Stainless steel square tubing is a versatile and durable material that is commonly used in various industries and applications. Its sleek and modern appearance adds an aesthetic appeal to any structure or project. However, like any other material, stainless steel square tubing requires regular maintenance to ensure its longevity and performance.

In this discussion, we will explore essential maintenance tips that will help you keep your stainless steel square tubing in pristine condition. From cleaning techniques to preventing corrosion, removing scratches, and maintaining outdoor structures, we will delve into the best practices that will keep your stainless steel square tubing looking as good as new.

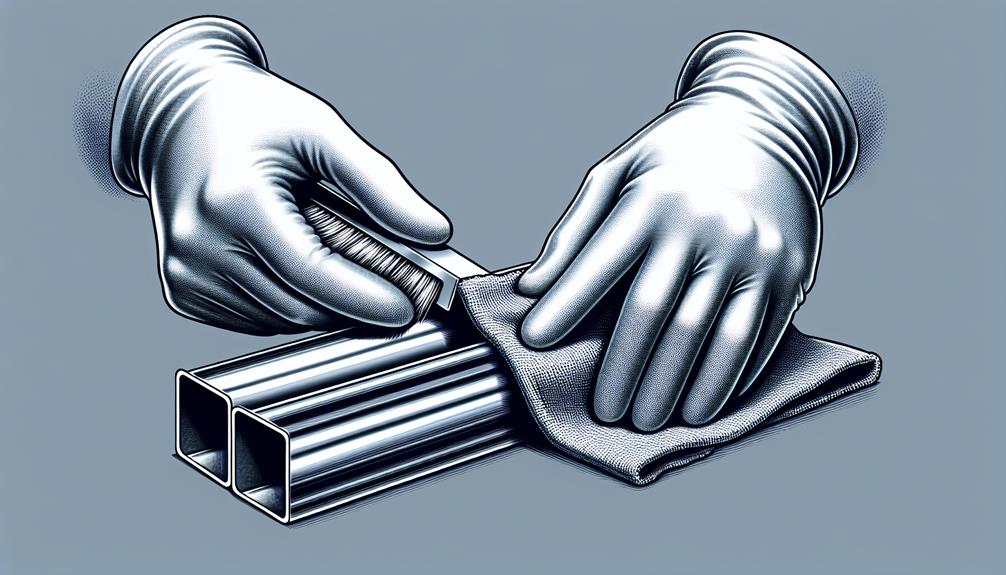

To maintain the cleanliness and appearance of stainless steel square tubing, it is recommended to follow a rigorous cleaning regimen using specialized cleaning agents and techniques that are specifically designed for stainless steel surfaces.

Stainless steel is known for its durability and resistance to corrosion, but it is not completely immune to stains and dirt buildup. Regular cleaning is essential to remove any surface dirt, fingerprints, or smudges that may accumulate over time.

When it comes to stain removal and deep cleaning techniques for stainless steel square tubing, there are several options available. One effective method is to use a mild detergent or soap solution with warm water and a soft cloth or sponge. This gentle yet effective cleaning solution can help remove most stains and grime without causing damage to the stainless steel surface.

For more stubborn stains or discoloration, specialized stainless steel cleaning agents or polishes can be used. These products are formulated to penetrate deep into the surface and remove tough stains, while also providing a protective barrier against future damage.

It is important to always follow the manufacturer's instructions when using any cleaning agents or polishes on stainless steel square tubing. Additionally, avoid using abrasive materials or harsh chemicals, as they can scratch or damage the surface.

Recommended: Advantages of Stainless Steel Square Tubing

Regular maintenance is crucial in preventing corrosion on stainless steel square tubing to ensure its longevity and optimal performance. Corrosion can occur when the protective layer of the stainless steel is compromised, exposing it to external elements. To protect stainless steel square tubing from corrosion, several techniques can be employed.

Firstly, applying a protective coating or finish can act as a barrier between the stainless steel and the environment. This can be done through methods such as painting, powder coating, or electroplating. These coatings provide an additional layer of protection, preventing moisture and corrosive substances from reaching the stainless steel surface.

Secondly, regular cleaning is essential to remove any contaminants that may promote corrosion. Using mild soapy water and a soft cloth, gently clean the stainless steel square tubing, ensuring to remove any dirt, grime, or salt deposits. Avoid using abrasive cleaners or tools that can scratch the surface, as these can compromise the protective layer.

Lastly, inspecting the stainless steel square tubing regularly is vital to identify any signs of corrosion or damage. Look for discoloration, pitting, or rust spots, and address them promptly to prevent further corrosion.

By implementing these corrosion prevention techniques and protecting stainless steel square tubing, you can ensure its longevity and maintain its optimal performance. Regular maintenance and careful monitoring are key to preserving the integrity of stainless steel square tubing.

| Corrosion Prevention Techniques | Protecting Stainless Steel Square Tubing |

|---|---|

| Apply protective coating or finish | Regular cleaning to remove contaminants |

| Inspect regularly for signs of corrosion or damage | Avoid using abrasive cleaners or tools |

Removing scratches and marks from stainless steel square tubing requires careful attention and the use of appropriate techniques to ensure a smooth and pristine surface. Stainless steel is known for its durability and resistance to corrosion, but over time, it can develop scratches and marks that mar its appearance. To restore the stainless steel tubing to its original condition, several scratch removal methods and buffing techniques can be employed.

One effective method for removing scratches from stainless steel square tubing is through abrasive rubbing. This involves using a fine-grit sandpaper or abrasive pad to gently rub the scratched area in the direction of the grain. It is important to maintain consistent pressure and avoid applying excessive force, as this could further damage the surface.

Another technique commonly used is the application of a stainless steel scratch removal product. These products typically contain a mild abrasive compound that can effectively remove light scratches and marks. They are applied using a soft cloth or sponge, and the surface is gently buffed in a circular motion until the scratches disappear.

In more severe cases, professional help may be required. Stainless steel fabrication experts have access to specialized equipment and buffing techniques that can restore heavily scratched or marked stainless steel square tubing to its original condition. These professionals have the expertise and knowledge to choose the appropriate buffing compound and technique for each specific situation, ensuring a flawless result.

Recommended: Stainless Steel Square Tube Manufacturers

Polishing and shining techniques are essential for achieving a flawless and mirror-like finish on stainless steel square tubing, complementing the efforts made in removing scratches and marks. Properly polishing and shining stainless steel not only enhances its aesthetic appeal but also helps to protect it from corrosion and maintain its longevity. To achieve optimal results, it is important to follow the correct techniques and use appropriate maintenance products.

The table below provides an overview of recommended polishing and shining techniques for stainless steel square tubing:

| Technique | Description |

|---|---|

| Hand Polishing | Involves using a soft cloth or sponge with a stainless steel cleaner to gently rub the surface in a circular motion, removing any remaining marks or stains. |

| Machine Polishing | Utilizes a polishing machine with a buffing pad and a stainless steel polishing compound to achieve a high-gloss finish. This method is efficient for larger surface areas. |

| Electrolytic Polishing | A specialized technique that uses an electric current and a chemical solution to remove surface imperfections and enhance the shine of stainless steel. This method is best for intricate designs and hard-to-reach areas. |

| Acid Pickling | Involves using a chemical solution to remove oxide scales and impurities from the surface of stainless steel. It also restores the natural shine and improves corrosion resistance. |

When selecting maintenance products for polishing and shining stainless steel square tubing, it is important to choose those specifically designed for stainless steel care. These products are formulated to effectively remove dirt, stains, and fingerprints, while also providing a protective layer to prevent future damage and maintain the shine. It is recommended to follow the manufacturer's instructions and test the product on a small, inconspicuous area before applying it to the entire surface.

Learn More: Polished Stainless Steel Square Tubing

To ensure the longevity and optimal performance of outdoor stainless steel square tubing, including durable options like 304 stainless steel square tubing, it is crucial to implement effective maintenance practices that protect against environmental factors and minimize the risk of corrosion.

Outdoor stainless steel square tubing is constantly exposed to various weather conditions, such as rain, snow, and UV radiation, which can lead to rust and deterioration if not properly maintained.

One of the key maintenance tips for outdoor stainless steel square tubing is rust prevention. Applying a protective coating, such as a rust inhibitor or a clear sealant, can help create a barrier against moisture and prevent the formation of rust. Regularly inspecting the tubing for any signs of rust or corrosion and promptly addressing them is also essential to maintain its integrity.

Additionally, weatherproofing techniques can further enhance the durability of outdoor stainless steel square tubing. This includes ensuring proper drainage to prevent water accumulation, as well as using weather-resistant materials for any attachments or fixtures.

Regular cleaning with a mild detergent and a soft cloth or sponge is recommended to remove any dirt, debris, or pollutants that may accumulate on the surface and potentially cause damage.

Using regular household cleaning products to clean stainless steel square tubing is generally safe and effective. However, it is important to avoid abrasive cleaners and chlorine-based products, as they can cause corrosion and damage to the stainless steel surface.

Corrosion on stainless steel square tubing can be caused by various factors such as exposure to harsh chemicals, high humidity, and lack of proper cleaning and maintenance. Preventing corrosion requires regular cleaning and the use of corrosion-resistant coatings.

There are some DIY methods available for removing deep scratches on stainless steel square tubing, however, for professional scratch repair, it is recommended to consult with an expert who specializes in stainless steel maintenance.

Using a regular metal polish on stainless steel square tubing may not provide the desired shine. It is recommended to use a stainless steel polish specifically designed for this purpose. Proper cleaning steps should be followed to maintain the tubing's appearance.

Preventive measures for maintaining stainless steel square tubing in coastal areas include regular cleaning with mild detergent and water, applying a protective coating solution to prevent corrosion, and inspecting for any signs of damage or rust.

Blog Series:

In conclusion, maintaining stainless steel square tubing requires regular cleaning, corrosion prevention, scratch removal, and polishing techniques. By following these essential maintenance tips, the longevity and appearance of the tubing can be preserved.

It is crucial to ensure that outdoor stainless steel square tubing receives proper maintenance to withstand the elements. With expert care and attention, stainless steel square tubing can remain in optimal condition for extended periods, adding value and functionality to various applications.