides essential test methods for determining the average grain size of metals, which is crucial for assessing the quality and performance of stainless steel tubes. The significance of grain size can't be overstated, as it directly impacts material properties such as strength and ductility. By adhering to E112 testing methods, manufacturers ensure robust quality assurance protocols that enhance the reliability of their products.

| Grain Size | Impact on Properties | Testing Method |

|---|---|---|

| Coarse | Reduced strength | Optical Microscopy |

| Fine | Improved ductility | Electron Backscatter Diffraction |

| Ultra-fine | Enhanced toughness | X-ray Diffraction |

| Nanostructured | Superior performance | Scanning Electron Microscopy |

E213 outlines the ultrasonic examination practices for metal pipes and tubing, ensuring that manufacturers can effectively assess the integrity and quality of their products. This standard plays a crucial role in maintaining safety and performance in applications involving austenitic steels, particularly where intergranular attack may pose a risk.

Utilizing E213 ensures that you're not only compliant with regulations but also part of a community focused on excellence in manufacturing practices. This fosters trust and reliability in your offerings, enhancing your reputation in the industry.

E273 provides essential guidelines for ultrasonic examination practices specific to metal pipes and tubing, ensuring accurate detection of flaws that could affect structural integrity. By following these ASTM standards, you can effectively assess material properties and enhance quality assurance in your tubing applications. The guidelines detail how to perform ultrasonic tests that not only identify defects but also ensure compliance with established manufacturing processes.

Incorporating E273 into your quality assurance protocols allows you to maintain high standards throughout production. This means you're not just meeting specifications, but also boosting the reliability of your stainless steel tubes in demanding environments. Whether you're working with TP304 or TP316 grades, knowing the intricacies of ultrasonic examination will help you mitigate risks associated with structural failures.

Moreover, adherence to these standards fosters a culture of continuous improvement and innovation within your organization. This commitment to quality not only strengthens your products but also builds trust with your clients. Ultimately, implementing E273 ensures that you're equipped with the best practices for maintaining the integrity and performance of your stainless steel tubing.

E527 outlines additional requirements and practices for the examination and testing of stainless steel tubes, complementing the ultrasonic examination protocols established in previous standards. This standard is crucial for ensuring the integrity and reliability of welded applications, particularly where corrosion resistance and mechanical properties are critical.

ASTM A249: Tubes are generally welded and then cold-worked or heat-treated to improve mechanical properties. The welding process is key for efficient heat exchange applications.

ASTM A269: The tubes can be either seamless or welded depending on the specific application. Welded tubes are often cold-drawn to improve dimensional accuracy and surface finish.

ASTM A249 and ASTM A269 serve distinct applications, with A249 tailored for high-pressure environments like boilers and heat exchangers, while A269 is designed for a broader range of general-purpose uses.

When considering application benefits, A249 excels in performance characteristics under extreme conditions, ensuring reliability and safety in critical systems. Its compliance with industry standards guarantees that it meets stringent requirements for strength and durability.

On the other hand, A269 finds its place in various sectors where versatility is essential. It's commonly used in plumbing, food processing, and chemical transportation, making it an excellent choice for projects that require good corrosion resistance without the same high-pressure demands.

Both specifications necessitate conscientious maintenance practices to uphold their integrity over time, especially in challenging environments. Environmental considerations also play a role; while A249 is suited for high-temperature applications, A269's adaptability allows it to meet diverse environmental factors.

Ultimately, your choice between A249 and A269 should align with your specific operational needs, ensuring you select the right tube that meets both performance expectations and compliance with industry standards.

How do the testing methodologies differ between A249 and A269, and what implications do these differences have for their respective applications? Understanding these variations is crucial for ensuring Quality Assurance and Product Durability in your projects.

Testing Scope: A249 focuses on welded tubes for high-temperature applications, while A269 is more general, covering seamless and welded tubes for a variety of uses.

Test Frequency: A249 mandates specific tests like hydrostatic and reverse-bend tests for every 1500 ft of tubing, ensuring rigorous quality checks.

You'll find ASTM A249 stainless steel tubes widely used across industries like automotive applications, pharmaceutical manufacturing, food processing, chemical production, and power generation, ensuring durability and safety in demanding environments while meeting stringent regulatory standards.

When you compare ASTM A249 to other stainless steel specifications, you'll notice its advantages in corrosion resistance, diverse material grades, and efficient manufacturing processes, often leading to favorable cost comparisons for high-performance applications.

Yes, ASTM A249 tubes exhibit high temperature resistance, essential for thermal expansion and stress corrosion applications. However, be aware of application limitations depending on specific material properties, which may affect performance under extreme conditions.

The typical lifespan of stainless steel tubes hinges on corrosion resistance, manufacturing processes, and maintenance requirements. Effective welding techniques and cost considerations significantly influence durability, ensuring you maximize performance and longevity in various applications.

You may also like:

The Life Expectancy of 316 Stainless Steel

The Life Expectancy of 304 Stainless Steel

Yes, you can obtain custom tube dimensions tailored to your needs. With various fabrication options and manufacturing processes, you'll enjoy design flexibility while adhering to standard specifications for optimal performance and application suitability.

In conclusion, ASTM A249 stainless steel tubes provide essential qualities for demanding applications, showcasing superior corrosion resistance and mechanical strength.

By adhering to strict specifications regarding heat treatment, tensile properties, and size variations, these tubes ensure reliable performance.

Comprehensive testing and marking standards reinforce their integrity, while comparisons with ASTM A269 highlight their unique advantages.

Ultimately, choosing ASTM A249 tubes can significantly enhance the efficiency and longevity of heat exchangers and industrial systems.