| Material | 304 /304L/316L | |||

| Certificate | PED/ISO / AEO/ MTC | |||

| Diameter | 12mm-159mm | |||

| Thickness | 0.6mm-3.0mm | |||

| Surface Finish | Pickling , Bright Annealing | |||

| Length | 5.8 M ,6M ,20 Feet or Customized | |||

| Processing | Welding, bright anneling, inside bead removing, pickling | |||

| Delivery Time | 30 days for a container quantity | |||

| Payment Terms | T/T, LC, Cash, etc. Normally 30% by T/T in advance, balance to be paid before shipment. | |||

| Packing | Each tube will be packed in plastic bag, then several tubes will be packed by hollow plate. | |||

| Application | bolier , heat exchanger, super heater and condenser etc | |||

The Bright Annealing process in Vinmay is performed in a controlled atmosphere containing inert hydrogen gas at 1040℃. Annealing is a typically used to reduce hardness , increase ductility and eliminate internal stresses.While the controlled atmosphere reduces the surface oxidation to a minimum which results in a brighter surface and a much thinner oxide layer. Picking is not needed after bright annealing since the oxidation is minimal. Since there is no pickling , the surface of stainless steel sanitary tube is much smoother which results in better resistance to pitting corrosion.

After the process, bright annealed finish has a bright, reflective appearance, but may have some cloudiness slightly different from MF (Mill Finish)

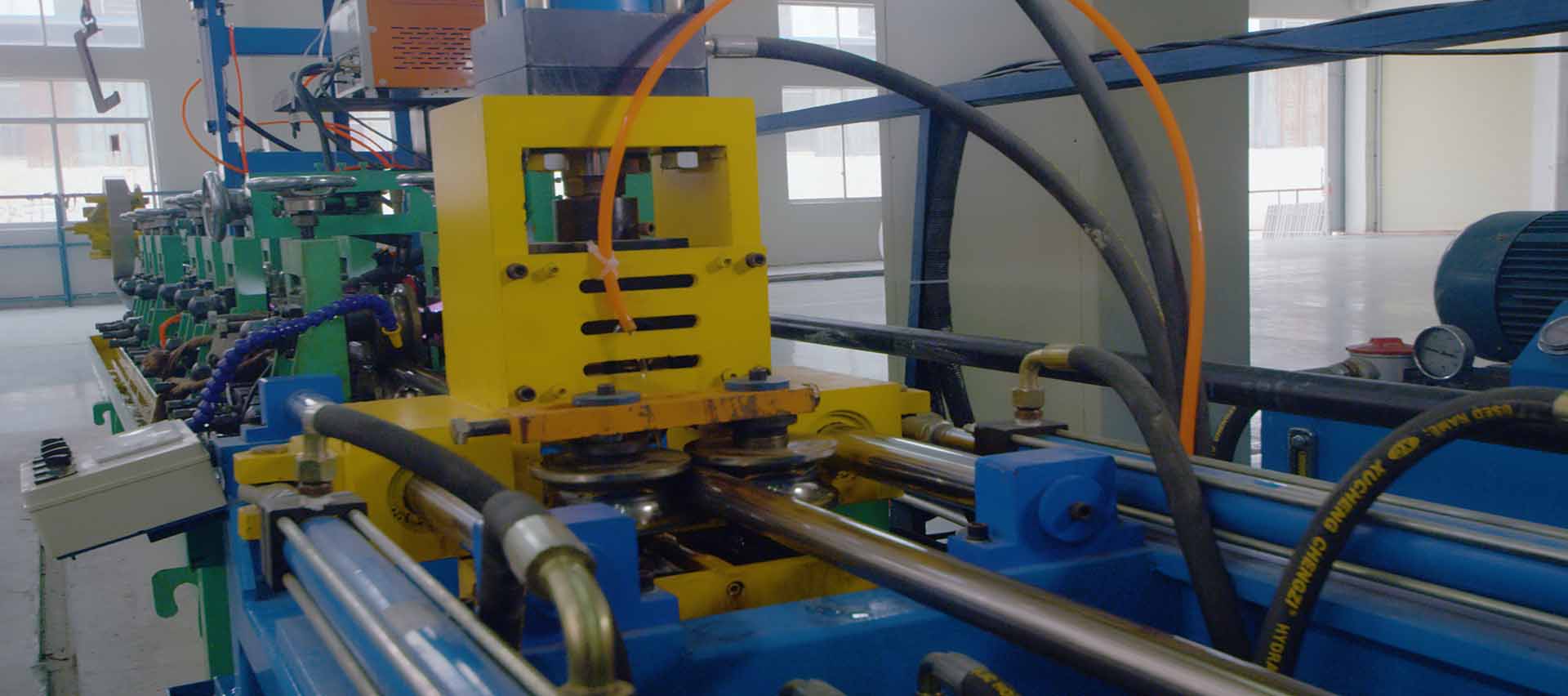

Vinmay has full set of online inside bead removing equipment,bringing smooth surface for inner weld seam to meet clean purpose, and controlling the height of weld seam for precision request. It's an important process for pipes of fluid field or food industry.

1.Spectrometer and chemical composition inspection

2. Material Incoming Inspection

3. Eddy Current Testing

4. Leak Tightness Testing

5. Hardness Inspection

6. Universal Testing Machine

7. Salt Spray Test

8. Metallographic Microscope

9. Surface Roughness

Foshan Vinmay Stainless Steel Co., Ltd. is a large-scale international enterprisewhich concentrates on producting stainless steel welded tubes and the related fittings. As a key partner for global stainless steel welded tube distributors, Vinmay serves the top importer of ss welded tube all over the world. We are committed to assisting our customers in becoming the top distributor in their country or worldwide.