Stainless steel pipes are a premier choice for exhaust systems due to their superior durability and resistance to corrosion. They excel in maintaining structural integrity even at high temperatures and in harsh environments. Available in various grades such as 304 and 316L, these pipes offer mechanical reliability that reduces maintenance costs and extends service life. With tailored solutions from manufacturers like Vinmay, they meet stringent quality standards, ensuring peak performance across automotive, marine, and industrial applications.

Stainless steel pipes are the ideal choice for exhaust systems due to their superior corrosion resistance, which guarantees longevity even in harsh environmental conditions. These pipes exhibit exceptional high-temperature tolerance, maintaining structural integrity and performance under the thermal stress typical of exhaust applications.

Additionally, the long-term cost efficiency of stainless steel, attributed to minimal maintenance and replacement needs, underscores its economic advantage over alternative materials. They also provide excellent mechanical reliability, with impact resistance and high yield strength that help withstand vibration and thermal cycling in exhaust environments.

For demanding environments, 316 stainless steel offers superior corrosion resistance thanks to its molybdenum content, making it highly suitable for marine or chemical exposure. Compared to other grades, 316’s molybdenum content and higher Nickel levels deliver enhanced pitting and crevice corrosion resistance in chloride-rich environments.

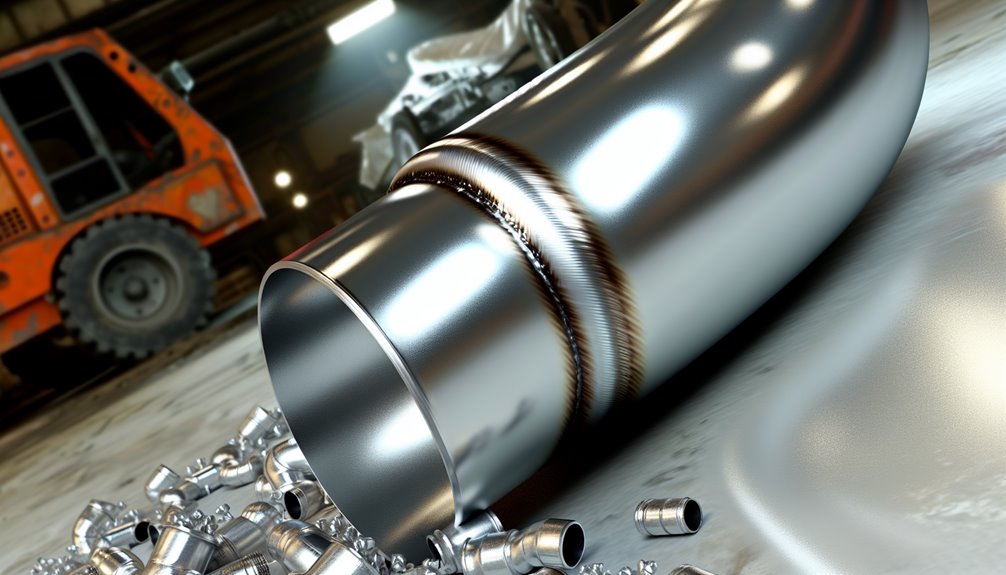

In welded exhaust assemblies, choosing 316L reduces the risk of carbide precipitation during welding, improving long-term corrosion resistance in high-temperature service. For architectural or visible exhaust components, selecting a satin finish or mirror finish can enhance aesthetics while maintaining corrosion resistance.

Corrosion resistance plays an essential role in the selection of materials for exhaust systems, making stainless steel pipes an ideal choice. The intrinsic properties of stainless steel, specifically its ability to resist rust, offer superior corrosion prevention compared to mild steel.

The inclusion of molybdenum in 316 stainless improves resistance to chlorides and acids, aligning with standards such as ASTM A554 used for welded stainless steel mechanical tubing. For applications facing elevated temperatures and dynamic loads, adherence to ASTM A270 helps ensure sanitary-grade quality and consistent mechanical performance.

Additionally, selecting grades with enhanced pitting resistance further mitigates chloride-induced degradation in harsh environments. This selection is supported by 316L austenitic chemistry and smooth surface finishes that reduce microbial adhesion in demanding environments.

This advantage is vital in environments with high moisture levels, salt exposure, or chemical contact, such as coastal cities or winter-salted roads. The durability of stainless steel guarantees a longer lifespan for exhaust systems, minimizing the frequency of replacements and thereby reducing environmental impact.

Rust resistance is not merely a convenience but a significant factor in maintaining the structural integrity and performance of exhaust systems. Consequently, stainless steel emerges as the material of choice for those prioritizing material durability and long-term reliability. Additionally, choosing grades like 316L stainless steel can enhance performance in chloride-rich environments, especially near coastal roads where salt exposure accelerates corrosion.

Beyond preventing corrosion, the capability of a material to endure high temperatures is a critical factor in the selection of exhaust system components.

In high performance applications, exhaust gases can reach temperatures exceeding 600°C. Stainless steel pipes offer extreme temperature resistance, maintaining structural integrity and performance under such conditions. This resilience is supported by their heat resistance, which stems from the alloy’s composition and processing.

Compared to 304, 316 stainless steel’s molybdenum content improves pitting resistance in chloride-rich environments often encountered in road salts and coastal areas. Additionally, 304 stainless steel rectangular tubes provide superior corrosion resistance, contributing to durability in harsh environmental conditions. For applications requiring standardized identification and performance, selecting grades per ASTM standards ensures appropriate chemical composition and heat treatment for exhaust service.

Unlike cheaper materials that may succumb to warping or cracking, stainless steel retains its strength and shape. This presents significant engineering benefits, ensuring longevity and reliability of exhaust systems.

The ability of stainless steel to withstand these extreme temperatures makes it an ideal choice for demanding environments. Consequently, selecting stainless steel pipes for exhaust systems enhances durability, minimizing the risk of mechanical failure and optimizing vehicle performance under high thermal stress conditions.

For extreme thermal and corrosive environments, 316-grade stainless steel—thanks to its molybdenum alloy addition—delivers superior resistance to chloride attack while retaining high-temperature strength.

Durability serves as a compelling rationale for the selection of stainless steel pipes in exhaust systems. Its corrosion resistance and low-maintenance characteristics make it especially suited for long-term performance in demanding environments.

Through meticulous cost analysis, stainless steel demonstrates superior long-term cost efficiency despite its higher initial expenditure compared to mild steel. This material's extended lifespan considerably reduces replacement frequency, directly impacting maintenance budgets. Its weldability supports reliable fabrication and repairs, enhancing uptime and reducing lifecycle costs.

Additionally, its high tensile strength helps maintain structural integrity under thermal cycling and vibration. For applications demanding both corrosion resistance and structural reliability, adherence to ASTM A312 ensures pipes meet rigorous mechanical and testing requirements.

The longevity of stainless steel guarantees that fewer labor resources are allocated towards replacement, translating into substantial labor savings over time. This efficiency is particularly advantageous in industrial settings where minimizing operational disruptions is critical.

Additionally, 304 stainless steel’s exceptional corrosion resistance extends service life in harsh exhaust environments, further lowering total lifecycle costs.

Stainless steel exhaust pipes are available in various grades, each offering distinct properties tailored to specific performance and environmental requirements.

Grade 304 stainless steel is widely utilized due to its excellent corrosion resistance and affordability, whereas 316/316L provides enhanced resistance to chloride environments, making it ideal for marine applications. For added durability in harsh environments, 316’s molybdenum content delivers superior corrosion resistance and lower maintenance over the service life.

Additionally, selecting the appropriate manufacturing process can influence seam quality, strength, and cost for exhaust applications. The choice of a reputable manufacturer is crucial because material quality directly affects performance and longevity, aligning with industry emphasis on quality assurance.

Compared to other materials like galvanized steel, stainless options typically offer better long-term resistance to internal rusting and water-quality impacts noted in mixed-service environments.

On the other hand, grades such as 321 and 409 are preferred for their thermal stability and cost-effectiveness, with 439 offering superior corrosion resistance and thermal expansion control, thereby catering to diverse automotive exhaust system needs.

For sanitary and high-purity applications, selecting tubing compliant with ASTM A270 can ensure verified material quality and hygienic performance.

Austenitic stainless steel stands as a premium choice in the domain of exhaust pipe manufacturing, primarily due to its exceptional corrosion resistance and durability.

This stainless steel type, renowned for its superior properties, is composed of approximately 18% chromium and 8% nickel. These elements confer significant advantages, making it highly resistant to rust, even in challenging environments like damp or salty conditions. It also adheres to industry standards compliance, ensuring quality and reliability across demanding applications.

Additionally, a polished surface finish helps minimize crevices for bacteria and improves hygiene, aligning with food industry best practices that emphasize cleanability. Many exhaust tubes are produced to the ASTM A554 standard, which defines mechanical properties, dimensions, and surface finishes for welded stainless steel mechanical tubing. ASTM A270 covers sanitary tubing used in hygienic applications and defines strict chemical composition and mechanical property requirements.

This particular stainless steel grade is valued for maintaining a polished appearance over prolonged use, a vital factor in performance and high-end exhaust systems.

The application of austenitic stainless steel in exhaust pipes guarantees longevity and reliability, qualities essential for demanding automotive applications where both aesthetics and performance are paramount.

Its robust properties make it an industry-standard choice.

Compared to 201 stainless, 304 offers superior corrosion resistance and heat tolerance, making it ideal for harsh exhaust environments, thanks to its higher nickel content.

316L stainless steel, known for its enhanced composition with molybdenum, stands out in the field of exhaust pipe materials due to its outstanding corrosion resistance.

This particular grade is ideal for harsh environments, such as coastal and marine applications, where its superior durability is vital. Its unique properties make it a preferred choice among stainless steel grades for industrial exhaust systems.

The integration of molybdenum in 316L enhances its resistance against pitting, particularly in chemically aggressive settings.

Regarding stainless steel fabrication, 316L offers excellent weldability and formability, ensuring reliability in construction and performance.

Significantly, the stainless steel applications of 316L extend beyond exhaust systems, proving indispensable in sectors demanding high resistance to corrosive elements, thereby ensuring longevity and efficiency.

In exploring the domain of stainless steel exhaust pipes, attention naturally shifts to various types that offer distinct advantages for specific applications. Among these, the modified 304 stainless steel, enhanced with titanium, stands out due to its robust stainless steel properties.

This grade is particularly well-suited for high-temperature environments, such as exhaust manifolds, where durability under continuous heat is paramount. The titanium addition fortifies the stainless steel structure, mitigating the risk of corrosion and thermal degradation.

Such stainless steel grades cater to demanding applications, ensuring longevity and reliability. The versatility of stainless steel applications extends to multiple sectors, reflecting the material's adaptability in addressing specific performance requirements.

Understanding these nuances empowers professionals to make informed decisions for optimized performance outcomes.

The domain of stainless steel exhaust pipes encompasses various types, each engineered to meet specific performance requirements. Among these, ferritic grades are significant for their cost efficiency and moderate heat handling capabilities. These grades are primarily used in factory exhaust systems where budget constraints are pivotal.

However, the composition of ferritic stainless steel, characterized by low chromium content and minimal to no nickel, poses a challenge to rust resistance. This makes them susceptible to corrosion over time, particularly in moist or saline environments.

Despite this limitation, their affordability and satisfactory performance under controlled conditions make them a viable option for applications where cost considerations outweigh the potential for rust. Such strategic selection optimizes the balance between performance and budget.

Stainless steel exhaust pipes, renowned for balancing durability and cost-effectiveness, are categorized into various types, each tailored for distinct performance metrics. The grades of stainless steel utilized in exhaust pipe designs are essential in determining their corrosion resistance and cost.

Selecting the appropriate grade involves balancing these factors against budget and performance needs.

Stainless steel exhaust pipes are integral to various applications, including automotive exhaust systems, marine exhaust systems, and industrial ventilation and exhaust.

These systems benefit from stainless steel's corrosion resistance, durability, and ability to withstand high temperatures, meeting the rigorous demands of each sector.

In addition, the material's compliance with standards such as ASTM A249 and A269 enhances its suitability for diverse environments and guarantees reliability and longevity in performance.

Automotive exhaust systems harness stainless steel pipes for their critical roles in mufflers, catalytic converters, tailpipes, and downpipes. This material maximizes exhaust flow, enhancing vehicle performance and sound quality.

Stainless steel's high temperature resistance and corrosion protection guarantee durability and reliability. Common grades include 409 and 304 stainless steel, chosen for their specific properties aligned with automotive needs.

In the domain of marine applications, exhaust systems demand materials that can withstand the unique challenges posed by a maritime environment.

Stainless steel exhaust pipes, particularly in grades such as 316L or super-austenitic stainless steel, are essential in maintaining marine engine performance by resisting saltwater corrosion and other harsh marine elements. These materials guarantee ideal exhaust gas flow, which is vital for efficient engine operation.

Additionally, the integration of noise reduction techniques within these systems is imperative to minimize acoustic disturbances on vessels, enhancing onboard comfort.

Stainless steel’s durability and resistance to corrosive elements make it an indispensable choice for exhaust systems in ships, yachts, and offshore platforms, where reliability and performance consistency are paramount.

Industrial ventilation systems play a pivotal role in maintaining safe and efficient working environments, especially in sectors involving high-temperature processes and chemical handling.

Stainless steel exhaust pipes are integral to these systems, ensuring ideal exhaust efficiency and managing industrial airflows effectively. The robustness of stainless steel is vital in environments like power plants, factories, and refineries, where they handle hot gases and chemicals.

Key considerations include:

Detailed analysis of these aspects underscores the importance of stainless steel in industrial applications.

Selecting the appropriate stainless steel pipe for exhaust applications necessitates a thorough evaluation of material-environment compatibility, particularly under varying atmospheric conditions.

The thermal properties and resistance to aging of the stainless steel grade must be meticulously assessed to guarantee peak performance and durability.

Additionally, a cost-benefit analysis should be conducted to balance initial investment against expected longevity, factoring in maintenance and replacement expenses.

Choosing the appropriate stainless steel pipe for an exhaust system necessitates a precise understanding of environmental conditions and material properties.

A thorough analysis of material durability, environmental impact, and performance comparison is essential for ideal selection.

When evaluating the suitability of stainless steel pipes for exhaust systems, considering the effects of heat and aging is essential. Exhaust systems often exceed 600°C, necessitating materials with robust heat resistance techniques.

Grade 304 stainless steel is noted for its ability to withstand high temperatures, maintaining its structural integrity. However, thermal expansion effects must be accounted for, as excessive expansion can lead to mechanical stress.

Detailed fatigue strength analysis is also vital to assess long-term durability under cyclic thermal loads, ensuring that the material does not succumb to premature failure. While high temperatures may cause superficial discoloration, this can be mitigated through regular maintenance.

Selecting the right stainless steel pipe involves understanding these factors to optimize performance and longevity.

Evaluating the cost versus longevity of stainless steel pipes for exhaust systems necessitates a precise evaluation of material properties and application demands.

A thorough cost analysis reveals that:

Precision in material selection is paramount for informed decision-making.

To guarantee the longevity and ideal performance of stainless steel exhaust pipes, regular maintenance is imperative.

Exhaust pipe maintenance involves several vital steps to confirm stainless steel durability. Initially, routine inspection for corrosion or damage is essential. This allows for early detection and correction, preventing further deterioration.

Subsequently, pipe cleaning techniques play a notable role. Utilizing a non-abrasive cleaner specifically designed for stainless steel guarantees the surface is free from debris without compromising the material's integrity.

Thirdly, applying a protective anti-corrosion coating can enhance resistance to environmental factors.

Finally, confirming proper alignment and secure fittings reduces stress on joints, enhancing overall performance.

After ensuring your stainless steel exhaust pipes last and perform at their best through proper maintenance, the next step is choosing the right supplier. That’s where we come in.

At Vinmay, we’ve built our reputation on delivering premium exhaust pipe materials and fully customized solutions. With our global reach and deep industry knowledge, we know how to meet the needs of clients who expect nothing but the best.

Here’s why we believe we’re the right choice for you:

Every feature of our service reflects our commitment to excellence in stainless steel exhaust applications. When you choose us, you’re choosing a partner who values quality, precision, and long-term results as much as you do.

📞 Let’s make your next exhaust project a success. Contact us today to discuss your requirements, request a free sample, or get a tailored quote from our expert team.

The cost of stainless steel exhaust pipes varies like the tides, influenced by cost comparison with other materials, installation factors, and material grades such as 304, 304L, or 316L, each affecting the final price.

Stainless steel pipes exhibit high temperature resistance and exhaust system durability, primarily due to their material composition, including chromium and nickel alloys. Detailed analysis confirms their capability to withstand thermal stress, ensuring reliable performance in demanding environments.

Stainless steel exhaust pipes exhibit excellent corrosion resistance due to their chromium content. Material advantages include durability and low maintenance. To optimize longevity, users should implement regular inspections and cleaning to mitigate environmental and operational factors.

Stainless steel exhaust pipes enhance vehicle performance by improving thermal efficiency, thereby optimizing engine output. They reduce vehicle weight, contributing to better handling and fuel economy, while also refining exhaust sound, offering a more controlled auditory experience.

The lifespan of a stainless steel exhaust pipe varies based on lifespan factors such as quality, exhaust material comparison, and maintenance tips. Proper maintenance and material choice can extend longevity, outperforming alternatives like mild steel in durability and corrosion resistance.

In conclusion, stainless steel pipes, particularly grades 304 and 316L, offer unparalleled durability and corrosion resistance for exhaust systems across automotive, marine, and industrial sectors. Despite concerns about initial costs, their long-term benefits, including reduced maintenance and extended lifespan, prove cost-effective. Custom solutions from manufacturers like Vinmay further enhance application-specific performance, meeting rigorous quality standards. Selecting stainless steel guarantees reliability and efficiency under extreme conditions, making them an irreplaceable component of high-performance exhaust systems.