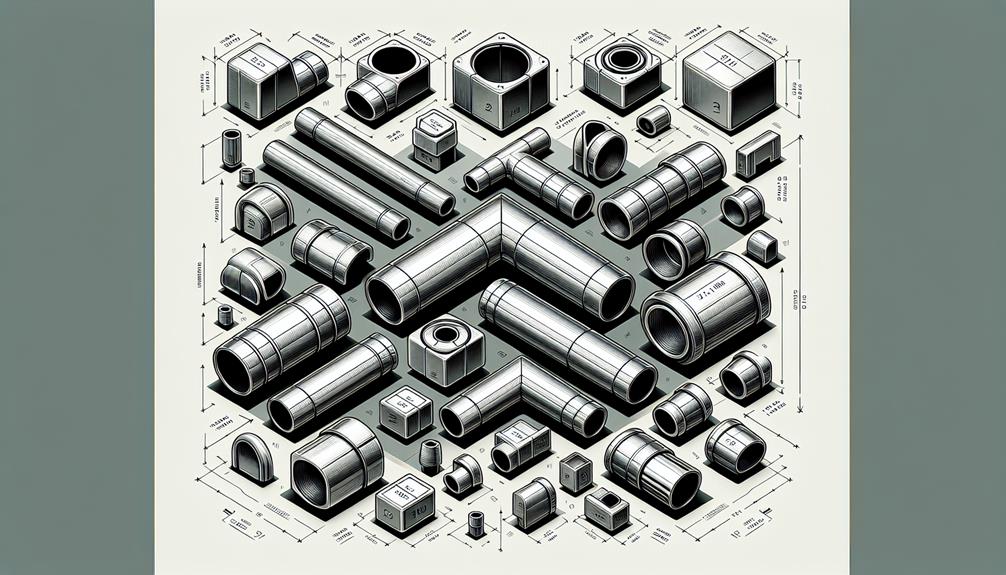

Stainless steel square tube fittings play a crucial role in various industries, providing a reliable and durable solution for connecting square tubing. These fittings are meticulously engineered to ensure seamless integration and optimal functionality.

From stainless square tubing connectors to square handrail fittings, the range of options available caters to a diverse array of applications. Whether it's for architectural, construction, or industrial purposes, stainless steel square tube fittings are designed to withstand the test of time and offer unparalleled strength.

In this discussion, we will explore the different types of fittings available, their uses, and the importance of selecting the right fittings for specific needs. So, let's embark on a journey that unveils the world of stainless steel square tube fittings and discover how they contribute to the success of countless projects.

When it comes to fittings for stainless steel square tubes, there are several options available.

These include:

Each of these fittings serves a specific purpose and can be used to create a variety of structures and configurations with stainless steel square tubes.

3-way corner fittings are an essential component for connecting and securing square tubing in stainless steel structures. These fittings provide a reliable and efficient solution for creating stable joints at corners, allowing for the construction of robust and durable frameworks.

3-way corner fittings are designed to fit perfectly with square tubing, ensuring a tight and secure connection. They are typically made from high-quality stainless steel, which offers excellent corrosion resistance and ensures long-lasting performance in various environments.

These fittings can be easily installed and adjusted, providing flexibility in design and assembly. With their precise dimensions and sturdy construction, 3-way corner fittings offer the control and stability required for demanding applications where structural integrity is paramount.

The next type of fitting to be discussed about stainless steel square tubing is the 3-Way Flush 'T' Fitting, which serves as a crucial component for creating secure and stable joints at corners. This fitting is designed to connect three pieces of square tubing at a 90-degree angle, allowing for the creation of complex structures with precision and control. The 3-way Flush 'T' Fitting is manufactured from high-quality stainless steel, ensuring durability and resistance to corrosion. It features a flush design, which means that the fitting sits flat against the tubing, providing a seamless appearance and minimizing any potential obstructions. The table below provides a visual representation of the dimensions and specifications of the 3-way Flush 'T' Fitting for stainless steel square tubing.

The 90 Degree Elbow Fitting for square tubing is an essential component in the assembly of stainless steel square tube structures, ensuring seamless and secure connections at angles. This type of fitting allows for a 90-degree change in direction, making it ideal for creating corners or turns in a square tube system.

Here are five key features and benefits of Degree Elbow Fittings:

When it comes to creating angled connections in stainless steel square tube assemblies, Degree Elbow Fittings are the go-to choice for their reliability, durability, and ease of use.

Anchorage flanges for square tubing are critical components in stainless steel square tube assemblies. They provide secure and reliable support for structural connections. These flanges are designed to anchor square tubing securely in place, ensuring stability and preventing any movement or displacement. Made from high-quality stainless steel, these flanges offer excellent corrosion resistance and durability, making them suitable for various applications in demanding environments.

Anchorage flanges are available in different sizes and configurations to accommodate various square tubing dimensions and installation requirements. They feature a square plate with pre-drilled holes that align with corresponding holes on the square tubing, allowing for easy attachment using bolts or screws. Once installed, the flanges provide a solid anchor point for the square tubing, ensuring that it remains in position and can withstand the applied loads.

When selecting anchorage flanges for square tubing, it is essential to consider factors such as load requirements, environmental conditions, and compatibility with the square tubing material. Proper installation and regular inspection of these flanges are essential to maintain the integrity and stability of the square tube assemblies.

Continuing the exploration of stainless steel square tube fittings, the next subtopic focuses on the various types of connector fittings available for square tubing. Connector fittings play a crucial role in joining square tubes securely and efficiently.

Here are five types of connector fittings commonly used:

With a range of connector fittings available, users have control over their square tube assembly, ensuring a secure and durable structure.

Square Tube End Socket is a crucial type of fitting used in stainless steel square tube assemblies. It plays a vital role in providing structural integrity and stability to the assembly by securely connecting the square tubes at their ends.

The end socket is designed with precision to ensure a tight and secure fit, minimizing any potential movement or misalignment of the tubes. This fitting is typically made from durable and corrosion-resistant stainless steel, ensuring long-lasting performance in various environments.

The square tube end socket is available in different sizes and configurations to accommodate different square tube dimensions and assembly requirements. Its design and construction make it suitable for a wide range of applications, including architectural, industrial, and construction projects.

Proper selection and installation of the square tube end socket are essential to ensure the overall strength and stability of the stainless steel square tube assembly.

A flange canopy for square tubing is an essential fitting used in stainless steel square tube assemblies to provide support and stability. It is designed to be mounted on top of the square tubing, creating a secure connection and preventing any movement or displacement. The flange canopy is typically made of stainless steel, ensuring durability and resistance to corrosion.

Here are five key features of a flange canopy for square tubing:

The next important fitting to discuss in the context of stainless steel square tube assemblies is the flat end cap for square tubing.

As the name suggests, the flat-end cap is designed to provide a secure and finished end to square tubing. It is made from stainless steel, ensuring durability and resistance to corrosion.

The flat-end cap is precision-engineered to fit seamlessly onto the end of the square tubing, providing a clean and professional look. Its installation is straightforward and requires no additional tools or equipment.

This fitting is commonly used in various applications, such as architectural designs, handrails, and furniture. The flat-end cap not only enhances the aesthetic appeal of the square tubing but also offers protection against moisture, dirt, and debris.

The Square Tube Footrail Bracket is an essential fitting for stainless steel square tube assemblies, providing structural support and stability while maintaining a sleek and elegant aesthetic. This bracket is designed to securely hold the square tube in place, ensuring that it remains level and secure.

Here are five key features of the Square Tube Footrail Bracket:

Continuing our exploration of fittings for stainless steel square tube assemblies, we now turn our attention to the Square Tube Handrail Bracket, a crucial component that ensures the secure and stable installation of handrails while maintaining the sleek and sophisticated aesthetic of the overall assembly.

The Square Tube Handrail Bracket is designed to provide a strong and durable connection between the handrail and the square tube. It is typically made from high-quality stainless steel, ensuring corrosion resistance and longevity.

The bracket features a square shape that matches the square tube, allowing for a seamless and precise fit. It is engineered with precision to provide maximum strength and stability, minimizing any potential movement or wobbling of the handrail.

The Square Tube Handrail Bracket offers control over the installation process, giving users the confidence that their handrails will remain securely in place, providing safety and support for users while enhancing the overall visual appeal of the square tube assembly.

To further explore the types of fittings for stainless steel square tube assemblies, we now delve into the crucial role of Stainless Steel Handrail Support. The handrail support is an essential component in ensuring the stability and safety of a stainless steel handrail system.

Here are five key points to consider:

With these key features, stainless steel handrail supports provide a robust and visually pleasing solution for securing stainless steel square tube handrail assemblies.

Building upon the discussion of Stainless Steel Handrail Support, we now shift our focus to the crucial component known as the Lateral Anchorage Flange, which plays a pivotal role in the structural integrity of stainless steel square tube assemblies.

The Lateral Anchorage Flange is a type of fitting that is specifically designed to provide lateral support and anchorage for square tube structures. This flange is typically made from stainless steel, ensuring durability and resistance to corrosion.

It is installed at the end of the square tube, where it connects to other tubes or structural elements. The Lateral Anchorage Flange is designed to securely hold the square tube in place, preventing any lateral movement or displacement.

This critical fitting ensures the stability and strength of the entire assembly, making it an essential component for any stainless steel square tube structure.

The Square Tube Adjustable Flush Angle is a vital fitting used in stainless steel square tube structures to provide precise and customizable angular connections. This fitting allows for adjustments in the angle of the square tube, ensuring a flush and seamless connection between the two tubes. It is commonly used in applications where precise alignment is required, such as in architectural designs, furniture construction, and industrial frameworks.

The Square Tube Adjustable Flush Angle offers several advantages, including:

Recommended: Advantages of Stainless Steel Square Tubing

The discussion of the stainless square tubing connector will focus on three main points:

The STC, or Stainless Square Tubing Connector, is a versatile and efficient solution for creating structures using square profiles, with the added convenience of easy assembly and no need for screws or fasteners. This connector consists of two parts made out of polyamide (PA) based technopolymer, available in black or grey color with a matte finish. It can be reinforced with zinc-plated steel or stainless steel for added strength and durability.

The STC comes in various standard executions, including two-way, three-way, and four-way connectors, allowing for flexibility in design and construction. The maximum limit static load for each arm of the connectors is provided, ensuring safety and reliability.

The STC is an excellent choice for those seeking control over their structures, with precise and reliable connections.

The STE, or Stainless Square Tubing Expander Connector, is a highly effective and reliable solution for joining square profiles together, providing unparalleled strength and stability without the need for additional screws or fasteners. The connector consists of two parts connected by pins housed in special counter-seats. Inside the connector, there are two cavities for housing a hexagonal-head screw or nut. When the screw or nut is tightened, the tapered shape of the cavity exerts pressure on the inner walls of the tube, ensuring a strong connection. The level of tensile strength depends on factors such as tube dimensional tolerances, roughness of the tube inner surfaces, and tightening torque applied. This connector allows for easy assembly by simply positioning it inside the tube. Additionally, alternative assembly options using screws or nuts are available.

Assembly Options:

After understanding the design and functionality of the Stainless Square Tubing Expander Connector in the previous subtopic, we can now explore the crucial installation advice for connecting square tubes using this innovative and reliable connector.

When it comes to stainless steel square handrail fittings, there are a few key points to consider.

These include the post-base plate, which provides stability and support for the handrail system.

The post cover plate adds a finishing touch to the posts, while the 90-degree elbow allows for smooth changes in direction.

Additionally, the in-line flush joiner and tee joiner are essential for connecting and securing handrail sections.

Each of these fittings plays a crucial role in creating a strong and aesthetically pleasing stainless steel square handrail system, especially when meticulously selected for their durability and design. Explore our diverse collection of square tube fittings for stainless steel handrails to elevate your railing project with both strength and style.

An essential component of stainless steel square handrail fittings is the post base plate. The base plate is designed to securely fasten the balustrade post to flat surfaces while providing a clean and aesthetically pleasing appearance. It is commonly used as a base plate for balustrade posts and is intended to be welded onto the post and fixed to flat surfaces to hold the post in place. Once fastened, the cover can be placed over the base plate to hide the fixings and create a nice, clean look.

The post-base plate serves several important functions. First, it securely fastens the balustrade post to flat surfaces, ensuring that the handrail system is stable and secure. It also provides stability and support for the handrail system, ensuring that it can withstand the weight and pressure applied to it. Additionally, the base plate ensures a strong and durable connection between the post and the surface, reducing the risk of the post becoming loose or unstable over time.

In addition to its functional benefits, the post-base plate also contributes to the overall visual appeal of the handrail system. By creating a seamless and visually appealing finish, the base plate enhances the aesthetic quality of the balustrade. Furthermore, the base plate allows for easy installation and maintenance of the handrail system, making it a convenient and practical component to work with.

The post cover plate is an integral component of stainless steel square handrail fittings. It serves to provide a sleek and polished finishing touch to the balustrade post while concealing any visible fixings.

Designed to be used in conjunction with the base plate, the post cover plate is commonly used as a base plate for balustrade posts. It is welded onto the post and fixed to flat surfaces to hold the post in place.

Once the base plate is fastened, the cover plate is placed over it to hide the fixings and create a clean and seamless look.

Made from stainless steel with a mirror polish finish, the post cover plate enhances the overall aesthetics of the handrail system. It ensures a visually appealing and controlled appearance.

Continuing our exploration of stainless steel square handrail fittings, the next subtopic to be examined is the degree elbow, a crucial component in the construction of functional and visually appealing handrail systems.

The 90 Degree Elbow is commonly used in handrail systems and is designed to be used in conjunction with stainless steel tubes and other handrail fittings. Here are five key points to emphasize the importance and features of the degree elbow:

The degree elbow plays a vital role in creating sturdy and aesthetically pleasing handrail systems, offering both functionality and visual appeal.

The In-line Flush Joiner is an essential component of stainless steel square handrail fittings, serving a crucial role in the construction of functional and visually appealing handrail systems. Designed to be used in conjunction with Stainless Steel tubes and other Handrail Fittings, the In-line Flush Joiner enables the creation of handrails of all shapes and sizes.

This fitting is specifically designed to join two sections of stainless steel square tube in a seamless and flush manner, without any visible gaps or irregularities. Its precise construction ensures a secure and stable connection, providing structural integrity to the handrail system.

The In-line Flush Joiner offers a sleek and streamlined appearance, enhancing the overall aesthetic of the handrail while maintaining its functionality. With its technical design and precise construction, this fitting allows for precise control over the handrail system, ensuring a safe and reliable solution for various applications.

A crucial component in stainless steel square handrail fittings, the Tee Joiner plays a vital role in the construction of functional and visually appealing handrail systems. Designed to be used in conjunction with stainless steel tubes and other handrail fittings, Tee Joiners allow for the creation of handrails of various shapes and sizes.

Here are five key features and benefits of Tee Joiners:

The 90-degree Tee Joiner is an essential component in stainless steel square handrail fittings. It serves as a crucial element in the construction of functional and visually appealing handrail systems.

This particular joiner is designed to create a 90-degree angle in the handrail. This allows for smooth transitions and secure connections between sections of stainless steel tubes.

It is specifically engineered to be used in conjunction with other handrail fittings, such as end caps, corner joiners, and brackets. This allows for the creation of handrails of various shapes and sizes.

The 90-degree Tee Joiner is made from high-quality stainless steel. This ensures durability, corrosion resistance, and a sleek aesthetic.

With its precise design and tight tolerances, the 90-degree Tee Joiner offers excellent stability and strength. This makes it an ideal choice for both residential and commercial applications.

An integral component in stainless steel square handrail fittings, the oblong flange with two holes is commonly utilized to create functional and aesthetically pleasing handrail systems of various shapes and sizes.

This versatile fitting allows for secure attachment of the handrail to walls or other surfaces, providing stability and support. The oblong shape provides a sleek and modern look, while the two holes offer flexibility in installation options.

Not only does the oblong flange with two holes offer a visually appealing design, but it also ensures the safety and durability of the handrail system. With its corrosion-resistant properties, this fitting is ideal for both indoor and outdoor applications.

Whether it's for residential or commercial use, the oblong flange with two holes is a reliable choice for creating sturdy and attractive handrail systems.

Corner Flange 2 Holes, an essential component in Stainless Steel Square Handrail Fittings, serve to create highly functional and visually appealing handrail systems, allowing for seamless integration with Stainless Steel Tubes and other fittings. These flanges are designed to provide sturdy support and stability to the handrail, ensuring the safety of users. With two holes, they offer installation flexibility, making them suitable for various handrail configurations. The flanges are made from high-quality stainless steel, which provides excellent strength, durability, and corrosion resistance.

To further understand the specifications and dimensions of Corner Flange 2 Holes, refer to the table below:

| Dimension (mm) | Material | Finish |

|---|---|---|

| 50 x 50 x 2 | 304/316 | Satin |

| 60 x 60 x 2 | 304/316 | Satin |

| 80 x 80 x 2 | 304/316 | Satin |

| 100 x 100 x 2 | 304/316 | Satin |

| 120 x 120 x 2 | 304/316 | Satin |

These precise dimensions ensure a perfect fit with the Stainless Steel Tubes, resulting in a professional and polished finish. The satin finish adds an elegant touch, making them suitable for both residential and commercial applications. With Corner Flange 2 Holes, you can achieve a secure and aesthetically pleasing handrail system that meets your exact needs.

With its crucial role in enhancing the functionality and aesthetics of handrail systems, the 37 Degree Wall Flange (Stainless Steel Square Handrail Fittings) emerges as a vital component, seamlessly integrating with Stainless Steel Tubes and other fittings while ensuring utmost durability and safety.

This specific type of flange, commonly used in handrail systems, is designed to be used in conjunction with Stainless Steel Tubes and other handrail fittings to create functional handrails of all shapes and sizes.

The 37 Degree Wall Flange offers several key features that make it an ideal choice for handrail systems:

The Square Flange 4 Holes (Stainless Steel Square Handrail Fittings) play an integral role in handrail systems, effectively complementing Stainless Steel Tubes and other fittings to create functional and aesthetically pleasing handrails.

These fittings are designed with four holes, allowing for secure attachment to various surfaces. The square shape of the flange provides stability and support, ensuring the handrail remains firmly in place.

Made from high-quality stainless steel, these fittings offer excellent corrosion resistance and durability, making them suitable for both indoor and outdoor applications. The four-hole design allows for flexible installation options, accommodating different angles and orientations.

With their precise engineering and sleek design, Square Flange 4 Holes add a professional and polished finish to any handrail system, providing both safety and style.

The Tapered Post Reducer, a key component of Stainless Steel Square Handrail Fittings, is utilized in Handrail Systems to create functional and precise handrails of various dimensions. This fitting plays a crucial role in connecting different sections of the handrail system, enabling a smooth transition between posts of different sizes.

Here are five key features of the Tapered Post Reducer:

Utilized in Handrail Systems alongside the Tapered Post Reducer, the Adjustable Rail Support Flat Top is a vital component of Stainless Steel Square Handrail Fittings. It provides a customizable and secure foundation for creating functional and aesthetically pleasing handrails of various sizes and shapes.

The Adjustable Rail Support Flat Top is designed to be used in conjunction with Stainless Steel Tubes and other Handrail Fittings. This combination creates sturdy and reliable handrail systems. It allows for easy adjustment and leveling of the handrail, making it suitable for installations on uneven surfaces or staircases.

With its flat top design, the Adjustable Rail Support Flat Top offers a sleek and modern appearance. This enhances the overall aesthetic appeal of the handrail. It is a versatile solution that ensures stability and control over the handrail system, meeting the demands of discerning customers.

The Perpendicular Joiner Flush Fit is a crucial component in the realm of Stainless Steel Square Handrail Fittings, playing a vital role in the creation of functional and diverse handrail systems. It is designed to connect two square handrail sections perpendicularly, ensuring a secure and seamless join.

Here are five key points about the Perpendicular Joiner Flush Fit:

The Perpendicular Joiner Flush Fit offers control and precision in creating robust and visually appealing square handrail systems. Its functionality, durability, and adaptability make it an essential fitting in the construction of modern handrails.

Stainless steel square tube fittings are widely employed in various industries for their durability, corrosion resistance, and versatility. These fittings are used in a range of applications where strength and reliability are required. Let's explore some of the common uses of stainless steel square tube fittings:

| Industry | Application |

|---|---|

| Architecture | Staircases, handrails, and balustrades |

| Construction | Structural supports, framework, and scaffolding |

| Manufacturing | Conveyor systems, assembly lines, and machinery |

| Automotive | Exhaust systems, roll cages, and chassis |

| Marine | Boat railings, ladders, and deck fittings |

| Food and beverage | Hygienic piping systems, tanks, and processing equipment |

In the architecture industry, stainless steel square tube fittings are popular for their aesthetic appeal and ability to withstand harsh weather conditions. They are commonly used in the construction of staircases, handrails, and balustrades. In construction, these fittings provide structural support, form the framework, and are used in scaffolding systems. Manufacturers rely on stainless steel square tube fittings for conveyor systems, assembly lines, and machinery due to their strength and durability. In the automotive industry, these fittings are used in exhaust systems, roll cages, and chassis to ensure safety and reliability. Marine applications include boat railings, ladders, and deck fittings, where the corrosion resistance of stainless steel is vital. Finally, the food and beverage industry utilizes these fittings for hygienic piping systems, tanks, and processing equipment to maintain sanitary conditions.

Stainless steel square tube fittings are distinct from other types of fittings due to their specific shape and material composition. They offer enhanced strength, durability, and corrosion resistance, making them ideal for applications requiring secure and long-lasting connections in square tube structures.

Stainless steel square tube fittings are designed specifically for use with square tubing, ensuring a precise and secure connection. While they may not be directly compatible with other tubing materials, adapters can be used to facilitate compatibility if needed.

Stainless steel square tube fittings are suitable for both indoor and outdoor applications. Their corrosion resistance and durability make them ideal for various environments, providing a reliable and long-lasting solution for connecting square tubes.

The maximum weight capacity for stainless steel square tube fittings depends on various factors such as the dimensions, material grade, and design. It is important to consult the manufacturer's specifications for accurate and precise information on weight capacity.

Regular maintenance and cleaning are essential for stainless steel square tube fittings to ensure their longevity and optimal performance. Specific requirements may vary, but generally, using mild soap, warm water, and a soft cloth is recommended.

Blog Series:

In conclusion, stainless steel square tube fittings are essential components for connecting and securing stainless steel square tubing in various applications. They provide structural support and enable the creation of sturdy and aesthetically pleasing square handrails.

For example, in a case study of a commercial building, stainless steel square tube fittings were used to construct a modern and durable handrail system, enhancing the overall safety and visual appeal of the space.