The fatigue strength of stainless steel is its capacity to endure cyclic stresses without failure. This property is essential for applications necessitating reliability under repeated loading. Fatigue strength is often expressed via the S-N curve, with austenitic grades ranging from 300 to 650 MPa for 10^7 cycles. Factors such as surface conditions and environmental exposure markedly impact fatigue performance. Innovations like microshot peening enhance longevity. Further exploration reveals vital insights into material endurance under cyclic loading.

Fatigue strength in stainless steel refers to the material's ability to withstand repeated cyclic stresses without undergoing mechanical failure. This property is critical for applications subjected to continuous loading and unloading cycles.

The stainless steel fatigue limit, a key parameter, defines the stress level below which the material can endure infinite cycles without failure. Typically, this limit is evaluated through rigorous testing to determine endurance over 10^6 or 10^7 cycles.

The fatigue limit of stainless steel determines stress levels for enduring infinite cycles without failure.

Austenitic and duplex stainless steels exhibit fatigue limits near 0.2% of their proof strength, with duplex types often achieving limits around 50% of their ultimate tensile strength.

Variations in fatigue strength are influenced by factors such as surface finish, stress fluctuation frequency, and the specific stainless steel composition used.

Building on the advancements in materials science, the distinction between fatigue strength and fatigue limit is essential in understanding the mechanical performance of stainless steels under cyclic loading conditions.

Fatigue strength defines the maximum stress withstood for a specified cycle count before failure occurs, crucial for engineering designs to prevent premature fatigue. Conversely, the fatigue limit, or endurance limit, signifies the stress threshold below which infinite cycles can be sustained without failure, important for long-term reliability.

Fatigue strength ensures durability for a cycle count, while the fatigue limit promises infinite endurance without failure.

The fatigue behavior of stainless steel is characterized by the Stress-Life (S-N) curve, which illustrates the relationship between cyclic stress amplitudes and the number of cycles to failure.

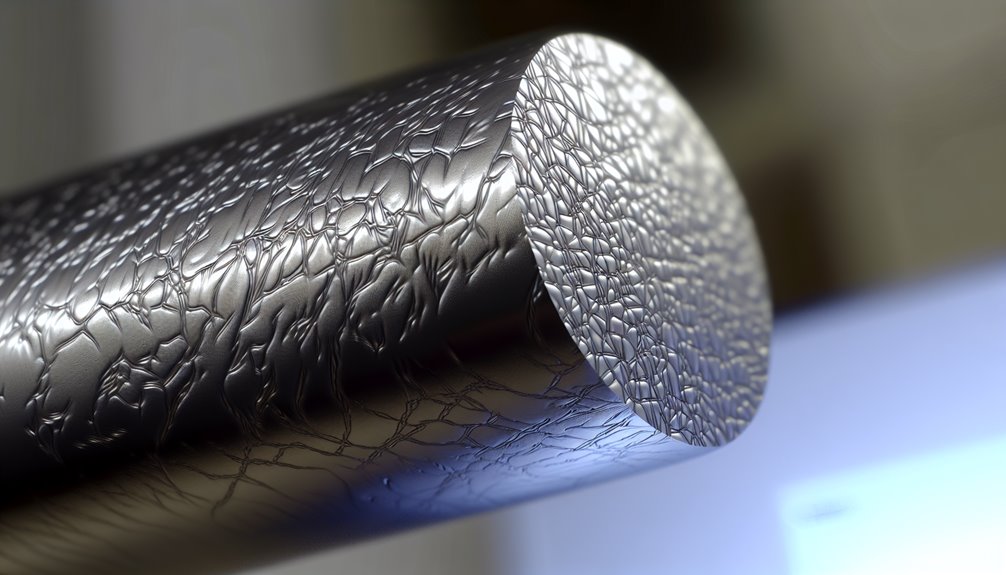

Crack initiation and propagation mechanisms greatly influence fatigue performance, as microstructural features and surface conditions determine the onset and growth of fatigue cracks.

High-cycle fatigue involves a greater number of cycles at lower stress levels, whereas low-cycle fatigue occurs under fewer cycles with higher stress amplitudes, impacting design and material selection in engineering applications.

When analyzing the fatigue behavior of stainless steel, the Stress-Life (S–N) curve is a critical tool that visualizes the relationship between cyclic stress and the number of cycles to failure.

For 304 stainless steel, the S–N curve demonstrates the fatigue strength at various stress levels, providing data essential for predicting component longevity under cyclic loads. Typically, the fatigue strength of 304 stainless steel falls within the range of 300 to 650 MPa for 10^7 cycles.

The S–N curve stainless steel analysis reveals that as stress levels decrease, the number of cycles to failure increases, indicating a higher fatigue life. This relationship is pivotal for engineers aiming to optimize design life and guarantee reliability in applications subjected to repetitive stress cycles.

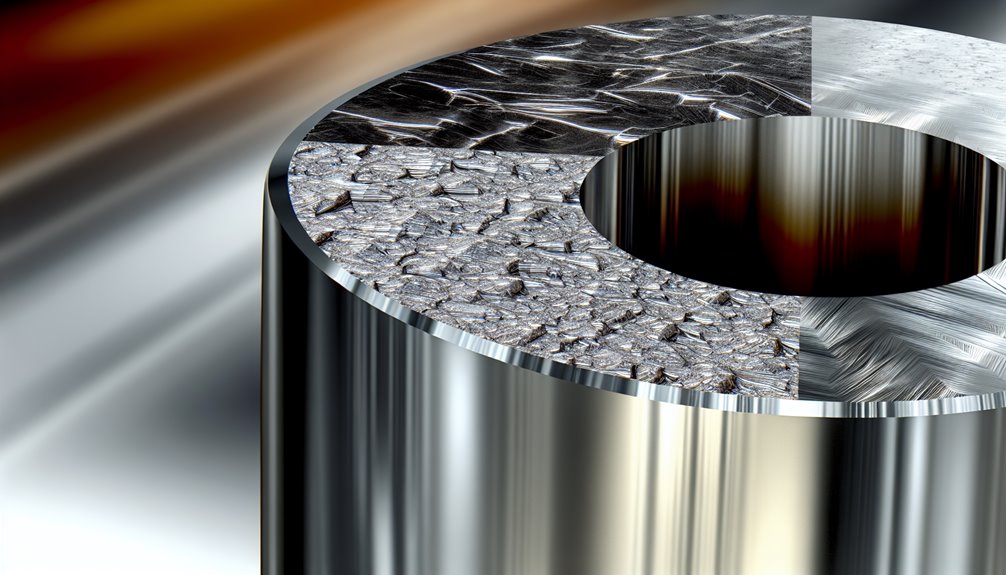

Crack initiation in stainless steel under cyclic loading is a critical precursor to fatigue failure. The mechanisms of crack initiation and propagation greatly influence stainless steel fatigue life and fatigue resistance. Microstructural features, such as grain boundaries and inclusions, often serve as stress concentrators leading to crack initiation.

Understanding these mechanisms allows for improved design and material selection, enhancing the reliability of stainless steel components.

Accurate prediction of fatigue behavior under cyclic stresses is essential for optimizing performance and extending the lifespan of engineering applications.

Understanding the mechanisms of crack initiation and propagation provides a foundation for exploring the distinct behaviors of high-cycle and low-cycle fatigue in stainless steel. In addition, selecting appropriate grades based on environment and service conditions—such as choosing 316 stainless steel for chloride-rich or marine settings—can significantly improve long-term performance as noted in industry comparisons. Additionally, the inclusion of molybdenum in 316 enhances corrosion resistance, supporting longer fatigue life in aggressive environments.

High-cycle fatigue stainless steel is characterized by stress levels below the fatigue limit, allowing materials to endure millions of stress cycles with minimal plastic deformation. In demanding environments, selecting grades with enhanced chloride resistance helps mitigate corrosion-assisted fatigue and extend service life. In such settings, selecting 316L stainless steel can further improve durability due to its superior corrosion resistance in chloride-rich environments.

Conversely, low-cycle fatigue involves higher stress levels, leading to significant plastic deformation and failure within fewer cycles.

Stainless steel exhibits a well-defined fatigue limit, essential in high-cycle applications to prevent failure. Data indicates that while austenitic stainless steel can endure cycles exceeding 10^6 under high-cycle conditions, low-cycle fatigue often results from stress levels surpassing 0.2% proof strength, necessitating careful consideration in design parameters and material selection. Additionally, surface treatments like passivation can enhance corrosion resistance and thereby improve fatigue performance in chloride-rich environments.

Although fatigue strength is primarily determined by the inherent material properties, mechanical and environmental factors greatly influence its performance under cyclic loading.

The endurance limit of stainless steel can be notably affected by external stressors. Corrosion fatigue in stainless steel manifests when exposed to aggressive environments, where corrosive agents create stress concentrators that reduce fatigue life. Incorporating proper post-weld cleaning and heat control during fabrication can limit sensitization and surface defects that accelerate corrosion fatigue. In addition, controlling exposure to chlorides and maintaining low humidity can reduce corrosion-assisted crack initiation and extend fatigue life. Regular inspections and cleaning to prevent surface contamination help reduce crack initiation sites and preserve fatigue life.

Mechanical factors such as surface finish and residual stresses also play an essential role in fatigue performance.

Understanding these factors is vital for optimizing design and ensuring material reliability. Regular inspection and maintenance help identify early signs of corrosion and mitigate pitting corrosion, thereby preserving fatigue performance.

In evaluating the fatigue performance of stainless steel grades, various mechanical and environmental factors must be considered to achieve ideal material reliability.

Fatigue testing ASTM E466 provides standardized methods to assess fatigue strength under cyclic loading. Typical fatigue strength levels vary with stainless steel types, including austenitic, ferritic, martensitic, and duplex.

Fatigue testing ASTM E466 standardizes methods for assessing fatigue strength in various stainless steel types under cyclic loading.

Austenitic stainless steels exhibit fatigue strengths ranging from 300 MPa to 650 MPa for 10^7 cycles, while duplex grades often demonstrate fatigue limits near 50% of their ultimate tensile strength.

Thermal fatigue stainless steel considerations are significant, especially for applications involving temperature fluctuations.

Consistent fatigue data is essential for reliable engineering design, ensuring components withstand operational stresses and maintain structural integrity over extended cycles.

Corrosion fatigue and thermal fatigue resistance are critical considerations in the application of stainless steels, particularly in environments experiencing cyclic stresses and temperature fluctuations. Leading tube factories employ rigorous testing & quality control to validate fatigue performance alongside corrosion resistance in demanding service conditions.

Stainless steels, known for their superior corrosion resistance, demonstrate varying degrees of resilience against fatigue when subjected to corrosive agents and thermal cycling. Standards such as ASTM A270 provide application-specific guidance that supports consistent performance expectations in sanitary and corrosive service. In architectural and structural contexts, finish selection such as satin finish and mirror polish can influence surface condition and thereby impact fatigue initiation behavior. 316 and 316L tubes offer improved resistance in harsh conditions due to their molybdenum content and low-carbon weldability, making them suitable for applications demanding exceptional corrosion resistance.

Duplex stainless steels offer notable advantages due to their enhanced pitting resistance and thermal properties. Understanding the mechanisms of fatigue in such conditions is essential for predicting material performance.

In marine and chemical environments, Grade 316 structural tubes are often selected because their molybdenum-enhanced corrosion resistance supports better fatigue performance under cyclic loading.

Fatigue testing of stainless steel is governed by standards such as ASTM E466, ISO 1099, and EN 6072, which outline methodologies for evaluating fatigue behavior under cyclic loading conditions.

Commonly employed testing methods include rotary bending, axial loading, and thermographic analysis, each providing specific insights into material performance.

The use of infrared thermography offers a rapid technique for determining the fatigue limit, enabling efficient evaluation of material endurance in engineering applications.

Standards such as ASTM E466, ISO 1099, and EN 6072 provide thorough frameworks for conducting fatigue testing, ensuring consistency and reliability in evaluating the fatigue properties of materials.

These standards establish protocols for specimen preparation, testing conditions, and data interpretation, enabling reproducibility across experiments. The guidelines are essential for industries aiming to predict component lifespan under cyclic loading accurately.

These standards collectively support the design of reliable, fatigue-resistant components.

Building upon the established frameworks provided by ASTM, ISO, and EN standards, the examination of common testing methods such as rotary bending, axial, and thermographic analysis emerges as a critical aspect of fatigue testing standards and evaluation methods.

Rotary bending tests utilize rotating specimens subjected to bending stress, enabling high-cycle fatigue assessments. Axial loading applies cyclic tension-compression forces along the specimen's axis, offering insights into material behavior under fluctuating loads.

Thermographic analysis, on the other hand, employs infrared technology to detect temperature changes associated with fatigue damage, facilitating non-destructive evaluation. These methodologies enable thorough characterization of fatigue properties, ensuring the reliability and durability of stainless steel components.

Data-driven results from these tests guide engineers in optimizing material performance under cyclic stresses.

While advancements in material science have introduced various techniques for evaluating fatigue properties, infrared thermography offers a rapid and innovative approach to determining fatigue limits. This method capitalizes on the correlation between temperature changes and material stress responses, enabling non-destructive evaluation of fatigue behavior.

Infrared thermography efficiently identifies the onset of microstructural changes by detecting localized temperature increases, which are indicative of stress concentrations. This technique enhances precision in predicting fatigue limits through real-time monitoring and data acquisition.

Infrared thermography represents a significant leap in fatigue testing, reducing time and resource expenditure while improving accuracy.

To enhance the fatigue life of components, engineers employ a series of targeted design guidelines that mitigate stress concentration and material degradation.

Key strategies include optimizing geometric features to reduce notch effects, implementing smooth shifts, and avoiding sharp corners that serve as stress risers.

Material selection prioritizes alloys with high fatigue limits and superior microstructures, such as duplex stainless steels, known for their balanced strength and corrosion resistance.

Surface treatments like shot peening induce compressive residual stresses, effectively impeding crack initiation.

Additionally, proper heat treatments refine grain size, enhancing fatigue properties.

Engineers incorporate safety factors and conduct finite element analysis (FEA) to predict stress distribution, ensuring designs remain within endurance limits under operational conditions, thereby extending component lifespan.

Engineers adopt a range of strategies to optimize fatigue life, emphasizing the significance of material selection and design precision.

Fatigue-resistant stainless steel is essential in applications demanding durability under cyclic loading. In aerospace, the material's high fatigue strength guarantees the longevity and reliability of aircraft components subjected to varying stress levels. A polished surface finish that minimizes crevices for bacteria also reduces micro-notches that can initiate fatigue cracks, aligning with food-grade practices seen in sanitary pipe finishes. In structural applications, selecting an appropriate wall thickness in stainless steel tubing improves stiffness and delays crack initiation under cyclic loads. The use of 304 stainless steel rectangular tubes with high tensile strength supports structural durability while maintaining corrosion resistance in demanding environments. A key advantage in corrosive settings is the superior resistance of 316 stainless steel, which helps mitigate corrosion-assisted fatigue.

Automotive industries utilize these steels to enhance the endurance of parts like suspension systems and drive shafts, which experience continuous stress reversals.

Furthermore, in the energy sector, fatigue-resistant stainless steels are fundamental in constructing offshore platforms and wind turbines, where environmental factors can exacerbate fatigue failure.

Additionally, fatigue-resistant stainless steels are widely used in the oil and gas industry for high-pressure pipelines and offshore applications where corrosion and cyclic loading coexist.

As advancements in materials science continue to evolve, emerging research is increasingly focusing on enhancing the fatigue performance of stainless steels. Novel methods are being explored, including surface treatments and alloying modifications, aimed at improving fatigue resistance. Data-driven studies are analyzing microstructural changes and their impact on fatigue properties. Research highlights the importance of nanostructuring techniques and advanced coating technologies in achieving superior fatigue strength.

| Research Focus | Key Findings |

|---|---|

| Surface Treatments | Enhanced fatigue life through microshot peening |

| Alloying Modifications | Increased chromium content improves resistance |

| Nanostructuring Techniques | Grain refinement enhances fatigue strength |

| Advanced Coating Technologies | Protective coatings reduce stress concentrators |

These technological advancements are poised to considerably impact future applications of stainless steels, ensuring durability and reliability in demanding environments.

Surface finish greatly affects stainless steel fatigue strength by acting as stress concentrators. Rough surfaces introduce micro-cracks, reducing fatigue life, while polished surfaces enhance performance by minimizing defect sites, thereby improving resistance to cyclic stress-induced failures.

Welding can greatly affect stainless steel's fatigue performance by introducing residual stresses and microstructural changes, potentially reducing fatigue strength. Proper techniques and post-weld treatments are essential to mitigate these effects and enhance fatigue resistance.

Grain size considerably influences fatigue resistance by altering dislocation movement and stress distribution. Smaller grains enhance resistance through increased grain boundary area, hindering dislocation propagation, akin to a fortress's walls strengthening against invasion, optimizing material performance.

The cost implications of high-fatigue-strength stainless steel involve higher initial material expenses due to alloying and processing. However, its extended service life and reduced maintenance costs provide long-term economic benefits, justifying the investment in demanding applications.

"Different strokes for different folks." Austenitic stainless steels generally exhibit superior fatigue strength compared to ferritic and martensitic types, offering fatigue limits near 0.2% proof strength. Duplex grades balance strength and corrosion resistance, providing competitive fatigue performance.

The exploration of fatigue strength in stainless steel reveals that austenitic alloys can endure up to 50% of their tensile strength under cyclic loads, showcasing their robust performance. This understanding is essential for designing components in demanding environments. Factors such as alloy composition, microstructure, and environmental conditions play significant roles in fatigue behavior. Future research will likely focus on optimizing these parameters to enhance fatigue resistance, ensuring the longevity and reliability of stainless steel components in various industrial applications.