The 316 Stainless Steel Rectangular Tube is recognized for its exceptional corrosion resistance and durability, making it a crucial element in industries such as aerospace and petroleum. Despite its lower malleability compared to its 304 counterpart, its versatility in size, thickness, and finish offers sufficient flexibility in shaping and forming.

This discourse aims to provide an in-depth exploration of its specifications, thermal properties, and pricing details, providing a comprehensive understanding of its industrial and commercial application potential.

The utility of 316 stainless steel rectangular tube is largely attributed to its chemical composition and mechanical properties. This grade of stainless steel pipe is endowed with a distinctive blend of Chromium, Molybdenum, Nickel, Carbon, Manganese, Silicon, Phosphorus, and Sulfur, thus ensuring superior strength and corrosion resistance.

Furthermore, its workability, coupled with its equivalents in terms of grades, solidifies its position as a preferred choice in various industrial applications.

Composed of a unique blend of Chromium, Molybdenum, Nickel, Carbon, Manganese, Silicon, Phosphorus, and Sulfur, the 316 Stainless Steel Rectangular Tube exhibits robust chemical properties. The chemical composition analysis of this stainless steel tube is crucial in determining its suitability for specific industrial applications. It also informs the corrosion resistance testing, material strength assessment, and surface finish evaluation.

| Element | 316 Stainless Steel | Industrial Application |

|---|---|---|

| Chromium | 16.0-18.0% | Enhances corrosion resistance |

| Nickel | 10.0-14.0% | Improves toughness |

| Molybdenum | 2.0-3.0% | Increases strength |

| Carbon | Max 0.08% | Controls hardness |

The table above presents a glimpse of the chemical composition and its implications on the tube's performance. Understanding these elements can guide you in making an informed decision when selecting stainless steel tubes for your project.

316L and 316 stainless steel rectangular tubes, owing to their specific mechanical properties, exhibit remarkable durability and resistance to environmental factors, making them instrumental for use in diverse industrial applications.

A rigorous mechanical properties analysis reveals superior tensile strength and excellent toughness, contributing to their longevity. The material composition study of these alloys indicates a high concentration of Chromium, Nickel, and Molybdenum, which ensures significant corrosion resistance, as demonstrated through rigorous corrosion resistance testing.

Heat treatment evaluation further validates their resilience even under extreme temperature fluctuations. A comparison of welding techniques attests to their adaptability, with both grades showing excellent weldability.

Thus, the 316 and 316L stainless steel rectangular tubes prove to be robust, versatile, and reliable materials for a wide array of industrial applications.

In the realm of industrial materials, it should be noted that the 316 and 316L grades of stainless steel pipes have equivalent grades that offer similar traits and characteristics, making them suitable alternatives in certain applications.

Beyond the considerations of grade equivalencies and their respective applications, the workability of 316L and 316 stainless steel rectangular tubes plays a pivotal role in determining their suitability for specific industrial use.

These tubes display excellent weldability, accommodating a variety of welding techniques that further enhance their adaptability. In terms of surface finishes, their natural shine can be maintained or altered to meet aesthetic or functional requirements. Customization options are vast, allowing for tailored solutions that meet unique industrial demands.

The 316 and 316L grades offer superior corrosion resistance, contributing to their longevity and performance under various conditions. Temperature durability is another key aspect of their workability, ensuring stability and resilience in high-temperature environments.

The specifications of a 316 Stainless Steel Rectangular tube are pivotal to its functionality and application in various industries. Key parameters to consider include:

A thorough understanding of these specifications is vital for the selection of an appropriate stainless steel rectangular pipe.

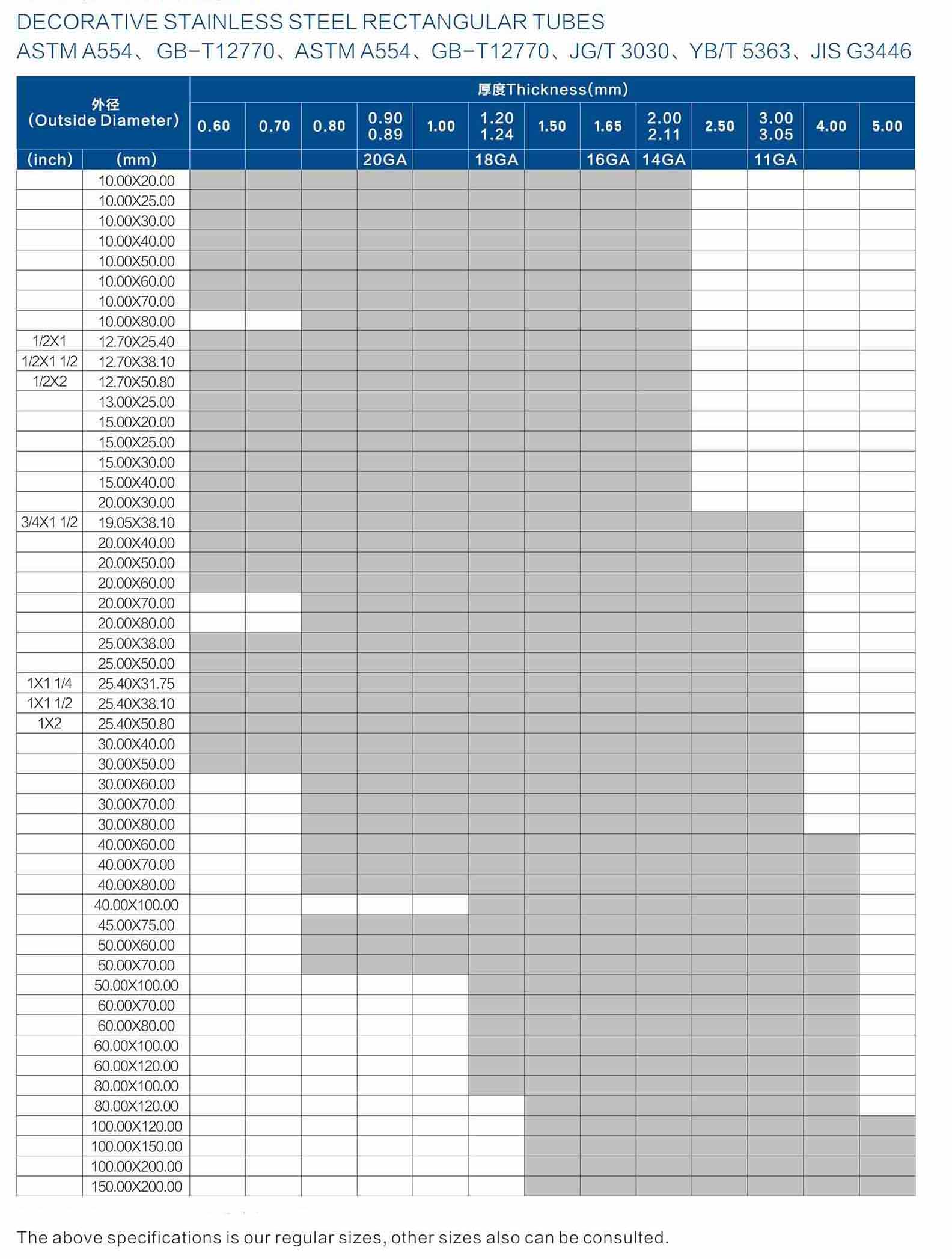

Regarding the specification of Stainless Steel 316 Rectangular Pipes, the outside diameter can range from 6.00 mm OD up to 914.4 mm OD, making it versatile for various industrial applications.

Each specification contributes to the pipe's overall performance, ensuring a durable and reliable solution for a range of industrial uses.

In addition to the varied outside diameters, the thickness of the Stainless Steel 316 Rectangular Pipes also offers a wide range, from as thin as 0.3mm to as thick as 50mm, catering to diverse industrial requirements.

This thickness variation not only influences the mechanical strength of the pipes but also their welding techniques and surface finishes. The material composition of the SS 316, an alloy of chromium, nickel, and molybdenum, contributes to its enhanced resistance against corrosion, making it suitable for numerous demanding applications.

The choice of welding technique depends on the pipe thickness, while the surface finish, often a result of post-welding treatment, can range from matt to high gloss, aligning with the specific aesthetic and functional needs of the industry.

Download the size list of Vinmay

A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

Offering flexibility in installation and design, the length of Stainless Steel 316 Rectangular Pipes can be customized to suit various industrial applications, with standard lengths typically ranging from 6 meters to 12 meters. Depending on the specific industrial application, customization of length can significantly enhance the functionality and efficiency of the pipe installation.

In the realm of 316 Stainless Steel Rectangular Tubes, it's critical to consider various tolerances. These tolerances encompass aspects such as twist tolerances, straightness tolerance, and maximum radii of corners.

Understanding these specifications is paramount for ensuring precision, quality, and consistency in application and performance.

Adhering to stringent standards, the 316 stainless steel rectangular tube is manufactured with specific twist tolerances to ensure superior quality and precision. This involves:

These procedures underline our commitment to delivering top-tier products.

Just as critical as twist tolerances, the straightness tolerance of the 316 stainless steel rectangular tube plays a significant role in ensuring the quality and precision of the final product.

Straightness tolerance evaluation is performed through rigorous material composition analysis, mechanical properties assessment, surface finish comparison, and application suitability analysis, ensuring the tube's proficient performance in a myriad of applications.

The specification tolerances for the maximum radius of corners in 316 stainless steel rectangular pipes play a pivotal role in determining their suitability for various industrial applications. These include:

These factors collectively contribute to the overall robustness and dependability of the stainless steel rectangular pipes.

The surface finish of the 316 stainless steel rectangular tube significantly impacts its functional attributes and aesthetic appeal. The three primary surface finishes include polished, mill, and brush finish, each with unique characteristics.

Polished rectangular tubing offers a reflective surface, mill finish provides a rougher, unpolished texture, and brush finish delivers a fine satin appearance, thereby catering to diverse application requirements.

The surface finish of a 316 Stainless Steel Rectangular Tube is a crucial factor that determines its aesthetic appeal and its resistance to environmental factors.

It is noteworthy to mention the different grit finishes available, which include 180, 240, 320, 400, and 600.

Each of these polished finishes offers a distinct level of smoothness and shine, impacting the tube's overall performance and suitability for various applications.

Offering an enhanced aesthetic appeal alongside increased durability, the 316 Stainless Steel Rectangular Tube is available in two polished grit finishes - 180 and 320. These finishes provide:

Each variant ensures a balance of aesthetics and performance, satisfying the desire for belonging in industrial spaces.

Building on the topic of 180 grit finish rectangular tubing, we now turn our focus to the surface finish of 316 Stainless Steel Rectangular Tubes, specifically polished rectangular tubing.

This finish, renowned for its surface durability and corrosion resistance, is highly suitable for various industrial applications.

The custom lengths cater to specific grit finish applications, providing a tailored solution for robust, enduring, and aesthetically pleasing stainless steel constructions.

Polishing 316 Stainless Steel Rectangular Tubes significantly enhances their corrosion resistance, making them ideal for various industrial applications. The grit finish benefits include:

This surface modification technique significantly boosts the tube's utility and performance.

The surface finish of 316 Stainless Steel Rectangular Tubes, particularly when polished, significantly enhances its corrosion resistance and aesthetic appeal, making it an ideal choice for various industrial applications.

A comparison of surface finishes reveals grit finish applications offer superior corrosion resistance benefits.

Additionally, customized lengths are available, catering to diverse needs. However, pricing variations may occur depending on the chosen finish and size specifications.

Continuing our exploration of surface finishes, it is crucial to discuss the grit finish of the 316 stainless steel rectangular tube, specifically its polished variant, due to its significant impact on both aesthetic appeal and corrosion resistance.

In the realm of stainless steel applications, the mill finish on a 316 Stainless Steel Rectangular Tube is a noteworthy attribute, given its impact on the tube's aesthetic and functional qualities. This surface finish is the result of specific manufacturing processes and is characterized by its dull, matte appearance. It not only provides a smooth, uniform look but also enhances the corrosion resistance of the material, an essential factor for applications exposed to harsh environments.

Customization options are available, considering different weight calculations, which allow for the adjustment of the tube's dimensions to meet specific project needs. Hence, the mill finish, while understated, plays a significant role in the performance and versatility of the 316 Stainless Steel Rectangular Tube.

Shifting focus to another surface finish, the brush finish on a 316 Stainless Steel Rectangular Tube provides a uniquely textured appearance while maintaining the material's inherent durability and corrosion resistance. This finish offers a myriad of benefits further enhancing the product's application versatility.

You may also like: Comparisons of hairline finish, brushed finish and satin finish stainless steel tube

Exploring the World of Polished Stainless Steel Round Tubes

The superb corrosion resistance of 316 stainless steel, particularly against harsh marine environments, is primarily attributed to its molybdenum-bearing alloy composition. This chemical composition makes 316 stainless steel exceptionally resistant to corrosive environments, hence its preference in marine, chemical, and industrial applications.

Several welding techniques can be employed on 316 stainless steel rectangular tubes. These techniques influence the tube's strength, corrosion resistance, and overall performance. Among these methods, gas tungsten arc welding and shielded metal arc welding are widely used due to their effectiveness in maintaining the alloy's strong corrosion resistance.

Customization options for 316 stainless steel rectangular tubes are extensive, ranging from desired lengths, widths, and wall thicknesses. This flexibility allows for the creation of tailored solutions for various applications, enhancing the tube's utility in diverse industrial settings.

In terms of pricing comparison, 316 stainless steel often ranks higher due to its superior corrosion resistance and durability. However, cost should be weighed against long-term benefits like reduced maintenance and replacement costs.

Lastly, account security is paramount when placing orders or accessing customization options online. Reputable steel suppliers invest in secure platforms to protect client data, ensuring safe transactions and preserving customer trust.

Understanding the pricing structure for Stainless Steel Rectangular Tubes is crucial, as it significantly varies based on factors such as size, wall thickness, and the specific type of stainless steel used.

A detailed pricing comparison reveals:

1. The cost of a standard-sized tube typically ranges from $50 to $200 per piece. This price can significantly increase for larger sizes or customizations.

2.Customization options, such as specific lengths or finishes, can also impact the cost. For instance, tubes with a polished finish are usually more expensive due to the additional processing required.

3. Account security is vital when making online purchases. Reputable suppliers ensure secure payment gateways, protecting the customer's financial information.

4. Order modifications, such as changing the tube size or quantity after placing an order, may affect the final price. It's important to carefully review all details before finalizing the purchase.

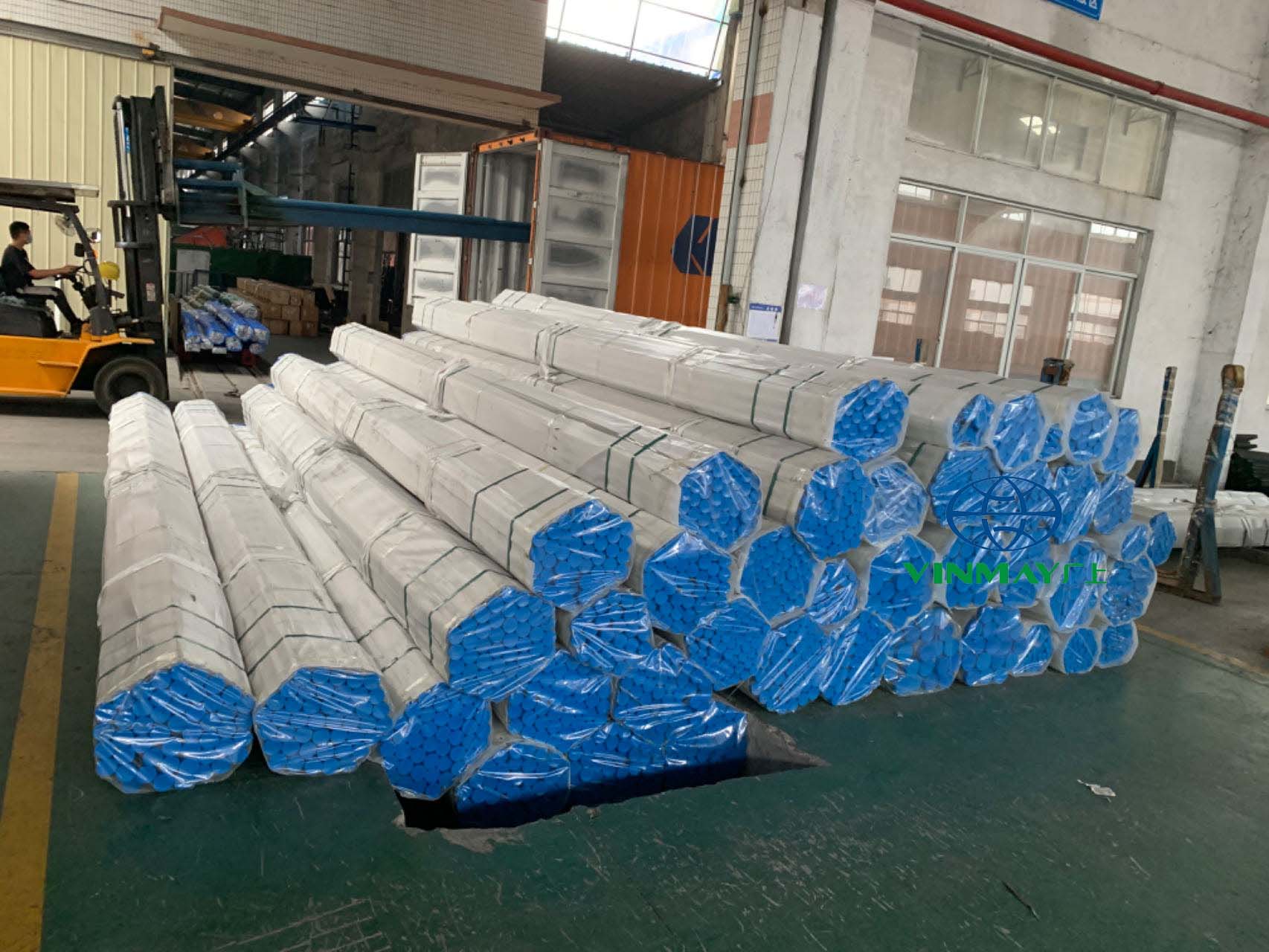

The packaging of 316 Stainless Steel Rectangular Tubes is an integral process to ensure product integrity during transportation and storage. It involves careful consideration of packing materials and end protection to prevent any physical damage or contamination.

Let's examine the critical aspects of packaging such as the selection of packing materials, packing methods, and end protection strategies for stainless steel rectangular tubes.

The packaging of 316 Stainless Steel Rectangular Tubes is a critical process that ensures product protection during transit.

This involves the use of robust wooden pallets or cases, along with waterproof paper and plastic coverage for added security.

These materials not only safeguard the tubes from physical damages but also from environmental factors, ensuring the product reaches the end-users in optimal condition.

In terms of packaging for the 316 Stainless Steel Rectangular Tube, it is meticulously secured within wooden pallets or cases to ensure its safe transportation and preservation of quality. This packaging solution provides:

Beyond the use of wooden pallets or cases, waterproof paper serves as a crucial component in the packaging process of the 316 Stainless Steel Rectangular Tube. This waterproofing method enhances corrosion resistance, ensuring material durability for diverse industrial applications. These tubes, available in custom lengths, are secured using waterproof paper to maintain their pristine condition.

Ensuring the highest level of protection for 316 Stainless Steel Rectangular Tubes during transportation, plastic coverage serves as a robust packing technique. This method offers:

Ultimately, plastic coverage enhances the product's marine durability and architectural appeal.

To adequately safeguard the integrity of the 316 Stainless Steel Rectangular Tube during transportation and storage, robust end protection measures are incorporated into the packaging process. These measures primarily focus on surface protection and rust prevention, ensuring the tube's impact resistance and adherence to durability standards.

Design considerations are taken into account during custom fabrication of the end protection, ensuring it fits the tube perfectly. Maintenance tips are provided for long term preservation of the tube, aiding in maintaining its structural integrity.

| End Protection Aspects | Description |

|---|---|

| Rust Prevention | Coatings applied to prevent oxidation |

| Impact Resistance | Protective caps or plugs to absorb shocks |

These strategies prove crucial for industry applications where the tube's durability and performance are paramount.

The process of marking stainless steel pipes is an integral part of the manufacturing process, serving as an essential means of identification. This system incorporates various details such as Nominal Pipe Size (or Nominal Bore), Schedule (referencing Wall Thickness), Specification, Grade, and the Method of Manufacture,Heating number

These markings allow for efficient categorization and accurate usage of the pipes in different industrial applications.

The processing of 316 Stainless Steel Rectangular Tube involves several key stages. These include structural cutting and tubular cutting, wherein precise measurements and techniques are crucial to maintain the integrity of the material.

The process then moves onto production cutting and structural polishing, which are significant in ensuring the tube's functional excellence and aesthetic appeal.

Structural cutting, a critical process in the fabrication of 316 Stainless Steel Rectangular Tubes, involves precise machining techniques to ensure the product meets exact design specifications. This process is paramount to the structural fabrication and involves a series of steps:

This intricate process guarantees the production of high-quality 316 Stainless Steel Rectangular Tubes.

After the initial structural cutting and welding of the 316 Stainless Steel Rectangular Tubes, the next crucial phase is Tubular Cutting, a detailed process integral to the production of these stainless steel products. Tubular cutting, a key part of tubular fabrication, involves precise metal cutting to achieve custom lengths, ensuring the tubes are suited for various industrial applications.

| Key Aspect | Description |

|---|---|

| Technique | Precision metal cutting |

| Purpose | Produce custom lengths for diverse applications |

This process not only dictates the tube's functionality but also its durability and corrosion resistance, significant attributes of stainless steel products. Accuracy is paramount in this phase, as any inaccuracies could compromise the intended application of the tube, leading to potential operational pitfalls or safety hazards.

In the realm of Stainless Steel Rectangular Tube Processing, Production Cutting plays an indispensable role, frequently involving intricate techniques for precisely cutting the stainless steel tube material to meet specific industrial needs.

Moving beyond the precision of Production Cutting, the process of Structural Polishing enhances the aesthetic and functional attributes of Stainless Steel Rectangular Tubes. This procedure, essential in the metal fabrication industry, works hand in hand with structural design principles to refine surface finishes, emphasizing material strength and resilience.

Various polish techniques are employed, ranging from abrasive to electro-polishing, each tailored to specific application requirements. The result is a smooth, reflective surface that not only improves the tube's visual appeal but also increases its resistance to corrosion and other environmental impacts.

This meticulous attention to detail during polishing ensures that the stainless steel rectangular tubes meet the highest standards of quality and functional performance.

The application of 316 Stainless Steel Rectangular Tubes spans various industries due to its versatile properties.

Its high strength and excellent corrosion resistance make it well-suited for sectors such as natural gas, petroleum, aerospace, food and beverage, and other industrial applications.

Furthermore, it maintains its properties even in cryogenic or high temperatures, making it ideal for environments with extreme conditions.

Utilizing 316 stainless steel rectangular tubes in the natural gas industry has proven advantageous due to their high strength, excellent corrosion resistance, and durability even in harsh environments.

Just as their robustness and corrosion resistance make 316 stainless steel rectangular tubes ideal for natural gas applications, these properties also significantly benefit the petroleum and oil industry.

The tubes' corrosion resistance is particularly valuable in petroleum applications where exposure to harsh chemicals and high temperatures is a regular occurrence. This resistance prolongs the tube's lifespan, reducing maintenance and replacement costs.

In terms of industrial uses, these tubes are utilised in a myriad of petroleum extraction and processing equipment. They are available in custom lengths to meet specific project requirements.

When it comes to price comparison, despite the higher initial cost, their durability and longevity make them a cost-effective solution in the long run, particularly in high-demand petroleum applications.

In the aerospace industry, 316 stainless steel rectangular tubes serve a vital role due to their high strength, excellent corrosion resistance, and ability to maintain their properties at both cryogenic and high temperatures.

As evident in the aerospace industry, the 316 stainless steel rectangular tube also proves integral within the food and beverage sector, showcasing similar attributes of strength, corrosion resistance, and customization options.

These tubes are utilized extensively in the production, packaging, and distribution phases, meeting high sanitation standards due to their non-porous and smooth surfaces. This ensures food safety, a key concern in the beverage industry.

Additionally, the inherent strength of these tubes makes them excellent for packaging requirements, withstanding high pressure and temperatures without compromising integrity. The stainless steel benefits include sustainability and cost-effectiveness, which enhance the long-term operations of food and beverage facilities.

Recommend:

What Is Food Grade 304 Stainless Steel?

Frequently used in industrial applications, 316 stainless steel rectangular tubes exhibit unparalleled versatility due to their robustness, corrosion resistance, and high-temperature tolerance. They are integral to industries such as oil and gas, construction, and manufacturing, where durability and reliability are paramount.

Beyond its widespread industrial applications, the 316 stainless steel rectangular tube also proves invaluable in cryogenic environments due to its exceptional properties. The material properties of this grade of stainless steel, including high ductility, strength, and corrosion resistance, make it ideal for cryogenic applications.

These applications often require a high degree of customization, and the 316 stainless steel rectangular tube can be easily tailored to specific usage requirements. Its suitability for various welding techniques further enhances its versatility.

While its price point may be higher compared to other materials, a comparison based on longevity, performance at extreme temperatures, and low maintenance needs, shows that it provides excellent value for money.

In the realm of architectural applications, the 316 stainless steel rectangular tube is highly prized for its exceptional durability, aesthetic appeal, and resistance to harsh environmental conditions.

The 316 stainless steel rectangular tube is highly valued in marine applications due to its superior resistance to corrosion, especially in harsh seawater conditions. These tubes, available in custom lengths, offer a cost-effective solution to the marine industry, providing both durability and reliability.

| Feature | Benefits |

|---|---|

| Corrosion resistance | Stays intact in harsh seawater conditions |

| Custom lengths | Meets specific application requirements |

| Pricing options | Offers affordability without compromising quality |

Their corrosion resistance makes them a preferred choice for various marine applications such as shipbuilding, offshore platforms, and desalination plants. Furthermore, we ensure account security for all our customers, providing a safe environment for transactions. Thus, the 316 stainless steel rectangular tube is an excellent choice for marine applications, offering a blend of durability, affordability, and account security.

While the 316 grade is widely recognized for its superior corrosion resistance, other grades of stainless steel also offer distinctive properties that are suitable for specific applications.

Particularly, the 304, 201, and 430 grades of stainless steel rectangular tubes exhibit unique characteristics in terms of strength, ductility, and resistance to oxidation and corrosion.

It is integral to understand these variations to select the appropriate grade for the desired application.

Diverse in its applications, 304 stainless steel rectangular tubing also offer a myriad of characteristics suitable for various industrial needs. These tubings provide a unique blend of material properties, including excellent corrosion resistance, making them highly coveted in many industries.

Beyond the popular 304 grade, another noteworthy category in the realm of 201 stainless steel rectangular tubing is the uniquely versatile and durable other grades, each offering its distinct set of characteristics and applications.

The manufacturing process of these tubes typically involves cold-forming, ensuring high structural integrity and durability. A variety of surface finishes are available, from the raw mill finish to a polished mirror finish, offering customization options to suit different aesthetic preferences.

These grades are renowned for their excellent corrosion resistance, making them ideal for industrial applications in harsh environments. Whether it's for architectural structures, automotive parts, or chemical processing equipment, the rectangular stainless steel tube of other grades is a reliable choice for those seeking superior strength and longevity.

In addition to the 201 and 304 grades, there are other varieties of stainless steel rectangular tubes, each possessing unique properties and applications, which cater to specific industrial requirements.

Discover More:

What is the difference between 201 and 304 stainless steel?

The difference between 316 and 316L stainless steel rectangular tubes lies in their welding techniques, material durability, tube dimensions, cost, and application versatility, with 316L offering lower carbon content and enhanced corrosion resistance.

The molybdenum content in 316 stainless steel plays a pivotal role in enhancing its corrosion resistance. By fortifying the alloy composition, molybdenum effectively mitigates corrosion mechanisms, making it an invaluable element in industrial usage.

Yes, due to its high temperature tolerance, 316 stainless steel rectangular tube can be used in high-temperature applications. The thermal expansion attributes offer structural benefits, supporting various industrial uses while withstanding heat effects.

The surface finish of a material like 316 stainless steel can significantly impact its application. Surface polishing and protective coatings enhance finish durability, ensuring application suitability across diverse environments by reducing wear and corrosion potential.

The production process involves shaping the raw materials into a tube, followed by cooling methods for hardening. It's monitored by quality control to ensure stainless steel tube standards, and production costs are analyzed for efficiency and cost-effectiveness.

Taking into account the comprehensive information provided, it is evident that the 316 stainless steel rectangular tube exhibits superior qualities such as high strength, excellent corrosion resistance, and adaptability to a wide range of temperatures, making it an ideal choice for various industrial applications.

In the conclusion summary, it is crucial to highlight the practical applications of this versatile material, from aerospace to the food and beverage industry, to cryogenic and marine applications. Case studies further illustrate the value of this product, with industry impact being most noticeable in sectors requiring durable, resistant materials capable of withstanding extreme conditions.

Future trends indicate a continued reliance on 316 stainless steel rectangular tubes, given the consistent high demand from various industries. As technology advances, we can expect to see an increase in the customization options available, potentially enhancing the product's adaptability even further.

This thorough analysis underscores the significant role of the 316 stainless steel rectangular tube in modern industry, its versatility and strength positioning it as a vital resource in an ever-evolving technological landscape. The continuous development and implementation of this material undoubtedly ensure its prominence in future industry advancements.