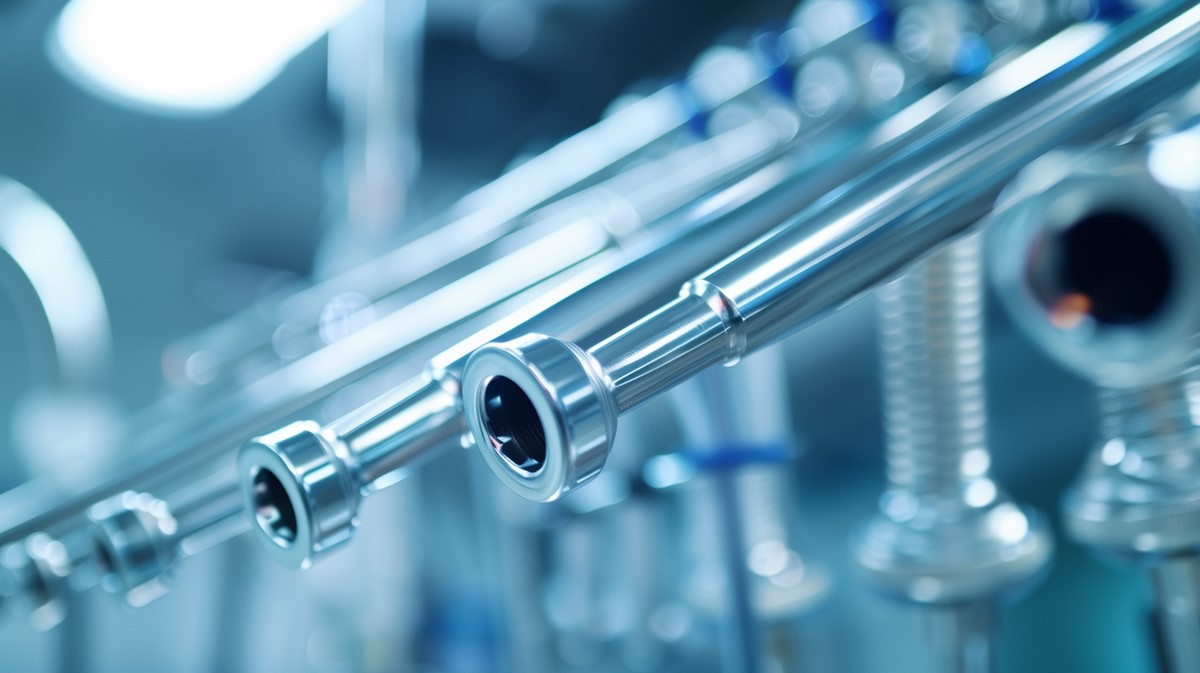

In the medical industry, precision and safety are not optional—they’re critical. Whether it's a surgical instrument, a catheter, or a gas delivery system, every component must meet the highest standards for cleanliness, strength, and reliability. This is where medical stainless steel tubing plays a vital role.

Renowned for its corrosion resistance, biocompatibility, and ability to withstand sterilization, stainless steel tubing is the go-to material for a wide range of medical applications. From operating rooms to diagnostic equipment, it's trusted to perform under the most demanding conditions without compromising patient safety.

As healthcare technology continues to advance, the demand for high-performance, medical-grade materials only grows stronger. In this guide, we’ll explore what makes stainless steel tubing ideal for medical use, how it’s applied across the industry, and what to consider when sourcing it for your next project.

Medical stainless steel tubing is a specialized, precision-engineered form of tubing used across a wide range of medical applications—from surgical instruments to implants and fluid delivery systems. These tubes are manufactured to strict hygienic, mechanical, and biocompatibility standards, making them ideal for use in sterile and safety-critical environments.

Produced to stringent specifications, this tubing ensures exceptional corrosion resistance, structural integrity, and biological safety—key factors for the reliability of medical devices and the health of patients.

Medical stainless steel tubing combines strength, safety, and precision, making it a cornerstone material in the development of reliable, compliant medical products.

Medical stainless steel tubing is used across a wide range of healthcare and life science applications. Its durability, corrosion resistance, and biocompatibility make it a critical component in both invasive and non-invasive medical technologies.

From scalpels to forceps and endoscopic tools, stainless steel tubing provides the structural integrity and hygiene standards required for surgical precision. Its ability to be repeatedly sterilized without degrading makes it ideal for reusable surgical devices.

Precision tubing is essential for hypodermic needles, IV catheters, and cannulas. Ultra-fine diameters with smooth inner walls ensure safe and controlled fluid delivery while minimizing patient discomfort.

High-purity grades like 316LVM are commonly used in orthopedic implants, stents, and pacemaker components due to their excellent biocompatibility and resistance to bodily fluids over time.

Stainless steel tubing is also used in medical diagnostic equipment such as biopsy tools, endoscopy channels, and blood analyzers, where cleanliness and structural precision are crucial.

Hospitals and surgical suites rely on stainless steel tubing for the safe and sterile delivery of oxygen, nitrogen, CO2, and medical vacuum lines. It ensures leak-free, contamination-resistant operation under high pressure.

Outside traditional hospital settings, medical-grade tubing is also widely used in dental drills, veterinary instruments, and portable diagnostic units.

Medical stainless steel tubing offers a unique combination of mechanical strength, biocompatibility, and resistance to harsh environments. These advantages make it one of the most trusted materials in modern medical device manufacturing.

Medical-grade stainless steel is non-toxic, non-reactive, and does not trigger allergic responses when in contact with bodily fluids or tissues. This is especially important for implants, surgical instruments, and devices used in invasive procedures.

Stainless steel tubing resists corrosion caused by sterilization, saline solutions, blood, and other aggressive substances found in medical environments. Grades like 316L and 316LVM are particularly effective in preventing pitting and rusting over time.

Despite its lightweight, stainless steel provides the durability needed for both structural and precision applications. It performs well under pressure, torsion, and dynamic movement without deformation.

Stainless steel tubing can withstand repeated autoclaving, chemical disinfection, and other sterilization methods without degrading or warping. Its smooth surface finish minimizes bacterial adhesion, ensuring long-term hygiene.

Medical stainless steel tubing can be fabricated with tight tolerances, uniform wall thickness, and custom dimensions. This precision is critical for devices like catheters, needles, and laparoscopic tools, where accuracy is vital.

Due to its high strength and resistance to environmental stress, stainless steel tubing offers exceptional longevity, reducing the need for frequent replacement or failure-related downtime.

The remarkable properties of stainless steel tubing in the medical field necessitate adherence to stringent industry standards and compliance requirements to guarantee peak performance and safety.

Regulatory compliance involves conforming to standards such as ISO 13485, which governs medical device quality management systems. This secures consistent quality assurance throughout the manufacturing process.

Conforming to ISO 13485 ensures consistent quality assurance in medical device manufacturing processes.

The ASTM International also provides specific standards for the mechanical and chemical properties of stainless steel tubing, assuring material integrity. Compliance with these standards mitigates risks associated with device failure, thereby safeguarding patient health.

Manufacturers must implement rigorous quality control procedures, including regular audits and inspections, to maintain compliance. Adhering to these standards is vital for ensuring the tubing's reliability, biocompatibility, and performance in medical applications.

Selecting a reliable supplier for medical stainless steel tubing is crucial to ensuring product safety, regulatory compliance, and long-term performance. Whether you're sourcing tubing for implants, instruments, or fluid systems, the right supplier can significantly impact product quality and project timelines.

Look for suppliers with proven experience in the medical sector and certifications like ISO 13485 and FDA registration. These credentials demonstrate a commitment to quality and compliance with global medical manufacturing standards.

A trustworthy supplier provides full material traceability, including heat lot numbers, certificates of compliance, and mill test reports. This documentation is essential for audits, quality assurance, and regulatory approval processes.

Medical applications require tight tolerances and custom geometries. Choose a supplier with advanced fabrication capabilities like micro-welding, centerless grinding, electro-polishing, and automated inspection systems.

Suppliers should offer cleanroom production and packaging to reduce contamination risks. Tubing intended for invasive use should be delivered in sterile or ready-to-sterilize packaging formats.

Partner with a supplier who can provide rapid prototyping, small-batch runs, and design support during product development. This flexibility is especially valuable for OEMs, startups, and custom medical device manufacturers.

Evaluate the supplier’s ability to meet your volume, delivery, and geographic needs. A robust global supply chain ensures timely delivery and consistent quality, even across borders or during disruptions.

Working with a trusted supplier like Vinssco ensures that your tubing meets the highest medical-grade standards while supporting efficient production and regulatory compliance.

While both medical and pharmaceutical stainless steel tubing require high standards of cleanliness, precision, and corrosion resistance, they serve very different purposes and are governed by distinct performance and regulatory requirements.

Though both categories use similar base alloys, the intended application, compliance standards, and finishing requirements vary significantly. Choosing the right tubing type is essential to ensure product safety, performance, and regulatory approval.

Like a fortress against time, stainless steel's corrosion resistance is essential, especially when sterilization processes introduce fluctuating temperatures and chemicals. Environmental factors such as humidity and exposure to bodily fluids also challenge its durability, demanding careful material selection.

Alloy selection greatly influences cost analysis in tubing production due to varying alloy properties. For instance, 316 LVM, with superior purity and corrosion resistance, is more expensive than 304, impacting overall material and manufacturing costs.

One might jest that the art of surface finishes resembles a clandestine alchemy; nevertheless, polishing techniques offer bright drawn, centerless ground OD, and polished OD finishes. Each surface finish type guarantees precise functionality, meeting stringent medical standards.

316 stainless steel tubing exhibits temperature resistance suitable for applications from cryogenic conditions to 800°F. Its mechanical properties, including strength and corrosion resistance, make it ideal for environments requiring reliable performance under varying thermal stresses.

The 17-7 stainless steel alloy is preferred for orthopedic applications due to its exceptionally high-strength properties and corrosion resistance, making it a reliable titanium alternative for demanding environments, ensuring long-term performance and structural integrity.

In summary, medical stainless steel tubing serves as the backbone of the medical industry, guaranteeing safety and efficacy in critical applications like surgical instruments and implants. Its unparalleled biocompatibility and resistance to corrosion make it indispensable. Like a well-oiled machine, adherence to stringent industry standards guarantees reliability and trust. Choosing the right supplier requires careful consideration, akin to a surgeon selecting the finest scalpel, to maintain the high standards required for life-saving medical devices.