316 stainless steel welded pipes are a reliable and versatile choice for applications requiring high corrosion resistance, strength, and durability. Their ability to withstand harsh environments and maintain their mechanical properties at high temperatures makes them indispensable in many industries.

ASTM A249 /EN10217-7 : Standard for Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubes.

ASTM A269 / EN10217-7: Standard for Seamless and Welded Austenitic Stainless Steel Tubing for General Service.

ASTM A213: Standard for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

ASTM A312 : Standard for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes.

ASTM A358 : Standard for Electric-Fusion-Welded Austenitic Chromium-Nickel Stainless Steel Pipe for High-Temperature Service and General Applications.

ASTM A554/EN10296-2: Standard for construction and ornamental purpose stainless steel pipe

ASTM A270/EN10357: Standard for food industry stainless steel pipe and tube

This sector involves chemical containers, pressure vessels, and industrial equipment.

Stainless Steel Pipe for water treatment purposes, woven or welded screens are utilized to filter water.

In the pulp and paper industry, these materials are employed in paper machines to prevent iron contamination.

The automotive industry relies on threaded fasteners, springs, and furnace components.

In the medical sector, they find applications in medical equipment and orthopedic implants.

Dental implants, orthodontic devices, and various dental instruments are essential in dental applications.

Semiconductor manufacturing depends on this material for equipment and cleanroom environments.

For food processing purposes, these materials are used in food preparation surfaces, equipment, and appliances.

The aerospace sector utilizes them in aircraft structures, fasteners, turbine blades, and exhaust systems.

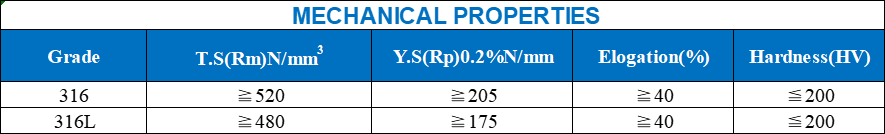

316L and 316 stainless steel welded pipe are two grades of stainless steel commonly used in many industrial applications. They are chosen for their excellent corrosion resistance and superior mechanical properties. The chemical content of these grades is the same, but the mechanical properties may differ slightly.

The following form will show about the chemical content, mechanical properties and standards of 316L and 316 stainless steel welded pipe

The "L" in 316L stainless steel indicates a lower carbon content, which is the primary distinction between 316L and 316 stainless steels. The reduced carbon content makes 316L softer than 316, affecting its machinability, weldability, and corrosion resistance.

316L stainless steel is particularly weld-friendly. It can be welded to other steels or metals without welding issues, allowing you to form the required shapes for your project. Conversely, 316 stainless steel is prone to weld decay, making the welded areas more susceptible to corrosion and potentially weakening the weld bond.

Both types of stainless steel are highly malleable, making them suitable for forming into various shapes without cracking or breaking. Once formed, they both offer excellent corrosion resistance and high tensile strength.

316L stainless steel is more resistant to corrosion than 316. While this difference might not be noticeable in everyday applications, 316L's superior weldability makes it the better option for environments where corrosion resistance is crucial. Welding 316 stainless steel necessitates annealing, whereas 316L remains effective against corrosion without additional steps.

If 316L has better corrosion resistance, why would anyone choose 316 stainless steel? Although the prices of the two types are usually comparable, 316 stainless steel generally possesses better mechanical properties. It has higher tensile strength, is harder, and is more ductile than 316L. When deciding between these steels, consider the specific requirements of your application.

304 stainless steel welded pipe is composed of 18% chromium and 8% nickel, while 316 stainless steel welded pipe contains 16% chromium, 10% nickel, and 2% molybdenum.

304 stainless steel is the most commonly used formula in both industrial and consumer applications. Comprising chromium and nickel alloys, 304 offers excellent resistance to various forms of corrosion. Additionally, it is widely favored for numerous applications because it does not require post-weld annealing—a reheating and slow cooling process that relieves stress in metals after exposure to high heat.

316 stainless steel is chemically similar to 304 but includes molybdenum, which significantly enhances its corrosion resistance. Like 304, the 316 formula does not require post-weld annealing.

316L stainless steel is nearly identical to 316, with the primary difference being its lower carbon content. This reduced carbon content further improves corrosion resistance, and like 304 and 316, 316L does not require post-weld annealing.

Learn More:

what is the difference between 201 and 304 stainless steel

You may also like: